Your Ultimate Guide to Sourcing Vending Machine Moving

Guide to Vending Machine Moving Company

- Introduction: Navigating the Global Market for vending machine moving company

- Understanding vending machine moving company Types and Variations

- Key Industrial Applications of vending machine moving company

- Strategic Material Selection Guide for vending machine moving company

- In-depth Look: Manufacturing Processes and Quality Assurance for vending machine moving company

- Comprehensive Cost and Pricing Analysis for vending machine moving company Sourcing

- Spotlight on Potential vending machine moving company Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for vending machine moving company

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine moving company Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vending machine moving company

- Strategic Sourcing Conclusion and Outlook for vending machine moving company

Introduction: Navigating the Global Market for vending machine moving company

In an era where convenience and efficiency dominate consumer expectations, the demand for vending machines has surged globally. However, the successful deployment of these machines hinges significantly on the expertise of professional vending machine moving companies. These specialists not only ensure the safe transportation of machines but also facilitate their installation and setup, which is crucial for businesses aiming to optimize their operations and enhance customer satisfaction.

This comprehensive guide serves as a valuable resource for international B2B buyers from Africa, South America, the Middle East, and Europe, including key markets like Turkey and the UAE. It delves into various aspects of vending machine moving services, including the types of machines commonly handled, the materials used in their construction, and the manufacturing and quality control processes that underpin them. Additionally, it provides insights into cost structures, market trends, and a compilation of frequently asked questions that address common concerns.

By leveraging the information in this guide, buyers will be empowered to make informed sourcing decisions, ensuring they select the right vending machine moving company that aligns with their operational needs and budget constraints. The knowledge gained here will facilitate smoother transactions, reduce logistical challenges, and ultimately contribute to the successful integration of vending solutions into diverse business environments.

Understanding vending machine moving company Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Local Vending Machine Movers | Focus on regional relocations, often with smaller fleets | Retail stores, small offices | Pros: Cost-effective, quick service. Cons: Limited long-distance capabilities. |

| National Vending Machine Movers | Operate across multiple states with larger equipment | Large corporations, franchises | Pros: Extensive reach, experience with complex logistics. Cons: Higher costs, longer lead times. |

| Specialized Vending Machine Movers | Expertise in handling specific types of machines (e.g., refrigerated) | Restaurants, food service industries | Pros: Tailored services for unique needs, reduced risk of damage. Cons: Niche focus may limit availability. |

| Full-Service Vending Relocation Companies | Comprehensive service including installation and maintenance | Enterprises with ongoing vending needs | Pros: All-in-one solution, minimizes operational downtime. Cons: Higher overall expense, may require long-term contracts. |

| Self-Service Vending Machine Movers | Allow clients to rent equipment for DIY moves | Small businesses, startups | Pros: Cost-saving for smaller operations, flexible scheduling. Cons: Requires client expertise, potential for mishandling. |

Local Vending Machine Movers

Local vending machine movers are ideal for businesses that require quick and cost-effective relocation within a specific region. They typically operate with smaller fleets and can offer flexible scheduling to meet tight timelines. This type is suitable for retail stores and small offices that need to move machines frequently or respond to changes in demand. However, while they excel in local moves, their capacity for long-distance relocations is limited, which may necessitate additional arrangements for broader geographic needs.

National Vending Machine Movers

National vending machine movers provide extensive service across multiple states, making them suitable for large corporations and franchises that require the relocation of multiple machines simultaneously. These companies have the resources and experience to handle complex logistics, including compliance with regulations across different regions. While they offer a vast network and reliability, buyers should be prepared for higher costs and potentially longer lead times, which could affect operational schedules.

Specialized Vending Machine Movers

Specialized vending machine movers focus on specific types of machines, such as refrigerated units or high-tech vending solutions. They cater primarily to industries like restaurants and food service, where the unique handling requirements of these machines necessitate expertise. This specialization reduces the risk of damage during transit and ensures that the machines are set up correctly in their new locations. However, businesses should consider the availability of these services, as they may be limited to certain regions or types of equipment.

Full-Service Vending Relocation Companies

Full-service vending relocation companies offer comprehensive solutions that include not just moving but also installation and maintenance of machines. This type is particularly beneficial for enterprises with ongoing vending needs, as it minimizes operational downtime and ensures a seamless transition. While this all-in-one approach can be highly convenient, buyers should be aware of the higher overall expenses and the potential for long-term contracts that may require commitment.

Self-Service Vending Machine Movers

Self-service vending machine movers provide an option for businesses that prefer to handle the relocation themselves. This model allows clients to rent equipment and manage the moving process, which can be particularly appealing for small businesses and startups looking to save costs. However, this approach requires a level of expertise from the client, and there is a risk of mishandling during the move, which could result in damage or operational delays. This option is best suited for those with experience in logistics and machine handling.

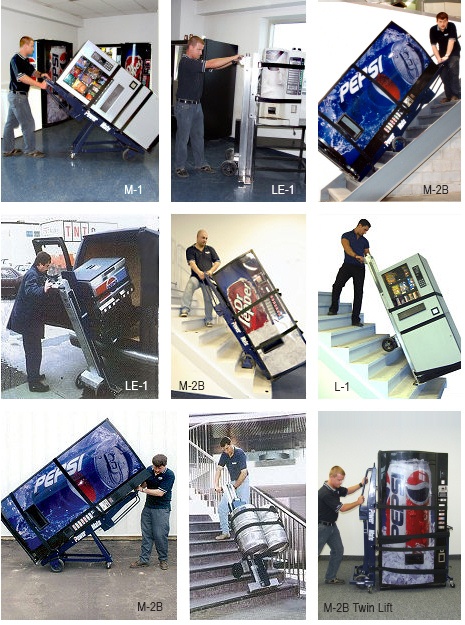

Illustrative Image (Source: Google Search)

Key Industrial Applications of vending machine moving company

| Industry/Sector | Specific Application of vending machine moving company | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Relocation of vending machines in shopping malls | Increased foot traffic and sales opportunities | Local regulations, accessibility, and logistical support |

| Hospitality | Installation and maintenance of vending machines in hotels | Enhanced guest satisfaction and convenience | Machine selection, product offerings, and service frequency |

| Education | Setup of vending machines in schools and universities | Improved access to snacks and beverages for students | Compliance with health standards, machine variety, and payment systems |

| Healthcare | Moving vending machines in hospitals | Provision of quick snacks and drinks for staff and visitors | Hygiene standards, product selection, and machine reliability |

| Corporate Offices | Installation of vending machines in office environments | Boosts employee morale and productivity | Customization options, payment methods, and service response times |

Retail Sector

In the retail industry, vending machine moving companies are essential for relocating machines within shopping malls or retail spaces. This service enhances visibility and accessibility, which can lead to increased foot traffic and sales. International buyers should consider local regulations regarding machine placement and ensure logistical support is available for seamless transitions. Additionally, understanding the target market’s preferences for products offered in these machines can significantly impact sales performance.

Hospitality Industry

In hotels and resorts, vending machines serve as a convenient option for guests seeking snacks and beverages. A vending machine moving company helps install and maintain these machines in strategic locations, such as lobbies and poolsides. This not only enhances guest satisfaction but also generates additional revenue streams for the hotel. Buyers in this sector must focus on machine selection, ensuring that offerings align with guest preferences, while also considering the frequency of service and maintenance.

Education Sector

Schools and universities often utilize vending machines to provide students with quick access to snacks and beverages. Vending machine moving companies play a crucial role in setting up these machines in high-traffic areas. For international buyers, ensuring compliance with health and safety standards is paramount, as well as selecting machines that cater to dietary restrictions. Additionally, the payment systems integrated into these machines should be user-friendly and cater to the student demographic.

Healthcare Sector

Hospitals and healthcare facilities benefit from vending machines that offer quick snacks and drinks for staff and visitors. The moving company is tasked with ensuring these machines are placed in convenient locations, facilitating easy access during busy hours. Buyers must prioritize hygiene standards and the reliability of machines, given the sensitive environment of healthcare. Product selection should also cater to health-conscious choices, enhancing the overall experience for users.

Corporate Offices

In corporate environments, vending machines are a valuable addition that can boost employee morale and productivity by providing convenient snack options. Vending machine moving companies assist in the installation of these machines in common areas, ensuring they are accessible to all employees. Buyers should consider customization options for product offerings based on employee preferences, as well as the integration of various payment methods to facilitate ease of use. Additionally, service response times are critical to maintain machine functionality and employee satisfaction.

Related Video: How to Start a Vending Machine Business, Cost, Tips, How Much You Make

Strategic Material Selection Guide for vending machine moving company

When selecting materials for a vending machine moving company, it is essential to consider various properties that can impact performance, durability, and cost-effectiveness. Below is an analysis of four common materials used in this industry, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Carbon Steel

Key Properties: Carbon steel is known for its high tensile strength and durability. It can withstand significant pressure and is available in various grades, allowing for tailored applications. However, it has a lower corrosion resistance compared to other materials unless treated with protective coatings.

Pros & Cons:

– Advantages: Cost-effective, good strength, and widely available.

– Disadvantages: Susceptible to corrosion if not protected, which can lead to maintenance issues over time.

Impact on Application: Carbon steel is suitable for structural components of vending machines, such as frames and supports, where strength is critical. However, its limited corrosion resistance may restrict its use in humid or corrosive environments.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN. In regions like the Middle East, where humidity can be high, protective coatings may be necessary.

2. Stainless Steel

Key Properties: Stainless steel is renowned for its excellent corrosion resistance and durability. It can withstand high temperatures and is easy to clean, making it ideal for environments where hygiene is a priority.

Pros & Cons:

– Advantages: High durability, corrosion resistance, and aesthetic appeal.

– Disadvantages: Higher cost compared to carbon steel and may require specialized manufacturing techniques.

Impact on Application: Stainless steel is often used in the external casing of vending machines, ensuring longevity and maintaining a clean appearance. Its resistance to corrosion makes it suitable for outdoor installations.

Considerations for International Buyers: Compliance with food safety standards is crucial, especially in regions with strict regulations like Europe. Buyers should also consider the grade of stainless steel, as different grades offer varying levels of corrosion resistance.

3. Aluminum

Key Properties: Aluminum is lightweight yet strong, with good corrosion resistance. It is also an excellent conductor of heat, which can be beneficial in specific applications.

Pros & Cons:

– Advantages: Lightweight, corrosion-resistant, and easy to fabricate.

– Disadvantages: Lower strength compared to steel, which may limit its use in structural applications.

Impact on Application: Aluminum is often used for components that require weight reduction, such as panels and frames. Its corrosion resistance makes it suitable for outdoor vending machines.

Considerations for International Buyers: Aluminum is generally compliant with international standards, but buyers should ensure that the specific alloy used meets their application requirements. In regions like Africa, where transport conditions may vary, lightweight materials can facilitate easier handling.

4. Polypropylene

Key Properties: Polypropylene is a thermoplastic polymer known for its chemical resistance and lightweight nature. It can withstand a range of temperatures and is often used in non-structural applications.

Pros & Cons:

– Advantages: Cost-effective, excellent chemical resistance, and lightweight.

– Disadvantages: Limited structural strength and may not be suitable for high-load applications.

Impact on Application: Polypropylene is ideal for internal components of vending machines, such as trays and bins, where chemical exposure is a concern. Its lightweight nature can also aid in transport.

Considerations for International Buyers: While polypropylene is generally compliant with various international standards, buyers should verify its suitability for specific applications, especially in regions with extreme temperatures or chemical exposure.

Summary Table

| Material | Typical Use Case for vending machine moving company | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural components like frames and supports | Cost-effective, good strength | Susceptible to corrosion if unprotected | Low |

| Stainless Steel | External casing and components requiring hygiene | High durability, corrosion resistance | Higher cost, may require specialized mfg | High |

| Aluminum | Lightweight panels and frames | Lightweight, corrosion-resistant | Lower strength compared to steel | Medium |

| Polypropylene | Internal components like trays and bins | Cost-effective, excellent chemical resistance | Limited structural strength | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for vending machine moving company

Manufacturing Processes for Vending Machine Moving Companies

Manufacturing vending machines involves a series of structured processes that ensure quality, reliability, and functionality. For B2B buyers, understanding these processes is essential for making informed purchasing decisions. Below is a breakdown of the main stages involved in manufacturing vending machines, along with the key techniques employed at each stage.

Illustrative Image (Source: Google Search)

1. Material Preparation

The first step in the manufacturing process is material preparation, which involves sourcing and selecting high-quality materials that meet the specifications for vending machine production. Common materials include:

- Metals: Steel and aluminum are typically used for the frame and exterior due to their durability and resistance to corrosion.

- Plastic: Used for internal components and panels to reduce weight and costs.

- Glass: Utilized for display cases, requiring tempered glass for safety and durability.

Key Techniques:

– Supplier Evaluation: Assessing suppliers based on their material quality and compliance with international standards.

– Material Testing: Conducting tests for tensile strength, corrosion resistance, and thermal stability.

2. Forming

The forming stage involves shaping the prepared materials into the required components of the vending machine. This includes processes such as:

- Sheet Metal Fabrication: Techniques like laser cutting and CNC machining are used to create precise metal parts.

- Injection Molding: Employed for manufacturing plastic components, allowing for complex shapes and designs.

- Bending and Stamping: Used to create structural parts that require specific angles and contours.

Key Techniques:

– Computer Numerical Control (CNC): Ensures high precision in cutting and shaping materials.

– 3D Printing: Increasingly used for prototyping parts to evaluate design before full-scale production.

3. Assembly

During the assembly phase, all components are brought together to form the complete vending machine. This involves:

- Mechanical Assembly: Installing parts such as motors, compressors, and electronic systems.

- Electrical Assembly: Wiring control systems and integrating payment mechanisms like coin acceptors and card readers.

Key Techniques:

– Lean Manufacturing: Adopting principles that minimize waste and optimize assembly line efficiency.

– Modular Assembly: Allowing for easier upgrades and repairs by using interchangeable components.

4. Finishing

The final stage is finishing, which enhances the aesthetic appeal and functionality of the vending machines. This includes:

- Painting and Coating: Applying protective coatings and finishes that improve durability and visual appeal.

- Quality Control Checks: Conducting inspections to ensure that the assembly meets design specifications.

Key Techniques:

– Powder Coating: A process that provides a durable finish and is environmentally friendly.

– Screen Printing: Used for branding and user interface labeling on machines.

Quality Assurance in Vending Machine Manufacturing

Quality assurance (QA) is crucial in the manufacturing process to ensure that vending machines meet international standards and customer expectations. This involves a series of checks and compliance with relevant standards.

International Standards

For B2B buyers, understanding the relevant quality standards is key to ensuring that suppliers meet the necessary criteria. Key standards include:

- ISO 9001: This standard focuses on quality management systems and continuous improvement, ensuring that manufacturing processes are efficient and effective.

- CE Marking: Indicates that the product complies with European health, safety, and environmental protection standards.

- API Certification: Relevant for machines that involve mechanical and electronic components, ensuring they meet industry-specific requirements.

QC Checkpoints

Quality control checkpoints are integral to maintaining high manufacturing standards. Common checkpoints include:

- Incoming Quality Control (IQC): Inspection of materials and components upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify defects early.

- Final Quality Control (FQC): Comprehensive checks on the finished product to ensure it functions correctly and meets all quality standards.

Common Testing Methods

Testing methods employed in the quality assurance process include:

- Functional Testing: Assessing the operational capabilities of the vending machine.

- Durability Testing: Simulating real-world usage to evaluate how the machine holds up under stress.

- Safety Testing: Ensuring that all electrical components comply with safety regulations.

Verifying Supplier Quality Control

B2B buyers must take steps to verify the quality control measures of their suppliers. Here are actionable insights on how to do this:

- Supplier Audits: Conducting regular audits of suppliers’ manufacturing processes to ensure compliance with quality standards.

- Requesting Quality Reports: Asking suppliers for documentation of their quality control processes and results from recent inspections.

- Third-Party Inspections: Engaging independent organizations to evaluate the manufacturing processes and quality control systems of suppliers.

QC and Certification Nuances for International Buyers

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is vital. Here are some considerations:

- Local Regulations: Be aware of specific regulations that may differ from one region to another, impacting the certification process.

- Cultural Sensitivities: Different cultures may have varying expectations regarding quality and service; understanding these can enhance supplier relationships.

- Language Barriers: Ensure that all quality documentation and communication are clear and comprehensible to avoid misunderstandings.

By understanding the manufacturing processes and quality assurance measures involved in vending machine production, B2B buyers can make informed decisions and ensure they partner with reliable suppliers that meet their quality expectations.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for vending machine moving company Sourcing

When sourcing vending machine moving services, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This analysis focuses on key cost components, price influencers, and actionable buyer tips that can lead to more informed purchasing decisions.

Cost Components

-

Materials: This includes the physical resources required for moving vending machines, such as packing materials, crates, and any specialized equipment needed to ensure the machines are transported safely. Depending on the complexity of the job, costs can vary significantly.

-

Labor: Labor costs encompass wages for the moving crew, which can fluctuate based on the local labor market. Skilled labor might demand higher rates, particularly if the job requires specialized knowledge of vending machines.

-

Manufacturing Overhead: While this may not apply directly to moving services, any company engaged in manufacturing vending machines may include overhead costs in their service pricing, particularly if the moving company is part of a larger operation.

-

Tooling: Specialized tools for handling and moving machines, such as dollies or hoists, represent a significant part of the cost. If the moving company needs to invest in custom tools for particular vending machines, this will be reflected in the pricing.

-

Quality Control (QC): Ensuring that machines are not damaged during the move requires quality control processes, which can add to the overall cost. Companies may charge for additional inspections or guarantees against damage.

-

Logistics: This includes route planning, transportation costs, fuel, and potential storage fees if the move requires temporary holding. The geographical distance between the origin and destination significantly impacts logistics costs.

-

Margin: Moving companies will typically add a markup to cover their operational costs and profit margin. Understanding the average margins within the industry can help buyers gauge whether they are receiving competitive pricing.

Price Influencers

-

Volume / Minimum Order Quantity (MOQ): Larger orders often lead to discounted rates. Buyers should consider consolidating multiple moves to benefit from lower pricing.

-

Specifications / Customization: Custom requirements, such as specific handling procedures for high-value machines, can increase costs. Clearly defining specifications upfront can help avoid unexpected charges.

-

Materials: The choice of materials for packing and transport can affect pricing. Opting for more robust, protective materials may incur higher costs but provide better protection.

-

Quality and Certifications: Companies with recognized certifications or a reputation for quality may charge a premium. Buyers should weigh the benefits of these certifications against cost.

-

Supplier Factors: The reputation, experience, and location of the moving company can significantly influence pricing. Established companies may charge more due to their track record and reliability.

-

Incoterms: Understanding the International Commercial Terms (Incoterms) that apply to the shipping of vending machines can clarify responsibilities and costs, impacting the total price.

Buyer Tips

-

Negotiation: Always negotiate pricing. Companies may have flexibility, especially for larger contracts or repeat business.

-

Cost Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the upfront costs but also potential costs associated with downtime or damage during the move.

-

Pricing Nuances for International Buyers: B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import/export duties, and local taxes that can impact overall costs.

-

Research and Compare: Don’t settle for the first quote. Gather multiple quotes to understand the market rate and ensure you are getting a competitive price.

-

Seek References: Look for testimonials or case studies from similar businesses to gauge the reliability and service quality of the moving company.

Disclaimer

Prices can vary widely based on location, the complexity of the move, and market conditions. Always request detailed quotes and breakdowns to ensure transparency in pricing.

Spotlight on Potential vending machine moving company Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘vending machine moving company’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for vending machine moving company

Key Technical Properties for Vending Machine Moving Companies

When engaging with a vending machine moving company, understanding specific technical properties is crucial for making informed decisions. Here are some essential specifications to consider:

-

Weight Capacity: This refers to the maximum weight a moving team can safely transport. Vending machines can vary significantly in weight, often ranging from 300 to over 1,000 pounds. Knowing the weight capacity ensures that the moving company has the appropriate equipment and manpower to handle the job safely and efficiently.

-

Material Grade: Vending machines are typically made from various materials, including steel and aluminum. The grade of material can affect durability and security. A higher-grade material may indicate a more robust machine, which may require specialized handling during transport to avoid damage.

-

Dimensions and Tolerance: The dimensions of a vending machine (height, width, and depth) must be accurately measured to ensure it fits through doorways and into transportation vehicles. Tolerance levels refer to the acceptable variance in these dimensions, which is essential for ensuring a snug fit during transport to prevent damage.

-

Electrical Specifications: Many vending machines require electrical connections for operation. Understanding the electrical specifications, such as voltage and amperage, is crucial for ensuring that the machine can be safely moved and reconnected at its new location without electrical issues.

-

Transport Equipment: The type of transport equipment used, such as dollies, lifts, and trucks, is vital for the safe moving of vending machines. Ensure the moving company uses appropriate equipment that complies with industry safety standards.

Understanding these technical properties helps B2B buyers assess the capabilities of vending machine moving companies and ensures a smooth transition during relocation.

Common Trade Terminology in Vending Machine Moving

Familiarity with industry jargon can facilitate better communication and negotiation with vending machine moving companies. Here are some common terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce the original vending machines. Understanding OEM relationships can help buyers source compatible replacement parts or ensure that machines are moved by those familiar with their specific design.

-

MOQ (Minimum Order Quantity): In the context of vending machine moving, MOQ may refer to the minimum number of machines that can be moved as a single order. Knowing the MOQ helps buyers plan their logistics and budget effectively.

-

RFQ (Request for Quotation): An RFQ is a standard business process used to invite suppliers to bid on specific products or services. When moving vending machines, issuing an RFQ allows buyers to compare costs and services from various moving companies, ensuring they get the best deal.

-

Incoterms (International Commercial Terms): These are pre-defined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers. For international buyers, understanding Incoterms is critical for clarifying who bears the risk and costs associated with transporting vending machines.

-

Lead Time: This refers to the amount of time it takes from placing an order to the delivery of the vending machines. Knowing the lead time is essential for planning and ensuring that machines are available when needed.

-

Installation Services: Some vending machine moving companies offer installation services post-move. Understanding whether these services are included can save time and additional costs for buyers.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of the vending machine moving industry more effectively, ensuring a seamless and cost-effective experience.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine moving company Sector

Global dynamics are reshaping the vending machine moving sector, driven by technological advancements, changing consumer behavior, and increased demand for convenience. The market is witnessing a surge in automation and smart technology integration, which enhances operational efficiency and customer engagement. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these trends is crucial for making informed sourcing decisions.

Current and Emerging Trends:

1. Technological Integration: The adoption of IoT (Internet of Things) in vending machines allows for real-time monitoring of inventory and machine performance, enabling predictive maintenance and reducing downtime.

2. E-commerce Influence: The rise of online shopping is prompting vending operators to diversify their offerings, including healthier options and niche products that cater to specific consumer needs.

3. Local Sourcing: There is a growing preference for local suppliers to mitigate risks associated with supply chain disruptions and reduce transportation costs. B2B buyers should consider partnerships with local moving companies that understand regional logistics.

Market Dynamics:

The vending machine moving sector is becoming increasingly competitive, with companies seeking to differentiate themselves through service quality and technological capabilities. Buyers must assess potential partners not only on price but also on their ability to provide innovative solutions and adapt to changing market demands.

Sustainability & Ethical Sourcing in B2B

The environmental impact of the vending machine moving industry is a critical concern. As sustainability becomes a priority for businesses globally, companies are under pressure to reduce their carbon footprints and implement eco-friendly practices.

Importance of Ethical Supply Chains:

B2B buyers should prioritize suppliers who demonstrate a commitment to sustainability through ethical sourcing and responsible waste management practices. This includes:

– Utilizing recyclable materials in vending machines.

– Implementing energy-efficient technologies that reduce power consumption.

– Ensuring that labor practices comply with international standards, promoting fair wages and safe working conditions.

Green Certifications:

Obtaining certifications such as ISO 14001 (Environmental Management) can enhance a company’s reputation and appeal to environmentally conscious consumers. Buyers should look for vendors who hold such certifications, as they reflect a commitment to minimizing environmental impact and promoting sustainable practices.

Brief Evolution/History

The vending machine moving industry has evolved significantly over the past few decades. Initially dominated by manual operations, advancements in technology have transformed the sector, introducing automated systems that streamline logistics and enhance service delivery. The introduction of smart vending solutions has further shifted the landscape, allowing operators to offer more diverse products and improve customer experiences. This evolution is crucial for B2B buyers to understand, as it influences current sourcing strategies and partnership considerations.

In summary, navigating the complexities of the vending machine moving sector requires B2B buyers to stay informed about market dynamics, prioritize sustainability, and leverage technological advancements to foster successful partnerships.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of vending machine moving company

-

What factors should I consider when vetting a vending machine moving company?

When vetting a vending machine moving company, prioritize their experience in handling similar projects, especially in your region. Request references and check reviews from previous clients to assess reliability. Ensure they have the necessary insurance and certifications, which can protect you against potential damages during the move. Additionally, inquire about their logistics capabilities, including equipment used and their familiarity with local regulations related to transporting heavy machinery. -

Can I customize the moving services to fit my specific needs?

Yes, most vending machine moving companies offer customizable services tailored to your requirements. Discuss your specific needs, such as the type and size of the vending machines, the distance of the move, and any special handling requirements. A reputable company will be open to tailoring their services, including packing, transportation, and installation, to ensure a seamless experience. -

What are the typical minimum order quantities (MOQ) and lead times for international moving?

Minimum order quantities (MOQ) can vary significantly between companies and depend on the scale of your operation. Generally, for international moves, expect a MOQ that allows for cost-effective transportation. Lead times can also differ, typically ranging from a few days to several weeks, depending on the destination and logistical complexities. It’s essential to communicate your timeline and needs upfront to align expectations with the moving company. -

What payment options are available, and are there any upfront costs?

Payment options for vending machine moving services may include bank transfers, credit cards, or payment through escrow services for larger projects. Some companies may require a deposit upfront, especially for international moves, to secure your booking. Clarify the payment terms, including total costs, any additional fees for customization, and the timeline for payments to avoid misunderstandings. -

How do I ensure quality assurance and certifications from the moving company?

To ensure quality assurance, request documentation of the company’s certifications and adherence to industry standards. Look for certifications from recognized organizations that validate their expertise in moving heavy equipment. Additionally, inquire about their quality control processes and whether they conduct regular training for their staff to maintain high service standards throughout the moving process. -

What logistics should I consider when moving vending machines internationally?

International logistics for moving vending machines involve several critical considerations, including customs regulations, import/export documentation, and the mode of transportation. Work closely with your moving company to understand the specific requirements for your destination country. Ensure they have a clear logistics plan that covers loading, transportation, unloading, and installation, while also considering the timeframes involved to avoid delays. -

How are disputes typically resolved if issues arise during the moving process?

Dispute resolution processes should be clearly outlined in your contract with the moving company. Typically, issues such as damage to equipment or delays can be addressed through direct communication. Many reputable companies will have a formal procedure for handling disputes, including mediation or arbitration. It’s advisable to document any issues and communicate them promptly to the company to facilitate a swift resolution. -

What should I do if my vending machine is damaged during transport?

In the event of damage during transport, immediately report the issue to the moving company. Most companies will require you to provide evidence, such as photographs of the damage, and will guide you through their claims process. Review the terms of your contract to understand your rights regarding claims and compensation. A reliable moving company should have insurance to cover damages, and they should assist you in filing a claim efficiently.

Strategic Sourcing Conclusion and Outlook for vending machine moving company

In conclusion, strategic sourcing for vending machine moving companies is essential for optimizing operations and enhancing service delivery. By focusing on reliable partnerships, buyers can ensure that logistics are managed effectively, minimizing downtime and reducing costs. Key takeaways include the importance of evaluating suppliers based on their experience, technology adoption, and capacity to meet diverse regional needs.

International buyers from Africa, South America, the Middle East, and Europe, particularly in Turkey and the UAE, should leverage strategic sourcing to tap into local expertise and navigate the complexities of cross-border logistics. This approach not only fosters efficiency but also enhances customer satisfaction by ensuring timely and safe relocation of vending machines.

As the vending machine market continues to evolve, embracing innovative solutions and maintaining flexibility in sourcing strategies will be crucial. We encourage businesses to take proactive steps in identifying and partnering with top-tier moving companies that align with their operational goals. By doing so, they position themselves for sustainable growth and competitive advantage in an increasingly interconnected marketplace.