Your Ultimate Guide to Sourcing Vending Machine Profit

Guide to Vending Machine Profit

- Introduction: Navigating the Global Market for vending machine profit

- Understanding vending machine profit Types and Variations

- Key Industrial Applications of vending machine profit

- Strategic Material Selection Guide for vending machine profit

- In-depth Look: Manufacturing Processes and Quality Assurance for vending machine profit

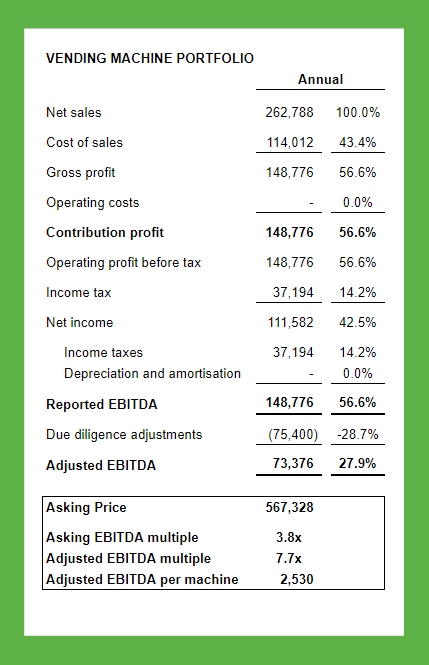

- Comprehensive Cost and Pricing Analysis for vending machine profit Sourcing

- Spotlight on Potential vending machine profit Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for vending machine profit

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine profit Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vending machine profit

- Strategic Sourcing Conclusion and Outlook for vending machine profit

Introduction: Navigating the Global Market for vending machine profit

The global vending machine market is a dynamic and profitable sector, offering B2B buyers a unique opportunity to tap into diverse revenue streams. With the rise of cashless transactions and an increasing demand for convenient, on-the-go solutions, vending machines have evolved beyond simple snack dispensers to high-tech, multifunctional retail platforms. This evolution underscores the critical importance of understanding vending machine profit—not only as a revenue generator but also as a strategic asset for companies looking to diversify their offerings in competitive markets.

In this comprehensive guide, we will explore various facets of vending machine profit, including types of machines, materials used in manufacturing, quality control processes, and sourcing reliable suppliers. We’ll also delve into cost considerations and market trends that can impact your investment decisions. Our focus will be on empowering international B2B buyers from Africa, South America, the Middle East, and Europe, including regions like Australia and Thailand, to make informed choices that align with their unique business needs.

By providing actionable insights and addressing frequently asked questions, this guide aims to equip you with the knowledge required to navigate the complexities of the vending machine market effectively. Whether you are a seasoned investor or a newcomer, understanding these elements is crucial to maximizing profitability and ensuring long-term success in your vending ventures.

Understanding vending machine profit Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Snack Vending | Offers a variety of packaged snacks and drinks | Offices, schools, hospitals | Pros: Low initial investment; Cons: Limited product variety and lower margins. |

| Healthy Vending Machines | Focus on nutritious options like fruits and salads | Gyms, schools, corporate wellness | Pros: Attracts health-conscious consumers; Cons: Higher product costs and sourcing challenges. |

| Specialty Coffee Machines | Provides gourmet coffee and beverages on-demand | Cafés, offices, hotels | Pros: High profit margins; Cons: Requires maintenance and higher upfront costs. |

| Automated Retail Solutions | Combines vending with e-commerce for diverse items | Airports, malls, universities | Pros: Wide range of products and convenience; Cons: Complex technology may require training. |

| Cashless Payment Systems | Integrates mobile payments and digital wallets | All vending applications | Pros: Improves transaction speed and security; Cons: Initial setup costs and technology dependency. |

Traditional Snack Vending Machines

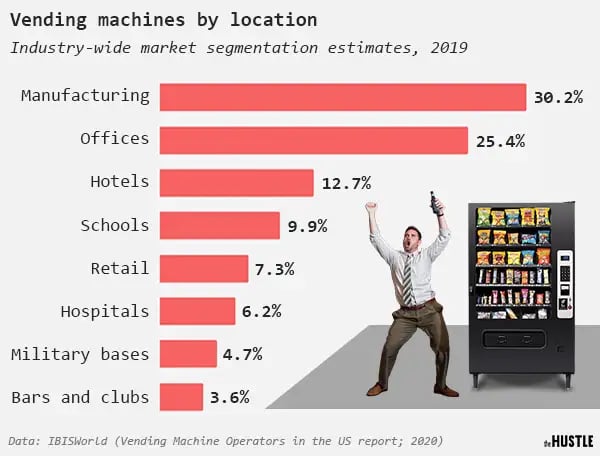

Traditional snack vending machines are characterized by their straightforward design, offering a selection of packaged snacks and beverages. They are widely used in environments such as offices, schools, and hospitals where quick access to refreshments is essential. For B2B buyers, these machines represent a low entry point into the vending market with minimal maintenance requirements. However, they often yield lower profit margins due to high competition and limited product variety, making it crucial for buyers to consider location and foot traffic when investing.

Healthy Vending Machines

Healthy vending machines cater to the growing demand for nutritious snacks, featuring products like fruits, salads, and organic options. These machines are particularly suitable for gyms, schools, and corporate wellness programs, appealing to health-conscious consumers. While they can command higher prices, the sourcing of quality ingredients can be challenging and costly. B2B buyers should evaluate local market trends and consumer preferences to determine the viability of this option in their target demographics.

Specialty Coffee Machines

Specialty coffee vending machines offer high-quality coffee and beverages, often using advanced brewing technology to deliver gourmet drinks. They are commonly found in cafés, offices, and hotels, where premium products can significantly enhance customer experience. The potential for high profit margins makes these machines attractive to B2B buyers. However, they require more maintenance and a higher initial investment, necessitating careful consideration of operational capabilities and customer demand.

Automated Retail Solutions

Automated retail solutions extend beyond traditional vending by incorporating e-commerce elements, allowing for a diverse range of products from electronics to apparel. These machines are often placed in high-traffic areas such as airports, malls, and universities, capitalizing on convenience and impulse buying. While they provide a broad selection and enhanced customer engagement, their complexity may necessitate additional training and support for operators. B2B buyers should assess their capacity to manage advanced technology and inventory logistics.

Cashless Payment Systems

Cashless payment systems in vending machines enable transactions through mobile payments and digital wallets, enhancing convenience and security. This feature is becoming increasingly important across all vending applications, as consumers prefer seamless payment options. For B2B buyers, implementing cashless systems can lead to improved transaction speeds and reduced cash handling. However, the initial setup costs and reliance on technology can pose challenges, making it essential to weigh the benefits against potential risks in their specific market context.

Related Video: How to Start a Vending Machine Business, Cost, Tips, How Much You Make

Key Industrial Applications of vending machine profit

| Industry/Sector | Specific Application of vending machine profit | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Automated inventory management | Reduced labor costs, increased efficiency | Integration with existing inventory systems, scalability |

| Hospitality | On-demand food and beverage services | Enhanced guest experience, increased revenue | Quality of products, supplier reliability, local sourcing |

| Education | Student convenience services | Increased satisfaction, reduced wait times | Payment options, machine durability, energy efficiency |

| Transportation | Travel essentials vending | Improved passenger experience, additional revenue | Location optimization, product variety, security features |

| Healthcare | Medical supply dispensing | Fast access to essential items, reduced staff workload | Regulatory compliance, product safety, replenishment logistics |

Retail: Automated Inventory Management

In the retail sector, vending machines can serve as automated inventory management systems, effectively tracking product sales and stock levels. This application helps businesses reduce labor costs associated with manual inventory checks while increasing overall efficiency. For international buyers, particularly from regions like Africa and South America, understanding the integration capabilities with existing inventory systems is crucial. Scalability is also a key consideration to accommodate future growth.

Hospitality: On-Demand Food and Beverage Services

Vending machines in the hospitality industry offer guests quick access to food and beverages, enhancing their experience and satisfaction. This application can significantly increase revenue by providing 24/7 service without the need for additional staffing. International B2B buyers must focus on the quality of the products offered and the reliability of suppliers to ensure guest satisfaction. Local sourcing can also enhance the appeal of offerings while supporting regional economies.

Education: Student Convenience Services

In educational institutions, vending machines provide students with convenient access to snacks and beverages, reducing wait times and increasing satisfaction. This application is particularly beneficial in high-traffic areas like libraries and dormitories. For buyers in Europe and the Middle East, it is essential to consider payment options that cater to diverse student populations, as well as the durability of machines to withstand heavy use. Energy efficiency is also a significant factor, given the focus on sustainability in many educational settings.

Transportation: Travel Essentials Vending

In the transportation sector, vending machines that dispense travel essentials cater to passengers’ needs, enhancing their overall travel experience. This application can generate additional revenue streams for transport companies, especially in airports and train stations. Buyers should prioritize location optimization to ensure machines are placed where foot traffic is highest. Additionally, offering a diverse product variety and incorporating security features can help mitigate theft and ensure passenger safety.

Healthcare: Medical Supply Dispensing

Vending machines designed for dispensing medical supplies provide fast access to essential items, reducing the workload on healthcare staff. This application is particularly valuable in hospitals and clinics, where time is critical. International buyers must consider regulatory compliance and product safety standards, which can vary significantly by region. Efficient replenishment logistics are also vital to ensure that machines are stocked with necessary supplies at all times, ultimately improving patient care.

Strategic Material Selection Guide for vending machine profit

When selecting materials for vending machines, it is crucial to consider various properties that will impact performance, durability, and overall profitability. This guide analyzes four common materials used in vending machine construction: Stainless Steel, Aluminum, Polycarbonate, and Glass. Each material has unique characteristics that can influence the machine’s efficiency and longevity, particularly in diverse international markets.

Stainless Steel

Key Properties: Stainless steel is known for its high corrosion resistance, strength, and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 800°F (427°C) and can handle pressures exceeding 2000 psi, depending on the grade.

Pros & Cons: The primary advantages of stainless steel include its durability, aesthetic appeal, and ease of cleaning. However, it can be costlier than other materials and may require specialized manufacturing processes, which can complicate production timelines.

Impact on Application: Stainless steel is ideal for vending machines that dispense food and beverages, as it ensures hygiene and compliance with health standards. Its resistance to corrosion makes it suitable for humid environments.

Considerations for International Buyers: Buyers should be aware of different grades of stainless steel (e.g., 304, 316) and their compliance with local standards such as ASTM or DIN. In regions like Africa and the Middle East, where humidity can be high, selecting the right grade is critical to prevent corrosion.

Aluminum

Key Properties: Aluminum is lightweight and has good corrosion resistance, with a melting point around 1220°F (660°C). It is also non-magnetic and has a relatively low density.

Pros & Cons: The key advantage of aluminum is its lightweight nature, which can reduce shipping costs and installation complexity. However, it is less durable than stainless steel and can be prone to dents and scratches, affecting its aesthetic appeal over time.

Impact on Application: Aluminum is often used in vending machines designed for outdoor use due to its resistance to rust. However, its lower strength may limit its use in high-pressure applications.

Considerations for International Buyers: Buyers should consider the local availability of aluminum and its grades, as well as compliance with standards like JIS in Japan or EN in Europe. In South America, understanding local recycling practices can also influence material selection.

Polycarbonate

Key Properties: Polycarbonate is a thermoplastic known for its high impact resistance and transparency. It can withstand temperatures up to 240°F (115°C) and is often used in environments where visibility is important.

Pros & Cons: The main advantage of polycarbonate is its shatter resistance, making it ideal for vending machine windows. However, it can be more susceptible to scratching and UV degradation over time, which may require additional coatings.

Impact on Application: Polycarbonate is suitable for vending machines that require visibility of the products inside, such as snack or beverage dispensers. Its lightweight nature also aids in reducing overall machine weight.

Considerations for International Buyers: Buyers should evaluate the UV resistance of polycarbonate materials, especially in sunny regions like parts of Africa and South America. Compliance with health and safety standards is also essential.

Glass

Key Properties: Glass is a rigid material that offers excellent clarity and is resistant to chemical corrosion. It can handle a wide range of temperatures, typically up to 500°F (260°C).

Pros & Cons: Glass provides a premium look and feel to vending machines, enhancing product visibility. However, it is heavy and can be prone to breakage, which may increase maintenance costs.

Impact on Application: Glass is often used in high-end vending machines that require aesthetic appeal and product visibility, such as those in luxury settings.

Considerations for International Buyers: Buyers must consider the transportation and handling challenges associated with glass, especially in regions with less developed infrastructure. Compliance with local safety standards is also a must to mitigate liability.

Summary Table

| Material | Typical Use Case for vending machine profit | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and beverage dispensing machines | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Outdoor vending machines | Lightweight, reduces shipping costs | Less durable, prone to dents | Medium |

| Polycarbonate | Snack and beverage dispensers | High impact resistance, visibility | Susceptible to scratching and UV damage | Medium |

| Glass | High-end vending machines | Premium look and product visibility | Heavy and prone to breakage | High |

This strategic material selection guide provides actionable insights for international B2B buyers, enabling them to make informed decisions that enhance the profitability and performance of vending machines across various markets.

In-depth Look: Manufacturing Processes and Quality Assurance for vending machine profit

Manufacturing Processes for Vending Machines

The manufacturing of vending machines is a complex process that involves multiple stages, each critical to ensuring the final product is durable, functional, and profitable. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Materials: The primary materials used in vending machine manufacturing include steel, aluminum, plastics, and electronic components. Buyers should prioritize suppliers that utilize high-quality, corrosion-resistant materials to enhance durability.

– Pre-processing: Materials undergo cutting, bending, and machining to prepare them for assembly. Advanced techniques like laser cutting or CNC machining can provide precision and reduce waste. -

Forming

– Shaping Components: This stage involves forming parts such as panels, doors, and trays. Techniques include stamping and injection molding, which allow for intricate designs and efficient production.

– Quality Control in Forming: Regular checks during this stage can prevent defects. B2B buyers should inquire about the forming techniques used and the frequency of quality checks. -

Assembly

– Integration of Components: The assembly process combines all pre-formed parts, including mechanical, electrical, and software components. Automated assembly lines can improve efficiency and consistency.

– Testing During Assembly: Incorporating in-line testing for functionality can catch issues early. Buyers should look for suppliers who implement rigorous assembly checks. -

Finishing

– Surface Treatment: This stage may involve painting, powder coating, or applying protective films. Proper finishing enhances aesthetics and protects against environmental factors.

– Final Quality Assurance: After finishing, a comprehensive inspection should be performed to ensure all components meet design specifications.

Quality Assurance in Manufacturing

Quality assurance (QA) is crucial in the manufacturing process of vending machines to ensure reliability and customer satisfaction. Here’s how B2B buyers can navigate the QA landscape.

Relevant International Standards

- ISO 9001: This standard outlines criteria for a quality management system, focusing on continuous improvement and customer satisfaction. Suppliers adhering to ISO 9001 demonstrate a commitment to quality.

- CE Marking: For suppliers in Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards. B2B buyers should ensure that products are CE compliant, especially when operating in European markets.

- API Standards: The American Petroleum Institute (API) standards can be relevant for vending machines dispensing liquids. Buyers should verify that suppliers adhere to these standards if applicable.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– This initial checkpoint assesses the quality of incoming materials and components. Suppliers should have a robust IQC process to ensure only high-quality inputs are used. -

In-Process Quality Control (IPQC)

– IPQC involves monitoring the manufacturing process at various stages. Regular inspections can identify defects early, minimizing waste and reducing rework costs. -

Final Quality Control (FQC)

– FQC is the last line of defense before products are shipped. This stage should include thorough testing of the finished vending machines to ensure they meet specified requirements.

Common Testing Methods

- Functional Testing: This method evaluates whether the vending machine operates as intended. Tests should cover dispensing mechanisms, payment systems, and user interfaces.

- Stress Testing: This assesses how the machine holds up under various conditions, including temperature fluctuations and heavy usage.

- Safety Testing: Ensures compliance with safety standards, focusing on electrical safety and mechanical integrity.

Verifying Supplier Quality Control

B2B buyers must take proactive steps to verify the quality control measures of their suppliers. Here are key strategies:

-

Conduct Audits: Regular audits of supplier facilities can provide insight into their manufacturing processes and quality assurance practices. Buyers should request audit reports and follow up on any identified issues.

-

Request Documentation: Suppliers should provide documentation of their quality management systems, including ISO certifications and internal quality reports. This transparency can build trust and verify compliance with international standards.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of product quality. This step is particularly important for international buyers who may not have the capacity to conduct on-site inspections.

Quality Control Nuances for International Buyers

B2B buyers from Africa, South America, the Middle East, and Europe must navigate various nuances in quality control:

-

Regulatory Compliance: Understanding the local regulations and standards applicable to vending machines is essential. For instance, machines sold in the EU must comply with CE marking, while those in the Middle East may need to meet different local standards.

-

Cultural Considerations: Cultural differences can influence supplier practices and communication styles. Buyers should approach negotiations with sensitivity to these factors, ensuring clear expectations are established regarding quality standards.

-

Logistics and Supply Chain Management: International shipping can impact product quality. Buyers should discuss logistics with suppliers to ensure that products remain intact during transportation, minimizing the risk of damage.

In conclusion, a comprehensive understanding of manufacturing processes and quality assurance practices is essential for B2B buyers in the vending machine industry. By focusing on material quality, rigorous QA standards, and supplier verification methods, buyers can enhance their purchasing decisions and ensure profitable outcomes in their vending machine investments.

Related Video: China’s Top 5 Manufacturing and Mass Production Videos | by @miracleprocess

Comprehensive Cost and Pricing Analysis for vending machine profit Sourcing

Understanding the cost structure and pricing factors for vending machine sourcing is crucial for B2B buyers aiming to optimize profit margins. A comprehensive analysis of the cost components and price influencers will empower international buyers, particularly from Africa, South America, the Middle East, and Europe, to make informed purchasing decisions.

Cost Components

-

Materials: The quality and type of materials used in vending machines significantly impact costs. Common materials include steel for the body, plastic for internal components, and electronic parts for payment systems. Buyers should consider sourcing high-quality materials to ensure longevity and reliability, as these can reduce maintenance costs in the long run.

-

Labor: Labor costs can vary widely based on the manufacturing location. When sourcing from regions with lower labor costs, such as parts of Asia, it’s essential to assess the trade-offs in quality and compliance with international labor standards.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and administrative expenses. Understanding a supplier’s overhead can provide insights into their pricing structure. Suppliers with higher overhead might offer superior quality or services, which can justify their prices.

-

Tooling: Custom tooling can be a significant upfront cost for buyers seeking bespoke vending machines. Investing in specialized tooling can lead to better production efficiency and lower per-unit costs in the long run.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability and reduces the risk of returns. Buyers should inquire about the supplier’s QC procedures and certifications, as these can affect overall costs and product quality.

-

Logistics: Shipping costs can be a hidden expense in the total cost of ownership. Buyers should consider the distance from the supplier and the associated logistics costs, including tariffs and customs duties, especially when sourcing internationally.

-

Margin: Suppliers will typically include a margin in their pricing to cover risks and ensure profitability. Understanding the average industry margin can help buyers gauge whether a price is competitive.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should evaluate their demand forecasts to negotiate favorable pricing based on volume.

-

Specifications/Customization: Custom features can increase costs. Buyers should balance the need for customization against their budget to ensure they are not overpaying for unnecessary features.

-

Materials and Quality/Certifications: Higher quality materials and certifications (such as ISO or CE) can justify higher prices. Buyers should weigh these factors against their operational requirements and market expectations.

-

Supplier Factors: The reputation and reliability of a supplier can influence pricing. Established suppliers may charge more but can offer better service and product guarantees.

-

Incoterms: Understanding Incoterms is essential for pricing negotiations. These terms dictate who bears the cost and risk during shipping, impacting the overall cost structure for international buyers.

Buyer Tips

-

Negotiation: Always be prepared to negotiate. Having a clear understanding of the market price range can empower buyers to push for better terms.

-

Cost-Efficiency: Evaluate total costs, including shipping, tariffs, and maintenance, rather than just upfront purchase prices. This approach helps identify the best value over the product’s lifecycle.

-

Pricing Nuances: Different regions may have varying pricing strategies due to local demand, economic conditions, and currency fluctuations. Buyers should conduct market research specific to their region to identify competitive pricing.

Disclaimer

Prices and costs mentioned in this analysis are indicative and can vary based on current market conditions, supplier negotiations, and specific requirements of the vending machines. It’s advisable for buyers to conduct thorough due diligence when sourcing to ensure the best pricing and quality for their needs.

Spotlight on Potential vending machine profit Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for vending machine profit.)*

Essential Technical Properties and Trade Terminology for vending machine profit

Key Technical Properties for Vending Machines

Understanding the critical specifications of vending machines is essential for B2B buyers aiming to maximize profitability. Here are some vital technical properties to consider:

1. Material Grade

The material grade refers to the quality of the materials used in the construction of vending machines, such as stainless steel, plastic, or aluminum. Higher-grade materials offer better durability and resistance to corrosion, which is crucial for machines located in high-traffic or outdoor environments. Selecting the right material can lead to reduced maintenance costs and longer service life.

Illustrative Image (Source: Google Search)

2. Power Consumption

This property measures the energy usage of the vending machine, typically expressed in watts. Machines with lower power consumption are more cost-effective in the long run, especially in regions with high electricity costs. Understanding power requirements helps buyers select machines that align with their operational budgets and sustainability goals.

3. Capacity

Capacity indicates the number of products a vending machine can hold, which directly impacts revenue potential. Machines with larger capacities can offer a wider selection, catering to diverse consumer preferences. Buyers should evaluate their target market’s needs to determine the optimal capacity for maximizing sales.

4. Temperature Range

For vending machines that dispense perishable items, temperature range is a critical specification. Machines must maintain specific temperatures to ensure food safety and product quality. Buyers should verify that machines comply with local health regulations and are capable of operating efficiently in varying climatic conditions.

5. User Interface

The user interface includes the display, buttons, and payment systems. A user-friendly interface enhances customer experience, leading to increased sales. Buyers should consider machines equipped with modern payment options, such as contactless payments or mobile wallets, to cater to tech-savvy consumers.

6. Connectivity Features

Modern vending machines often come with IoT capabilities, allowing for remote monitoring and management. Connectivity features enable real-time inventory tracking, sales data analysis, and predictive maintenance alerts. These capabilities can significantly reduce operational costs and improve service efficiency.

Common Trade Terminology in Vending Machine Procurement

Familiarity with industry jargon is crucial for effective communication in the B2B vending machine market. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of vending machines, buyers may source components from OEMs to ensure compatibility and quality. Understanding OEM relationships can lead to better pricing and product reliability.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is critical for budgeting and inventory management. Buyers should negotiate MOQs to ensure they can meet demand without overstocking, which ties up capital.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers requesting pricing and terms for specific products. This process is essential for comparing offers and negotiating favorable terms. Buyers should provide clear specifications in their RFQs to receive accurate quotes.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations in international transactions, ensuring compliance and minimizing risks.

5. Lead Time

Lead time is the time taken from placing an order to receiving the goods. Understanding lead times is essential for inventory planning and ensuring that vending machines are available when needed. Buyers should inquire about lead times during negotiations to align with their operational timelines.

6. Warranty and Service Agreements

These terms refer to the commitments made by manufacturers regarding the repair and maintenance of vending machines. A strong warranty and service agreement can significantly reduce long-term costs and provide peace of mind for buyers. It’s important to understand the terms and duration of warranties before making a purchase.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance profitability in the vending machine sector.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine profit Sector

Market Overview & Key Trends

The global vending machine market is experiencing significant transformation, driven by technological advancements and shifting consumer preferences. One of the primary drivers is the rise of cashless payment systems, which enhance user convenience and expand the customer base. International B2B buyers should note that contactless payment options, such as mobile wallets and QR codes, are becoming standard in vending operations across Africa, South America, the Middle East, and Europe.

Emerging trends also include the integration of artificial intelligence (AI) and data analytics. These technologies allow operators to optimize inventory management, predict consumer behavior, and enhance machine performance. For example, AI can help identify popular products and automate restocking schedules, leading to improved profitability. B2B buyers should consider partnerships with tech firms that specialize in vending machine software and analytics.

Illustrative Image (Source: Google Search)

Sourcing trends are shifting towards local procurement to reduce supply chain disruptions and transportation costs, particularly relevant for regions like Africa and South America, where infrastructure challenges persist. Additionally, there is a growing emphasis on product diversity, including healthy snacks and beverages, to cater to health-conscious consumers. Buyers should prioritize suppliers that offer a wide range of products to meet these evolving demands.

Sustainability & Ethical Sourcing in B2B

In the context of vending machines, sustainability and ethical sourcing are increasingly critical for B2B buyers. The environmental impact of vending operations can be significant, from energy consumption to waste generation. Companies are now seeking vending machines that are energy-efficient and utilize eco-friendly materials. This trend aligns with the global push towards reducing carbon footprints and minimizing environmental harm.

Ethical supply chains are becoming a priority as consumers demand greater transparency regarding the origins of products. B2B buyers should look for suppliers who can provide information about their sourcing practices, including the use of sustainable materials and fair labor practices. Certifications such as Fair Trade and organic labels can serve as indicators of a supplier’s commitment to ethical standards.

Investing in “green” vending machines, which utilize renewable energy sources and recyclable components, can also enhance brand reputation. By aligning with sustainability goals, B2B buyers not only contribute to environmental preservation but also appeal to a growing segment of eco-conscious consumers.

Brief Evolution/History

The vending machine industry has evolved significantly since its inception in the late 19th century. Initially, vending machines offered simple items like postcards and candy. As technology advanced, machines began to dispense a wider variety of products, including beverages and fresh food, catering to changing consumer preferences.

In the 21st century, the introduction of digital payment systems and smart vending technologies has revolutionized the sector. Today, vending machines are equipped with touchscreens, inventory management systems, and IoT connectivity, allowing for real-time data tracking and enhanced user experiences. This evolution presents B2B buyers with numerous opportunities to capitalize on innovative solutions that drive profitability and meet market demands.

Related Video: How Global Trade Runs on U.S. Dollars | WSJ

Frequently Asked Questions (FAQs) for B2B Buyers of vending machine profit

-

What criteria should I use to vet suppliers for vending machines?

When vetting suppliers for vending machines, consider their industry experience, reputation, and financial stability. Request references and case studies to evaluate their reliability. Additionally, check for certifications relevant to your region, such as ISO standards or local compliance. Engage in direct communication to assess their responsiveness and willingness to customize offerings based on your market’s needs. This thorough vetting process helps ensure you partner with reputable suppliers who can meet your business requirements effectively. -

Can I customize vending machines to suit my market needs?

Yes, many suppliers offer customization options for vending machines to cater to local preferences and regulations. This can include adjusting product selections, branding the machines with your logo, or modifying payment systems to accept local currencies. When discussing customization, provide clear specifications and expectations to the supplier. Collaborating closely during the design phase ensures that the final product aligns with market demands and enhances the potential for profitability. -

What are typical minimum order quantities (MOQs) and lead times for vending machines?

MOQs can vary significantly based on the supplier and the type of vending machines you are interested in. Generally, expect MOQs to range from 10 to 50 units for standard models. Lead times typically span from 4 to 12 weeks, depending on customization requirements and supplier capacity. Always clarify these terms upfront to align your inventory planning with the supplier’s production schedule, ensuring timely delivery and minimizing stock shortages. -

What payment terms should I expect when sourcing vending machines internationally?

Payment terms can differ widely among suppliers. Common options include advance payment, letters of credit, or installment payments based on delivery milestones. For international transactions, consider using secure payment methods like escrow services to protect your investment. It’s crucial to negotiate terms that balance your cash flow needs with supplier security. Always read the fine print in contracts to understand any additional fees that may apply, such as currency conversion or bank transfer charges. -

How can I ensure quality assurance and compliance with vending machines?

To ensure quality assurance, request detailed product specifications and quality control protocols from your supplier. Verify that the machines meet international standards and any local regulations applicable to your market. Ask for certifications such as CE, UL, or other relevant marks that confirm compliance with safety and operational standards. Conducting a factory audit or third-party inspection prior to shipment can also help mitigate risks associated with product quality and compliance issues. -

What logistics considerations should I keep in mind when importing vending machines?

Logistics is critical in the vending machine supply chain. Ensure that your supplier has a reliable shipping partner familiar with international regulations and customs processes. Consider factors like shipping methods (air vs. sea), insurance coverage, and estimated delivery times. Additionally, evaluate the potential for tariffs or import duties specific to your region. Planning logistics thoroughly will help you avoid unexpected costs and delays that could impact your business operations. -

How can I resolve disputes with suppliers regarding vending machines?

To resolve disputes effectively, first, refer to the terms outlined in your contract regarding conflict resolution. Open communication is essential—discuss the issues directly with the supplier to seek a mutual understanding. If necessary, consider mediation or arbitration as outlined in your agreement. Keeping detailed records of all transactions and communications can provide clarity and support your position. Establishing a good relationship with your supplier can also facilitate smoother resolutions and future collaborations. -

What are the trends affecting the vending machine industry globally?

The vending machine industry is evolving with technology and consumer preferences. Key trends include the integration of cashless payment systems, healthier product offerings, and smart vending solutions equipped with IoT capabilities. Additionally, sustainability is becoming increasingly important, with machines designed for energy efficiency and eco-friendly products. Staying informed about these trends can help you make strategic sourcing decisions and align your offerings with market demands, ultimately increasing your competitiveness in the industry.

Strategic Sourcing Conclusion and Outlook for vending machine profit

The landscape of vending machine profitability is evolving rapidly, driven by technological advancements and changing consumer preferences. Strategic sourcing emerges as a pivotal approach for international B2B buyers aiming to maximize their margins. By aligning sourcing strategies with local market demands, businesses can enhance product offerings and improve inventory turnover.

Key takeaways for B2B buyers include:

- Supplier Relationships: Cultivating strong partnerships with suppliers can lead to better pricing, exclusive product access, and enhanced service levels.

- Market Adaptation: Understanding local consumer behavior is crucial. Tailoring product selections to regional tastes can significantly boost sales.

- Technology Integration: Investing in smart vending solutions can streamline operations and provide valuable consumer insights, ultimately driving profitability.

As the vending machine sector continues to grow, international buyers—particularly in Africa, South America, the Middle East, and Europe—should embrace a proactive sourcing strategy. This will not only optimize costs but also position your business to capitalize on emerging trends. The future of vending profitability is bright for those who are willing to innovate and adapt. Engage with your suppliers today to explore new opportunities and secure your competitive edge in this dynamic market.