Your Ultimate Guide to Sourcing Vending Machine Keypad

Guide to Vending Machine Keypad

- Introduction: Navigating the Global Market for vending machine keypad

- Understanding vending machine keypad Types and Variations

- Key Industrial Applications of vending machine keypad

- Strategic Material Selection Guide for vending machine keypad

- In-depth Look: Manufacturing Processes and Quality Assurance for vending machine keypad

- Comprehensive Cost and Pricing Analysis for vending machine keypad Sourcing

- Spotlight on Potential vending machine keypad Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for vending machine keypad

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine keypad Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vending machine keypad

- Strategic Sourcing Conclusion and Outlook for vending machine keypad

Introduction: Navigating the Global Market for vending machine keypad

Navigating the global market for vending machine keypads requires a keen understanding of both the technology and the diverse needs of international buyers. As essential components of vending machines, keypads serve as the primary interface between the consumer and the machine, making their design and functionality crucial for enhancing user experience and operational efficiency. With the rise of automated retail solutions across Africa, South America, the Middle East, and Europe, the demand for high-quality, durable, and user-friendly keypads has surged.

This comprehensive guide is tailored specifically for B2B buyers looking to make informed sourcing decisions. It covers a wide array of topics, including the different types of keypads available, the materials used in their construction, and manufacturing quality control processes. Additionally, it provides insights into reliable suppliers, cost considerations, and market trends that influence purchasing decisions.

Understanding these elements empowers international buyers to navigate the complexities of sourcing effectively. Whether you are in Saudi Arabia, Brazil, or any other region, this guide equips you with the knowledge necessary to select the right keypad that meets both operational requirements and budget constraints. By leveraging the information provided, you can ensure that your vending machines are equipped with the best keypads, ultimately enhancing customer satisfaction and driving sales.

Understanding vending machine keypad Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Membrane Keypad | Flat, sealed design with printed graphics | Snack and beverage vending | Pros: Easy to clean, customizable; Cons: Limited tactile feedback |

| Mechanical Keypad | Individual mechanical switches for each key | High-traffic vending locations | Pros: Durable, reliable; Cons: More prone to wear over time |

| Touchscreen Keypad | Interactive display with virtual buttons | High-end vending machines | Pros: User-friendly interface, versatile; Cons: Higher cost, sensitive to damage |

| Numeric Keypad | Simple layout focusing on number input | Ticketing and payment machines | Pros: Intuitive for transactions; Cons: Limited functionality beyond numbers |

| Hybrid Keypad | Combination of mechanical and touchscreen features | Multi-product vending solutions | Pros: Versatile, caters to diverse user preferences; Cons: Complexity in maintenance |

Membrane Keypad

Membrane keypads are known for their flat, sealed design, which often features printed graphics. They are widely used in snack and beverage vending machines due to their resistance to spills and easy cleaning. B2B buyers should consider their applications in environments where hygiene is crucial. While they offer customization options and are easy to maintain, the lack of tactile feedback can be a drawback for users who prefer a more traditional pressing experience.

Mechanical Keypad

Mechanical keypads consist of individual switches for each key, providing a satisfying tactile response. They are ideal for high-traffic vending locations where durability is essential. Buyers in industries that require robust and reliable equipment should consider this type. While mechanical keypads are known for their longevity, they can wear down over time, necessitating periodic replacements or maintenance.

Touchscreen Keypad

Touchscreen keypads are becoming increasingly popular in high-end vending machines. They provide an interactive display that allows users to select items with virtual buttons. This type is suitable for environments where user experience is paramount, such as in upscale locations or for customized vending solutions. However, while they offer a modern and versatile interface, their higher cost and susceptibility to damage should be carefully weighed by B2B buyers.

Numeric Keypad

Numeric keypads focus on number input and are commonly found in ticketing and payment machines. Their straightforward layout makes them intuitive for transactions, appealing to buyers in sectors where speed and efficiency are crucial. However, their limited functionality beyond numerical input may not meet the needs of all businesses, especially those requiring more complex interactions.

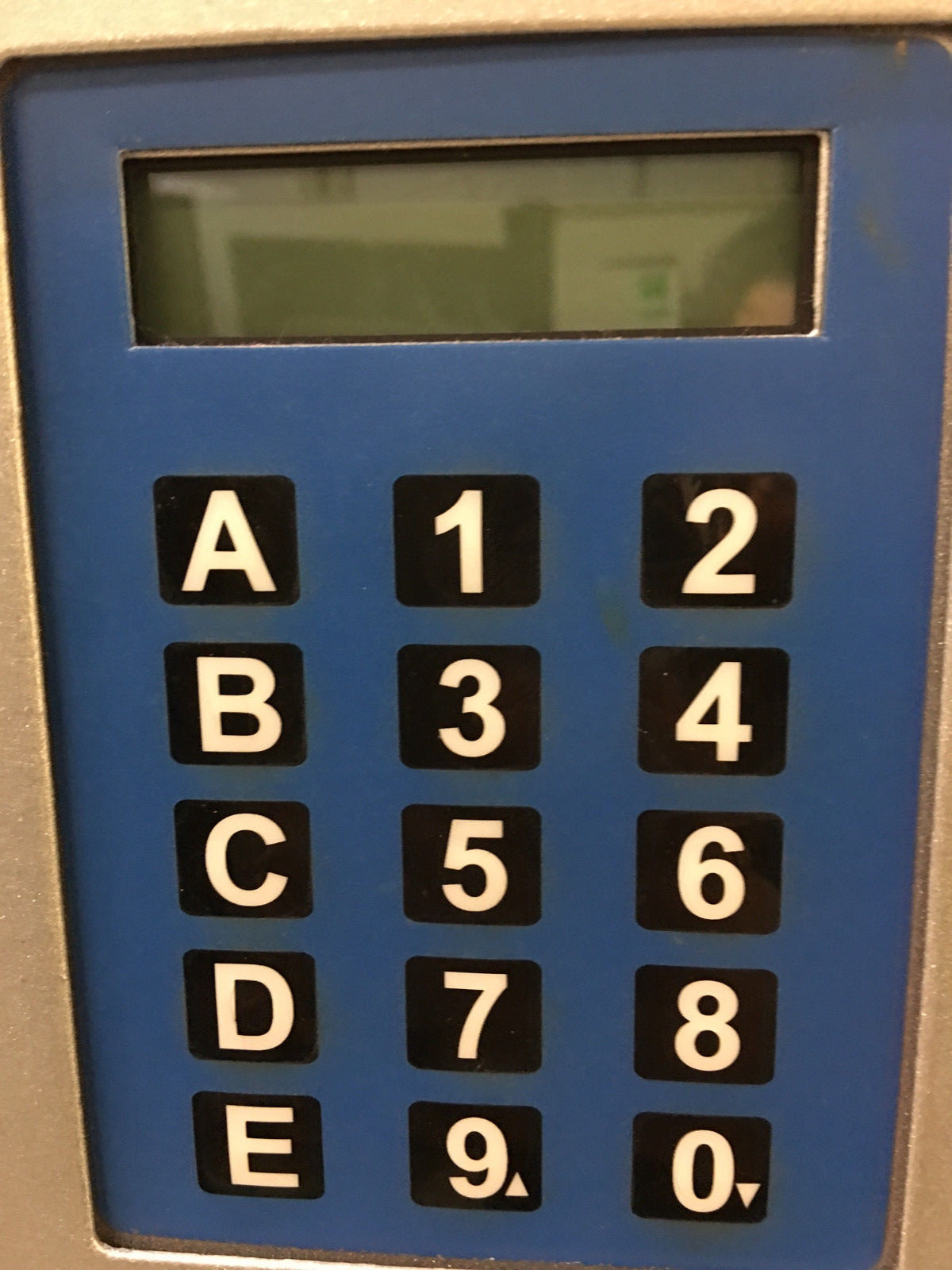

Illustrative Image (Source: Google Search)

Hybrid Keypad

Hybrid keypads combine mechanical and touchscreen features, offering a versatile solution for multi-product vending machines. This adaptability caters to diverse user preferences, making them a strong choice for B2B buyers looking for flexibility. While they provide a wide range of functionalities, the complexity of maintenance and potential technical issues can be a concern, necessitating thorough evaluation before purchase.

Key Industrial Applications of vending machine keypad

| Industry/Sector | Specific Application of vending machine keypad | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Self-service kiosks for product selection | Enhances customer experience and reduces wait time | Durability, ease of use, and multilingual support |

| Transportation | Ticket vending machines | Streamlines passenger flow and increases revenue | Compliance with local regulations and payment system integration |

| Food and Beverage | Automated food and drink dispensers | Increases sales opportunities and reduces labor costs | Hygiene standards, ease of cleaning, and temperature resistance |

| Healthcare | Prescription vending machines | Improves medication accessibility and reduces pharmacy workload | Security features, user authentication, and compliance with health regulations |

| Education | Campus vending solutions | Provides convenient access to snacks and beverages for students | Energy efficiency, customization options, and connectivity features |

In the retail sector, vending machine keypads are integral to self-service kiosks, allowing customers to easily navigate product selections. This application enhances the shopping experience by minimizing wait times, which is crucial in busy environments. For international buyers, especially in emerging markets like Africa and South America, sourcing keypads that support multiple languages and are intuitive to use can significantly improve customer satisfaction and loyalty.

Within the transportation industry, ticket vending machines equipped with user-friendly keypads facilitate quick transactions, thereby streamlining passenger flow at busy transit hubs. This not only boosts revenue through increased ticket sales but also enhances overall service efficiency. Buyers in this sector must consider local regulatory compliance and ensure compatibility with various payment systems, including mobile payments, which are increasingly popular in regions like the Middle East and Europe.

In the food and beverage industry, automated dispensers utilize vending machine keypads to allow customers to select from a variety of snacks and drinks. This application not only increases sales opportunities but also reduces the need for staff, thereby cutting labor costs. Buyers should prioritize hygiene standards and ensure that the keypads are designed for easy cleaning, particularly in regions with strict food safety regulations.

The healthcare sector benefits from vending machine keypads in prescription vending machines, which provide patients with easy access to medications outside regular pharmacy hours. This application addresses the growing demand for convenience in healthcare. Key sourcing considerations include robust security features to protect sensitive information and compliance with health regulations, particularly in regions like Europe where data protection laws are stringent.

Finally, in the education sector, vending solutions on campuses leverage keypads to give students convenient access to refreshments. This not only enhances student satisfaction but also generates additional revenue for educational institutions. When sourcing keypads for this application, buyers should focus on energy efficiency and the potential for customization to meet the unique needs of their student populations.

Related Video: DIY Vending Machine – Arduino based Mechatronics Project

Strategic Material Selection Guide for vending machine keypad

When selecting materials for vending machine keypads, international B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in the manufacturing of vending machine keypads, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Polycarbonate (PC)

Key Properties:

Polycarbonate is known for its high impact resistance and excellent clarity. It can withstand temperatures ranging from -40°C to 120°C, making it suitable for various environments. Additionally, polycarbonate has good electrical insulation properties.

Pros & Cons:

The primary advantage of polycarbonate is its durability; it is resistant to shattering and can endure heavy use. However, it is susceptible to scratching and may require additional coatings to enhance surface hardness. The manufacturing process can be more complex due to its need for precise molding.

Impact on Application:

Polycarbonate keypads are ideal for environments where visibility and tactile feedback are crucial. They perform well in both indoor and outdoor applications, but care must be taken to protect against UV degradation.

Considerations for International Buyers:

Buyers should ensure that the polycarbonate used complies with local regulations regarding safety and environmental impact. Standards such as ASTM and ISO may apply, particularly concerning fire resistance and chemical exposure.

2. Silicone Rubber

Key Properties:

Silicone rubber exhibits excellent temperature stability, with a range from -60°C to 200°C. It is highly resistant to UV light, ozone, and extreme weather conditions, making it a popular choice for outdoor applications.

Pros & Cons:

The key advantage of silicone rubber is its flexibility and ability to provide a soft touch, enhancing user experience. However, it can be more expensive than other materials and may have limitations in terms of color retention over time. Manufacturing can also be challenging due to the need for specialized molds.

Impact on Application:

Silicone rubber keypads are particularly effective in applications requiring frequent interaction, such as touch-sensitive devices. They are compatible with various media, including oils and solvents, making them versatile.

Considerations for International Buyers:

Buyers should verify that silicone materials meet regional compliance standards, especially in food and beverage applications where FDA approval may be necessary. Understanding local preferences for tactile feedback can also influence material choice.

3. Stainless Steel

Key Properties:

Stainless steel is renowned for its corrosion resistance, particularly in harsh environments. It can withstand high temperatures and is generally easy to clean, making it ideal for hygienic applications.

Pros & Cons:

The main advantage of stainless steel is its durability and longevity, which can lead to lower lifecycle costs. However, it is heavier and more expensive than plastic alternatives, and the manufacturing process can be complex, requiring specialized equipment.

Impact on Application:

Stainless steel keypads are suitable for high-traffic areas and environments prone to spills or contamination, such as food service locations. They offer a robust solution but may not provide the same tactile feedback as softer materials.

Considerations for International Buyers:

International buyers should ensure compliance with local standards for food safety and hygiene. The choice of stainless steel grade (e.g., 304 vs. 316) may depend on the specific environmental conditions, such as exposure to saltwater in coastal areas.

4. Thermoplastic Elastomer (TPE)

Key Properties:

TPE combines the properties of rubber and plastic, offering flexibility, durability, and resistance to various chemicals. It typically operates effectively within a temperature range of -40°C to 100°C.

Pros & Cons:

TPE is cost-effective and provides good tactile feedback, making it user-friendly. However, it may not be as durable as silicone or polycarbonate in extreme conditions, and its resistance to UV light can vary based on the specific formulation.

Impact on Application:

TPE keypads are suitable for a wide range of applications, including consumer electronics and outdoor vending machines. They can be tailored for specific media compatibility, enhancing their versatility.

Considerations for International Buyers:

Buyers should assess the specific TPE formulation to ensure it meets local compliance standards, particularly regarding environmental impact and user safety. Understanding the regional market’s preferences for feel and durability can guide material selection.

Summary Table

| Material | Typical Use Case for vending machine keypad | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | Outdoor and indoor keypads | High impact resistance | Susceptible to scratching | Medium |

| Silicone Rubber | Touch-sensitive applications | Excellent flexibility and touch feel | Higher cost, color retention issues | High |

| Stainless Steel | High-traffic and hygienic environments | Corrosion resistance and durability | Heavier and more expensive | High |

| Thermoplastic Elastomer (TPE) | General consumer electronics | Cost-effective and user-friendly | Varies in UV resistance | Medium |

This guide provides actionable insights for B2B buyers in selecting the most suitable materials for vending machine keypads, considering both performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for vending machine keypad

Manufacturing Processes for Vending Machine Keypads

The manufacturing of vending machine keypads involves several critical stages, each designed to ensure that the final product meets both functional and aesthetic standards. Understanding these processes can help B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation

Material Selection:

The first step in manufacturing vending machine keypads is selecting the appropriate materials. Common materials include:

– Polycarbonate or Acrylic: For the keypad surface, ensuring durability and clarity.

– Silicone or Rubber: For tactile feedback and protection against moisture.

– Metal or Plastic Substrates: For structural integrity.

Material Testing:

Before production begins, materials undergo testing to confirm they meet specifications for durability, resistance to wear, and environmental factors such as temperature and humidity.

2. Forming

Techniques:

– Injection Molding: This is the most common technique for creating the keypad’s plastic components. It allows for high precision and the production of complex shapes.

– Silkscreen Printing: Used to apply graphics or labels on the keypad surface, ensuring high visibility and resistance to fading.

– Laser Cutting: Employed for creating precise shapes and cutouts, particularly for backlit keypads.

Quality Control During Forming:

At this stage, manufacturers often conduct in-process inspections to ensure that dimensions and material properties are consistent with design specifications.

3. Assembly

Assembly Process:

– Component Assembly: Individual components (buttons, LED lights, circuit boards) are assembled using automated or manual methods.

– Adhesive Application: For components that require bonding, appropriate adhesives are applied, ensuring a strong and durable bond.

Integration Testing:

Once assembled, the keypad undergoes initial functionality tests to verify that all components operate correctly and meet performance standards.

4. Finishing

Surface Treatment:

Finishing processes may include:

– Coating: Application of protective coatings to enhance durability and aesthetics.

– Polishing: To achieve a smooth and attractive surface.

Final Inspection:

A thorough final inspection is conducted to ensure that the keypads are free from defects and meet all specifications before packaging and shipping.

Quality Assurance in Vending Machine Keypad Manufacturing

Quality assurance (QA) is critical in the production of vending machine keypads to ensure reliability and longevity, particularly in demanding environments.

International Standards

To guarantee quality, manufacturers often adhere to international standards, such as:

– ISO 9001: This standard focuses on quality management systems, emphasizing continuous improvement and customer satisfaction.

– CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

– API Standards: Particularly relevant in specific applications, ensuring that products meet industry-specific requirements.

Quality Control Checkpoints

Quality control is typically segmented into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC):

– Raw materials are inspected upon arrival to ensure they meet specified standards before production begins. -

In-Process Quality Control (IPQC):

– Continuous monitoring during the manufacturing process, checking dimensions, functionality, and any changes in material properties. -

Final Quality Control (FQC):

– A comprehensive inspection of the final product, including functional testing, visual inspection, and packaging checks.

Common Testing Methods

Various testing methods are employed to ensure product quality:

– Functional Testing: Verifying that the keypad responds correctly to inputs.

– Durability Testing: Assessing the keypad’s performance under simulated wear and environmental conditions.

– Electrical Testing: Ensuring that all electronic components function correctly under specified voltage and current levels.

Verification of Supplier Quality Control

For B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are some actionable steps:

- Supplier Audits: Conduct regular audits to evaluate the supplier’s manufacturing processes and quality assurance protocols.

- Quality Reports: Request detailed quality assurance reports and certifications from suppliers to understand their compliance with international standards.

- Third-Party Inspections: Engage independent third-party inspectors to assess product quality and compliance with industry standards before shipment.

Nuances for International B2B Buyers

When sourcing vending machine keypads internationally, buyers should be aware of specific nuances:

– Cultural Differences: Understanding regional business practices and negotiation styles can facilitate better supplier relationships.

– Regulatory Compliance: Ensure that products comply with local regulations in the buyer’s country, particularly regarding safety and environmental standards.

– Logistical Considerations: Factor in shipping times, tariffs, and import regulations that may affect overall costs and delivery schedules.

By being informed about manufacturing processes and quality assurance protocols, B2B buyers can make better purchasing decisions and foster successful partnerships with suppliers in the vending machine industry.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for vending machine keypad Sourcing

Cost Structure of Vending Machine Keypads

When sourcing vending machine keypads, understanding the cost structure is essential for effective budgeting and negotiation. The primary components of the cost include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include durable plastics, rubber for buttons, and electronic components. High-quality materials may increase the cost but can enhance durability and user experience.

-

Labor: Labor costs vary by region and depend on the complexity of the keypad design and production process. In countries with lower labor costs, such as some in Africa and South America, total production costs can be significantly reduced.

-

Manufacturing Overhead: This includes costs related to factory operations, equipment depreciation, and utilities. Efficient manufacturing processes can lower overhead costs, impacting the final price.

-

Tooling: The initial investment in molds and dies for producing keypads can be substantial. Custom designs may require additional tooling costs, which should be factored into the total cost.

-

Quality Control (QC): Ensuring product quality is crucial, particularly for electronic components. Implementing stringent QC processes may add to costs but can prevent future losses associated with faulty products.

-

Logistics: Shipping costs, including freight and insurance, can vary widely depending on the origin and destination of the keypads. Incoterms play a critical role here, influencing who bears responsibility for shipping costs and risks.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market competition and the buyer’s negotiation skills.

Price Influencers

Several factors influence the pricing of vending machine keypads, including:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit prices. Suppliers may offer discounts for bulk purchases, making it advantageous for buyers to consolidate orders.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should assess whether customization is necessary or if standard models suffice.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., CE, RoHS) can elevate costs but may also enhance product reliability and marketability.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their proven track record and quality assurance.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define responsibilities for shipping, insurance, and tariffs, which can affect the total landed cost of the keypads.

Buyer Tips

To navigate the complexities of sourcing vending machine keypads effectively, consider the following strategies:

-

Negotiation: Leverage your purchasing power by negotiating terms with suppliers. Discuss volume discounts and payment terms to achieve better pricing.

-

Cost-Efficiency: Assess the total cost of ownership (TCO), which includes not only the purchase price but also maintenance, operational costs, and potential replacement costs.

-

Evaluate Pricing Nuances: Be aware that international buyers may face additional costs related to tariffs, taxes, and currency fluctuations. Always request a detailed breakdown of costs from suppliers to understand all components involved.

-

Supplier Diversity: Engage multiple suppliers to compare offerings. This can provide leverage in negotiations and help identify the best value for your needs.

-

Focus on Quality: While lower prices may be tempting, prioritize quality and reliability to avoid costly issues in the long run. Consider suppliers that offer warranties or guarantees on their products.

Disclaimer

Prices for vending machine keypads can fluctuate due to market conditions and specific buyer requirements. It is advisable to obtain quotes from multiple suppliers and to regularly review costs to ensure competitive pricing.

Spotlight on Potential vending machine keypad Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘vending machine keypad’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for vending machine keypad

When sourcing vending machine keypads, it is crucial for international B2B buyers to understand the essential technical properties and trade terminology that govern their quality and procurement processes. Here are the key specifications and terms that will aid decision-making.

Key Technical Properties

-

Material Grade

– Definition: The quality of materials used in manufacturing the keypad, typically ranging from plastics like polycarbonate to metals like stainless steel.

– Importance: Higher-grade materials provide durability, resistance to wear, and protection against environmental factors, which is essential for vending machines located in various climates. -

Operational Temperature Range

– Definition: The range of temperatures within which the keypad can operate effectively, often specified in degrees Celsius (e.g., -20°C to +70°C).

– Importance: Ensures that the keypad functions reliably in diverse environments, from hot climates in Africa to colder regions in Europe. -

Ingress Protection (IP) Rating

– Definition: A classification that indicates the degree of protection against dust and water ingress, typically denoted as IPXX (e.g., IP65).

– Importance: A higher IP rating signifies better protection, which is vital for outdoor vending machines exposed to the elements. -

Tactile Feedback

– Definition: The physical sensation provided by the keypad when a button is pressed, often described as ‘clicky’ or ‘soft’.

– Importance: Enhances user experience, encouraging repeat use and customer satisfaction. This is particularly relevant in markets where customer interaction is critical. -

Key Life Cycle

– Definition: The number of presses a keypad can withstand before failure, commonly measured in millions of presses (e.g., 5 million cycles).

– Importance: Indicates longevity and reduces the need for frequent replacements, ultimately saving costs for operators. -

Mounting Type

– Definition: Refers to how the keypad is installed, such as surface mount or flush mount.

– Importance: Affects the aesthetic and functional integration of the keypad into the vending machine design, which can influence customer engagement.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Usage: Understanding OEM can help buyers identify reliable suppliers and ensure that components meet specific quality standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Usage: Knowing the MOQ is essential for budgeting and inventory planning, particularly for smaller businesses or startups. -

RFQ (Request for Quotation)

– Definition: A document used to invite suppliers to bid on specific products or services.

– Usage: RFQs help buyers obtain competitive pricing and assess supplier capabilities, crucial for informed purchasing decisions.

Illustrative Image (Source: Google Search)

-

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms published by the International Chamber of Commerce (ICC).

– Usage: Understanding Incoterms is critical for clarifying responsibilities and costs associated with shipping and delivery, which can vary significantly between regions. -

Lead Time

– Definition: The time taken from placing an order to receiving the goods.

– Usage: Buyers should account for lead time in their planning to ensure timely availability of products, especially in industries with high demand. -

Warranty Period

– Definition: The duration during which a manufacturer guarantees the product against defects or failures.

– Usage: A longer warranty can indicate confidence in product quality and provides buyers with assurance regarding their investment.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they select keypads that not only meet their operational requirements but also align with their strategic business goals.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine keypad Sector

Market Overview & Key Trends

The global vending machine keypad market is experiencing significant growth, driven by increasing demand for automated solutions in retail and public spaces. Key trends influencing this sector include the rise of contactless payment systems, integration with mobile technology, and the growing emphasis on user-friendly interfaces. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking keypads that support multiple languages and currencies, catering to diverse consumer bases.

Emerging technologies such as touchless sensors and biometric authentication are becoming prevalent, enhancing the user experience and security of vending transactions. In addition, the demand for smart vending machines—equipped with IoT capabilities for real-time inventory management and consumer analytics—is reshaping sourcing strategies. Buyers should prioritize suppliers who offer innovative keypad solutions that align with these technological advancements, ensuring they remain competitive in a rapidly evolving marketplace.

Furthermore, sustainability is becoming a key consideration in purchasing decisions. Buyers are increasingly looking for manufacturers that utilize eco-friendly materials and processes. This shift not only addresses environmental concerns but also meets the growing consumer preference for sustainable products, making it a crucial factor in vendor selection.

Sustainability & Ethical Sourcing in B2B

As the global focus on sustainability intensifies, the vending machine keypad sector is not left behind. Environmental impacts of production processes, including energy consumption and waste generation, are under scrutiny. B2B buyers are encouraged to engage with suppliers who prioritize ethical sourcing and demonstrate a commitment to reducing their carbon footprint. This includes using recycled materials in keypad manufacturing and implementing waste reduction strategies throughout their supply chains.

Moreover, obtaining certifications such as ISO 14001 for environmental management and certifications for sustainable materials can provide buyers with assurance regarding the eco-friendliness of their products. Buyers should actively seek out suppliers who can demonstrate their commitment to sustainability through transparent reporting and certification achievements. By doing so, they not only support ethical practices but also enhance their brand reputation among environmentally-conscious consumers.

Brief Evolution/History

The evolution of vending machine keypads has mirrored advancements in technology and consumer behavior. Initially, keypads were simple mechanical devices, primarily focused on functionality. With the advent of digital technology in the late 20th century, keypads evolved to incorporate electronic components, allowing for features like illuminated keys and numeric displays.

In the early 2000s, the introduction of smart technology transformed vending machines into interactive platforms, leading to the integration of touchscreens and payment options such as credit cards and mobile wallets. This evolution has continued, with a strong push towards integrating IoT technologies and enhancing user interface design, reflecting broader trends in consumer electronics and retail automation. For international B2B buyers, understanding this evolution is vital for making informed decisions about product features and supplier capabilities in today’s competitive landscape.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of vending machine keypad

-

What should I look for when vetting suppliers for vending machine keypads?

When vetting suppliers, focus on their experience in the industry, production capacity, and reputation. Request references and check reviews from other B2B clients. Verify their certifications, such as ISO standards, which indicate quality management practices. Additionally, assess their ability to meet your specific requirements, such as customization options and adherence to international regulations, particularly for your target markets in Africa, South America, the Middle East, and Europe. -

Can I customize the vending machine keypads to fit my specific needs?

Yes, many suppliers offer customization options for vending machine keypads. You can request modifications in design, size, button layout, and functionality. When discussing customization, ensure you communicate your requirements clearly and inquire about any additional costs or lead times associated with these modifications. This will help you align your expectations and ensure the final product meets your operational needs. -

What are the typical minimum order quantities (MOQs) and lead times for vending machine keypads?

MOQs for vending machine keypads can vary significantly depending on the supplier and the level of customization required. Generally, MOQs range from 100 to 1,000 units. Lead times can also differ, typically ranging from 4 to 12 weeks, depending on the complexity of the order and the supplier’s production schedule. Always confirm these details upfront to avoid delays in your supply chain. -

What payment terms should I expect when sourcing vending machine keypads?

Payment terms can vary widely among suppliers. Common options include a deposit upfront (often 30-50%) with the balance due before shipment, or net terms (e.g., 30-60 days post-delivery). It’s crucial to discuss payment methods accepted, such as bank transfers or letters of credit, particularly for international transactions. Ensure that the terms are clearly outlined in your purchase agreement to avoid any misunderstandings. -

How can I ensure quality assurance and certification compliance for the keypads?

To ensure quality, request detailed information about the supplier’s quality assurance processes. Inquire about certifications relevant to your market, such as CE for Europe or UL for North America. Ask for sample products before placing a large order to assess quality firsthand. Regular communication and updates during production can also help identify and resolve potential issues before shipment. -

What logistics considerations should I keep in mind when importing keypads?

When importing vending machine keypads, consider shipping methods (air vs. sea), customs duties, and import regulations specific to your region. Work with a logistics provider familiar with international shipping to streamline the process. Ensure that all necessary documentation, such as commercial invoices and packing lists, is prepared to avoid delays at customs. Additionally, factor in potential lead times for clearance and delivery to your warehouse. -

What steps should I take if there is a dispute with my supplier?

In the event of a dispute, maintain clear communication with your supplier to resolve issues amicably. Start by documenting all correspondence related to the dispute, including contracts and agreements. If necessary, escalate the matter through formal channels, such as mediation or arbitration, as specified in your contract. Understanding the legal framework governing international trade in your region can also provide clarity on your rights and obligations. -

Are there specific regulations I need to consider when sourcing keypads for different markets?

Yes, each market may have specific regulations regarding electronic devices, including safety, environmental, and import standards. For instance, in Europe, products must comply with CE marking requirements, while in the Middle East, you may need to adhere to GSO standards. Research the relevant regulations for your target markets and ensure that your supplier can provide products that meet these standards to avoid compliance issues.

Strategic Sourcing Conclusion and Outlook for vending machine keypad

In conclusion, strategic sourcing for vending machine keypads is crucial for optimizing operational efficiency and enhancing customer satisfaction. By focusing on quality, compatibility, and innovative features, international B2B buyers can ensure they select keypads that not only meet current demands but also anticipate future trends. Key considerations include evaluating supplier reliability, understanding regional compliance standards, and leveraging technology for better integration.

Key Takeaways:

– Quality Matters: Invest in high-quality keypads to reduce maintenance costs and increase longevity.

– Supplier Relationships: Build strong relationships with reliable suppliers to facilitate better negotiation terms and access to cutting-edge products.

– Regional Insights: Understand the specific needs and preferences of consumers in your target market, whether in Africa, South America, the Middle East, or Europe.

Looking ahead, the vending machine industry is poised for growth, driven by technological advancements and changing consumer behaviors. Buyers are encouraged to act now by exploring diverse sourcing options and integrating innovative keypads that enhance user experience. This proactive approach will not only drive sales but also position businesses favorably in a competitive landscape.