Your Ultimate Guide to Sourcing Start A Vending Machine

Guide to Start A Vending Machine Business

- Introduction: Navigating the Global Market for start a vending machine business

- Understanding start a vending machine business Types and Variations

- Key Industrial Applications of start a vending machine business

- Strategic Material Selection Guide for start a vending machine business

- In-depth Look: Manufacturing Processes and Quality Assurance for start a vending machine business

- Comprehensive Cost and Pricing Analysis for start a vending machine business Sourcing

- Spotlight on Potential start a vending machine business Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for start a vending machine business

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the start a vending machine business Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of start a vending machine business

- Strategic Sourcing Conclusion and Outlook for start a vending machine business

Introduction: Navigating the Global Market for start a vending machine business

Starting a vending machine business presents a unique opportunity for international B2B buyers to tap into a growing market characterized by convenience and innovation. As urban lifestyles evolve, the demand for quick and accessible retail solutions is surging, making vending machines a lucrative investment. This guide serves as a comprehensive resource, empowering buyers from Africa, South America, the Middle East, and Europe to make informed sourcing decisions.

In this guide, we delve into various types of vending machines, covering traditional snack and beverage dispensers to modern options offering fresh food and healthy choices. We explore essential materials and components that enhance machine durability and user experience. Additionally, we address manufacturing and quality control practices to ensure reliability and compliance with international standards.

Understanding the cost structure is vital for budgeting and financial forecasting, which we outline in detail. The guide also examines current market trends and consumer preferences, providing insights into potential profitability and competitive advantages. To further assist buyers, we include a section dedicated to frequently asked questions, addressing common concerns and providing expert tips.

By equipping B2B buyers with critical knowledge and actionable insights, this guide not only fosters informed decision-making but also enhances the overall success of starting a vending machine business in diverse international markets. Whether you are a seasoned entrepreneur or a new investor, navigating this landscape can lead to rewarding outcomes.

Understanding start a vending machine business Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Snack Vending Machines | Dispenses packaged snacks; often customizable | Offices, schools, gyms | Pros: Low maintenance, popular items. Cons: Limited product variety. |

| Beverage Vending Machines | Focus on drinks; can include healthy options | Cafeterias, airports, hotels | Pros: High demand, diverse choices. Cons: Requires refrigeration. |

| Fresh Food Vending Machines | Offers perishable items; often refrigerated | Hospitals, universities, corporate cafes | Pros: Attracts health-conscious consumers. Cons: Higher spoilage risk. |

| Specialty Vending Machines | Unique offerings (e.g., electronics, cosmetics) | Events, malls, tourist attractions | Pros: Niche markets, higher margins. Cons: Limited customer base. |

| Automated Retail Kiosks | Combines vending with interactive shopping experience | Retail spaces, airports, train stations | Pros: Innovative, enhances customer engagement. Cons: Higher initial investment. |

Snack Vending Machines

Snack vending machines are designed to dispense packaged snacks such as chips, candies, and granola bars. They are often customizable to fit specific branding and product preferences. These machines are particularly suitable for high-traffic areas like offices, schools, and gyms where quick, convenient snack options are in demand. When considering a purchase, buyers should evaluate the machine’s capacity, product selection, and maintenance requirements, ensuring it aligns with consumer preferences and traffic patterns.

Beverage Vending Machines

Beverage vending machines primarily focus on dispensing drinks, including soft drinks, water, and healthy alternatives like juices and flavored waters. They are commonly found in locations such as cafeterias, airports, and hotels, catering to the constant need for hydration. Buyers should consider the machine’s refrigeration capabilities, the variety of beverages offered, and the payment options available. The ability to provide popular and diverse drink choices can significantly influence sales and customer satisfaction.

Fresh Food Vending Machines

These machines offer fresh and perishable items such as salads, sandwiches, and fruit, often requiring refrigeration to maintain quality. They are ideal for environments like hospitals, universities, and corporate cafes where there is a growing demand for healthy eating options. Buyers should focus on the machine’s ability to manage freshness and spoilage, as well as the types of food that can be offered. The investment in fresh food vending can attract health-conscious consumers, but it comes with the risk of higher spoilage rates.

Specialty Vending Machines

Specialty vending machines provide unique items that go beyond traditional snacks and beverages, such as electronics, cosmetics, or even local crafts. They are often placed in strategic locations like malls, events, and tourist attractions to cater to niche markets. Buyers should assess the target audience and potential demand for the specialty items, as well as the machine’s ability to handle various product types. While these machines can yield higher profit margins, they may also attract a more limited customer base.

Automated Retail Kiosks

Automated retail kiosks merge vending with an interactive shopping experience, allowing customers to browse and purchase items through a touchscreen interface. These kiosks are increasingly popular in retail spaces, airports, and train stations, enhancing customer engagement. When purchasing, buyers should consider the initial investment, technology integration, and ongoing maintenance costs. While they offer innovative solutions and can attract tech-savvy customers, the upfront costs may be higher compared to traditional vending machines.

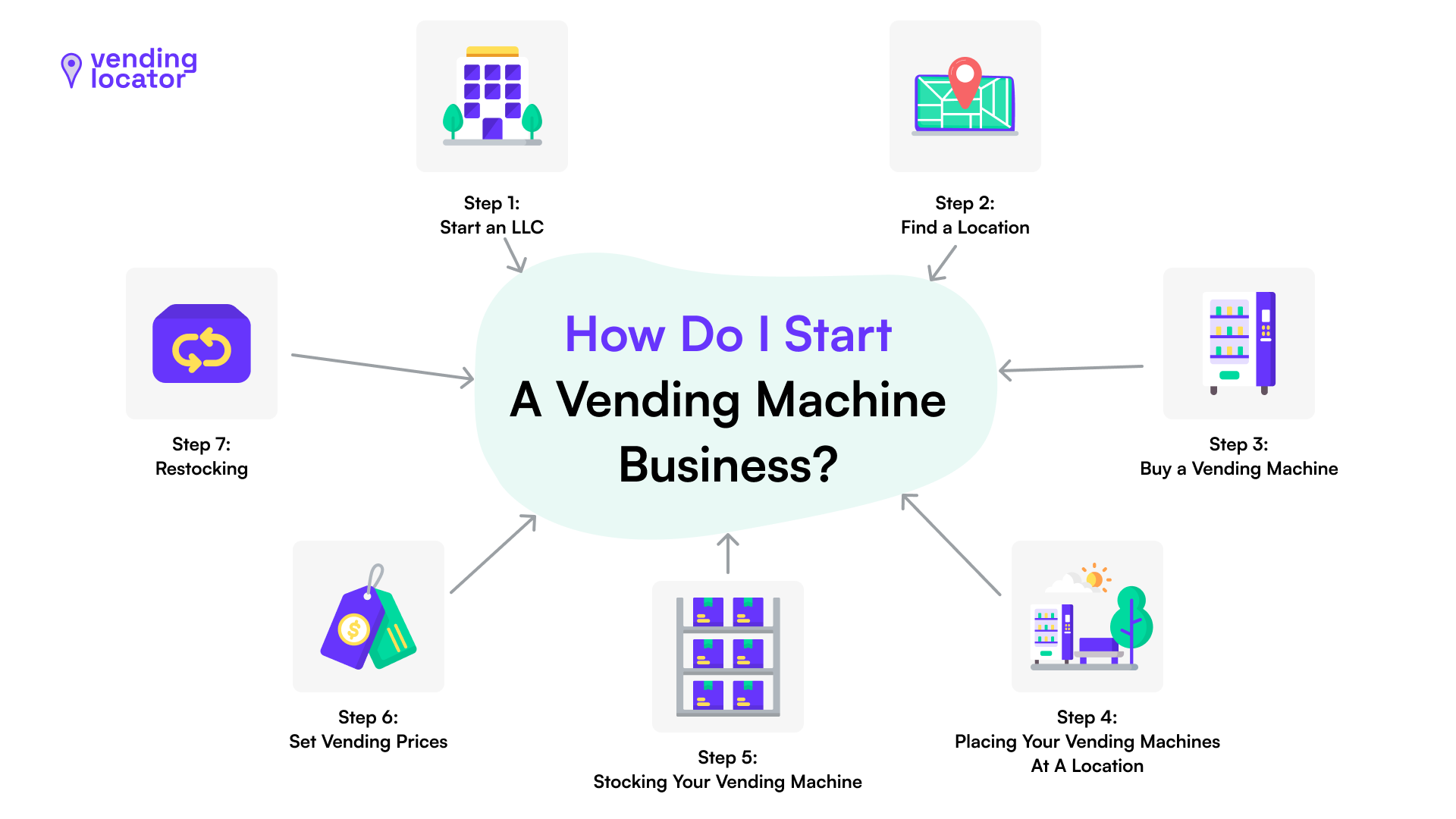

Related Video: How To Start A Vending Machine Business Step-By-Step (With $0)

Key Industrial Applications of start a vending machine business

| Industry/Sector | Specific Application of start a vending machine business | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Automated medication dispensing | Improved patient compliance and reduced pharmacy workload | Regulatory compliance, security features, and reliability |

| Corporate Offices | Snack and beverage vending | Enhanced employee satisfaction and reduced downtime | Variety of product offerings, payment systems, and maintenance support |

| Education | Campus convenience stores | Increased accessibility for students and staff | Product selection, machine placement, and operational hours |

| Transportation Hubs | Travel essentials vending | Convenience for travelers and increased revenue streams | Product turnover rates, machine durability, and payment options |

| Retail | Self-service checkouts and kiosks | Streamlined customer experience and reduced labor costs | Technology integration, inventory management, and service agreements |

Healthcare

In the healthcare sector, vending machines can be utilized for automated medication dispensing. These machines ensure that patients receive their medications accurately and on time, which significantly improves compliance rates. For international B2B buyers, particularly in regions like Africa and South America, key considerations include meeting local regulatory standards, incorporating security features to prevent theft, and ensuring the machines are reliable and easy to maintain.

Corporate Offices

Corporate offices can benefit from snack and beverage vending machines that cater to employees’ needs throughout the workday. This not only enhances employee satisfaction but also minimizes downtime as staff can quickly grab refreshments without leaving the premises. Buyers in Europe and the Middle East should focus on sourcing machines that offer a variety of popular products, efficient payment systems, and strong maintenance support to keep machines operational.

Education

In educational institutions, vending machines serve as convenient stores for students and staff, providing quick access to snacks, drinks, and even school supplies. This accessibility can significantly enhance the campus experience. Buyers from regions like Africa and the Middle East must consider product selection to cater to diverse dietary needs, machine placement for maximum visibility, and operational hours that align with campus schedules.

Transportation Hubs

Vending machines located in transportation hubs, such as airports and train stations, can offer travel essentials like snacks, beverages, and personal care items. This application addresses the needs of travelers who seek convenience and quick access to products while on the go. B2B buyers in South America and Europe should evaluate product turnover rates, the durability of machines to withstand high traffic, and the availability of various payment options to accommodate international travelers.

Retail

In the retail sector, self-service checkouts and kiosks can streamline the customer experience, allowing shoppers to make purchases quickly and efficiently. This can lead to reduced labor costs and increased sales during peak hours. International buyers must consider technology integration to ensure compatibility with existing systems, inventory management capabilities to track sales, and service agreements for prompt maintenance and support.

Related Video: How to Start a Vending Machine Business (Full Guide)

Strategic Material Selection Guide for start a vending machine business

When starting a vending machine business, selecting the right materials is crucial for ensuring durability, functionality, and compliance with international standards. This guide analyzes several common materials used in vending machine construction, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures and pressures. It is often used in environments where hygiene is a concern, such as food and beverage vending machines.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust and corrosion, making it ideal for outdoor or humid environments. However, it can be more expensive than other materials and may require specialized manufacturing processes, which can increase costs.

Impact on Application: Stainless steel is compatible with a wide range of media, including food and beverages, due to its non-reactive nature. This makes it a preferred choice for vending machines that dispense consumables.

Considerations for International Buyers: Compliance with food safety standards is critical, especially in regions like Europe and the Middle East. Buyers should ensure that the stainless steel used meets standards such as ASTM A240 or EN 10088. Additionally, local preferences for finishes (e.g., brushed vs. polished) may influence material selection.

2. Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It is often used in vending machine frames and panels.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which can reduce shipping costs and ease installation. However, it is less durable than stainless steel and may not withstand heavy impacts or extreme conditions as effectively.

Impact on Application: Aluminum is suitable for non-food applications or for vending machines that primarily dispense packaged goods. Its thermal properties can help maintain the temperature of items, such as cold beverages.

Considerations for International Buyers: Buyers should be aware of the various grades of aluminum and their respective standards, such as ASTM B221. In regions with high humidity, additional coatings may be necessary to enhance corrosion resistance.

3. Polycarbonate

Key Properties: Polycarbonate is a high-performance plastic known for its impact resistance and clarity. It is often used for vending machine windows and protective coverings.

Pros & Cons: The key advantage of polycarbonate is its excellent impact resistance, making it less likely to shatter compared to glass. However, it can be susceptible to scratching and may degrade under UV exposure unless treated.

Impact on Application: Polycarbonate is ideal for applications where visibility is essential, such as showcasing products in vending machines. Its lightweight nature also contributes to easier installation and maintenance.

Considerations for International Buyers: Buyers should verify the UV resistance and impact ratings of polycarbonate materials to ensure they meet local safety standards. Compliance with regulations such as RoHS (Restriction of Hazardous Substances) is also essential in Europe.

4. Carbon Steel

Key Properties: Carbon steel is a versatile material known for its strength and durability. It is often used in structural components of vending machines.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and high tensile strength. However, it is prone to corrosion if not properly coated or treated, which can limit its lifespan in certain environments.

Impact on Application: Carbon steel is suitable for internal components and structural frames but may not be ideal for external surfaces exposed to moisture or corrosive environments.

Considerations for International Buyers: Buyers should consider the need for protective coatings, such as galvanization, to enhance corrosion resistance. Compliance with standards like ASTM A36 is essential for ensuring quality and safety.

Summary Table

| Material | Typical Use Case for start a vending machine business | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and beverage vending machines | Excellent corrosion resistance | Higher cost, requires specialized mfg | High |

| Aluminum | Frames and panels for vending machines | Lightweight, reduces shipping costs | Less durable than stainless steel | Medium |

| Polycarbonate | Windows and protective coverings | High impact resistance | Susceptible to scratching, UV degradation | Medium |

| Carbon Steel | Structural components | Cost-effective, high strength | Prone to corrosion without protection | Low |

This material selection guide provides valuable insights for international B2B buyers looking to start a vending machine business, ensuring informed decisions that align with performance, durability, and regulatory compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for start a vending machine business

The manufacturing process and quality assurance (QA) for vending machines are critical components for any B2B buyer looking to invest in this industry. Understanding these aspects not only ensures product reliability but also enhances the overall business strategy. This guide provides an in-depth look at the typical manufacturing stages, key techniques used, and relevant quality control measures, particularly for international buyers from Africa, South America, the Middle East, and Europe.

Manufacturing Processes

The manufacturing of vending machines can be broken down into several main stages:

1. Material Preparation

This initial stage involves selecting and preparing raw materials, which typically include steel, plastics, and electronic components. The following key techniques are employed:

– Material Selection: High-quality materials must be chosen to ensure durability and longevity. For instance, stainless steel is often preferred for its resistance to corrosion.

– Cutting and Shaping: Materials are cut and shaped using CNC machines to ensure precision. Laser cutting technology is commonly used to achieve intricate designs.

2. Forming

Once the materials are prepared, they undergo various forming processes:

– Bending and Punching: Metal sheets are bent into the required shapes, and holes are punched for assembly. This is often done using hydraulic presses.

– Injection Molding: For plastic components, injection molding is used, allowing for complex shapes and designs that can be produced in bulk.

3. Assembly

The assembly stage is where the vending machine begins to take its final shape:

– Sub-Assembly: Smaller components, such as control panels and payment systems, are assembled separately before being integrated into the main structure.

– Final Assembly: All components are brought together, including shelves, dispensing mechanisms, and electronic systems. Robotic arms may be utilized to enhance efficiency and precision.

4. Finishing

The final stage involves finishing touches to ensure the product is ready for market:

– Painting and Coating: Vending machines are often painted or coated to prevent rust and improve aesthetics. Powder coating is a popular method due to its durability.

– Quality Checks: Each machine undergoes rigorous quality checks before packaging, ensuring that all components function correctly.

Quality Assurance

Quality assurance is essential in manufacturing vending machines to meet international standards and customer expectations. The following aspects are critical for B2B buyers:

Relevant International Standards

- ISO 9001: This standard is crucial for ensuring quality management systems are in place. Suppliers should provide documentation proving their compliance with ISO 9001.

- CE Marking: For machines sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Certification: While more specific to certain components, API certifications can be relevant for mechanical parts within the machines.

Quality Control Checkpoints

Quality control should occur at various stages of the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps catch defects early. This includes machine calibration checks and component functionality tests.

– Final Quality Control (FQC): Before shipping, a comprehensive evaluation is performed to ensure the vending machine meets all operational and safety standards.

Common Testing Methods

Testing methods can vary based on components but typically include:

– Electrical Testing: Ensures that all electronic components function correctly.

– Mechanical Testing: Assesses the durability and reliability of mechanical parts, such as the dispensing mechanism.

– Performance Testing: Evaluates the overall functionality, including user interface and responsiveness to payments.

Verifying Supplier Quality Control

B2B buyers can implement several strategies to verify the quality control processes of suppliers:

– Supplier Audits: Conducting on-site audits provides insight into the manufacturing processes and quality control measures in place.

– Requesting Quality Reports: Buyers should request documentation on quality control checks and any certifications the supplier holds.

– Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the manufacturing processes and quality standards.

Quality Control Nuances for International Buyers

International buyers should be aware of several nuances that may affect their purchasing decisions:

– Cultural Differences: Understanding the local manufacturing culture can provide insights into potential quality control issues. For example, certain regions may prioritize cost over quality, impacting the final product.

– Compliance with Local Regulations: Different markets may have specific regulations that must be adhered to. Buyers should ensure that suppliers are compliant with both local and international standards.

– Communication Barriers: Language differences can lead to misunderstandings regarding quality expectations. Establishing clear communication channels is essential for ensuring that all parties are aligned.

By focusing on these manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions and establish fruitful partnerships in the vending machine business. Prioritizing quality and compliance will not only enhance product reliability but also contribute to long-term business success.

Comprehensive Cost and Pricing Analysis for start a vending machine business Sourcing

When considering the establishment of a vending machine business, understanding the comprehensive cost structure and pricing analysis is crucial for success. Various components contribute to the overall costs, while several factors influence pricing strategies. Below is a detailed exploration designed for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The cost of materials includes the machinery, vending machine parts, and consumables (like snacks and beverages). Sourcing high-quality components can lead to higher upfront costs but may reduce maintenance and replacement expenses over time.

-

Labor: Labor costs encompass wages for employees involved in machine assembly, maintenance, and restocking. In regions with lower labor costs, such as parts of Africa and South America, buyers may find opportunities to reduce overall expenses.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses associated with the manufacturing process. Understanding the overhead structure of suppliers can provide insights into potential cost savings.

-

Tooling: Initial tooling costs for custom vending machines can be significant, especially if the design requires specialized molds or parts. Buyers should evaluate the necessity of custom tooling against standard solutions to optimize costs.

-

Quality Control (QC): Implementing rigorous QC processes ensures the reliability and safety of vending machines. While this adds to costs, it can prevent losses from faulty machines and enhance customer satisfaction.

-

Logistics: Shipping and handling costs can vary widely based on the distance and the mode of transportation. Buyers should be aware of logistics expenses, especially when importing machines from overseas suppliers.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the industry standard margins can aid in negotiations and help buyers assess whether they are receiving competitive pricing.

Price Influencers

-

Volume/MOQ: Purchasing in bulk often leads to significant discounts. Buyers should consider their expected sales volume when negotiating Minimum Order Quantities (MOQs) with suppliers.

-

Specifications/Customization: Custom features increase costs. Buyers should weigh the benefits of customization against the potential for higher prices and longer lead times.

-

Materials and Quality/Certifications: Higher-quality materials often come with a premium price tag. Certifications can also add to costs but may be essential for compliance in certain markets.

-

Supplier Factors: The reputation and reliability of suppliers impact pricing. Established suppliers may charge more due to their proven track record, while newer or less reputable suppliers may offer lower prices at the risk of quality issues.

-

Incoterms: Understanding shipping terms is vital as they dictate the responsibilities of buyers and sellers in logistics and cost management. Incoterms can affect the final landed cost of goods.

Buyer Tips

-

Negotiation: Engage suppliers in negotiation to secure better prices. Leverage information about competing suppliers to strengthen your position.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO), not just the initial purchase price. Consider maintenance, operational, and replacement costs when evaluating suppliers.

-

Pricing Nuances: International buyers should be aware of currency fluctuations, tariffs, and trade regulations that may affect pricing. It is advisable to include these factors in financial forecasts.

-

Market Research: Conduct thorough market research to understand local demand and pricing strategies. This knowledge can help in making informed purchasing decisions and negotiating better terms with suppliers.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on location, supplier, and market conditions. It is essential for buyers to conduct their own due diligence and obtain quotes from multiple suppliers to ensure competitive pricing.

By comprehensively analyzing these cost components and pricing influencers, international B2B buyers can make informed decisions that align with their business objectives, leading to a successful vending machine operation.

Spotlight on Potential start a vending machine business Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘start a vending machine business’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for start a vending machine business

When embarking on a vending machine business, understanding essential technical properties and industry-specific terminology is crucial for making informed decisions. This knowledge not only aids in selecting the right machines but also enhances negotiations and operational efficiency.

Key Technical Properties

-

Material Grade

– Definition: This refers to the quality of the materials used in the construction of vending machines, such as stainless steel or high-grade plastic.

– Importance: Higher material grades ensure durability and resistance to corrosion, which is vital for machines placed in various environments, especially in humid or outdoor locations. Choosing the right material can significantly affect maintenance costs and machine longevity. -

Power Consumption

– Definition: The amount of electricity a vending machine uses, typically measured in watts.

– Importance: Understanding power consumption helps in estimating operational costs. Machines with lower power consumption can lead to substantial savings, especially in regions where electricity costs are high, such as parts of Africa and South America. -

Capacity

– Definition: The maximum number of items a vending machine can hold, often specified in terms of product types and quantities.

– Importance: Capacity is critical for ensuring that the machine meets demand. A machine with a higher capacity can reduce restocking frequency, which is particularly beneficial in high-traffic areas. -

Dimensions and Weight

– Definition: The size and weight of the vending machine, which can influence installation and placement options.

– Importance: Understanding dimensions is essential for selecting appropriate locations. Heavy machines may require additional structural support, while larger machines might not fit in smaller retail spaces. -

User Interface Technology

– Definition: This encompasses the technology used for user interaction, such as touch screens, cashless payment systems, or traditional buttons.

– Importance: Advanced user interfaces can improve customer experience and increase sales. For example, machines that accept mobile payments are increasingly popular and can attract tech-savvy customers.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships can help buyers source high-quality components for their vending machines, ensuring reliability and performance. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ is essential for budgeting and inventory management. For startups, negotiating lower MOQs can help manage cash flow effectively.

Illustrative Image (Source: Google Search)

- RFQ (Request for Quotation)

– Definition: A business process in which a company solicits quotes from suppliers for a specific product or service.

– Relevance: Issuing RFQs allows businesses to compare prices and terms from different suppliers, fostering competitive pricing and better deals.

Illustrative Image (Source: Google Search)

-

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce (ICC).

– Relevance: Familiarity with Incoterms is crucial for international shipping agreements, as they clarify the responsibilities of buyers and sellers in terms of delivery, insurance, and risk management. -

Lead Time

– Definition: The amount of time it takes from placing an order to receiving the goods.

– Relevance: Understanding lead times is vital for inventory planning and ensuring that machines are available when needed, particularly in seasonal markets. -

Warranty and Service Agreements

– Definition: Contracts that outline the terms of service, maintenance, and repairs for the vending machines.

– Relevance: Knowing the warranty terms helps buyers gauge the reliability of their investment and plan for potential maintenance costs.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions, ultimately leading to a successful vending machine business.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the start a vending machine business Sector

Market Overview & Key Trends

The vending machine sector is witnessing a significant transformation driven by technological advancements and shifting consumer behaviors. Globally, the demand for automation in retail is on the rise, particularly in emerging markets like Africa and South America, where rapid urbanization is creating new opportunities for vending solutions. Key trends include the integration of cashless payment systems, enhanced user interfaces through touchscreens, and the use of IoT devices for real-time inventory management. These technologies enable operators to streamline operations and provide customers with a more convenient purchasing experience.

For international B2B buyers, understanding local market dynamics is crucial. In regions like the Middle East and Europe, there is a growing preference for healthy and organic product offerings in vending machines, aligning with global wellness trends. Buyers should also be aware of the regulatory landscape, as different regions impose varying standards for health and safety compliance. Additionally, the trend towards customization in vending solutions is gaining traction, with businesses seeking machines that can be tailored to specific consumer preferences and branding requirements.

As sustainability becomes a focal point for many businesses, vending machine operators are increasingly adopting eco-friendly practices, from sourcing biodegradable materials to implementing energy-efficient technologies. International buyers should consider these factors when evaluating potential suppliers and partners, ensuring alignment with both market trends and consumer expectations.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer just a buzzword; it is a critical factor in the vending machine business. The environmental impact of vending operations can be significant, particularly concerning energy consumption and waste generation. As such, international buyers should prioritize vendors that employ energy-efficient machines and utilize renewable energy sources where possible. This not only reduces operational costs but also enhances brand reputation among environmentally conscious consumers.

Ethical sourcing is equally vital. Buyers should look for suppliers who demonstrate transparency in their supply chains and adhere to ethical labor practices. Certifications such as Fair Trade, Rainforest Alliance, and ISO 14001 for environmental management can serve as indicators of a supplier’s commitment to sustainability. Furthermore, incorporating sustainable materials, such as recyclable plastics and biodegradable packaging, into vending offerings can appeal to a growing segment of eco-conscious consumers.

Investing in sustainability and ethical sourcing is not just about compliance; it can also drive profitability. By aligning product offerings with consumer values, businesses can differentiate themselves in a competitive market and foster customer loyalty.

Brief Evolution/History

The vending machine industry has evolved significantly since its inception in the late 19th century. Initially, vending machines offered simple products like postcards and chewing gum. However, the introduction of electronic payment systems in the 1980s marked a pivotal shift, enabling the sale of a wider range of products, including snacks and beverages.

In recent years, the advent of digital technologies has further transformed the sector. Smart vending machines equipped with touchscreens and IoT capabilities have revolutionized the customer experience, providing operators with valuable data insights. As consumer preferences continue to evolve, the vending machine sector is poised for further innovation, particularly in terms of sustainability and product offerings that cater to health-conscious consumers. For B2B buyers, understanding this historical context can provide valuable insights into the direction of the market and the opportunities it presents.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of start a vending machine business

-

What should I consider when vetting suppliers for vending machines?

When vetting suppliers, prioritize those with proven track records in international trade. Check their business licenses, certifications, and customer reviews. Request references from other B2B buyers to gauge reliability. Ensure they have experience in exporting to your region, as this can affect compliance with local regulations and logistics. Additionally, assess their communication responsiveness and willingness to provide post-sale support, which is crucial for ongoing operations. -

Can I customize vending machines to suit my market needs?

Yes, many manufacturers offer customization options. Discuss your specific requirements, such as machine size, branding, and product selection, during initial negotiations. Ensure the supplier can accommodate your requests within their production capabilities. Customization can enhance your competitive edge, particularly in diverse markets like Africa and South America, where consumer preferences vary significantly. Be clear about the specifications and ensure they are documented in your agreement. -

What are the typical minimum order quantities (MOQs) for vending machines?

MOQs can vary widely based on the supplier and the type of vending machine. Generally, expect MOQs ranging from 5 to 50 units for bulk orders. Suppliers may be more flexible with lower MOQs for initial orders or pilot projects. It’s crucial to discuss your needs upfront to find a supplier willing to work with your budget and scale. Additionally, consider the potential for volume discounts if you plan to expand your operations. -

What are the lead times for ordering vending machines?

Lead times depend on the supplier’s location, production capacity, and your customization requests. Standard lead times range from 4 to 12 weeks. It’s advisable to request a detailed timeline during negotiations, including production, quality assurance, and shipping phases. Be mindful of potential delays due to international shipping and customs clearance, especially when dealing with suppliers from different continents. Planning ahead can help you align your inventory with market demand. -

How can I ensure the quality of the vending machines I purchase?

Quality assurance is vital when sourcing vending machines. Request samples or visit the supplier’s factory if feasible. Inquire about their quality control processes, including certifications like ISO 9001. Ensure that all machines meet relevant safety standards and regulations for your market. Consider implementing a third-party inspection service before shipment to validate quality and compliance. This proactive approach minimizes the risk of defects and operational issues. -

What certifications should I look for in vending machine suppliers?

Look for suppliers with certifications that indicate compliance with international standards, such as CE, UL, or ISO certifications. These certifications ensure that the machines meet safety, quality, and environmental standards. Additionally, inquire about any specific certifications required for your local market, as these can vary by region. Understanding these requirements will help you avoid costly compliance issues down the line. -

What logistics considerations should I keep in mind when sourcing vending machines?

Logistics play a critical role in the successful import of vending machines. Assess the supplier’s ability to handle international shipping and customs clearance. Discuss shipping methods, costs, and delivery timelines upfront. Consider using freight forwarders who specialize in your destination region to streamline the process. Additionally, plan for potential tariffs and taxes that may apply to your imports, which can impact your overall costs. -

How should I handle disputes with suppliers?

Establish clear communication protocols and terms in your contract to mitigate disputes. Include clauses for conflict resolution, such as mediation or arbitration, to provide a structured approach to handling disagreements. Keep detailed records of all communications and transactions to support your position if disputes arise. If issues persist, consider involving a legal advisor familiar with international trade laws to navigate the complexities of cross-border disputes effectively.

Strategic Sourcing Conclusion and Outlook for start a vending machine business

In conclusion, strategic sourcing plays a pivotal role in establishing a successful vending machine business, particularly for international B2B buyers from Africa, South America, the Middle East, and Europe. By prioritizing supplier relationships, leveraging local market insights, and utilizing data-driven decision-making, businesses can optimize their procurement processes. This approach not only reduces costs but also enhances product quality and reliability.

Key takeaways include the importance of diversifying suppliers to mitigate risks and the need for continuous market analysis to stay ahead of trends. Engaging in thorough due diligence when selecting suppliers ensures that businesses can maintain a competitive edge while fostering innovation in their offerings.

As you embark on this journey, consider how strategic sourcing can empower your business to adapt to evolving market demands and consumer preferences. Embrace the opportunities presented by global supply chains and local partnerships, and position your vending machine venture for sustainable growth. The future is bright for those who harness the power of strategic sourcing—take the first step today and explore the vast potential that awaits you in this dynamic industry.