Your Ultimate Guide to Sourcing Vending Machine Inventory

Guide to Vending Machine Inventory Software

- Introduction: Navigating the Global Market for vending machine inventory software

- Understanding vending machine inventory software Types and Variations

- Key Industrial Applications of vending machine inventory software

- Strategic Material Selection Guide for vending machine inventory software

- In-depth Look: Manufacturing Processes and Quality Assurance for vending machine inventory software

- Comprehensive Cost and Pricing Analysis for vending machine inventory software Sourcing

- Spotlight on Potential vending machine inventory software Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for vending machine inventory software

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine inventory software Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vending machine inventory software

- Strategic Sourcing Conclusion and Outlook for vending machine inventory software

Introduction: Navigating the Global Market for vending machine inventory software

In an increasingly competitive global market, the efficiency and effectiveness of vending machine operations are paramount. Vending machine inventory software serves as a crucial tool for businesses looking to streamline their inventory management, enhance customer satisfaction, and maximize profitability. By leveraging this technology, organizations can gain real-time insights into stock levels, automate restocking processes, and reduce waste—ultimately leading to improved operational efficiency and cost savings.

This comprehensive guide delves into the various facets of vending machine inventory software, covering essential topics such as types of software, materials used, manufacturing and quality control, key suppliers, cost analysis, and market trends. Additionally, we address common frequently asked questions that international B2B buyers may encounter while navigating this complex landscape.

For buyers from regions such as Africa, South America, the Middle East, and Europe—particularly in countries like Saudi Arabia and Italy—this guide offers actionable insights tailored to your unique market needs. With a focus on informed sourcing decisions, readers will be equipped with the knowledge necessary to select the right software solutions that align with their business objectives. Whether you are a seasoned operator or new to the vending industry, understanding these critical elements will empower you to make strategic decisions that drive growth and success in your operations.

Understanding vending machine inventory software Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cloud-Based Inventory Software | Accessible from any device, real-time updates | Multi-location vending operations | Pros: Scalability, flexibility, and ease of use. Cons: Dependent on internet connectivity. |

| On-Premises Inventory Software | Installed on local servers, high customization | Large enterprises with specific needs | Pros: Greater control and customization. Cons: Higher upfront costs and maintenance. |

| Mobile Inventory Management | Mobile app for inventory tracking and management | Field operations and remote management | Pros: Convenience and real-time data access. Cons: Limited features compared to full software. |

| Automated Inventory Systems | Automated stock tracking and alerts | High-volume vending operations | Pros: Reduces human error and improves efficiency. Cons: Initial setup can be complex. |

| Integrated POS Systems | Combines POS and inventory management | Retail environments with vending machines | Pros: Streamlined operations and sales reporting. Cons: Can be costly and complex to implement. |

Cloud-Based Inventory Software

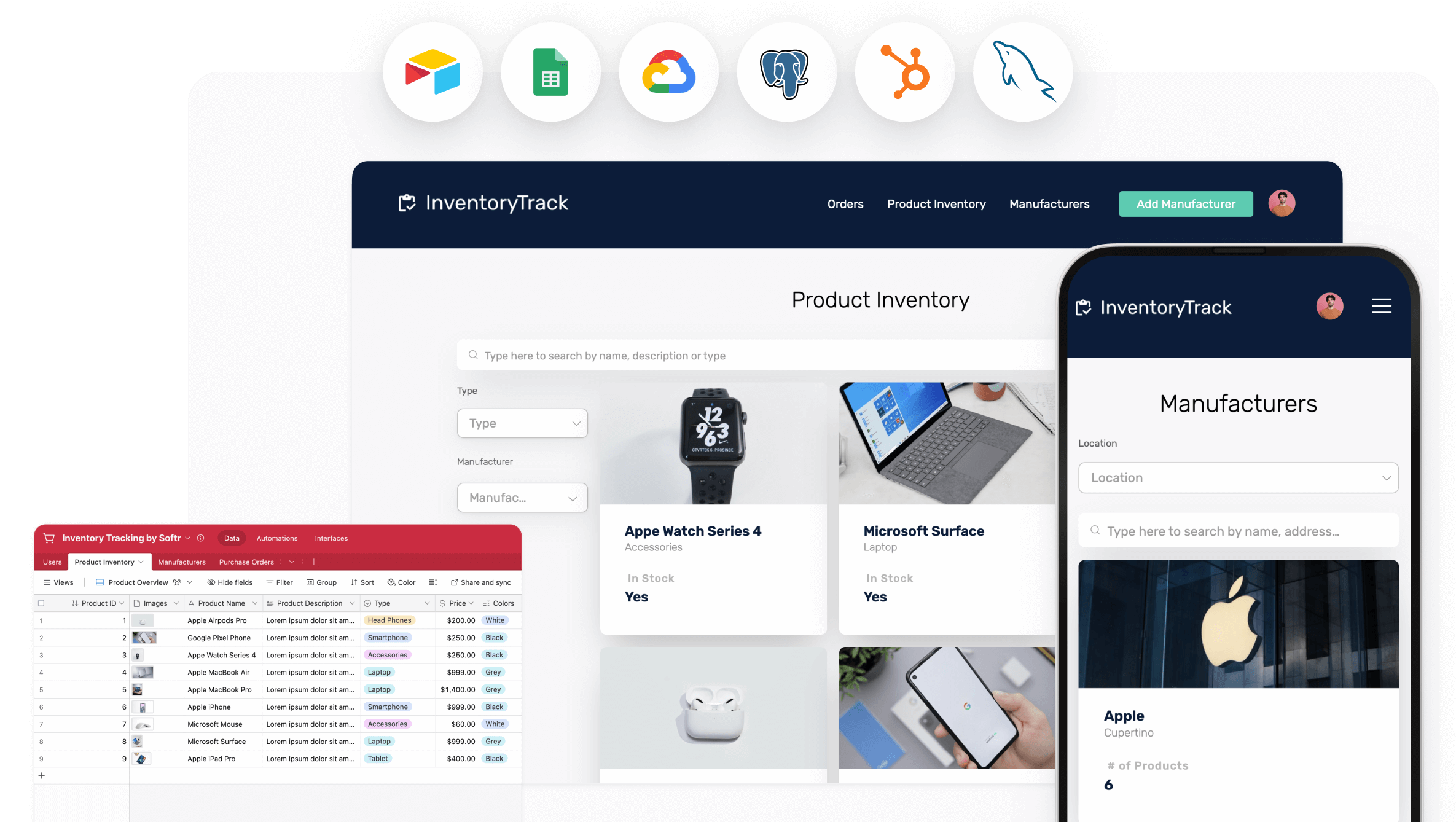

Cloud-based inventory software allows businesses to access their vending machine data from any internet-connected device. This type is particularly suitable for companies operating multiple locations, as it provides real-time updates and centralized control. B2B buyers should consider the scalability and flexibility of these solutions, as they can easily adapt to growing business needs. However, potential buyers must also be aware of their reliance on stable internet connections, which could affect performance in areas with poor connectivity.

On-Premises Inventory Software

On-premises inventory software is installed directly on a company’s local servers, providing extensive customization options tailored to specific business requirements. This type is ideal for large enterprises that require detailed control over their inventory processes. B2B buyers should weigh the benefits of enhanced security and customization against the higher initial investment and ongoing maintenance costs associated with these systems. For businesses with stringent data protection needs, this option may be particularly appealing.

Mobile Inventory Management

Mobile inventory management solutions are designed to facilitate inventory tracking and management through mobile applications. This type is especially beneficial for field operations where quick access to data is essential. B2B buyers should consider the convenience of managing inventory on-the-go, which can significantly enhance operational efficiency. However, these solutions may lack some advanced features found in more comprehensive software, which could limit their effectiveness for larger operations.

Automated Inventory Systems

Automated inventory systems utilize technology to track stock levels and generate alerts for reordering. This type is ideal for businesses with high-volume vending operations, as it minimizes human error and optimizes stock management. B2B buyers should evaluate the potential efficiency gains against the complexity of initial setup and integration into existing systems. While these systems can greatly enhance productivity, the upfront investment and training may be considerable.

Integrated POS Systems

Integrated POS systems combine point-of-sale functions with inventory management, providing a seamless solution for businesses that operate vending machines alongside retail environments. This type is particularly advantageous for companies looking to streamline operations and improve sales reporting. B2B buyers should assess the overall cost versus the potential for enhanced operational efficiency. While these systems can be complex and costly to implement, the benefits of integrated data and streamlined processes often outweigh the drawbacks.

Related Video: 12 Process Models in Software – Types , SDLC & its Phases |SE|

Key Industrial Applications of vending machine inventory software

| Industry/Sector | Specific Application of vending machine inventory software | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Automated stock tracking and replenishment | Reduces stockouts and improves customer satisfaction | Integration with existing POS systems, real-time data access |

| Healthcare | Medication dispensing and inventory management | Enhances medication availability and compliance with regulations | Compliance with health regulations, secure access controls |

| Education | Snack and beverage vending in schools and universities | Increases convenience for students and staff, boosts sales | User-friendly interface, multi-currency support for diverse student bodies |

| Corporate Offices | Office pantry management and employee refreshment stations | Streamlines inventory control and enhances employee morale | Flexible reporting features, ability to handle diverse product ranges |

| Events and Venues | Concession stand inventory management during events | Optimizes inventory levels, reduces waste, and maximizes profits | Scalability for high-demand events, ease of integration with ticketing systems |

Retail

In the retail sector, vending machine inventory software is instrumental in automating stock tracking and replenishment. Retailers can ensure that popular items are always available, reducing the risk of stockouts that can lead to lost sales. For international buyers, especially in regions with diverse consumer preferences, the software must integrate seamlessly with existing Point of Sale (POS) systems and provide real-time data access to enable quick decision-making.

Healthcare

In healthcare, vending machine inventory software plays a crucial role in managing medication dispensing and inventory. This application ensures that medications are readily available while adhering to stringent compliance regulations. For buyers in the healthcare industry, particularly in the Middle East and Europe, it is essential to consider software that offers secure access controls and complies with local health regulations to ensure patient safety and operational efficiency.

Education

Educational institutions utilize vending machine inventory software to manage snack and beverage vending operations efficiently. This enhances convenience for students and staff while boosting sales for the institution. Buyers from Africa and South America should prioritize user-friendly interfaces and multi-currency support to accommodate diverse student populations, ensuring that the software meets the needs of various demographic groups.

Corporate Offices

For corporate offices, vending machine inventory software aids in managing pantry supplies and employee refreshment stations. By streamlining inventory control, companies can enhance employee morale and satisfaction through accessible snacks and beverages. When sourcing solutions, businesses should look for flexible reporting features that can adapt to changing office needs and accommodate a wide range of product offerings.

Events and Venues

In the context of events and venues, vending machine inventory software is vital for managing concession stand inventory. This application optimizes inventory levels, reduces waste, and maximizes profits during high-demand events. International buyers should seek scalable solutions that can handle varying demand levels and integrate smoothly with ticketing systems, ensuring a seamless experience for event-goers while maintaining efficient operations.

Related Video: How to refill and manage your vending machine inventory using an app | Vending machine app [Wendor]

Strategic Material Selection Guide for vending machine inventory software

When selecting materials for vending machine inventory software, international B2B buyers must consider various factors that impact product performance, cost, and compliance with local standards. Here, we analyze four common materials used in the development of such software, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Polycarbonate

Key Properties: Polycarbonate is known for its high impact resistance and transparency. It can withstand temperatures ranging from -40°C to 120°C and has good dimensional stability.

Pros & Cons:

– Pros: Lightweight, durable, and resistant to shattering. It also offers excellent clarity, making it suitable for display panels in vending machines.

– Cons: Although it has good resistance to heat, prolonged exposure to UV light can cause yellowing. It is also more expensive than other plastics.

Impact on Application: Polycarbonate is ideal for applications requiring visibility and robustness, such as screens and protective covers for vending machines. However, its UV sensitivity requires consideration in regions with high sunlight exposure.

Considerations for International Buyers: Buyers should ensure compliance with local safety standards, such as ASTM in the U.S. and EN standards in Europe. In regions like Saudi Arabia, where temperatures can soar, selecting UV-stabilized polycarbonate is advisable.

2. Stainless Steel

Key Properties: Stainless steel is known for its corrosion resistance and strength. It can withstand high temperatures and is often rated for food safety, making it suitable for vending machine components.

Pros & Cons:

– Pros: Highly durable and resistant to rust and corrosion, making it ideal for outdoor vending machines. It also has a sleek appearance that enhances product aesthetics.

– Cons: Higher manufacturing costs and can be heavier than other materials, which may affect installation and transportation.

Impact on Application: Stainless steel is particularly effective in environments where hygiene is critical, such as food and beverage vending machines. Its resistance to corrosion ensures longevity, especially in humid or coastal areas.

Considerations for International Buyers: Compliance with food safety regulations (like FDA in the U.S. and EFSA in Europe) is essential. Buyers in regions such as South America should consider local corrosion factors, especially in coastal areas.

3. Aluminum

Key Properties: Aluminum is lightweight, has good corrosion resistance, and can be easily machined. It typically performs well in temperatures ranging from -40°C to 150°C.

Pros & Cons:

– Pros: Cost-effective and lightweight, making it easy to transport and install. It also offers good thermal conductivity.

– Cons: Less durable than stainless steel and may require protective coatings to enhance corrosion resistance.

Impact on Application: Aluminum is suitable for structural components in vending machines, such as frames and panels. Its lightweight nature makes it ideal for portable machines.

Considerations for International Buyers: Buyers should be aware of the local availability of aluminum and its alloys, which can vary by region. Compliance with local standards (like DIN in Europe) is crucial for ensuring product quality.

4. ABS Plastic

Key Properties: ABS plastic is known for its toughness and impact resistance. It can operate within a temperature range of -20°C to 80°C and is easily molded.

Pros & Cons:

– Pros: Cost-effective and easy to manufacture, making it suitable for complex shapes. It also provides good insulation properties.

– Cons: Not as heat-resistant as other materials and can deform under high temperatures.

Impact on Application: ABS is often used for internal components of vending machines, such as housing and control panels. Its ease of molding allows for custom designs.

Considerations for International Buyers: Buyers should consider the thermal properties of ABS in their specific climates. Compliance with local plastic regulations is also essential, especially in regions where environmental standards are stringent.

Summary Table

| Material | Typical Use Case for vending machine inventory software | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Display panels and protective covers | Lightweight and durable | UV sensitivity over time | Medium |

| Stainless Steel | Structural components and food-safe surfaces | Highly durable and corrosion-resistant | Higher manufacturing costs | High |

| Aluminum | Frames and structural components | Cost-effective and lightweight | Requires protective coatings | Medium |

| ABS Plastic | Internal housing and control panels | Easy to manufacture and mold | Lower heat resistance | Low |

This material selection guide provides actionable insights for international B2B buyers, enabling them to make informed decisions based on performance, cost, and compliance considerations tailored to their regional markets.

In-depth Look: Manufacturing Processes and Quality Assurance for vending machine inventory software

The manufacturing and quality assurance processes for vending machine inventory software are critical for ensuring that businesses can efficiently manage their inventory and meet customer demands. Here’s a detailed look at the typical stages involved in manufacturing, the key techniques used, and the quality control measures that B2B buyers should consider when selecting suppliers.

Manufacturing Processes

1. Material Preparation

In the context of vending machine inventory software, material preparation involves the gathering of all necessary components that make up the software. This includes:

– Hardware Components: Such as sensors, microcontrollers, and communication devices.

– Software Components: The programming languages, frameworks, and libraries needed to develop the application.

During this phase, it is essential to select high-quality components to ensure the reliability and longevity of the software. B2B buyers should inquire about the suppliers’ sourcing practices and whether they use reputable manufacturers for these components.

2. Forming

This stage focuses on the initial coding and development of the software. Techniques used during this phase include:

– Prototyping: Creating a minimum viable product (MVP) to test core functionalities.

– Agile Development: Utilizing iterative cycles to refine software features based on user feedback.

Engaging in a collaborative approach with developers during the forming stage can help B2B buyers ensure that their specific inventory management needs are met.

3. Assembly

Assembly in software manufacturing refers to the integration of various software modules and components into a cohesive system. Key practices include:

– Continuous Integration/Continuous Deployment (CI/CD): This technique allows for regular updates and bug fixes, ensuring that the software remains current and functional.

– Version Control Systems: These systems help manage changes to the software, providing a clear history of updates and enabling easier rollbacks if needed.

B2B buyers should evaluate the development methodologies employed by suppliers to ensure they align with industry best practices.

4. Finishing

The finishing stage encompasses final testing and preparation for deployment. Important activities include:

– User Acceptance Testing (UAT): This process involves real users testing the software to confirm it meets their requirements.

– Documentation: Comprehensive user manuals and technical documentation should be prepared to facilitate ease of use.

Before committing to a supplier, B2B buyers should request samples of finished software and documentation to assess quality and usability.

Quality Assurance

International Standards

For B2B buyers, understanding the quality assurance measures that suppliers adhere to is crucial. Key international standards include:

– ISO 9001: This standard focuses on quality management systems and is applicable across various industries, ensuring that suppliers maintain a high level of quality in their processes.

– CE Marking: This certification indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

Buyers should confirm that their suppliers are compliant with these standards, as they reflect a commitment to quality.

Industry-Specific Certifications

In addition to international standards, certain certifications are specific to the technology and vending machine industries:

– API Standards: Relevant for software that interfaces with other systems, ensuring interoperability and security.

– Data Protection Compliance: Certifications related to GDPR in Europe and other regional regulations that protect user data.

Buyers should ensure that their suppliers possess the necessary certifications, as this can mitigate risks associated with data breaches and non-compliance.

Quality Control Checkpoints

Quality control should be integrated into every stage of the manufacturing process. Common checkpoints include:

– Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to identify defects early.

– Final Quality Control (FQC): Comprehensive testing of the finished product to ensure it meets all requirements before delivery.

B2B buyers should ask suppliers about their quality control protocols and request documentation to verify compliance.

Common Testing Methods

Various testing methods can be employed to ensure software quality, including:

– Functional Testing: Verifying that the software performs its intended functions.

– Performance Testing: Assessing how the software behaves under load and ensuring it can handle peak usage scenarios.

– Security Testing: Identifying vulnerabilities to protect against potential threats.

Understanding the testing methods used by suppliers can provide B2B buyers with confidence in the software’s reliability and security.

Verifying Supplier Quality Control

To ensure that suppliers maintain high-quality standards, B2B buyers should consider the following approaches:

– Audits: Conducting regular audits of suppliers’ facilities and processes can provide insights into their quality management systems.

– Quality Reports: Requesting regular reports that detail quality metrics and any corrective actions taken can help monitor supplier performance.

– Third-Party Inspections: Engaging independent third-party inspectors to assess supplier compliance with quality standards can add an extra layer of assurance.

Conclusion

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance practices for vending machine inventory software is essential. By focusing on suppliers that adhere to recognized standards, employ robust quality control measures, and maintain transparent practices, buyers can mitigate risks and ensure they receive reliable, high-quality software solutions.

Related Video: Plex Manufacturing ERP: Advanced Scheduling & Planning Software Demo

Comprehensive Cost and Pricing Analysis for vending machine inventory software Sourcing

When sourcing vending machine inventory software, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis breaks down the key cost components, pricing influencers, and offers actionable insights tailored for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

- Materials: The software’s core functionality often relies on the integration of various technologies and programming languages. The choice of materials, including servers, cloud storage, and software licenses, significantly influences costs. Advanced features such as real-time inventory tracking or analytics may require more expensive components.

Illustrative Image (Source: Google Search)

-

Labor: Development and maintenance of vending machine inventory software necessitate skilled personnel. This includes software developers, data analysts, and IT support staff. Labor costs can vary significantly depending on the region, with skilled labor being more expensive in Europe compared to some regions in Africa or South America.

-

Manufacturing Overhead: While not directly applicable as in physical goods, overhead in software development encompasses utilities, office space, and administrative costs. Efficient management of these overheads can lead to reduced overall software costs.

-

Tooling: The tools and platforms used for development (e.g., Integrated Development Environments, testing tools) can add to the cost. Opting for open-source or less expensive tools can mitigate these expenses.

-

Quality Control (QC): Ensuring the software meets quality standards involves testing phases that require additional resources. Rigorous QC processes help in minimizing errors post-deployment, which can be costly.

-

Logistics: For software, logistics primarily concerns the delivery of updates and support services. Consideration of the geographical spread of users may affect support costs and response times.

- Margin: Vendors typically include a profit margin in their pricing, which can vary based on competition, market demand, and perceived value of the software.

Price Influencers

-

Volume/MOQ: Software vendors often offer tiered pricing based on the number of licenses purchased. Higher volume orders can lead to significant discounts.

-

Specifications/Customization: Tailored solutions that meet specific business needs may incur additional costs. Understanding the balance between necessary customizations and off-the-shelf solutions is critical for cost management.

-

Materials and Quality Certifications: The quality of the software, including certifications (like ISO), can influence pricing. Higher quality and certified software often commands a premium price.

-

Supplier Factors: The reputation and reliability of the vendor can affect pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer competitive rates to gain market share.

-

Incoterms: For international transactions, Incoterms can dictate responsibility for costs and risks. Understanding these terms helps in assessing the total cost involved in sourcing software.

Buyer Tips

-

Negotiation: Leverage your position as a buyer by comparing multiple vendors. Do not hesitate to negotiate terms, especially for larger orders.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), including ongoing support and maintenance costs, not just the initial purchase price. This provides a more accurate picture of long-term expenses.

-

Pricing Nuances: Be aware of regional pricing strategies. In Africa and South America, for instance, vendors may offer more flexible payment terms or lower upfront costs to accommodate local market conditions.

-

Market Research: Stay informed about market trends and competitor offerings. Understanding the competitive landscape can provide leverage in negotiations.

Disclaimer

Prices for vending machine inventory software can vary widely based on specifications, vendor reputation, and regional economic conditions. Always seek updated quotes and consider multiple factors before finalizing your purchase.

Spotlight on Potential vending machine inventory software Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘vending machine inventory software’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for vending machine inventory software

Key Technical Properties of Vending Machine Inventory Software

Understanding the technical specifications of vending machine inventory software is crucial for international B2B buyers, especially those in diverse markets like Africa, South America, the Middle East, and Europe. Here are some essential properties to consider:

-

Scalability

Scalability refers to the software’s ability to handle increasing amounts of data or transactions as your business grows. This is vital for companies planning to expand their vending machine operations across multiple locations. A scalable system ensures that performance remains consistent, regardless of the number of machines or the volume of transactions processed. -

Integration Capabilities

The ability to integrate with existing systems (e.g., ERP, CRM) allows for seamless data flow and process automation. This is particularly important for B2B buyers who want to maintain efficiency and minimize disruptions during the transition to new software. Robust integration capabilities also enhance data analytics, enabling businesses to make informed decisions based on real-time data. -

User Interface (UI) and User Experience (UX)

A user-friendly interface is essential for ease of use across different staff levels. Vending machine operators and managers should be able to navigate the software effortlessly. A well-designed UI/UX reduces training time and increases productivity, making it a key consideration for B2B buyers. -

Real-Time Reporting and Analytics

This feature allows businesses to monitor sales trends, inventory levels, and machine performance in real-time. For international buyers, having access to analytics can inform strategic decisions, such as which products to stock or how to optimize machine placements. Real-time insights can also enhance customer satisfaction by ensuring popular items are always available. -

Security Features

Given the sensitivity of financial transactions and personal data, security features such as data encryption, user authentication, and compliance with regulations (like GDPR for European buyers) are critical. Ensuring robust security measures protects the business and builds trust with customers and stakeholders. -

Support and Maintenance

Reliable customer support and maintenance services are essential for minimizing downtime. B2B buyers should consider vendors that offer comprehensive support packages, including training, technical assistance, and regular software updates to keep the system running smoothly.

Common Trade Terminology in Vending Machine Inventory Software

Familiarity with industry-specific jargon can significantly enhance communication and negotiation with suppliers. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of vending machines, understanding OEM relationships helps buyers identify which software solutions are compatible with specific machine brands. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is crucial when negotiating software licenses or hardware purchases, as it impacts budgeting and inventory management. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific goods or services. For buyers, issuing an RFQ can help compare costs and features across different vendors, ensuring informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers to avoid misunderstandings regarding shipping costs, insurance, and liability. -

API (Application Programming Interface)

An API allows different software applications to communicate with one another. For vending machine inventory software, APIs can facilitate integration with other business systems, enhancing functionality and data sharing. -

Cloud-Based Solutions

This term refers to software that is hosted on the cloud rather than on local servers. Cloud-based solutions offer flexibility, lower upfront costs, and easier updates, making them attractive options for B2B buyers looking to enhance their vending operations.

By grasping these technical properties and terminology, international B2B buyers can make more informed decisions when selecting vending machine inventory software, ensuring alignment with their operational needs and strategic goals.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine inventory software Sector

Market Overview & Key Trends

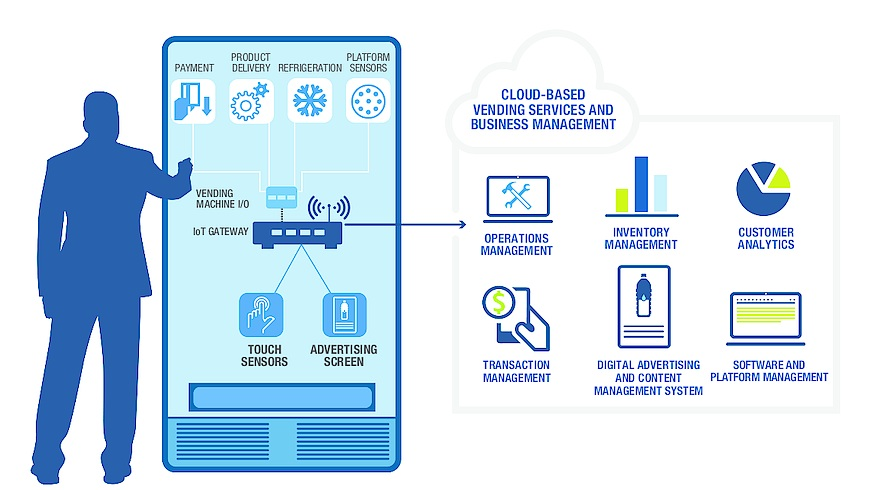

The vending machine inventory software sector is experiencing significant transformation driven by technological advancements and changing consumer preferences. The global push for automation and efficiency has led to the adoption of sophisticated software solutions that provide real-time inventory tracking, predictive analytics, and remote monitoring capabilities. B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should be aware of several key trends shaping the market:

-

Integration of IoT and AI: The convergence of Internet of Things (IoT) technologies and Artificial Intelligence (AI) is enhancing the functionality of vending machines. Smart vending solutions can analyze consumer behavior and inventory levels, optimizing restocking schedules and reducing waste.

-

Mobile Payment Solutions: As cashless transactions become the norm, vending machines equipped with mobile payment options are gaining traction. This trend is particularly relevant in urban areas where convenience is paramount, and consumers prefer seamless payment experiences.

Illustrative Image (Source: Google Search)

-

Customization and Personalization: Businesses are increasingly seeking software that allows for tailored vending experiences. Customizable interfaces and personalized product offerings can help companies cater to specific consumer demographics, enhancing customer satisfaction and loyalty.

-

Data-Driven Decision Making: With the rise of big data, vending machine operators are leveraging analytics to gain insights into sales trends, customer preferences, and inventory performance. This data-driven approach empowers businesses to make informed decisions about product offerings and operational efficiency.

-

Sustainability Initiatives: There is a growing emphasis on sustainable practices within the vending sector. Software solutions that facilitate eco-friendly inventory management and promote the sale of sustainable products are becoming vital for companies aiming to enhance their corporate social responsibility (CSR) profiles.

These trends indicate a vibrant and evolving market landscape. International buyers should prioritize software vendors that demonstrate a commitment to innovation and sustainability while providing robust support and integration capabilities.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly becoming a central concern for businesses in the vending machine inventory software sector. The environmental impact of operations, from sourcing materials to waste management, has prompted companies to adopt more sustainable practices. Here are some critical aspects of sustainability and ethical sourcing:

-

Environmental Impact: The production and disposal of vending machines and their components can significantly affect the environment. Buyers should consider software solutions that promote efficient inventory management, reducing waste and ensuring optimal product turnover.

-

Ethical Supply Chains: Establishing an ethical supply chain is crucial for modern businesses. This involves sourcing materials responsibly and ensuring that suppliers adhere to fair labor practices. Buyers should seek software vendors who prioritize ethical sourcing and transparency in their supply chains.

-

Green Certifications and Materials: Companies are increasingly turning to eco-friendly materials and practices. Look for software that supports the tracking of green certifications for products sold through vending machines, such as organic or sustainably sourced items. This not only enhances brand reputation but also aligns with consumer preferences for environmentally responsible options.

-

Waste Reduction: Effective inventory software can help minimize waste by optimizing stock levels and reducing overproduction. Solutions that provide insights into sales patterns can help businesses adjust their inventory accordingly, thus supporting sustainability goals.

By prioritizing sustainability and ethical sourcing, international B2B buyers can not only meet regulatory demands but also appeal to a growing segment of environmentally conscious consumers.

Brief Evolution/History

The vending machine inventory software sector has evolved significantly over the last few decades. Initially, vending machines operated on a basic mechanical system, offering limited payment options and product selection. However, the introduction of digital technology in the late 1990s marked the beginning of a new era.

As internet connectivity became more prevalent, remote monitoring and management capabilities emerged, allowing operators to track inventory levels and sales data in real-time. The last decade has seen a surge in demand for integrated software solutions that leverage IoT and AI technologies, reflecting a broader shift towards automation and data-driven decision-making in various industries.

Today, the focus on sustainability and ethical sourcing further shapes the evolution of vending machine inventory software, making it a crucial consideration for international B2B buyers looking to stay competitive in a dynamic marketplace.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of vending machine inventory software

-

What criteria should I use to vet suppliers of vending machine inventory software?

When vetting suppliers, prioritize their experience in the industry, customer reviews, and case studies showcasing successful implementations. Check if they offer local support in your region, as this can be crucial for troubleshooting. Additionally, evaluate their software’s scalability to ensure it can grow with your business. Certifications like ISO or industry-specific endorsements can also indicate a supplier’s reliability and commitment to quality. -

Can vending machine inventory software be customized to fit my specific needs?

Most reputable vendors offer customization options tailored to your operational requirements. Discuss your specific needs during initial consultations to understand the flexibility of their solutions. Request demos to see how the software can be adapted. Ensure the supplier provides ongoing support for any custom features, as this can affect long-term usability and satisfaction. -

What are the minimum order quantities (MOQs) and typical lead times for vending machine inventory software?

MOQs can vary by supplier, but many offer scalable solutions that cater to both small and large enterprises. Discuss your initial needs with potential vendors to negotiate terms that fit your business size. Lead times for implementation typically range from a few weeks to several months, depending on the complexity of the software and customization. Always confirm these details during the procurement process to avoid delays. -

What payment options are available for purchasing vending machine inventory software?

Payment terms can differ significantly among suppliers. Common options include upfront payments, installment plans, or subscription-based models. Review each supplier’s terms carefully, considering factors like total cost, maintenance fees, and potential hidden charges. International buyers should also consider currency exchange rates and any additional fees related to cross-border transactions. -

How can I ensure the quality and reliability of the vending machine inventory software?

Request documentation of quality assurance processes and certifications from potential suppliers. Look for software that has undergone rigorous testing and is backed by a solid warranty or service agreement. Additionally, ask for references from current users to gauge their satisfaction and experience with the software’s performance over time. -

What logistics considerations should I keep in mind when sourcing vending machine inventory software?

Understand the logistics of software delivery, including installation and integration with existing systems. Inquire about the supplier’s support for training your staff and ongoing technical assistance. If sourcing internationally, consider potential customs delays and how they might impact the timeline for software deployment. -

What should I do if a dispute arises with my software supplier?

Establish clear communication channels and procedures for addressing disputes before finalizing contracts. Many suppliers offer formal dispute resolution processes, including mediation or arbitration. Document all interactions with the supplier and maintain records of agreements to support your position if disagreements arise. Understanding local laws regarding contract disputes in both your country and the supplier’s can also be beneficial. -

Are there specific regulations I need to be aware of when purchasing vending machine inventory software internationally?

Yes, international buyers should familiarize themselves with local regulations regarding software usage, data privacy, and consumer protection. Compliance with standards such as GDPR for European buyers or specific regional laws in Africa and South America is crucial. Suppliers should provide information on how their software meets these regulatory requirements, ensuring your business remains compliant while using their solutions.

Strategic Sourcing Conclusion and Outlook for vending machine inventory software

In the rapidly evolving landscape of vending machine inventory software, strategic sourcing emerges as a critical component for international B2B buyers seeking efficiency and profitability. By leveraging robust software solutions, businesses can streamline inventory management, enhance operational visibility, and respond to consumer demands with agility. Key takeaways include the importance of integration capabilities, data analytics, and user-friendly interfaces, which collectively empower organizations to make informed decisions and reduce costs.

As markets in Africa, South America, the Middle East, and Europe continue to expand, the demand for innovative vending solutions is set to rise. Investing in advanced inventory software not only optimizes supply chains but also supports sustainability efforts by minimizing waste and improving resource allocation.

Looking ahead, international buyers are encouraged to evaluate their current systems and consider upgrading to solutions that foster adaptability and scalability. Embracing these technologies will not only position businesses for future growth but also enhance their competitive edge in a dynamic marketplace. Now is the time to act and secure the advantages that come with strategic sourcing in vending machine inventory software.