Your Ultimate Guide to Sourcing Vending Machine For Rent

Guide to Vending Machine For Rent

- Introduction: Navigating the Global Market for vending machine for rent

- Understanding vending machine for rent Types and Variations

- Key Industrial Applications of vending machine for rent

- Strategic Material Selection Guide for vending machine for rent

- In-depth Look: Manufacturing Processes and Quality Assurance for vending machine for rent

- Comprehensive Cost and Pricing Analysis for vending machine for rent Sourcing

- Spotlight on Potential vending machine for rent Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for vending machine for rent

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine for rent Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vending machine for rent

- Strategic Sourcing Conclusion and Outlook for vending machine for rent

Introduction: Navigating the Global Market for vending machine for rent

In today’s fast-paced global economy, vending machines for rent are emerging as a strategic asset for businesses looking to enhance service delivery and customer engagement. This innovative solution allows companies across various industries to offer convenience and accessibility to their clients without the heavy capital investment associated with purchasing machines outright. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the dynamics of this market is crucial for making informed decisions.

This guide provides a comprehensive overview of the vending machine rental landscape, covering essential topics such as types of machines available, materials used in manufacturing, quality control processes, and key suppliers. Additionally, it delves into cost considerations and market trends, ensuring that buyers are equipped with the necessary insights to navigate negotiations effectively.

By leveraging the information within this guide, businesses can identify the right vending machine solutions that align with their operational needs and customer preferences. Whether you are in Colombia seeking to enhance retail offerings, or in the Middle East exploring new avenues for customer service, this resource empowers you to make strategic sourcing decisions. With a thorough understanding of the global market, your business can capitalize on the benefits of vending machine rentals, driving growth and customer satisfaction in an increasingly competitive landscape.

Understanding vending machine for rent Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Snack Machines | Dispenses packaged snacks and beverages | Offices, schools, public spaces | Pros: Familiarity, easy maintenance; Cons: Limited product variety, less interactive. |

| Fresh Food Vending Machines | Refrigerated units for fresh meals | Hospitals, universities, corporate dining | Pros: Healthier options, appeals to modern consumers; Cons: Requires more maintenance, higher initial cost. |

| Specialty Vending Machines | Offers niche products (e.g., electronics) | Airports, malls, tech stores | Pros: Unique offerings can attract specific customers; Cons: Higher risk if niche market fails. |

| Coffee Vending Machines | Provides various coffee beverages | Offices, cafes, hotels | Pros: High demand for coffee; Cons: Requires regular supply of fresh ingredients. |

| Automated Retail Kiosks | Combines vending with e-commerce features | Retail locations, events | Pros: Innovative shopping experience, can sell a wide range of products; Cons: Requires tech-savvy maintenance. |

Traditional Snack Machines

Traditional snack machines are designed to dispense packaged snacks and beverages, making them a staple in various environments such as offices, schools, and public spaces. They are typically easy to operate and maintain, appealing to buyers looking for reliable, low-maintenance solutions. However, these machines may not cater to diverse dietary preferences or trends, which can limit their appeal in more health-conscious markets.

Fresh Food Vending Machines

These machines are equipped with refrigeration to store and dispense fresh meals, salads, and healthy snacks. They are particularly suitable for environments like hospitals, universities, and corporate dining facilities, where consumers are increasingly seeking nutritious options. While they can command higher rental fees and require regular maintenance to ensure food safety, their ability to meet modern consumer demands makes them a valuable investment for businesses aiming to enhance employee or customer satisfaction.

Specialty Vending Machines

Specialty vending machines focus on niche products, such as electronics, beauty products, or local artisanal foods. Ideal for high-traffic areas like airports, malls, and tech stores, these machines can attract specific customer demographics. However, they come with a higher risk, as their success is closely tied to the popularity of the niche market. Businesses must conduct thorough market research before investing in these machines to ensure demand is sufficient.

Coffee Vending Machines

Coffee vending machines offer a variety of coffee beverages, catering to the high demand for coffee in offices, cafes, and hotels. They can provide a convenient solution for businesses looking to enhance their offerings. However, these machines require a consistent supply of fresh ingredients, which can complicate maintenance and logistics. Buyers should consider the cost of supplies and the potential for high turnover when evaluating this option.

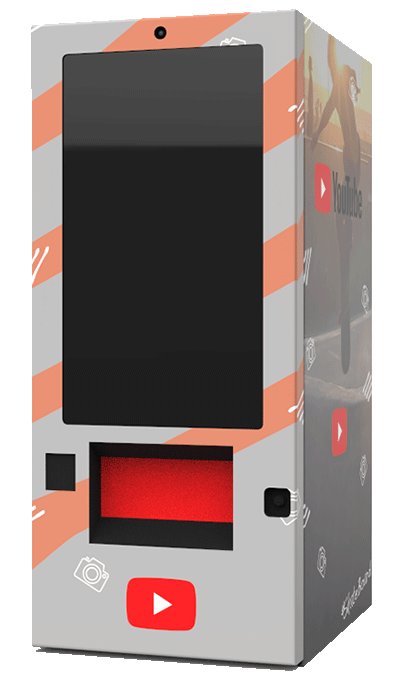

Automated Retail Kiosks

Automated retail kiosks blend vending with e-commerce, allowing businesses to sell a wide range of products in an interactive manner. These kiosks are suitable for retail locations and events, providing an innovative shopping experience that can attract tech-savvy consumers. While they offer significant advantages in terms of product variety and customer engagement, they also require more complex maintenance and support, making them a consideration for businesses ready to invest in technology.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of vending machine for rent

| Industry/Sector | Specific Application of vending machine for rent | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Mini-bar solutions in hotels and resorts | Increased guest satisfaction, reduced labor costs | Customization options, payment systems, inventory management |

| Education | Snack and beverage vending in schools and universities | Convenient access to food, promotes healthy eating habits | Compliance with health regulations, variety of offerings |

| Healthcare | Medicine and hygiene product vending in hospitals | Improved patient care, quick access to essential supplies | Security features, temperature control, ease of use |

| Office Environments | Breakroom vending solutions | Boosts employee morale, enhances productivity | Product variety, payment flexibility, maintenance support |

| Manufacturing | Tools and parts vending machines | Streamlined operations, reduced downtime | Inventory tracking, machine durability, supplier reliability |

Hospitality

Vending machines for rent are increasingly utilized in the hospitality sector, particularly in hotels and resorts, where mini-bar solutions can enhance guest experiences. These machines offer a variety of snacks and beverages, providing guests with convenient access to refreshments without the need for staff intervention. This not only increases guest satisfaction but also significantly reduces labor costs associated with traditional mini-bars. International buyers should focus on customization options and advanced payment systems to cater to diverse guest preferences and ensure seamless transactions.

Education

In educational institutions, vending machines serve as an essential source of snacks and beverages for students. They promote healthier eating habits by offering nutritious options while providing convenient access to food during busy school hours. The ability to rent these machines allows schools to adapt to changing dietary trends without the significant upfront investment. Buyers in this sector must consider compliance with health regulations, ensuring that the offerings meet nutritional standards and that the machines are regularly stocked and maintained.

Healthcare

The healthcare industry benefits from vending machines that dispense medicines and hygiene products, particularly in hospitals and clinics. These machines ensure that patients and staff have quick access to essential supplies, which is crucial in emergency situations. The rental model allows healthcare facilities to upgrade their offerings without large capital expenditures. Key considerations for international B2B buyers include security features to prevent unauthorized access, temperature control for sensitive products, and ease of use for diverse patient demographics.

Office Environments

In modern office environments, vending machines enhance breakroom offerings, providing employees with snacks and beverages that boost morale and productivity. Renting these machines allows companies to offer a variety of products tailored to employee preferences without the hassle of ownership. When sourcing vending machines for offices, businesses should look for options with diverse product offerings, flexible payment methods, and reliable maintenance support to ensure continuous service and satisfaction.

Manufacturing

In the manufacturing sector, vending machines that dispense tools and parts are invaluable for streamlining operations. These machines provide quick access to necessary items, reducing downtime and increasing efficiency on the production floor. Renting these machines allows manufacturers to adapt their inventory based on real-time needs without significant upfront investment. Key sourcing considerations include robust inventory tracking systems to monitor usage and ensure availability, as well as machine durability to withstand the demanding industrial environment.

Related Video: How to Start a Vending Machine Business, Cost, Tips, How Much You Make

Strategic Material Selection Guide for vending machine for rent

When selecting materials for vending machines intended for rent, international B2B buyers must consider several factors, including durability, cost, and compliance with local standards. The choice of material directly impacts the machine’s performance, maintenance requirements, and overall customer satisfaction. Below, we analyze four common materials used in vending machines, providing insights tailored for buyers from Africa, South America, the Middle East, and Europe.

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. It typically has a temperature rating up to 800°C (1472°F) and can handle pressures of up to 150 psi, depending on the specific grade.

Pros & Cons: Stainless steel is highly durable and easy to clean, making it ideal for environments where hygiene is paramount, such as food and beverage vending. However, it is more expensive than other materials, which can impact the initial investment cost. Manufacturing complexity can also be higher due to the need for specialized equipment.

Impact on Application: Stainless steel is compatible with various media, including food products and beverages, making it a versatile choice. Its resistance to rust and staining ensures longevity, even in humid or wet conditions.

Considerations for International Buyers: Buyers should ensure compliance with local health and safety regulations, which may vary significantly across regions. For instance, European standards (EN) and ASTM standards in the U.S. may differ in terms of material specifications.

2. Powder-Coated Steel

Key Properties: Powder-coated steel combines the strength of steel with a protective coating that enhances corrosion resistance. The temperature rating can vary, but it generally performs well in moderate temperature environments.

Pros & Cons: This material is cost-effective and offers a wide range of aesthetic options due to the variety of colors available. However, the coating can chip or scratch, exposing the steel underneath, which may lead to corrosion over time.

Impact on Application: Powder-coated steel is suitable for vending machines that will be placed in indoor environments. It is less ideal for outdoor applications where exposure to the elements could compromise the coating.

Considerations for International Buyers: Buyers should check for compliance with local environmental regulations regarding coatings and emissions. In regions like Europe, adherence to REACH regulations is crucial, while in South America, local standards may vary.

3. Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has a good strength-to-weight ratio. It typically has a temperature rating up to 200°C (392°F) and is suitable for moderate pressure applications.

Pros & Cons: The lightweight nature of aluminum makes it easy to transport and install, reducing logistical costs. However, it is less durable than stainless steel and may not withstand heavy impacts or rough handling as well.

Impact on Application: Aluminum is suitable for vending machines in low to moderate usage environments. It is particularly effective in locations where weight is a concern, such as portable vending solutions.

Considerations for International Buyers: Buyers should be aware of the varying recycling regulations for aluminum in different regions, as well as any specific material standards that apply in their country.

4. High-Density Polyethylene (HDPE)

Key Properties: HDPE is a thermoplastic polymer known for its high strength-to-density ratio, excellent impact resistance, and good chemical resistance. It can withstand temperatures up to 120°C (248°F) and is not prone to rust or corrosion.

Pros & Cons: HDPE is lightweight and cost-effective, making it a popular choice for budget-conscious projects. However, it may not provide the same level of aesthetic appeal or durability as metal options, particularly in high-traffic areas.

Impact on Application: HDPE is best suited for vending machines that dispense non-perishable items or in environments where moisture is a concern. It is less ideal for machines that require a premium appearance or heavy-duty performance.

Considerations for International Buyers: Buyers should consider the environmental impact of using plastics and check for compliance with local regulations regarding the use of plastics, especially in regions like Europe where sustainability is a significant concern.

Summary Table

| Material | Typical Use Case for vending machine for rent | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and beverage vending machines | Excellent corrosion resistance | Higher initial cost | High |

| Powder-Coated Steel | Indoor vending machines | Cost-effective, aesthetic variety | Coating can chip, exposing steel | Medium |

| Aluminum | Portable or lightweight vending solutions | Lightweight, easy to transport | Less durable than steel | Medium |

| High-Density Polyethylene (HDPE) | Non-perishable item vending machines | Lightweight, cost-effective | Limited aesthetic appeal and durability | Low |

This strategic material selection guide provides a framework for international B2B buyers to make informed decisions when sourcing vending machines for rent, ensuring that they consider both performance and compliance factors relevant to their specific markets.

In-depth Look: Manufacturing Processes and Quality Assurance for vending machine for rent

The manufacturing of vending machines for rent involves a series of intricate processes that ensure the final product is both functional and reliable. Understanding these processes is crucial for B2B buyers aiming to procure high-quality machines that meet international standards. Below is an overview of the typical manufacturing stages, key techniques, and quality assurance measures relevant to vending machines.

Manufacturing Processes

1. Material Preparation

The first stage in manufacturing vending machines involves the selection and preparation of materials. Common materials include:

- Steel and Aluminum: Used for the frame and casing due to their strength and durability.

- Plastic Components: Utilized for the internal mechanisms and user interfaces.

- Electronic Components: Such as microcontrollers, sensors, and payment systems, which are critical for machine functionality.

Key Techniques:

– Material Sourcing: Buyers should ensure that suppliers source materials from reputable vendors to avoid quality issues.

– Pre-Treatment: Metals often undergo treatments like galvanization or powder coating to prevent corrosion and enhance aesthetics.

2. Forming

This stage involves shaping the prepared materials into the necessary components for the vending machine.

- Cutting: Laser cutting or CNC machining is commonly used to achieve precise dimensions for metal parts.

- Bending: Metal sheets are bent into required shapes using hydraulic presses, ensuring structural integrity.

Key Techniques:

– 3D Modeling: Advanced software is used to design components, allowing for efficient prototyping and adjustments before mass production.

3. Assembly

The assembly stage combines all the individual components into a complete vending machine.

- Mechanical Assembly: This includes the installation of frames, doors, and internal mechanisms such as coils and dispensers.

- Electrical Assembly: Integration of electronic components, wiring, and payment systems is performed in a controlled environment to prevent static damage.

Key Techniques:

– Modular Assembly: Some manufacturers utilize modular design principles, allowing for easier repairs and upgrades.

4. Finishing

The final stage involves applying finishes and conducting final adjustments to ensure the product is ready for market.

- Painting and Coating: Machines are often painted or coated with protective finishes to enhance durability and aesthetics.

- Labeling: Proper labeling is crucial for user instructions and compliance with safety standards.

Key Techniques:

– Quality Checks During Assembly: Continuous monitoring during assembly helps catch defects early in the process.

Quality Assurance

Quality assurance (QA) is an essential aspect of the manufacturing process that ensures the vending machines meet both international and industry-specific standards.

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems and ensures that manufacturers maintain high-quality processes.

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Certification: For components that require additional safety and reliability assurances, particularly in regions with stringent regulations.

QC Checkpoints

Quality Control (QC) involves several key checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials and components upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to identify defects early.

- Final Quality Control (FQC): Comprehensive testing of the completed vending machines to verify performance and safety.

Common Testing Methods

- Functional Testing: Ensures all mechanical and electronic components operate correctly.

- Durability Testing: Machines undergo stress tests to assess their performance under various conditions.

- Safety Testing: Compliance with safety standards, including electrical safety and user safety.

Verifying Supplier Quality Control

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is critical. Here are some actionable steps:

- Conduct Audits: Regularly audit potential suppliers to assess their manufacturing practices and QC measures. This can include on-site visits or third-party audits.

- Request QC Reports: Ask for detailed quality control reports that outline testing methods, results, and compliance with international standards.

- Third-Party Inspections: Engage independent inspection agencies to evaluate the manufacturing facility and the quality of the products being produced.

QC/Certifications Nuances for International Buyers

When dealing with suppliers from different regions, it is essential to understand the nuances of quality certifications and compliance standards:

- Regional Standards Variability: Standards may differ significantly between regions. For instance, CE marking is critical for European markets, while UL certification may be more relevant in North America.

- Documentation Requirements: Ensure that suppliers provide all necessary documentation for compliance with local regulations in your target market.

- Cultural Considerations: Be aware of the cultural factors that may influence manufacturing practices and quality perceptions in different regions.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for vending machines is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with stringent QC practices, buyers can ensure they procure high-quality machines that meet international standards and cater to their specific regional requirements.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for vending machine for rent Sourcing

When sourcing vending machines for rent, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis focuses on the components that contribute to the overall cost, the factors that influence pricing, and actionable tips for negotiating favorable terms.

Cost Components

-

Materials: The primary cost driver in the production of vending machines. Common materials include metal casings, plastic components, and electronic parts. Sourcing high-quality materials can increase durability but may elevate costs. Always consider local availability when evaluating material costs.

-

Labor: Labor costs can vary significantly based on the region where the vending machines are manufactured. For instance, countries with lower labor costs, such as certain parts of Africa and South America, may offer more competitive pricing. However, the quality of craftsmanship and skill level must also be assessed.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent for production facilities, and administrative expenses. Understanding the overhead of your supplier can help in evaluating their pricing strategy.

Illustrative Image (Source: Google Search)

-

Tooling: Custom tooling for specialized vending machines can incur substantial upfront costs. It is essential to determine whether your specifications warrant these costs and how they will impact the overall rental price.

-

Quality Control (QC): Implementing a robust QC process ensures that the machines meet safety and performance standards. However, this can add to the costs. Suppliers with established certifications (e.g., ISO) may charge more but can offer assurance of quality.

-

Logistics: Shipping costs depend on the distance, mode of transportation, and volume of the order. International buyers should consider the implications of Incoterms on logistics expenses, as these terms dictate the responsibilities of buyers and sellers during transport.

-

Margin: Supplier profit margins can vary based on market positioning and competition. Understanding typical margins within your target regions can provide insight into pricing flexibility during negotiations.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Buyers should negotiate for favorable terms, especially if planning to scale operations.

-

Specifications/Customization: Custom features can significantly affect pricing. Standard models tend to be more cost-effective, while bespoke designs may require additional investment.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications can impact both cost and perceived value. Buyers should weigh the importance of these factors against their budget.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may command higher prices due to their track record but can also offer greater assurance in terms of service and product reliability.

-

Incoterms: Understanding the Incoterms agreed upon in the contract is crucial for determining logistics responsibilities and costs. Different terms can lead to variations in total landed costs.

Buyer Tips

-

Negotiation: Approach negotiations with a clear understanding of your requirements and the market landscape. Leverage competition among suppliers to secure better pricing.

-

Cost-Efficiency: Evaluate not only the upfront rental cost but also the Total Cost of Ownership (TCO), which includes maintenance, service, and operational expenses throughout the rental period.

-

Pricing Nuances: Be aware of regional pricing trends and economic conditions that may affect costs. For example, currency fluctuations can impact pricing for international buyers, especially in volatile markets.

-

Regional Considerations: Tailor your approach based on the specific regions you are dealing with. For instance, buyers in Africa may encounter different logistical challenges compared to those in Europe, which could affect overall pricing.

Disclaimer

The prices and cost structures discussed herein are indicative and can vary based on market conditions, supplier negotiations, and specific requirements. Always conduct thorough due diligence and obtain multiple quotes to ensure a comprehensive understanding of the pricing landscape.

Spotlight on Potential vending machine for rent Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘vending machine for rent’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for vending machine for rent

Key Technical Properties of Vending Machines for Rent

When considering vending machines for rent, understanding their technical properties is crucial for making informed decisions. Here are several key specifications that impact functionality, durability, and overall operational efficiency:

-

Material Grade

The material used in vending machines typically includes high-grade steel, aluminum, or durable plastics. A higher material grade ensures resistance to corrosion, wear, and vandalism, which is essential for machines placed in public areas. For B2B buyers, investing in machines made from superior materials can reduce long-term maintenance costs and enhance the lifespan of the equipment. -

Temperature Control Range

For machines that dispense perishable goods or beverages, the temperature control range is vital. Most vending machines should maintain temperatures between 0°C to 5°C for refrigeration and up to 85°C for hot beverages. Understanding the temperature control capabilities ensures that products remain fresh and safe for consumption, directly impacting customer satisfaction and sales performance. -

Power Consumption

Energy efficiency is a significant concern for businesses looking to minimize operational costs. Vending machines vary in their power consumption, typically ranging from 200 to 600 watts. Opting for energy-efficient models can lead to substantial savings in electricity bills, making this a crucial specification for B2B buyers, especially in regions with high energy costs. -

Capacity and Size

The capacity of a vending machine, often measured in the number of products it can hold, directly influences its suitability for different locations. Machines can range from compact units holding 20 items to larger models accommodating over 100 items. Understanding the space available and the anticipated foot traffic can help buyers select the right machine that meets their operational needs without compromising on product variety. -

User Interface

The user interface of a vending machine, including touchscreen functionality and payment options (credit card, mobile payment, etc.), can significantly affect user experience. A more intuitive interface can lead to higher sales and customer satisfaction. B2B buyers should prioritize machines with modern interfaces that cater to diverse customer preferences, especially in tech-savvy markets. -

Security Features

Security is paramount for vending machines, particularly in high-traffic or remote locations. Features such as reinforced locks, surveillance systems, and anti-theft mechanisms are essential for protecting inventory and revenue. Buyers should assess the security features of machines to mitigate risks and ensure a safe investment.

Essential Trade Terminology

Understanding industry jargon can significantly streamline the procurement process and enhance communication with suppliers. Here are some common terms relevant to vending machines for rent:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of vending machines, knowing the OEM can help buyers assess the quality and reliability of the machines and their components. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. For B2B buyers, understanding MOQ is crucial for budgeting and inventory management, particularly when renting multiple machines or when entering new markets. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. For international buyers, issuing an RFQ can clarify expectations and facilitate negotiations, ensuring competitive pricing and favorable conditions for renting vending machines. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping and delivery terms. Familiarity with these terms can help B2B buyers understand their obligations regarding transportation costs, insurance, and risk management during the rental process. -

Lead Time

This term refers to the period between placing an order and receiving the goods. Understanding lead times is essential for planning and ensuring that vending machines are available when needed, particularly in seasonal markets or during product launches. -

Service Level Agreement (SLA)

An SLA outlines the expected service standards between the rental company and the client, including maintenance schedules and response times for service issues. For B2B buyers, a well-defined SLA ensures accountability and clarity, leading to improved service reliability and customer satisfaction.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make more informed decisions when renting vending machines, optimizing their operational efficiency and enhancing customer experience.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine for rent Sector

Market Overview & Key Trends

The vending machine rental sector is experiencing a significant transformation driven by technological advancements and changing consumer preferences. International B2B buyers should note that the integration of smart technology into vending machines is a primary market driver. Features such as cashless payment options, remote inventory management, and data analytics are becoming standard, enhancing operational efficiency and consumer engagement. In regions like Africa and South America, the growth of mobile payment systems is particularly influential, enabling seamless transactions and attracting tech-savvy consumers.

Emerging sourcing trends indicate a shift towards localized suppliers, especially in the Middle East and Europe, where logistical challenges and import tariffs can impact costs. Buyers are increasingly looking for vendors that can provide not only the machines but also the necessary support and maintenance, creating opportunities for partnerships with local service providers. Furthermore, the rise of health-conscious consumers has led to a demand for vending machines that offer healthier snack options and fresh products, pushing suppliers to innovate their offerings.

Additionally, sustainability is becoming a crucial consideration for B2B buyers. As organizations increasingly prioritize corporate social responsibility (CSR), vending machine rentals that align with these values—such as energy-efficient machines and sustainable product sourcing—are gaining traction. Buyers should actively seek out suppliers who demonstrate a commitment to sustainability, as this can enhance brand reputation and appeal to environmentally conscious consumers.

Sustainability & Ethical Sourcing in B2B

The environmental impact of vending machines extends beyond their operation; it encompasses the entire supply chain from manufacturing to disposal. For B2B buyers, understanding the importance of ethical sourcing is vital. Machines constructed from recyclable materials and designed for energy efficiency can significantly reduce carbon footprints. Buyers should prioritize vendors that adhere to sustainability certifications, such as ISO 14001, which signifies an organization’s commitment to environmental management.

In addition to environmental concerns, ethical sourcing involves ensuring that the materials used in vending machines are sourced responsibly. This includes verifying that suppliers uphold fair labor practices and engage in transparent sourcing methods. Buyers can benefit from establishing partnerships with suppliers who have robust sustainability policies and who can provide documentation of their sourcing practices.

Implementing a sustainability strategy not only fulfills regulatory requirements but also resonates with end consumers, who are increasingly making purchasing decisions based on a company’s environmental impact. By choosing vending machine rentals that prioritize sustainability, businesses can enhance their market positioning and attract a broader customer base.

Brief Evolution/History

The vending machine sector has evolved significantly since its inception in the early 20th century, where machines primarily dispensed snacks and beverages. The introduction of electronic payment systems in the late 1990s marked a pivotal shift, making transactions more convenient. Over the past decade, the rise of smart vending machines equipped with IoT technology has revolutionized the industry, allowing operators to gather data on consumer behavior and preferences. This evolution has led to the emergence of vending machine rentals, providing businesses with flexible solutions to meet changing market demands without the burden of ownership. As technology continues to advance, the sector is poised for further innovation, creating new opportunities for international B2B buyers.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of vending machine for rent

-

What should I consider when vetting suppliers for vending machines?

When vetting suppliers, prioritize their experience in the vending machine industry, especially in international markets. Check their reputation through client testimonials and case studies. Ensure they have a robust support system in place for maintenance and customer service. Verify their certifications, such as ISO or local industry standards, which indicate compliance with quality and safety regulations. Additionally, assess their financial stability to ensure they can fulfill long-term contracts without issues. -

Can vending machines be customized for my specific needs?

Yes, many suppliers offer customization options for vending machines. This can include tailored product selections, branding with your logo, and specific machine configurations to suit your business model. Discuss your requirements upfront to ensure the supplier can accommodate them. It’s essential to understand any associated costs and lead times for customization, as these factors can impact your overall investment and timeline. -

What are the typical minimum order quantities (MOQ) and lead times?

Minimum order quantities for vending machines can vary significantly by supplier and region. Generally, you may find MOQs ranging from 5 to 20 units, depending on the machine type and customization. Lead times can also differ; standard machines may take 4-6 weeks to deliver, while custom orders could take longer. It’s crucial to clarify these details during negotiations to align with your operational timelines and inventory needs. -

What payment terms are common in international vending machine transactions?

Payment terms can vary widely by supplier and may include options such as upfront payments, installment plans, or letters of credit. Many suppliers prefer a deposit (often 30-50%) upon order confirmation, with the balance due before shipping. Always ensure that the payment terms are clearly defined in your contract to avoid disputes later. Consider using secure payment methods that provide buyer protection, especially in international transactions. -

How can I ensure quality assurance and certifications for the machines?

Request documentation regarding quality assurance processes from potential suppliers. Look for certifications that indicate compliance with international standards, such as CE marking in Europe or other relevant local certifications. Many suppliers perform rigorous testing on their machines before shipment, so inquire about their QA procedures. Additionally, consider requesting samples or visiting the supplier’s facility to verify their manufacturing capabilities. -

What logistics considerations should I keep in mind when renting vending machines?

Logistics can be complex when dealing with international suppliers. Assess the shipping methods they use and the estimated delivery times. It’s also important to understand who will handle customs clearance and any associated duties or tariffs. Ensure that the supplier provides comprehensive shipping documentation and support to facilitate smooth transit. Consider working with a logistics partner experienced in international trade to streamline the process. -

How should I handle disputes with suppliers?

To manage disputes effectively, establish clear terms in your contract, including clauses on conflict resolution and jurisdiction. Open communication is vital; address issues promptly and professionally to seek a resolution. Many suppliers prefer mediation or arbitration over litigation, so be prepared to negotiate. If necessary, consult with legal experts familiar with international trade laws to guide you through the process. -

What ongoing support should I expect after renting the vending machines?

After renting vending machines, you should expect a clear support structure from your supplier. This typically includes maintenance services, troubleshooting assistance, and prompt response times for repairs. Ask about the availability of spare parts and the supplier’s policy on machine upgrades or replacements. Regular training for your staff on machine operation and customer service can also enhance your business’s efficiency and customer satisfaction.

Strategic Sourcing Conclusion and Outlook for vending machine for rent

In conclusion, the strategic sourcing of vending machines for rent presents a significant opportunity for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Key takeaways highlight the importance of understanding local market dynamics, consumer preferences, and technological advancements. By leveraging strategic partnerships with reliable suppliers, businesses can enhance operational efficiency, reduce costs, and cater to evolving consumer demands.

Investing in quality vending machines and rental agreements not only ensures a steady stream of revenue but also positions companies to capitalize on the growing trend of automated retail solutions. Flexibility in sourcing allows organizations to adapt to changing market conditions, while comprehensive market research can uncover new opportunities for expansion and customer engagement.

As we look ahead, international B2B buyers should actively explore innovative vending solutions that align with sustainability goals and technological advancements. Embrace the potential of vending machines as a vital part of your business strategy, and take action today to secure partnerships that will drive growth and profitability in the competitive marketplace.