Your Ultimate Guide to Sourcing Tattoos For Vending Machines

Guide to Tattoos For Vending Machines

- Introduction: Navigating the Global Market for tattoos for vending machines

- Understanding tattoos for vending machines Types and Variations

- Key Industrial Applications of tattoos for vending machines

- Strategic Material Selection Guide for tattoos for vending machines

- In-depth Look: Manufacturing Processes and Quality Assurance for tattoos for vending machines

- Comprehensive Cost and Pricing Analysis for tattoos for vending machines Sourcing

- Spotlight on Potential tattoos for vending machines Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for tattoos for vending machines

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the tattoos for vending machines Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of tattoos for vending machines

- Strategic Sourcing Conclusion and Outlook for tattoos for vending machines

Introduction: Navigating the Global Market for tattoos for vending machines

Navigating the intricate landscape of the global market for tattoos designed for vending machines presents an array of opportunities for international B2B buyers. In a world where personalization and instant gratification are paramount, these innovative products cater to a diverse clientele, from children to adults, making them an enticing addition to vending machine offerings. The importance of tattoos for vending machines lies not only in their novelty but also in their potential to drive sales and enhance customer engagement.

This comprehensive guide aims to equip buyers from Africa, South America, the Middle East, and Europe—including key markets like Spain and Turkey—with the insights needed to make informed sourcing decisions. Within these pages, you will explore various types of tattoos, the materials used, and the manufacturing and quality control processes that ensure product integrity. Additionally, we will delve into supplier options, analyze cost factors, and assess market trends that influence purchasing strategies.

By addressing frequently asked questions, this guide empowers buyers to navigate supplier landscapes effectively, mitigating risks and enhancing value in their procurement processes. Whether you are looking to diversify your vending machine offerings or seeking competitive pricing, understanding the dynamics of this niche market will enable you to capitalize on emerging trends and consumer preferences, ultimately driving growth and profitability.

Understanding tattoos for vending machines Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Graphic Tattoos | Unique designs tailored to brand identity | Branding, promotional events | Pros: Enhances brand visibility; Cons: Higher production costs. |

| Seasonal/Promotional Tattoos | Limited-time designs for specific campaigns | Seasonal sales, limited-time offers | Pros: Creates urgency and boosts sales; Cons: Short lifespan. |

| Interactive QR Code Tattoos | Integrates QR codes for customer engagement | Marketing, interactive campaigns | Pros: Engages customers directly; Cons: Requires smartphone access. |

| Durable Vinyl Tattoos | Long-lasting, weather-resistant materials | Outdoor vending, high-traffic areas | Pros: Cost-effective and robust; Cons: Design may fade over time. |

| Eco-Friendly Tattoos | Made from sustainable materials | Green branding, eco-conscious markets | Pros: Appeals to environmentally aware consumers; Cons: May be pricier. |

Custom Graphic Tattoos

Custom graphic tattoos are designed to reflect a brand’s identity, featuring unique artwork that resonates with target audiences. They are particularly suitable for businesses aiming to enhance their branding efforts during promotional events or product launches. When purchasing, B2B buyers should consider the alignment of the design with their brand message, potential production costs, and the ability to create a strong visual impact that can attract customers’ attention.

Seasonal/Promotional Tattoos

These tattoos are designed for specific campaigns or seasons, often featuring limited-time graphics that create a sense of urgency among customers. They are ideal for businesses that wish to drive sales during holidays or special events. Buyers should weigh the benefits of increased customer engagement against the short lifespan of these tattoos, ensuring that the timing and messaging align with their marketing strategies.

Interactive QR Code Tattoos

Interactive QR code tattoos offer a modern twist by integrating QR codes that direct customers to digital content or promotions. This type of tattoo is particularly effective for marketing campaigns aimed at tech-savvy consumers. B2B buyers should consider the accessibility of the target audience to smartphones and the potential for increased customer engagement, while also factoring in the need for regular updates to keep the content relevant.

Durable Vinyl Tattoos

Durable vinyl tattoos are made from robust materials that withstand various environmental conditions, making them suitable for outdoor vending machines and high-traffic areas. Their longevity and cost-effectiveness make them a popular choice for businesses looking to maintain consistent branding. Buyers should evaluate the durability and weather resistance against the potential fading of designs over time, ensuring that they meet the intended usage conditions.

Eco-Friendly Tattoos

Eco-friendly tattoos are crafted from sustainable materials and are increasingly sought after by businesses aiming to appeal to environmentally conscious consumers. These tattoos not only promote a brand’s commitment to sustainability but also align with the growing demand for green products. B2B buyers should assess the cost implications of sourcing eco-friendly materials while considering the potential positive impact on brand image and customer loyalty.

Related Video: Fine-tuning Large Language Models (LLMs) | w/ Example Code

Key Industrial Applications of tattoos for vending machines

| Industry/Sector | Specific Application of tattoos for vending machines | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Branding and promotions | Enhanced brand visibility, increased customer engagement | Customization options, durability of inks, compliance with local regulations |

| Food and Beverage | Nutritional information displays | Improved consumer awareness, compliance with labeling laws | Clarity of printing, resistance to moisture and grease, food safety standards |

| Healthcare | Medication dispensing information | Increased patient adherence, reduced errors in medication | Accuracy of information, durability against wear, compliance with health regulations |

| Transportation | Ticketing and fare information | Streamlined operations, reduced fraud | Integration with existing systems, security features, ease of application |

| Entertainment and Events | Event ticketing and access control | Enhanced security, improved customer experience | Compatibility with various ticketing systems, scalability, easy application |

Retail Applications

In the retail sector, tattoos for vending machines serve as an effective method for branding and promotions. By applying eye-catching designs, businesses can enhance brand visibility and engagement with consumers. This approach is particularly beneficial in high-traffic areas where vending machines are located. International buyers should focus on customization options and the durability of inks to ensure longevity, as well as compliance with local regulations regarding advertising.

Food and Beverage Sector

Within the food and beverage industry, tattoos are used to display nutritional information directly on vending machines. This not only improves consumer awareness but also ensures compliance with local labeling laws. For international buyers, considerations include the clarity of printing, resistance to moisture and grease, and adherence to food safety standards. These factors are crucial for maintaining the integrity of the information presented.

Healthcare Sector

In healthcare, tattoos for vending machines can provide essential medication dispensing information. This application enhances patient adherence to prescribed regimens and reduces the chances of medication errors. Key requirements for buyers include the accuracy of the information displayed, durability against wear and tear, and compliance with stringent health regulations. These aspects are vital for fostering trust and safety in healthcare environments.

Transportation Sector

The transportation industry utilizes tattoos for vending machines to display ticketing and fare information. This application streamlines operations and reduces the potential for fraud. Buyers in this sector should consider the integration capabilities with existing systems, security features of the tattoos, and the ease of application. Ensuring these elements are in place can significantly enhance operational efficiency.

Entertainment and Events

In the entertainment sector, tattoos for vending machines are applied for event ticketing and access control. This application not only enhances security but also improves the overall customer experience. Key sourcing considerations for international buyers include compatibility with various ticketing systems, scalability for large events, and the ease of application. Addressing these factors can lead to a smoother event management process.

Related Video: What is Industrial Automation?

Strategic Material Selection Guide for tattoos for vending machines

When selecting materials for tattoos intended for vending machines, it is essential to consider factors such as durability, cost, and compatibility with various media. Here, we analyze four common materials used in the production of tattoos for vending machines, focusing on their properties, advantages and disadvantages, and implications for international buyers, particularly in Africa, South America, the Middle East, and Europe.

1. Polyvinyl Chloride (PVC)

Key Properties: PVC is known for its excellent chemical resistance, flexibility, and durability. It can withstand temperatures up to 60°C and is resistant to many acids and bases.

Pros & Cons: PVC is cost-effective and easy to manufacture, making it a popular choice for tattoos. However, it is less durable under extreme temperatures and can become brittle over time when exposed to UV light.

Impact on Application: PVC tattoos are suitable for a variety of environments but may not perform well in high-temperature settings or direct sunlight, which is a consideration for outdoor vending machines.

Specific Considerations: International buyers should be aware of regulatory standards regarding PVC usage, particularly in Europe where REACH regulations apply. Compliance with local environmental standards is crucial.

2. Polyethylene (PE)

Key Properties: PE offers excellent impact resistance and is lightweight. It can handle temperatures ranging from -50°C to 80°C, making it versatile for various applications.

Pros & Cons: The material is highly resistant to moisture and chemicals, which is beneficial for vending machines that may be exposed to spills. However, it can be more expensive than PVC and may require specialized manufacturing processes.

Impact on Application: PE is ideal for tattoos that will be used in humid or wet environments, such as coastal areas. Its durability ensures that the tattoos maintain their appearance over time.

Specific Considerations: Buyers in regions with high humidity should prioritize PE for its moisture resistance. Additionally, understanding local manufacturing capabilities for PE is essential for sourcing.

3. Polyester

Key Properties: Polyester is known for its high tensile strength and resistance to stretching and shrinking. It can withstand temperatures up to 150°C, making it suitable for high-heat applications.

Pros & Cons: Polyester tattoos are extremely durable and resistant to fading, making them ideal for long-term use. However, they can be more costly than other materials and may require more complex manufacturing techniques.

Impact on Application: This material is particularly effective for tattoos that need to endure harsh environmental conditions, such as extreme temperatures or exposure to chemicals.

Specific Considerations: Buyers should consider the higher initial investment in polyester but recognize the long-term savings due to its durability. Compliance with international standards for textile materials is also important.

4. Vinyl

Key Properties: Vinyl is flexible, durable, and resistant to moisture and UV light. It can handle temperatures up to 70°C without degrading.

Pros & Cons: Vinyl tattoos are relatively inexpensive and easy to apply, making them a favorite for temporary applications. However, they may not be as durable as polyester or PE and can wear out more quickly.

Impact on Application: Vinyl is suitable for short-term use, such as promotional tattoos in vending machines. Its flexibility allows for easy application on various surfaces.

Specific Considerations: International buyers should ensure that vinyl tattoos meet safety and quality standards in their respective markets. Awareness of potential restrictions on vinyl use in certain regions is also crucial.

| Material | Typical Use Case for tattoos for vending machines | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride (PVC) | General use in indoor vending machines | Cost-effective, good chemical resistance | Brittle under UV exposure | Low |

| Polyethylene (PE) | Humid or wet environments, coastal areas | Excellent moisture resistance | Higher cost, specialized manufacturing needed | Medium |

| Polyester | High-heat applications, long-term use | Extremely durable, resistant to fading | Higher initial cost, complex manufacturing | High |

| Vinyl | Temporary tattoos for promotions | Inexpensive, easy application | Less durable, wears out quickly | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on specific applications and regional considerations. Understanding the properties and implications of each material ensures that the chosen tattoos for vending machines meet performance and regulatory requirements effectively.

In-depth Look: Manufacturing Processes and Quality Assurance for tattoos for vending machines

Manufacturing Processes for Tattoos for Vending Machines

The manufacturing of tattoos specifically designed for vending machines involves a series of well-defined stages that ensure the final product meets both aesthetic and functional requirements. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Common materials used for tattoos include:

- Vinyl Films: Durable and flexible, ideal for outdoor use.

- Ink: High-quality inks, often UV-resistant, are crucial for vibrant colors and longevity.

- Adhesives: Special adhesives that allow for easy application and removal without leaving residue.

During this stage, materials must be tested for compatibility, ensuring that inks adhere properly to the vinyl and that the final product can withstand environmental factors such as moisture and UV exposure.

Forming

Once materials are prepared, the next stage is forming. This involves:

- Printing: High-resolution printing techniques, such as digital or screen printing, are employed to transfer designs onto vinyl sheets. This step is critical as it affects the clarity and vibrancy of the final tattoo.

- Cutting: After printing, the tattoos are cut into specific shapes using precision cutting machines. This ensures uniformity and accuracy in size.

The forming stage is essential as it directly influences the visual appeal and usability of the tattoos.

Assembly

After forming, the tattoos undergo an assembly process, which may include:

- Layering: If the tattoos have multiple layers (for instance, a base layer and a protective overlay), they are carefully aligned and bonded together.

- Quality Checks: At this point, preliminary quality checks are conducted to ensure that the tattoos meet design specifications and are free from defects.

This stage is crucial for ensuring that each tattoo is ready for distribution and meets the expected quality standards.

Finishing

The final stage of the manufacturing process is finishing, which encompasses:

- Coating: A protective coating is applied to enhance durability and resistance to wear and tear. This coating can also provide additional features, such as water resistance.

- Packaging: The tattoos are then packaged appropriately for vending machines, ensuring they remain undamaged during transportation and display.

Quality Assurance for Tattoos for Vending Machines

Quality assurance (QA) is vital in ensuring that the tattoos produced meet international standards and satisfy buyer expectations. Various international standards and industry-specific certifications guide the QA process.

International Standards

Key international standards relevant to the manufacturing of tattoos include:

- ISO 9001: This standard outlines the criteria for a quality management system (QMS). Companies must demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: This certification indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA).

For B2B buyers, understanding these certifications can help assess the reliability and quality of potential suppliers.

Quality Control Checkpoints

Quality control (QC) is integrated into the manufacturing process through various checkpoints:

-

Incoming Quality Control (IQC): This initial check involves inspecting raw materials upon arrival to ensure they meet specified standards. Any subpar materials are rejected at this stage.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process ensures that any deviations from quality standards are identified and corrected promptly.

-

Final Quality Control (FQC): The finished tattoos undergo a final inspection to verify that they meet all specifications before packaging. This includes checking for print quality, adhesive performance, and overall appearance.

Common Testing Methods

To ensure the tattoos meet quality standards, several testing methods are typically employed, including:

- Adhesion Tests: Evaluating how well the tattoo adheres to various surfaces.

- Durability Tests: Assessing the longevity of the tattoos under different environmental conditions, such as exposure to UV light and moisture.

- Visual Inspections: Manual checks for defects in printing, cutting, and overall presentation.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control processes is crucial. Here are some actionable steps:

- Audits: Conduct regular audits of suppliers’ facilities to assess their adherence to quality standards and manufacturing processes.

- Quality Reports: Request detailed quality reports that outline QC processes, testing results, and compliance with relevant standards.

- Third-Party Inspections: Engage independent third-party inspectors to assess products before shipment, ensuring they meet agreed-upon specifications.

Nuances for International B2B Buyers

International buyers, particularly from Africa, South America, the Middle East, and Europe (e.g., Spain, Turkey), should be aware of specific nuances in QC and certification requirements:

- Regional Regulations: Different regions may have varying regulations regarding product safety and environmental impact. Understanding these regulations is crucial for compliance.

- Cultural Preferences: Preferences for designs and colors can vary significantly across regions, impacting the quality assessment process. Suppliers should be sensitive to these cultural nuances to ensure product acceptance.

- Supply Chain Considerations: Buyers should consider the supply chain logistics when assessing quality, as delays or issues in transportation can affect product quality upon arrival.

By understanding the manufacturing processes and quality assurance measures for tattoos for vending machines, B2B buyers can make informed decisions that ensure product quality and compliance with international standards. This knowledge also empowers buyers to foster strong relationships with suppliers, ultimately leading to successful business outcomes.

Related Video: Amazing scenes。Top 6 Most Popular Factory Manufacturing Videos in China

Comprehensive Cost and Pricing Analysis for tattoos for vending machines Sourcing

In the context of sourcing tattoos for vending machines, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis will highlight the key components affecting costs and pricing, as well as provide actionable insights tailored for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary cost driver in tattoo production is the quality of the materials used. High-grade inks, adhesives, and protective coatings can significantly impact overall costs. Buyers should evaluate suppliers based on their material sourcing practices and certifications, as these can affect both the quality and price of the final product.

-

Labor: Labor costs vary based on the region and the complexity of the tattoo design. Skilled artisans may demand higher wages, but their expertise can lead to better quality products. Assessing the labor market of the supplier’s location can provide insights into potential cost fluctuations.

-

Manufacturing Overhead: This includes the costs associated with utilities, equipment maintenance, and facilities. Suppliers with efficient production processes can lower their overhead, which can be advantageous for buyers seeking competitive pricing.

-

Tooling: The initial setup costs for custom designs can be significant. Buyers should inquire about tooling costs, especially if they require unique designs that differ from standard offerings.

-

Quality Control (QC): Ensuring product consistency and safety is vital. Suppliers with robust QC processes may charge more, but this can lead to fewer defects and returns, ultimately saving costs in the long run.

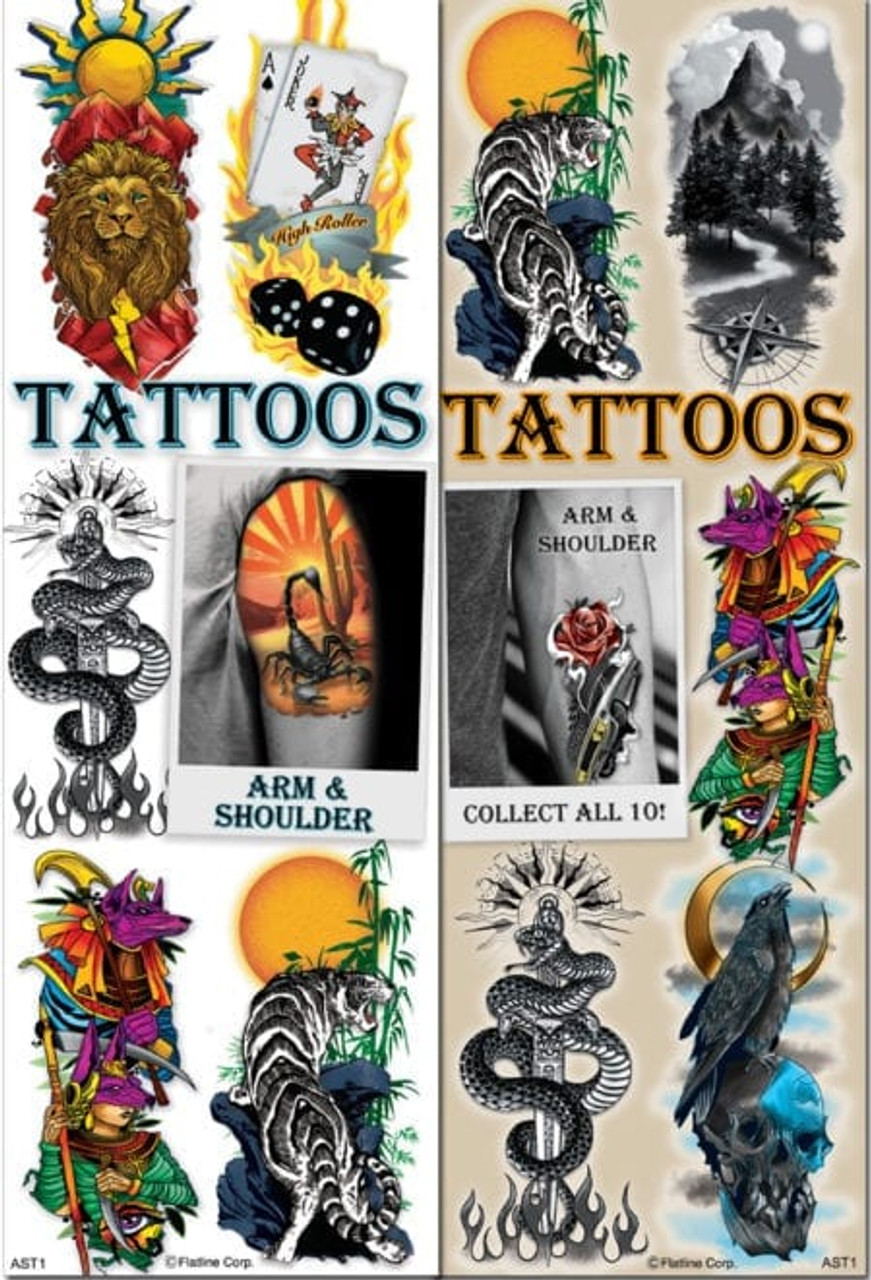

Illustrative Image (Source: Google Search)

-

Logistics: Shipping and handling costs can vary widely depending on the supplier’s location and the chosen Incoterms. Buyers should consider the total cost of logistics, including customs duties and taxes, when evaluating supplier pricing.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. Understanding the industry standard margins can help buyers negotiate better deals.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Buyers should assess their sales forecasts and negotiate terms that align with their purchasing power.

-

Specifications/Customization: Custom designs or specifications can increase costs. Buyers should clarify their requirements upfront to avoid unexpected charges.

-

Quality/Certifications: Tattoos for vending machines may need to meet specific safety and regulatory standards. Suppliers with relevant certifications may charge a premium but offer peace of mind regarding product safety.

-

Supplier Factors: The reliability and reputation of suppliers can influence pricing. Engaging with reputable suppliers often leads to better service and quality assurance.

-

Incoterms: Different Incoterms can significantly affect the final cost of goods. Buyers should choose terms that minimize their risk while ensuring they are fully aware of their responsibilities regarding shipping and customs.

Buyer Tips

-

Negotiation: Engage suppliers early in the sourcing process. Building a relationship can lead to better pricing and terms. Don’t hesitate to negotiate based on volume and long-term partnership potential.

-

Cost-Efficiency: Analyze the total cost of ownership rather than just the upfront price. Consider logistics, potential returns, and the quality of the product when making purchasing decisions.

-

Pricing Nuances: Be aware of regional pricing strategies. For example, suppliers in Europe may offer different pricing structures compared to those in Africa or South America due to varying economic conditions and production costs.

-

Cultural Considerations: Understanding cultural nuances in the regions of your target market can help tailor your product offerings and marketing strategies, potentially leading to increased sales.

Disclaimer

Prices and costs mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Buyers are encouraged to conduct thorough market research and engage multiple suppliers to ensure competitive pricing.

Spotlight on Potential tattoos for vending machines Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘tattoos for vending machines’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for tattoos for vending machines

Key Technical Properties for Tattoos in Vending Machines

When sourcing tattoos for vending machines, it’s crucial to consider several technical specifications that ensure product quality, safety, and usability. Here are the essential properties to evaluate:

-

Material Grade: Tattoos typically utilize high-quality, skin-safe inks and substrates. Look for materials that comply with international safety standards, such as FDA regulations for cosmetics. Higher-grade materials often result in better adhesion and longer-lasting tattoos, which can enhance customer satisfaction and repeat sales.

-

Adhesive Strength: The adhesive used in tattoos must be strong enough to ensure that they stay in place during application and wear. Testing for peel strength can help determine how well the tattoo adheres to the skin without causing irritation or discomfort. This property is vital for ensuring that customers have a positive experience with the product.

-

Water Resistance: For tattoos intended for use in various environments, including outdoor settings, water resistance is essential. Tattoos should be tested for their ability to withstand moisture without degrading. This property is crucial for maintaining the visual appeal and longevity of the tattoo, especially in humid climates or during activities like swimming.

-

Print Resolution: The print resolution affects the clarity and detail of the tattoo design. High-resolution printing ensures that intricate designs are rendered accurately, which is particularly important for attracting customers. Ensuring a minimum DPI (dots per inch) in printing can help maintain quality standards.

-

Shelf Life: Tattoos should have a specified shelf life that guarantees their effectiveness and safety over time. This property is especially important for B2B buyers to consider, as it impacts inventory management and the turnover rate of products in vending machines.

Industry Terms and Jargon

Understanding industry-specific terminology can facilitate better communication and negotiations with suppliers and manufacturers. Here are some common terms used in the trade of tattoos for vending machines:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce products or components that are used in another company’s end product. In the tattoo industry, OEMs may provide tattoos that can be branded or packaged under a different name. Buyers should consider OEM partnerships to expand their product lines efficiently.

-

MOQ (Minimum Order Quantity): This is the smallest number of units that a supplier is willing to sell. Understanding the MOQ is crucial for inventory management and cost calculation. Buyers from regions with smaller markets should negotiate for lower MOQs to avoid excess stock.

-

RFQ (Request for Quotation): An RFQ is a document used to solicit price quotes from suppliers for specific products. Including detailed specifications in an RFQ can help ensure that the quotes received are comparable and meet your needs. This process is vital for effective budgeting and procurement strategies.

-

Incoterms (International Commercial Terms): These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help buyers understand shipping costs, risk management, and delivery responsibilities.

-

SKU (Stock Keeping Unit): An SKU is a unique identifier for each distinct product and service that can be purchased. For vending machine operators, having a well-organized SKU system helps in inventory tracking and sales analysis.

Incorporating these specifications and terms into your purchasing strategy can significantly enhance your decision-making process, ensuring that you select the best products for your vending machine offerings while optimizing costs and efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the tattoos for vending machines Sector

Market Overview & Key Trends

The tattoos for vending machines sector is experiencing significant growth, driven by a combination of technological advancements, changing consumer preferences, and increased accessibility. Globally, the market is being influenced by a rising demand for unique, customizable products that appeal to younger demographics. This trend is particularly prominent in regions like Europe and South America, where street culture and body art have gained mainstream acceptance. In Africa and the Middle East, the market is expanding as urbanization increases and disposable incomes rise, creating a fertile ground for innovative vending solutions.

Emerging B2B tech trends include the integration of smart vending machines equipped with touch screens and payment systems that accept various digital currencies. This technological shift not only enhances the customer experience but also allows for real-time inventory management and data collection, enabling businesses to tailor their offerings based on consumer behavior. For international buyers, understanding these technological advancements is crucial for making informed purchasing decisions.

Additionally, sourcing trends indicate a shift toward local suppliers, particularly in Europe and Africa, where businesses are seeking to reduce lead times and transportation costs. Buyers are encouraged to explore partnerships with regional manufacturers who can provide high-quality tattoo products tailored to local tastes, ensuring faster turnaround times. This localized sourcing approach not only fosters community support but also enhances supply chain resilience.

Sustainability & Ethical Sourcing in B2B

As sustainability becomes a key consideration in purchasing decisions, the tattoos for vending machines sector is no exception. The environmental impact of tattoo inks and materials is under scrutiny, leading to a growing demand for eco-friendly alternatives. International B2B buyers should prioritize suppliers that offer biodegradable inks and sustainable materials, such as recycled paper or plant-based substrates for tattoo applications.

Moreover, ethical sourcing is increasingly important, particularly for buyers from Europe and North America, where consumers are more conscious of the origins of their products. Establishing an ethical supply chain can enhance brand reputation and customer loyalty. Companies should seek out suppliers with certifications like FSC (Forest Stewardship Council) for paper products or OEKO-TEX for textiles, ensuring that their products meet high environmental and social standards.

Buyers should also consider the full lifecycle of the products they source, aiming for options that minimize waste and promote recycling. Collaborating with vendors who embrace sustainable practices can not only reduce the carbon footprint but also align with the growing consumer preference for responsible brands.

Brief Evolution/History

The tattoos for vending machines sector has evolved significantly over the past decade. Initially focused on traditional vending options, the market has transformed with advancements in technology and changing consumer behaviors. The rise of body art culture, particularly among younger demographics, has led to increased interest in tattoo vending as an innovative way to engage consumers.

In the early 2010s, vending machines primarily dispensed temporary tattoos, often targeted at children and event-goers. However, as the popularity of tattoos surged, manufacturers began to diversify their offerings, introducing machines that provide a range of customizable designs for adults. This evolution reflects broader trends in personalization and on-demand services, positioning tattoo vending as a unique intersection of art and technology. Today, businesses are looking to capitalize on this growth by incorporating high-tech solutions that enhance the consumer experience, further driving the sector’s expansion.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of tattoos for vending machines

-

What should I consider when vetting suppliers for tattoos for vending machines?

When vetting suppliers, prioritize their industry experience and reputation. Check for customer reviews and case studies that highlight their previous work. It’s essential to request samples of their tattoos to evaluate quality and durability. Ensure they have the necessary certifications, such as ISO or CE, which reflect compliance with safety standards. Additionally, consider their manufacturing capabilities and whether they can scale production to meet your demand. -

Can I customize the tattoo designs for my vending machines?

Most suppliers offer customization options, including design, size, and packaging. Discuss your specific requirements upfront and ask for a portfolio of previous custom projects. Ensure that the supplier has a design team that can work closely with you to create unique and appealing tattoos. Be prepared to provide your branding guidelines and any specific themes or designs you wish to incorporate. -

What are the typical minimum order quantities (MOQs) and lead times for international orders?

MOQs can vary significantly based on the supplier and the complexity of the design. Generally, expect MOQs to range from 500 to 5,000 units. Lead times can also differ; typical production time ranges from 4 to 12 weeks, depending on the order size and complexity. Always confirm these details before finalizing your order to avoid unexpected delays. -

What payment terms should I expect when sourcing tattoos for vending machines?

Payment terms can vary, but many suppliers require a deposit upfront (usually 30-50%) with the balance due upon delivery or before shipment. Make sure to clarify these terms in advance and discuss acceptable payment methods, such as wire transfers or letters of credit. Be aware of any additional fees related to international transactions, which can impact your overall budget. -

How can I ensure quality assurance and certifications for the tattoos I purchase?

Request documentation of quality control processes and certifications from your supplier. This may include testing for harmful substances, adherence to safety regulations, and quality inspection reports. Suppliers should be willing to provide third-party testing results or certifications like SGS or TUV, which can assure you of the product’s safety and quality. -

What logistical considerations should I keep in mind when importing tattoos?

Logistics can be complex, especially for international shipments. Be aware of shipping costs, customs duties, and import regulations in your country. Work with a reliable freight forwarder who understands the specifics of your product category. Ensure that your supplier can provide the necessary documentation for customs clearance, including commercial invoices and packing lists. -

How should I handle disputes with suppliers regarding quality or delivery issues?

Establish clear communication channels with your supplier and document all agreements in writing. If a dispute arises, address it promptly and professionally, referencing your contract and any relevant documentation. Consider using a dispute resolution mechanism, such as mediation or arbitration, especially if the supplier is overseas. Building a strong relationship can also help in resolving issues amicably. -

Are there specific regulations I need to be aware of when importing tattoos for vending machines?

Yes, regulations can vary by country, so it’s crucial to research the specific import laws relevant to your market. Common regulations may include safety standards, labeling requirements, and restrictions on certain materials. Consulting with a local legal expert or compliance consultant can help ensure that you meet all necessary regulations to avoid fines or product recalls.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for tattoos for vending machines

As the tattoo vending machine market continues to evolve, strategic sourcing emerges as a critical component for international B2B buyers. By leveraging reliable suppliers, businesses can ensure product quality, compliance with local regulations, and optimal pricing structures. Buyers from diverse regions such as Africa, South America, the Middle East, and Europe must prioritize building relationships with manufacturers that understand their unique market needs and consumer preferences.

Key Takeaways:

– Quality Assurance: Establish partnerships with suppliers who emphasize product safety and compliance.

– Market Adaptation: Stay attuned to regional trends that influence consumer behavior towards tattoo vending machines.

– Cost Efficiency: Utilize strategic sourcing to negotiate favorable terms and reduce operational costs.

Looking ahead, the potential for innovation within this niche market is significant. As consumer interest in temporary tattoos rises, now is the ideal time for B2B buyers to invest in this sector. By focusing on strategic sourcing, you can position your business to capitalize on emerging opportunities and enhance your competitive advantage. Take action today—explore partnerships that will drive growth and success in the tattoo vending machine market.