Your Ultimate Guide to Sourcing That Time I Got

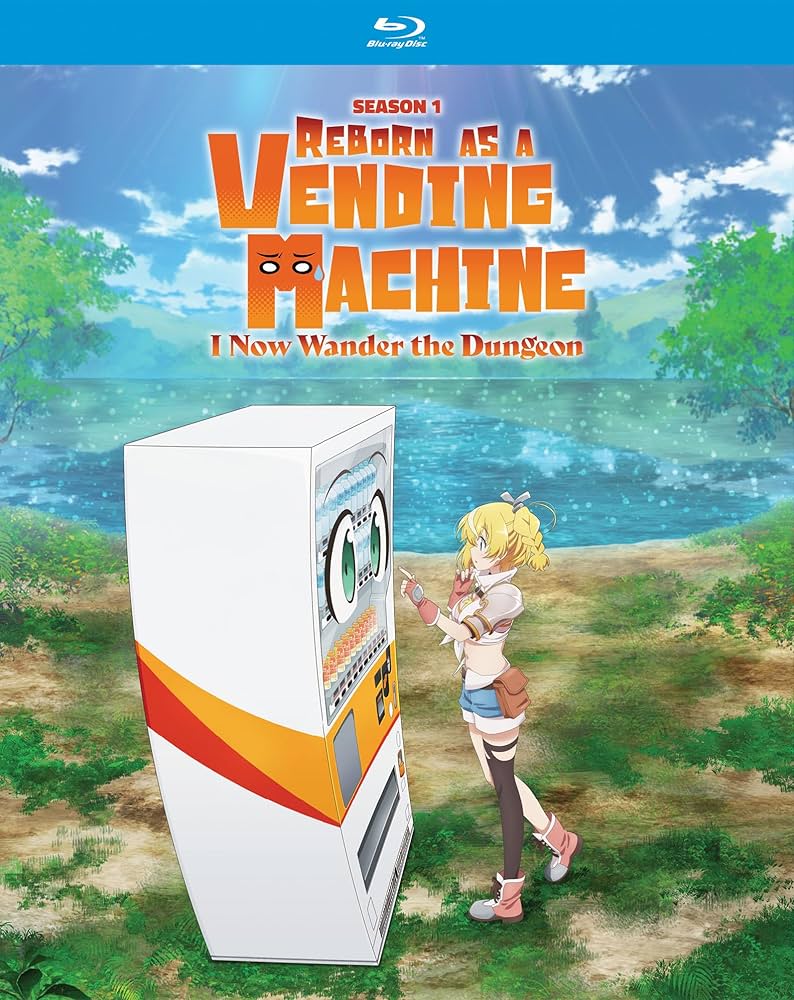

Guide to That Time I Got Reincarnated As A Vending Machine

- Introduction: Navigating the Global Market for that time i got reincarnated as a vending machine

- Understanding that time i got reincarnated as a vending machine Types and Variations

- Key Industrial Applications of that time i got reincarnated as a vending machine

- Strategic Material Selection Guide for that time i got reincarnated as a vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for that time i got reincarnated as a vending machine

- Comprehensive Cost and Pricing Analysis for that time i got reincarnated as a vending machine Sourcing

- Spotlight on Potential that time i got reincarnated as a vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for that time i got reincarnated as a vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the that time i got reincarnated as a vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of that time i got reincarnated as a vending machine

- Strategic Sourcing Conclusion and Outlook for that time i got reincarnated as a vending machine

Introduction: Navigating the Global Market for that time i got reincarnated as a vending machine

In an increasingly interconnected world, the demand for innovative solutions like those presented in “That Time I Got Reincarnated as a Vending Machine” is surging. This unique concept presents a lucrative opportunity for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. As businesses seek efficient ways to meet consumer needs, understanding the dynamics behind this vending machine phenomenon becomes essential for strategic sourcing.

This comprehensive guide aims to empower international buyers with insights into the various types of vending machines inspired by this popular narrative. We will explore the materials used in manufacturing, the rigorous quality control measures that ensure reliability, and the profiles of key suppliers in the industry. Additionally, we will provide an overview of cost structures, market trends, and frequently asked questions that address common concerns.

By delving into these critical areas, this guide equips decision-makers with the knowledge necessary to navigate the complexities of the global market. Whether you’re based in the bustling cities of Italy or the thriving markets of Egypt, informed sourcing decisions can lead to significant competitive advantages. Embracing the essence of this vending machine concept not only enhances product offerings but also aligns with evolving consumer preferences, making it a pivotal element in your business strategy.

Understanding that time i got reincarnated as a vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Snack Vending Machine | Dispenses snacks and beverages; coin-operated | Office break rooms, schools, hospitals | Pros: Low maintenance; Cons: Limited product variety |

| Health-Conscious Vending Machine | Offers healthy snacks and beverages; eco-friendly | Gyms, wellness centers, schools | Pros: Appeals to health-conscious consumers; Cons: Higher initial investment |

| Automated Retail Vending Machine | High-tech interface; accepts card and mobile payments | Airports, train stations, malls | Pros: Modern appeal; Cons: Requires reliable internet connection |

| Specialty Product Vending Machine | Dispenses niche products (e.g., electronics, cosmetics) | Specialty shops, events, festivals | Pros: Unique offerings attract specific clientele; Cons: Lower turnover rates |

| Customizable Vending Machine | Tailored product selection; adaptable to location needs | Corporate events, trade shows, festivals | Pros: Personalized experience for consumers; Cons: Potentially higher operational costs |

Traditional Snack Vending Machine

This type of vending machine is the most commonly recognized and typically dispenses a variety of snacks and beverages. It operates on a straightforward coin or cash system, making it easy to use in various settings such as offices, schools, and hospitals. B2B buyers should consider the location and customer preferences when selecting this type, as the product mix can significantly impact sales. Despite its low maintenance and initial investment costs, the limited variety may not cater to changing consumer tastes.

Health-Conscious Vending Machine

Designed to meet the growing demand for healthier options, health-conscious vending machines offer snacks and beverages with a focus on nutritional value. These machines are often eco-friendly and attract health-conscious consumers in gyms, wellness centers, and schools. Buyers should assess the target market’s preferences and the potential for higher initial investments due to the premium pricing of health-oriented products. While they can drive traffic from health-focused customers, they may face challenges in areas where traditional snack options dominate.

Automated Retail Vending Machine

These high-tech vending machines feature advanced interfaces that accept various payment methods, including credit cards and mobile payments. Commonly found in airports, train stations, and malls, they cater to consumers looking for convenience and modernity. B2B buyers should evaluate the need for reliable internet connectivity, as these machines often rely on it for transactions. While they appeal to tech-savvy customers, the initial setup costs and ongoing operational requirements can be significant.

Specialty Product Vending Machine

Specialty vending machines go beyond traditional snacks to offer niche products such as electronics, cosmetics, or gourmet foods. They are ideal for specialty shops, events, and festivals where unique offerings can attract specific clientele. Buyers should consider the location and demographics of potential customers, as these machines may experience lower turnover rates compared to traditional options. While they can create a unique shopping experience, the investment may be higher due to the specialized inventory.

Customizable Vending Machine

These machines allow businesses to tailor their product selections based on location and customer preferences, providing a personalized experience. Ideal for corporate events, trade shows, and festivals, customizable vending machines can adapt to various consumer needs. B2B buyers should weigh the benefits of personalization against potentially higher operational costs and inventory management challenges. Ultimately, the ability to meet specific consumer demands can enhance customer satisfaction and drive sales.

Related Video: All Machine Learning Models Clearly Explained!

Key Industrial Applications of that time i got reincarnated as a vending machine

| Industry/Sector | Specific Application of that time i got reincarnated as a vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Automated snack and beverage dispensing | Increased sales through 24/7 availability | Product variety, maintenance support, and supply chain reliability |

| Education | Campus food and beverage kiosks | Enhances student satisfaction and convenience | Location analysis, payment system integration, and inventory management |

| Healthcare | Patient and staff refreshment stations | Improves patient care experience and staff morale | Compliance with health regulations, product freshness, and variety |

| Hospitality | In-room vending services in hotels | Offers guests convenience and enhances their experience | Product selection, payment options, and service reliability |

| Events and Exhibitions | On-site vending for conferences and trade shows | Streamlines food and beverage service, reducing wait times | Traffic flow analysis, equipment durability, and staffing support |

Retail Applications

In the retail sector, vending machines inspired by the concept of “that time I got reincarnated as a vending machine” can serve as automated snack and beverage dispensers. They provide a 24/7 sales channel, catering to customer demands at all hours. For international B2B buyers, especially from regions like Africa and South America, it’s crucial to consider product variety and maintenance support. This ensures that machines remain stocked and functional, maximizing sales potential.

Educational Institutions

In educational settings, such vending machines can be installed in campuses to offer quick access to food and beverages. This application not only enhances student satisfaction but also promotes a culture of convenience. Buyers in Europe and the Middle East should focus on location analysis to place machines optimally, as well as on integrating efficient payment systems to cater to diverse student populations.

Healthcare Facilities

Healthcare environments benefit significantly from vending machines that provide refreshments for both patients and staff. By improving the overall care experience, these machines can positively impact patient satisfaction and staff morale. International buyers must ensure compliance with health regulations, emphasizing product freshness and a diverse selection to meet dietary needs.

Hospitality Industry

In the hospitality sector, in-room vending services can significantly enhance guest experience. By offering a range of snacks and beverages directly in rooms, hotels can provide convenience that guests appreciate. For B2B buyers in regions like Europe, considerations should include product selection tailored to guest preferences and reliable payment options to facilitate seamless transactions.

Events and Exhibitions

At conferences and trade shows, on-site vending machines can streamline food and beverage service, reducing wait times and improving attendee satisfaction. B2B buyers focusing on this application should conduct traffic flow analysis to determine optimal machine placement, ensuring high visibility and accessibility. Additionally, equipment durability and adequate staffing support are crucial for maintaining service quality during high-traffic events.

Related Video: Reborn as a Vending Machine, I Now Wander the Dungeon Season 2 – Opening | HD | 1080p | 60FPS

Strategic Material Selection Guide for that time i got reincarnated as a vending machine

When selecting materials for products inspired by “that time I got reincarnated as a vending machine,” international B2B buyers must consider various factors, including performance characteristics, cost, and regional compliance standards. Below is an analysis of four common materials used in the manufacturing of vending machines, focusing on their properties, advantages and disadvantages, and implications for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high tensile strength, and ability to withstand extreme temperatures. It typically has a temperature rating of up to 800°C and is resistant to various chemicals, making it suitable for diverse environments.

Pros & Cons:

The primary advantage of stainless steel is its durability and longevity, which translates into lower maintenance costs over time. However, it is more expensive than other materials, which could impact initial investment costs. Manufacturing complexity can also be higher due to the need for specialized tools and techniques.

Impact on Application:

Stainless steel is ideal for vending machines that dispense food and beverages, as it meets hygiene standards and is easy to clean. It is compatible with various media, including water, soft drinks, and snacks.

Considerations for International Buyers:

Buyers should ensure compliance with local food safety regulations and standards such as ASTM and DIN. In regions like Europe, specific grades of stainless steel may be preferred due to their enhanced corrosion resistance.

2. Aluminum

Key Properties:

Aluminum is lightweight, with a good strength-to-weight ratio, and is resistant to corrosion due to a natural oxide layer. It can typically withstand temperatures up to 600°C.

Pros & Cons:

One of the main advantages of aluminum is its cost-effectiveness compared to stainless steel. It is easier to fabricate, which can reduce manufacturing time. However, aluminum is less durable than stainless steel and may not perform well in high-temperature applications.

Impact on Application:

Aluminum is suitable for vending machines that require lightweight components, such as exterior panels. It is compatible with various media but may not be ideal for high-humidity environments without protective coatings.

Considerations for International Buyers:

Buyers in regions like Africa and South America should consider local availability and the potential for corrosion in humid climates. Compliance with local manufacturing standards is also essential.

3. Polycarbonate

Key Properties:

Polycarbonate is a high-performance thermoplastic known for its impact resistance and optical clarity. It can withstand temperatures up to 120°C and is resistant to UV radiation.

Pros & Cons:

The key advantage of polycarbonate is its lightweight nature and high impact resistance, making it ideal for transparent components of vending machines. However, it is less durable than metals and can be prone to scratching.

Impact on Application:

Polycarbonate is often used for display windows and protective covers in vending machines, allowing visibility of the products inside. It is compatible with a range of media but may not withstand extreme temperatures.

Considerations for International Buyers:

Buyers should be aware of the material’s limitations in high-temperature applications, especially in regions with extreme heat. Understanding local regulations regarding plastics is also crucial.

4. Mild Steel

Key Properties:

Mild steel is a low-carbon steel known for its malleability and ductility. It has a temperature rating of around 400°C and is not inherently corrosion-resistant.

Pros & Cons:

Mild steel is cost-effective and easy to work with, making it a popular choice for structural components. However, it requires protective coatings to prevent rusting, which can add to long-term maintenance costs.

Impact on Application:

Mild steel is suitable for the structural framework of vending machines but may not be ideal for components exposed to moisture or corrosive environments.

Considerations for International Buyers:

Buyers should consider the need for protective coatings and compliance with local standards for steel products. In regions like the Middle East, where humidity can be high, additional corrosion protection may be necessary.

Summary Table

| Material | Typical Use Case for that time i got reincarnated as a vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and beverage dispensing components | Durable, low maintenance | Higher initial cost, complex manufacturing | High |

| Aluminum | Exterior panels and lightweight components | Cost-effective, easy to fabricate | Less durable, may require protective coatings | Medium |

| Polycarbonate | Display windows and protective covers | Lightweight, high impact resistance | Prone to scratching, limited temperature range | Medium |

| Mild Steel | Structural framework for vending machines | Cost-effective, easy to work with | Requires protective coatings, prone to rust | Low |

This strategic material selection guide aims to equip international B2B buyers with the insights needed to make informed decisions when sourcing materials for vending machines, ensuring compliance with regional standards and optimizing product performance.

In-depth Look: Manufacturing Processes and Quality Assurance for that time i got reincarnated as a vending machine

Understanding Manufacturing Processes

For B2B buyers interested in the unique market of “That Time I Got Reincarnated as a Vending Machine,” a comprehensive understanding of the manufacturing processes is crucial. The production of vending machines involves several key stages, each with specific techniques that ensure the final product meets the desired quality and functionality.

Main Stages of Manufacturing

-

Material Preparation

– Sourcing Materials: The initial stage involves sourcing high-quality materials like steel, plastics, and electronic components. Buyers should ensure that suppliers adhere to sustainable practices, especially when sourcing from regions like Africa or South America where local regulations may vary.

– Material Testing: Conduct tests for material properties (e.g., tensile strength, corrosion resistance) to ensure they meet the required specifications. -

Forming

– Techniques Used: Various forming techniques such as stamping, molding, and welding are employed. For instance, steel panels may be stamped into shape, while plastic components can be injection molded.

– Precision Engineering: Investing in precision machinery helps in achieving accurate specifications, particularly important for electronic components that require tight tolerances. -

Assembly

– Integration of Components: The assembly stage integrates mechanical and electronic components, such as motors, sensors, and payment systems. Automated assembly lines are increasingly common, enhancing efficiency and reducing labor costs.

– Modular Design: Adopting a modular design allows for easier upgrades and repairs, which can be an attractive selling point for buyers looking for long-term value. -

Finishing

– Surface Treatments: Finishing processes such as powder coating, painting, or anodizing improve aesthetics and durability. Buyers should inquire about the techniques used and their environmental impact.

– Final Assembly and Quality Check: The final assembly includes thorough quality checks to ensure all components function correctly before the machines are packaged for distribution.

Quality Assurance Standards

Quality assurance is paramount in manufacturing, particularly in the vending machine sector, where reliability and safety are critical. International and industry-specific standards guide these practices.

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems, ensuring that organizations consistently provide products that meet customer and regulatory requirements. Buyers should verify that suppliers are ISO 9001 certified to ensure a commitment to quality.

- CE Marking: For products sold in the European market, CE marking indicates conformity with health, safety, and environmental protection standards. Understanding these requirements is crucial for buyers in Europe.

- API Standards: In regions where vending machines incorporate food or beverage dispensing, compliance with American Petroleum Institute (API) standards may be necessary, especially for machines that handle perishable goods.

Quality Control Checkpoints

Quality control involves several checkpoints throughout the manufacturing process to catch defects early and ensure product integrity.

-

Incoming Quality Control (IQC)

– Material Inspection: Before materials enter the production line, they undergo rigorous inspections to ensure they meet specified standards. Buyers should expect detailed reports from suppliers about IQC results. -

In-Process Quality Control (IPQC)

– Monitoring Production: During the manufacturing process, regular checks are performed to assess the assembly and functionality of components. Buyers should inquire about the frequency and methods of IPQC checks. -

Final Quality Control (FQC)

– End-of-Line Testing: The final inspection verifies that the finished product meets all specifications and performs as intended. This includes functional testing for all electronic systems and physical checks for structural integrity.

Illustrative Image (Source: Google Search)

Common Testing Methods

To ensure quality and safety, several testing methods are commonly utilized in the production of vending machines:

- Functional Testing: Verifying that all components interact correctly, including electronic systems and mechanical parts.

- Durability Testing: Simulating wear and tear to assess the longevity of materials and components.

- Safety Testing: Ensuring compliance with safety standards, particularly for electrical components.

Verifying Supplier Quality Control

B2B buyers must take proactive steps to verify the quality control practices of their suppliers:

-

Conduct Audits

– Regular audits of supplier facilities can provide insights into their manufacturing processes and quality control measures. Engage third-party auditors for an unbiased evaluation. -

Request Quality Reports

– Suppliers should provide detailed quality reports, including IQC, IPQC, and FQC results. Transparency in reporting is a sign of a reputable supplier. -

Third-Party Inspections

– Employ third-party inspection services to validate the quality of products before shipment, especially critical for buyers in regions where logistics and quality assurance can vary significantly.

Quality Control Nuances for International Buyers

When dealing with international suppliers, several nuances should be taken into account:

- Cultural and Regulatory Differences: Understanding local regulations and cultural attitudes towards quality can impact supplier relationships. Educate yourself on the specific regulations in countries like Egypt or Brazil that may affect manufacturing practices.

- Communication Barriers: Language differences can lead to misunderstandings regarding quality expectations. Establishing clear communication channels and using visual aids can mitigate these issues.

- Logistics Considerations: Quality assurance is often impacted by logistics. Ensure that suppliers have robust logistics systems to maintain product integrity during transport, particularly in regions with less developed infrastructure.

In conclusion, a thorough understanding of manufacturing processes and quality assurance is essential for B2B buyers in the vending machine sector. By focusing on material quality, production techniques, and rigorous quality control, buyers can ensure they are sourcing reliable products that meet international standards, thereby safeguarding their investments and enhancing customer satisfaction.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for that time i got reincarnated as a vending machine Sourcing

Understanding the Cost Structure

When sourcing products related to “That Time I Got Reincarnated as a Vending Machine,” it’s essential to break down the cost components to understand the total expenditure involved. The primary cost components include:

-

Materials: The cost of raw materials such as plastics, metals, and electronic components can significantly impact pricing. Sustainable and high-quality materials may carry a premium but enhance product durability and appeal.

-

Labor: Labor costs can vary widely based on the sourcing country. For example, countries in Europe may have higher labor costs compared to those in Africa or South America. Understanding local wage standards can help in negotiating better terms.

-

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance costs. Buyers should consider suppliers with efficient production processes to minimize overheads.

-

Tooling: Initial tooling costs can be substantial, especially for customized designs. It’s vital to assess whether the tooling costs are included in the quoted price or charged separately.

-

Quality Control (QC): Investing in rigorous QC processes ensures product consistency. This may incur additional costs but is crucial for maintaining quality standards and reducing returns.

-

Logistics: Shipping and handling fees can vary based on the shipping method, distance, and Incoterms chosen. Understanding these factors is essential for effective budgeting.

-

Margin: Suppliers will typically add a profit margin to cover their costs. This margin can vary significantly based on the supplier’s market positioning and the competitiveness of the region.

Influencers on Pricing

Several factors can influence the pricing of vending machine products:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) to optimize pricing.

-

Specifications/Customization: Customized products can lead to higher costs due to unique tooling or materials. Clearly defining specifications upfront can help avoid unexpected costs.

-

Materials: The choice of materials will directly affect pricing. Premium materials may enhance product quality but also increase costs.

-

Quality and Certifications: Certifications (e.g., ISO, CE) can add credibility but may also increase costs. Buyers should weigh the benefits against the potential price increase.

-

Supplier Factors: Established suppliers with a strong reputation may charge higher prices. However, they often provide better reliability and quality assurance, which can justify the cost.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) will determine who is responsible for shipping costs, insurance, and risks. Understanding these terms can lead to better negotiations and cost management.

Strategic Buyer Tips

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, consider the following strategies:

-

Negotiate Effectively: Leverage the competitive landscape to negotiate better prices. Understand the supplier’s cost structure to identify areas where you can negotiate effectively.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the purchase price. Consider operational costs, maintenance, and potential savings from high-quality products.

-

Understand Pricing Nuances: Be aware that currency fluctuations and economic conditions in the supplier’s country can affect pricing. Ensure that contracts account for potential changes in costs.

-

Build Relationships: Developing long-term relationships with suppliers can lead to better pricing and priority service. Frequent communication and feedback can enhance collaboration.

Disclaimer

Prices and costs mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and other variable factors. Buyers are encouraged to conduct thorough market research and engage directly with suppliers to obtain accurate pricing information.

Spotlight on Potential that time i got reincarnated as a vending machine Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for that time i got reincarnated as a vending machine.)*

Essential Technical Properties and Trade Terminology for that time i got reincarnated as a vending machine

Essential Technical Properties

When considering the integration of vending machines into business operations, understanding the essential technical properties is crucial. Here are some key specifications that international B2B buyers should pay attention to:

-

Material Grade

The material grade of vending machines typically refers to the type of materials used in construction, such as stainless steel, aluminum, or high-grade plastics. High-quality materials ensure durability, resistance to corrosion, and longevity, which are vital for machines placed in diverse environments, especially in regions with varying climates like Africa and the Middle East. -

Power Consumption

This specification indicates the amount of electricity the vending machine uses during operation. Lower power consumption is advantageous for cost savings and sustainability. Buyers should consider energy-efficient models, particularly in regions where electricity costs are high or where sustainable practices are increasingly prioritized. -

Storage Capacity

The storage capacity defines how many items the vending machine can hold at any given time. For B2B buyers, selecting a machine with an appropriate storage capacity ensures optimal inventory management and reduces the frequency of restocking, which is critical for maintaining product availability in markets with fluctuating demand. -

Dispensing Mechanism

This property pertains to the technology used to dispense products, such as spiral coil, elevator, or robotic systems. The choice of dispensing mechanism can impact product variety and customer experience. Understanding the mechanism allows buyers to select machines that align with their product offerings and customer expectations. -

Connectivity Features

This includes capabilities such as cashless payment options, remote monitoring, and inventory management systems. Connectivity features are essential for modern vending operations, enabling businesses to track sales data, manage stock levels, and enhance customer interaction, thereby improving overall operational efficiency.

Common Trade Terminology

Familiarity with industry terminology is vital for effective communication and negotiation. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships helps buyers identify reliable sources for high-quality components, which can be crucial when customizing vending machines to meet specific market needs. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For international buyers, knowing the MOQ is essential for budgeting and determining the feasibility of stock levels, especially when entering new markets where demand may be uncertain. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. This is a critical step in the procurement process, allowing businesses to compare offers and negotiate better terms, which is particularly important in competitive markets. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Understanding these terms helps B2B buyers clarify shipping costs, risk management, and delivery responsibilities, which are vital for smooth cross-border operations. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For B2B buyers, managing lead time is crucial for planning inventory and ensuring timely delivery to customers, which can significantly impact customer satisfaction and business reputation.

By understanding these essential technical properties and trade terms, international B2B buyers can make informed decisions, optimize their supply chain, and enhance their operational efficiency in the vending machine market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the that time i got reincarnated as a vending machine Sector

Market Overview & Key Trends

The global market for vending machines, especially in niche sectors like “That Time I Got Reincarnated as a Vending Machine,” is witnessing a surge driven by technological advancements and changing consumer preferences. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe must recognize the importance of integrating smart technologies into their vending solutions. Innovations such as IoT connectivity, mobile payment options, and AI-driven inventory management systems are becoming essential. These technologies not only enhance user experiences but also improve operational efficiency, allowing businesses to adapt to fluctuating consumer demands.

Emerging trends indicate a growing preference for personalized offerings in vending machines. This shift is largely influenced by data analytics, which enables businesses to tailor product selections based on local tastes and trends. For B2B buyers, this presents an opportunity to source machines that can be customized to suit regional preferences, thus increasing sales potential. Furthermore, the rise of contactless payments and cashless transactions is reshaping the landscape, particularly important in regions with high mobile penetration, such as parts of Africa and the Middle East.

Sourcing trends also emphasize the importance of multi-channel distribution strategies. Businesses are encouraged to explore partnerships with local distributors and e-commerce platforms to enhance their reach. By tapping into established networks, international buyers can optimize their supply chains and gain insights into local market dynamics.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer just a corporate buzzword; it is a critical component of business strategy, particularly in the vending machine sector. The environmental impact of manufacturing and operating vending machines is significant, leading to an urgent need for sustainable practices. B2B buyers should prioritize suppliers who demonstrate a commitment to reducing their carbon footprint, whether through energy-efficient machines or eco-friendly packaging.

The importance of ethical supply chains cannot be overstated. Companies should seek partners who adhere to fair labor practices and promote transparency within their operations. This commitment not only strengthens brand reputation but also resonates with increasingly conscientious consumers. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s dedication to sustainable practices.

Additionally, using green materials in machine production—such as recycled plastics or sustainably sourced components—can significantly mitigate environmental impact. B2B buyers should engage with manufacturers who prioritize these materials, as they not only contribute to sustainability goals but also cater to a growing market segment that values eco-friendly products.

Brief Evolution/History

The concept of vending machines has evolved significantly since their inception in the late 19th century. Originally designed to dispense simple products like postcards and gum, modern vending machines have transformed into sophisticated retail solutions. With the advent of technology, particularly in the 21st century, machines have adopted features like touchscreens, interactive interfaces, and real-time inventory management.

The rise of niche markets, such as themed vending machines inspired by popular culture—like “That Time I Got Reincarnated as a Vending Machine”—reflects changing consumer interests and the demand for unique experiences. This evolution presents a lucrative opportunity for B2B buyers to invest in innovative vending solutions that cater to specific demographics, ensuring they remain competitive in an ever-evolving marketplace. By understanding this historical context, buyers can better appreciate the trajectory of vending technology and its implications for future sourcing strategies.

Related Video: Global trade will never be the same again, says Christine Lagarde | Power & Politics

Frequently Asked Questions (FAQs) for B2B Buyers of that time i got reincarnated as a vending machine

-

What criteria should I use to vet suppliers for ‘that time I got reincarnated as a vending machine’?

When vetting suppliers, prioritize their experience in the industry, financial stability, and reputation. Look for suppliers with proven track records in international trade, particularly those who have successfully served markets similar to yours in Africa, South America, the Middle East, and Europe. Request references and conduct background checks. Additionally, consider their compliance with local regulations and international standards, as this can indicate reliability and quality. -

Can I customize the vending machines to meet specific market needs?

Yes, many suppliers offer customization options for vending machines. You can request modifications in design, features, and product offerings to cater to local preferences. Ensure you clearly communicate your requirements and expectations during negotiations. It’s advisable to work closely with the supplier’s design team to finalize specifications, as this can enhance market acceptance and boost sales in your region. -

What are the typical minimum order quantities (MOQ) and lead times for orders?

MOQs can vary widely depending on the supplier and the complexity of the vending machine. Generally, expect MOQs to range from 50 to 200 units. Lead times may vary from 3 to 12 weeks, depending on customization requests and production schedules. Always clarify these details with the supplier before placing an order to avoid unexpected delays and ensure that your supply chain remains efficient. -

What payment terms are commonly offered by suppliers, and are there options for financing?

Most suppliers will offer various payment terms, including upfront payment, partial payment upon order confirmation, and balance upon shipment. It’s essential to negotiate terms that align with your cash flow and financial capabilities. Some suppliers may also offer financing options, such as credit terms or installment payments, especially for larger orders. Discuss these options early in the negotiation process to ensure favorable arrangements. -

How can I ensure quality assurance and certifications for the vending machines?

Request detailed information about the supplier’s quality assurance processes and certifications. Look for ISO certifications or compliance with international safety standards, which can indicate a commitment to quality. Additionally, consider conducting a factory audit or hiring a third-party inspection service before shipment to verify that the machines meet your specifications and quality standards. -

What logistics options are available for shipping the vending machines internationally?

Logistics options for international shipping typically include sea freight, air freight, and courier services. Sea freight is cost-effective for larger orders but requires longer transit times, while air freight is faster but more expensive. Discuss with your supplier about their logistics partners and capabilities, and ensure they can handle customs clearance in your region. It’s also advisable to engage a freight forwarder to simplify the shipping process and minimize risks. -

What steps should I take if I encounter disputes with suppliers?

In the event of a dispute, first, attempt to resolve the issue directly with the supplier through open communication. If that fails, refer to the terms outlined in your contract regarding dispute resolution, which may include mediation or arbitration. Document all communications and agreements, as this will be crucial if legal action is required. Establishing a clear contract at the outset can also help minimize the risk of disputes arising. -

How can I effectively market the vending machines in my region?

To effectively market vending machines, conduct thorough market research to understand local consumer preferences and behaviors. Tailor your marketing strategies to address these insights, utilizing social media, local partnerships, and advertising campaigns. Consider showcasing the unique features of the vending machines and how they cater to local tastes. Engaging with local influencers or businesses for promotions can also enhance visibility and credibility in your target market.

Strategic Sourcing Conclusion and Outlook for that time i got reincarnated as a vending machine

In conclusion, strategic sourcing plays a critical role in maximizing value and efficiency for businesses exploring opportunities in the unique landscape of “That Time I Got Reincarnated as a Vending Machine.” By leveraging insights on market trends, supplier capabilities, and consumer preferences, international B2B buyers can make informed decisions that enhance their competitive edge.

Illustrative Image (Source: Google Search)

Here are key takeaways for effective strategic sourcing in this niche:

-

Understand Local Preferences: Tailor your offerings to align with the cultural and consumer behaviors specific to regions like Africa, South America, the Middle East, and Europe. This localized approach fosters stronger connections and drives sales.

-

Evaluate Supplier Relationships: Build partnerships with suppliers who demonstrate flexibility and innovation. The ability to adapt to changing market demands is crucial in a dynamic industry.

-

Invest in Technology: Utilize advanced analytics and procurement tools to streamline sourcing processes. This investment not only reduces costs but also improves responsiveness to market shifts.

Looking ahead, the potential for growth in the vending machine sector remains promising. As international B2B buyers, your proactive engagement in strategic sourcing will be pivotal in capitalizing on emerging trends. Embrace the opportunities that lie ahead and position your business to thrive in this evolving marketplace.