Your Ultimate Guide to Sourcing Vending Machine Locator

Guide to Vending Machine Locator Service

- Introduction: Navigating the Global Market for vending machine locator service

- Understanding vending machine locator service Types and Variations

- Key Industrial Applications of vending machine locator service

- Strategic Material Selection Guide for vending machine locator service

- In-depth Look: Manufacturing Processes and Quality Assurance for vending machine locator service

- Comprehensive Cost and Pricing Analysis for vending machine locator service Sourcing

- Spotlight on Potential vending machine locator service Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for vending machine locator service

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine locator service Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vending machine locator service

- Strategic Sourcing Conclusion and Outlook for vending machine locator service

Introduction: Navigating the Global Market for vending machine locator service

Navigating the global market for vending machine locator services is crucial for B2B buyers aiming to capitalize on the booming vending industry. As demand for convenient access to snacks and beverages continues to rise, the strategic placement of vending machines can significantly influence profitability. Vending machine locator services play an essential role in identifying high-traffic locations, ensuring that businesses can maximize their reach and sales potential.

This comprehensive guide serves as an invaluable resource for international B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Argentina. It will delve into various aspects of vending machine locator services, including types of locations, materials used, manufacturing and quality control processes, supplier options, and cost considerations.

Additionally, we will address market trends and provide answers to frequently asked questions, equipping you with the knowledge needed to make informed sourcing decisions. By leveraging these insights, you can optimize your vending machine placements, align your product offerings with consumer preferences, and foster fruitful partnerships with suppliers. This guide empowers you to navigate the complexities of the vending market effectively, positioning your business for success in a competitive landscape.

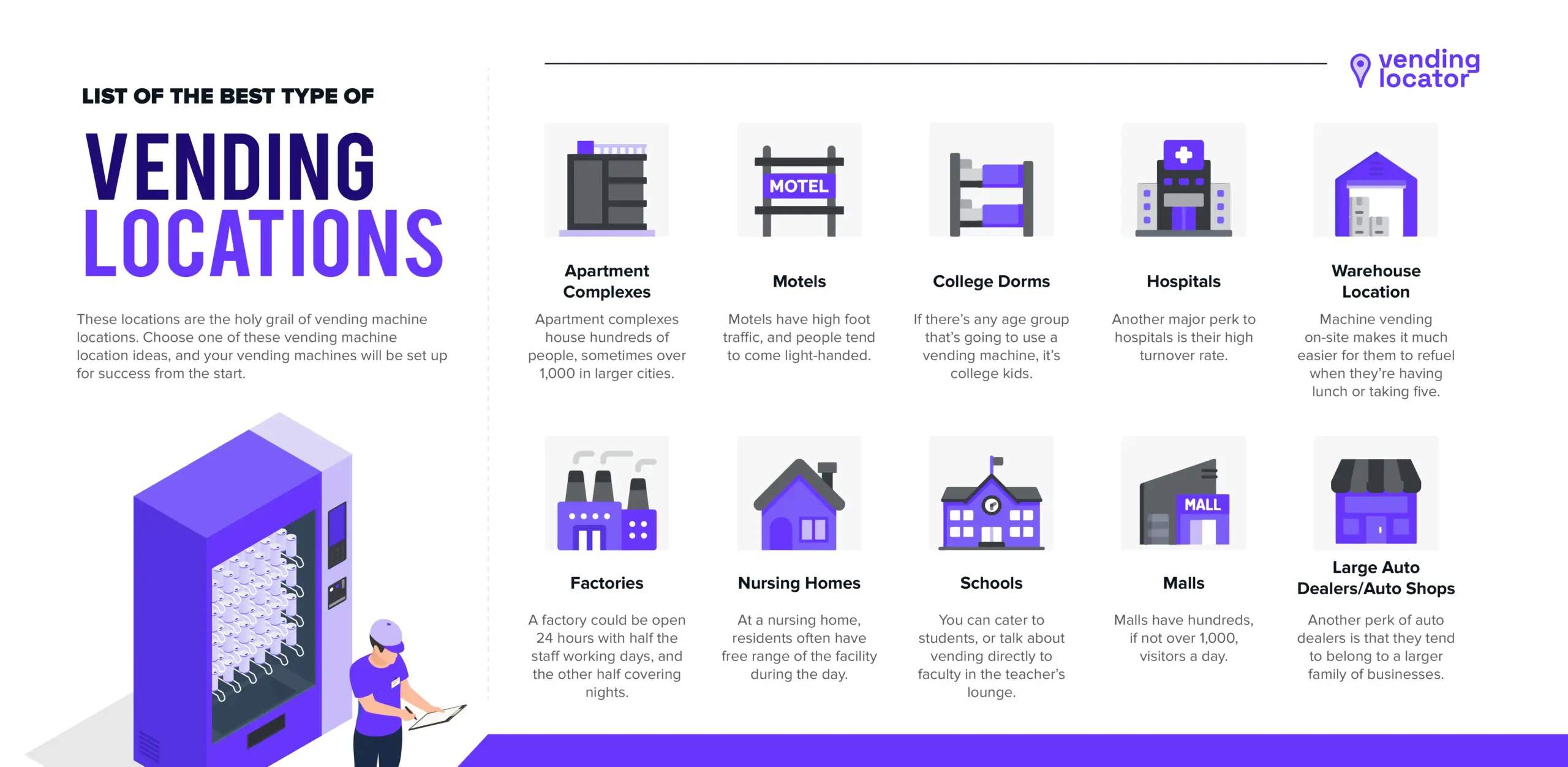

Illustrative Image (Source: Google Search)

Understanding vending machine locator service Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Data-Driven Locator Services | Utilizes analytics and location data for optimal placement | Retail, corporate offices, gyms | Pros: Precision in location selection; maximizes foot traffic. Cons: Potentially higher costs due to data services. |

| Traditional Locator Services | Manual identification of potential vending locations | Small businesses, local vendors | Pros: Lower cost; personal touch in service. Cons: Time-consuming; may lack data accuracy. |

| Mobile App-Based Services | Allows users to find locations via smartphone apps | On-the-go operators, tech-savvy businesses | Pros: Convenience; real-time updates. Cons: Dependent on technology; may exclude less tech-oriented users. |

| Franchise Locator Services | Specialized in finding locations for vending franchises | Franchise owners, multi-location operators | Pros: Tailored solutions for franchises; industry expertise. Cons: May not cater to independent operators. |

| Industry-Specific Locator Services | Focused on niche markets (e.g., health products, organic snacks) | Specialty vending, targeted demographics | Pros: Aligns with specific product offerings; addresses niche demands. Cons: Limited scope; may not be versatile. |

Data-Driven Locator Services

Data-driven locator services leverage advanced analytics and geographic information systems (GIS) to identify optimal vending machine placements. By analyzing foot traffic patterns, demographics, and local competition, these services provide businesses with actionable insights for maximizing their vending operations. B2B buyers seeking high-traffic locations will find this type particularly beneficial, despite potentially higher costs associated with sophisticated data services. The precision offered can lead to significantly increased sales and operational efficiency.

Traditional Locator Services

Traditional locator services rely on manual methods to scout and identify potential vending locations. This approach often involves local expertise and personal relationships, making it suitable for small businesses or vendors just starting out. While these services tend to be more affordable, they can be time-consuming and may lack the accuracy that data-driven methods provide. B2B buyers must weigh the benefits of lower costs against the potential for less optimal site selection.

Mobile App-Based Services

Mobile app-based locator services provide a modern solution for vending machine operators looking for convenience and real-time information. Users can quickly find and assess potential locations through user-friendly applications, making it ideal for on-the-go operators and tech-savvy businesses. However, reliance on technology can be a drawback, as it may alienate less tech-oriented users. B2B buyers should consider the technological capabilities of their teams before investing in these services.

Franchise Locator Services

Franchise locator services specialize in finding locations specifically for vending franchises, offering tailored solutions that cater to the unique needs of franchise owners. These services often come with industry expertise and a comprehensive understanding of market dynamics. While they are particularly beneficial for multi-location operators, independent vendors may find these services less applicable. Buyers should evaluate whether their business model aligns with the franchise-focused approach.

Industry-Specific Locator Services

Industry-specific locator services focus on niche markets, such as health-focused vending or organic products. By targeting specific demographics, these services help operators align their product offerings with consumer preferences, ensuring greater relevance and demand. However, the limited scope can be a drawback for businesses looking for more versatile solutions. B2B buyers in specialized markets should consider how well these services address their unique needs and customer bases.

Related Video: Cloud Computing Service Models | IaaS PaaS SaaS Explained | Cloud Masters Program | Edureka

Key Industrial Applications of vending machine locator service

| Industry/Sector | Specific Application of vending machine locator service | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Corporate Offices | Identifying high-traffic areas for vending machines | Increased employee convenience and satisfaction | Understanding office demographics and snack preferences |

| Educational Institutions | Locating vending opportunities in schools and universities | Steady revenue from students and staff | Compliance with health regulations, targeting youth trends |

| Healthcare Facilities | Finding vending locations in hospitals and clinics | Providing quick access to snacks and beverages for patients and visitors | Nutritional product sourcing, adherence to dietary guidelines |

| Fitness Centers | Locating vending machines in gyms and sports complexes | Catering to health-conscious consumers | Sourcing healthy snacks and beverages, understanding fitness trends |

| Hospitality Sector | Identifying placement opportunities in hotels | Enhancing guest experience with convenient options | Sourcing premium products, understanding guest demographics |

Corporate Offices

In corporate environments, vending machine locator services can identify high-traffic areas, such as break rooms or lobbies, where machines can be strategically placed. This service addresses the need for convenience among employees, ultimately enhancing job satisfaction and productivity. International buyers, especially in regions like Europe or South America, should consider local dietary preferences and snack trends when sourcing products to ensure they meet the needs of diverse workforces.

Educational Institutions

Vending machines in schools and universities offer an easy solution for students and staff seeking quick snacks and beverages. A vending machine locator service can pinpoint optimal locations within these institutions, addressing the challenge of finding high-traffic areas. For international B2B buyers, compliance with health regulations and an understanding of youth trends in snacks are crucial when sourcing products that appeal to this demographic, particularly in regions like Africa and South America.

Healthcare Facilities

Hospitals and clinics can benefit significantly from vending machine locator services by providing quick access to snacks and beverages for patients, visitors, and staff. These services help identify strategic locations that maximize foot traffic, thereby increasing sales. Buyers in the healthcare sector must consider sourcing products that comply with dietary guidelines and offer nutritional benefits, which is particularly important in regions with diverse health needs, such as the Middle East.

Fitness Centers

Fitness centers are prime locations for vending machines that cater to health-conscious consumers. A vending machine locator service can assist in identifying high-traffic areas within gyms and sports complexes, ensuring that the machines are placed where they will attract customers. International buyers should focus on sourcing healthy snacks and beverages that align with current fitness trends, particularly in regions like Europe where wellness culture is prominent.

Hospitality Sector

In the hospitality sector, vending machine locator services can help identify placement opportunities within hotels, enhancing the guest experience by providing convenient access to snacks and drinks. This service ensures that machines are located in high-traffic areas, such as lobbies or near meeting rooms. Buyers in this sector need to source premium products that cater to diverse guest demographics, focusing on quality and unique offerings to stand out in competitive markets, especially in regions like Africa and South America.

Related Video: 7 Ways To Find VENDING MACHINE LOCATIONS! | PAPPY G

Strategic Material Selection Guide for vending machine locator service

When selecting materials for a vending machine locator service, it’s crucial to consider how these materials will perform in various environments and applications. Below is an analysis of common materials used in vending machine locator services, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. It typically has a temperature rating of up to 800°F and is resistant to oxidation.

Pros & Cons: The durability of stainless steel makes it ideal for long-term applications, particularly in environments where moisture is prevalent. However, it can be more expensive than other materials, and its manufacturing process can be complex, often requiring specialized equipment.

Impact on Application: Stainless steel is highly suitable for components exposed to various media, including water and food products. Its non-reactive nature ensures that it does not contaminate the products it houses.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards regarding food safety and corrosion resistance. Common standards include ASTM and ISO certifications.

2. Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can withstand temperatures up to 400°F and is often treated to enhance its resistance to corrosion.

Pros & Cons: The primary advantage of aluminum is its low weight, making it easier to handle and install. However, it is less durable than stainless steel and can be prone to denting or deformation under heavy loads.

Impact on Application: Aluminum is suitable for components that require a lightweight solution without compromising too much on strength. It is particularly effective in applications where weight savings are critical.

Considerations for International Buyers: Buyers should be aware of the specific grades of aluminum that meet local standards. For instance, in Europe, compliance with EN standards is essential, while in the Middle East, buyers may prefer materials that withstand high humidity and temperature variations.

3. Polycarbonate

Key Properties: Polycarbonate is a high-impact-resistant plastic that can endure temperatures ranging from -40°F to 240°F. It offers excellent clarity and UV resistance, making it suitable for transparent components.

Pros & Cons: The major advantage of polycarbonate is its lightweight nature and high impact resistance, which makes it ideal for protective covers and displays. However, it can be susceptible to scratching and may not be suitable for high-temperature applications.

Impact on Application: Polycarbonate is often used for protective casings and viewing panels in vending machines. Its transparency allows for easy visibility of products, enhancing customer interaction.

Considerations for International Buyers: Buyers should ensure that the polycarbonate used is compliant with safety standards, especially in regions with stringent regulations like Europe. Furthermore, they should consider the environmental impact of plastic materials and opt for recyclable options when possible.

4. Carbon Steel

Key Properties: Carbon steel is known for its high strength and durability, with a typical temperature rating of up to 400°F. It is less resistant to corrosion compared to stainless steel but can be treated with coatings to enhance its resistance.

Pros & Cons: Carbon steel is often more cost-effective than stainless steel, making it a popular choice for budget-conscious projects. However, its susceptibility to rust and corrosion can limit its application in moist environments unless adequately protected.

Impact on Application: Carbon steel is suitable for structural components and frames where strength is a priority. However, it may not be ideal for parts exposed to moisture without protective coatings.

Considerations for International Buyers: Buyers should be aware of the need for protective coatings and ensure compliance with local standards for structural integrity. In regions like Nigeria and Argentina, understanding local environmental conditions can dictate the choice of protective measures.

Summary Table

| Material | Typical Use Case for vending machine locator service | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, protective casings | Excellent corrosion resistance, durability | Higher cost, complex manufacturing | High |

| Aluminum | Lightweight frames, covers | Lightweight, good corrosion resistance | Less durable, prone to deformation | Medium |

| Polycarbonate | Protective covers, viewing panels | High impact resistance, clarity | Susceptible to scratching, temperature limits | Low |

| Carbon Steel | Structural frames, non-corrosive environments | Cost-effective, high strength | Corrosion susceptibility without coating | Low |

This guide provides a comprehensive overview of materials that can be utilized in vending machine locator services, offering actionable insights for international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for vending machine locator service

Manufacturing Processes for Vending Machine Locator Services

The manufacturing process for a vending machine locator service involves several critical stages, each designed to ensure that the final product is reliable, efficient, and meets the specific needs of B2B buyers. Understanding these stages is essential for international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, as it influences their purchasing decisions and supplier evaluations.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Materials: The initial step involves selecting the right materials that can withstand various environmental conditions. This might include durable plastics, metals, and electronic components.

– Quality Checks: Materials undergo quality checks to ensure they meet required specifications. This includes evaluating the durability, weight, and compatibility of materials with the intended design. -

Forming

– Molding and Shaping: Techniques such as injection molding for plastics or metal stamping for metal parts are utilized. This allows for precise shaping of components that are critical for the functionality of the vending machine locator.

– Component Fabrication: This stage may also involve the fabrication of circuit boards and sensors that are essential for the locator’s operation. -

Assembly

– Integration of Components: The various parts are assembled, which includes integrating the hardware, software, and user interface elements. This is a crucial stage where the assembly must ensure that all components work seamlessly together.

– Use of Automation: Many manufacturers leverage automation to enhance efficiency and reduce human error during assembly, which is particularly important in high-volume production. -

Finishing

– Surface Treatment: After assembly, surface treatments such as painting, powder coating, or applying protective films are conducted. This not only enhances the aesthetics but also increases the durability of the locator service.

– Final Inspection: A thorough inspection is performed to check for any defects in the finish, which is vital for maintaining quality standards.

Quality Assurance (QA) Processes

Quality assurance is paramount in the manufacturing of vending machine locator services. Ensuring that each product adheres to international standards and meets customer expectations involves several processes.

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems and is applicable to any organization seeking to improve its processes. Manufacturers must implement processes that ensure consistent quality in their products.

- CE Marking: For products sold in the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: These may be relevant for certain electronic components used in vending machine locators, ensuring they meet industry-specific performance standards.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– This step involves inspecting materials and components upon arrival at the manufacturing facility. Suppliers must provide certificates of compliance to verify that materials meet specified standards. -

In-Process Quality Control (IPQC)

– During manufacturing, ongoing checks are performed to monitor the assembly process. This helps in identifying defects early and making necessary adjustments. -

Final Quality Control (FQC)

– After assembly, a comprehensive inspection is conducted. This includes functional testing of the locator service to ensure it operates as intended under various conditions.

Common Testing Methods

- Functional Testing: Verifying that the locator service performs all required functions accurately.

- Environmental Testing: Assessing the product’s performance under different environmental conditions, such as humidity and temperature fluctuations.

- Durability Testing: Ensuring that the product can withstand physical stress and wear over time.

Verifying Supplier Quality Control

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential for mitigating risks. Here are several actionable steps:

-

Audits

– Conducting audits of the manufacturing facility can provide insight into the quality control processes in place. This includes reviewing documentation, quality records, and inspection reports. -

Quality Reports

– Requesting detailed quality reports from suppliers can help buyers understand the consistency of product quality over time. These reports should include data on defect rates and corrective actions taken.

- Third-Party Inspections

– Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can be particularly useful for buyers unfamiliar with local manufacturing standards.

Quality Control and Certification Nuances for International Buyers

International buyers need to be aware of certain nuances regarding quality control and certification. Different regions may have varying standards and regulations, which can impact product compliance.

- Regional Regulations: Buyers from Europe may prioritize CE marking, while those in Africa might focus on local compliance certifications. Understanding these distinctions is crucial for ensuring market acceptance.

- Cultural Considerations: Building relationships with suppliers can also influence quality assurance. In many cultures, personal relationships can lead to better cooperation in addressing quality issues.

- Language Barriers: Clear communication regarding quality standards and expectations is vital. Buyers should ensure that all specifications are documented in a language understood by both parties.

By understanding the manufacturing processes and quality assurance practices involved in vending machine locator services, international B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who meet their quality and compliance needs.

Related Video: China’s Top 5 Manufacturing and Mass Production Videos | by @miracleprocess

Comprehensive Cost and Pricing Analysis for vending machine locator service Sourcing

When engaging in the procurement of vending machine locator services, understanding the cost structure and pricing dynamics is crucial for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe. This analysis will provide insights into the various cost components involved, the factors influencing pricing, and actionable tips for buyers.

Cost Components of Vending Machine Locator Services

-

Materials: The primary materials involved in vending machine locator services include software tools, databases, and proprietary algorithms that enhance location identification accuracy. High-quality software development can entail significant initial investment.

-

Labor: Labor costs encompass the salaries of data analysts, software developers, and support staff involved in providing the locator service. Skilled labor is essential for developing and maintaining the locator system and ensuring effective customer service.

Illustrative Image (Source: Google Search)

-

Manufacturing Overhead: This includes costs related to office space, utilities, and administrative expenses that support the operation of the service. Overhead can vary significantly based on geographic location and operational scale.

-

Tooling: Investment in technology and tools, such as GPS systems and mapping software, is critical for providing accurate and reliable location services. Continuous updates and maintenance of these tools contribute to long-term costs.

-

Quality Control (QC): Ensuring the accuracy of location data requires rigorous quality control processes, which may involve additional personnel and technology investments. This is vital for maintaining customer trust and service reliability.

-

Logistics: While not as prominent as in physical goods, logistics in this context refers to the management of data flow and information systems, ensuring that clients receive timely updates on available vending locations.

-

Margin: Service providers typically include a profit margin that can vary based on market competition, demand, and service differentiation. Understanding the margin can aid in price negotiations.

Price Influencers

Several factors can significantly influence the pricing of vending machine locator services:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract discounts, making it beneficial for buyers to consolidate needs where possible.

-

Specifications/Customization: Tailored services may come at a premium. Buyers should assess whether standard offerings meet their needs or if customization is necessary.

-

Materials and Quality Certifications: The quality of the software and technology used can impact pricing. Services utilizing advanced technology and possessing industry certifications may justify higher costs.

-

Supplier Factors: The reputation and experience of the supplier can affect pricing. Established providers with proven track records may charge more due to the added value they bring.

-

Incoterms: Understanding the delivery terms, including responsibilities for shipping and handling, can influence total costs. Buyers should clarify who bears the costs and risks at various stages of the service delivery.

Buyer Tips

For international B2B buyers, particularly in regions like Nigeria and Argentina, several strategies can enhance cost-efficiency:

-

Negotiate Pricing: Engage in discussions to secure favorable terms. Highlight your potential volume and long-term relationship to leverage better pricing.

-

Consider Total Cost of Ownership (TCO): Evaluate the overall cost implications of the locator service, including potential revenue generation from improved location placement, rather than just the upfront price.

-

Understand Pricing Nuances: Be aware of local market conditions and pricing benchmarks within your region. This knowledge can empower you during negotiations and help you avoid overpaying.

-

Seek References and Case Studies: Before committing, request case studies or references from similar businesses in your region. This can provide insights into the value and effectiveness of the service.

Disclaimer

Prices for vending machine locator services can vary significantly based on the above factors and are subject to change based on market conditions. Buyers are encouraged to conduct thorough market research and engage in direct discussions with service providers to obtain the most accurate and relevant pricing information.

Spotlight on Potential vending machine locator service Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘vending machine locator service’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for vending machine locator service

Critical Technical Properties of Vending Machine Locator Services

When engaging with vending machine locator services, understanding the technical properties that underpin their offerings is essential for making informed decisions. Here are some key specifications to consider:

-

Data Accuracy

– Definition: This refers to the precision of the location data provided by the service. Accurate data ensures that the vending machines are placed in high-traffic areas where they are most likely to generate sales.

– Importance: For B2B buyers, accurate data translates into higher revenue potential. Misplaced machines can lead to lost opportunities and wasted investment. -

Coverage Area

– Definition: The geographic range within which the locator service operates. This can vary from local to national or even international coverage.

– Importance: Understanding the coverage area is crucial for businesses looking to expand. A service that covers the desired market can facilitate growth, especially in diverse regions such as Africa or South America. -

Integration Capabilities

– Definition: The ability of the locator service to integrate with existing management systems (e.g., inventory management, sales tracking).

– Importance: Seamless integration ensures that businesses can efficiently manage their vending operations without having to adopt new systems or processes, enhancing operational efficiency. -

Real-Time Data Updates

– Definition: The frequency with which location data is refreshed. Real-time updates can provide insights into customer foot traffic and product demand.

– Importance: This feature allows businesses to adapt quickly to changing consumer behaviors and optimize their product offerings, maximizing sales potential. -

User Interface (UI) and Experience (UX)

– Definition: The design and usability of the platform through which users access locator services.

– Importance: A user-friendly interface simplifies the process of locating and managing vending machine placements, making it accessible even for non-technical users. -

Analytics and Reporting Tools

– Definition: Tools that provide insights into machine performance, location effectiveness, and consumer behavior.

– Importance: For decision-makers, access to detailed analytics aids in strategic planning and helps in identifying profitable locations and product offerings.

Common Trade Terminology in Vending Machine Locator Services

Navigating the vending machine locator service landscape requires familiarity with specific industry jargon. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships is vital for sourcing reliable vending machines and components, ensuring quality and compatibility. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: For B2B buyers, knowing the MOQ helps in budgeting and inventory management, particularly when initiating new partnerships. -

RFQ (Request for Quotation)

– Definition: A standard business process used to invite suppliers to bid on specific products or services.

– Relevance: Issuing an RFQ allows businesses to compare prices and services from different vendors, leading to more informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers.

– Relevance: Familiarity with Incoterms is crucial for international transactions, helping to avoid misunderstandings regarding shipping, insurance, and tariffs. -

Lead Time

– Definition: The time taken from placing an order until it is received.

– Relevance: Understanding lead time helps businesses plan their inventory needs and ensure that vending machines are stocked promptly to meet customer demand. -

SKU (Stock Keeping Unit)

– Definition: A unique identifier for each distinct product and service that can be purchased.

– Relevance: SKUs facilitate inventory management and tracking, ensuring that the right products are available in the vending machines.

Understanding these technical properties and trade terms is essential for B2B buyers looking to make strategic decisions in the vending machine locator service market, ultimately enhancing profitability and operational efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine locator service Sector

Global drivers in the vending machine locator service sector are increasingly shaped by digital transformation and evolving consumer behaviors. The integration of advanced technology, such as AI and data analytics, enhances the efficiency of locating high-traffic areas for vending machines. B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should note the growing trend of location-based services that utilize geospatial data to identify optimal sites, improving foot traffic and sales potential.

Emerging sourcing trends include a shift towards localized partnerships. In regions like Nigeria and Argentina, leveraging local suppliers not only reduces transportation costs but also aligns with consumer preferences for locally-sourced products. Additionally, the adoption of mobile applications for vending machine management is on the rise, allowing operators to monitor inventory and sales in real-time, which is crucial for maintaining product availability and ensuring customer satisfaction.

Market dynamics are characterized by increased competition and the need for differentiation. Buyers should focus on unique selling propositions, such as offering health-conscious products or catering to niche markets, which can set their vending services apart. Furthermore, as urbanization continues to drive demand for convenient food and beverage options, vending machine locator services must adapt to diverse consumer needs and behaviors across different regions.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a pivotal factor in the vending machine locator service sector. The environmental impact of vending operations, including waste generation and energy consumption, necessitates a shift towards sustainable practices. B2B buyers should prioritize suppliers that utilize eco-friendly materials and offer sustainable product options. This includes vending machines that are energy-efficient and use biodegradable packaging for their products.

Ethical sourcing is equally important, particularly in regions where social responsibility is paramount. Establishing supply chains that support fair labor practices and promote local economies not only enhances brand reputation but also fosters customer loyalty. Buyers should seek out vendors who possess certifications such as Fair Trade or organic, ensuring that the products they source meet ethical standards. Engaging in these practices not only aligns with global sustainability goals but also reflects positively on the brand, attracting environmentally-conscious consumers.

Brief Evolution/History

The vending machine locator service sector has evolved significantly over the past few decades. Initially reliant on manual methods for finding locations, the industry has transitioned to a more technology-driven approach, utilizing software and data analytics to enhance accuracy and efficiency. This evolution has allowed vending operators to optimize their placements in high-traffic areas, resulting in increased profitability. The rise of e-commerce and digital marketing has further transformed the landscape, enabling vending machine businesses to reach broader audiences and adapt to changing consumer preferences. As the industry continues to innovate, international B2B buyers must stay informed about these trends to maintain a competitive edge in their markets.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of vending machine locator service

-

What criteria should I use to vet suppliers of vending machine locator services?

When vetting suppliers, prioritize their experience in the vending industry, client testimonials, and case studies that demonstrate successful placements. Verify their technological capabilities, such as the use of data analytics for location selection. Additionally, consider their geographic reach, particularly in your target markets across Africa, South America, the Middle East, and Europe, to ensure they understand local consumer behaviors and trends. -

Can the vending machine locator service be customized to fit my specific business needs?

Yes, many vending machine locator services offer customizable solutions tailored to your business model and target demographics. Discuss your requirements regarding product types, target locations, and customer profiles with potential suppliers. Customization might include selecting specific industries, such as schools or gyms, ensuring that the locations align with your product offerings and marketing strategies. -

What are the typical minimum order quantities (MOQs) and lead times for these services?

Minimum order quantities and lead times can vary significantly between providers. Generally, MOQs may range from a few locations to several dozen, depending on the service’s scalability. Lead times for location acquisition can vary from a few weeks to several months. Always clarify these parameters upfront to align your expectations with the supplier’s capabilities, especially if you’re planning a market launch. -

How do I ensure quality assurance and certification from the locator service?

Inquire about the quality assurance processes the supplier employs to vet potential locations. Effective services should have a system for assessing foot traffic, demographic fit, and site suitability. Request any certifications or industry affiliations that validate their expertise. Establishing a clear communication channel for feedback on placements will also help maintain quality over time. -

What logistics support can I expect from the vending machine locator service?

Logistics support typically includes assistance with site visits, negotiations with site owners, and sometimes coordination with transport services for machine installation. Ensure the supplier provides a comprehensive logistics plan that considers local regulations and challenges, particularly in diverse markets across Africa, South America, the Middle East, and Europe. This support is crucial for a smooth operational launch. -

How should disputes regarding location placements be handled?

It’s essential to establish clear terms in your contract regarding dispute resolution. Discuss the protocol for addressing issues such as unsatisfactory locations or contractual disagreements. Many suppliers will have a dedicated support team for conflict resolution, but ensure you understand their process and timeline for resolving disputes to avoid potential disruptions in your business operations. -

What payment terms and options are typically available for these services?

Payment terms can vary widely, from upfront fees to installment plans based on milestones achieved. Many suppliers accept various payment methods, including bank transfers, credit cards, and even payment through escrow services for added security. Clarify these terms and ensure they are aligned with your cash flow management strategies, particularly if you are operating in multiple currencies across different regions. -

How does the service ensure ongoing support after the initial location placement?

Reputable vending machine locator services often provide ongoing support, which may include regular check-ins, performance analytics, and optimization recommendations based on sales data. Ask about their follow-up processes to ensure your machines remain profitable and well-placed. Continuous support is crucial for adapting to market changes and enhancing the effectiveness of your vending operations.

Strategic Sourcing Conclusion and Outlook for vending machine locator service

As we conclude this exploration of vending machine locator services, it’s essential to recognize the pivotal role of strategic sourcing in driving success in this industry. By effectively identifying and partnering with reliable wholesale suppliers, B2B buyers can ensure their vending machines are stocked with high-demand products that resonate with local consumers. Understanding the nuances of product sourcing—from aligning inventory with market trends to fostering strong supplier relationships—enables businesses to maximize profitability and operational efficiency.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the opportunities are vast. As urbanization and consumer preferences evolve, the demand for innovative vending solutions continues to grow. Investing in a robust vending machine locator service not only streamlines the process of securing prime locations but also positions your business to thrive in competitive landscapes.

Take action today by leveraging these insights to refine your sourcing strategies and expand your vending machine operations. Embrace the future of vending with confidence and capitalize on the burgeoning market potential in your region.