Your Ultimate Guide to Sourcing Sports Card Vending Machine

Guide to Sports Card Vending Machine

- Introduction: Navigating the Global Market for sports card vending machine

- Understanding sports card vending machine Types and Variations

- Key Industrial Applications of sports card vending machine

- Strategic Material Selection Guide for sports card vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for sports card vending machine

- Comprehensive Cost and Pricing Analysis for sports card vending machine Sourcing

- Spotlight on Potential sports card vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for sports card vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the sports card vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of sports card vending machine

- Strategic Sourcing Conclusion and Outlook for sports card vending machine

Introduction: Navigating the Global Market for sports card vending machine

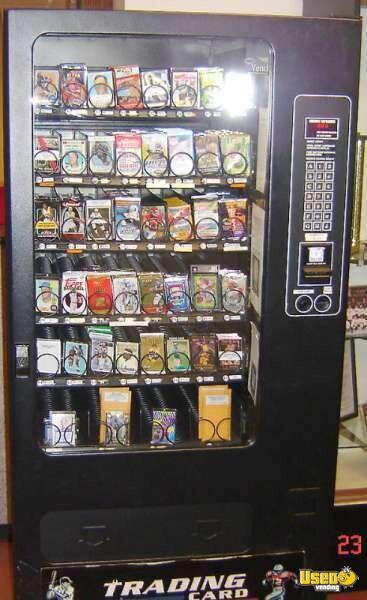

In today’s dynamic landscape of sports memorabilia, the demand for sports card vending machines is surging, creating a unique opportunity for international B2B buyers. These machines not only cater to the nostalgia of collectors but also tap into the evolving trends of impulse buying and convenience, making them a profitable addition to retail spaces, sports venues, and entertainment complexes. Understanding the nuances of this market is crucial for stakeholders aiming to capitalize on these emerging trends.

This comprehensive guide serves as your essential roadmap in navigating the global market for sports card vending machines. It covers a wide array of topics to empower your sourcing decisions, including various types of machines, the materials used in their construction, manufacturing processes, quality control standards, and a directory of reliable suppliers. Additionally, we delve into cost analysis and market trends specific to regions such as Africa, South America, the Middle East, and Europe—providing insights tailored to countries like Argentina and Kenya.

By equipping yourself with this knowledge, you will be better positioned to make informed decisions that enhance your business strategy. This guide not only aims to simplify the complexities of sourcing but also to maximize your return on investment in the sports memorabilia sector. Prepare to explore the exhilarating world of sports card vending machines and unlock potential revenue streams for your business.

Understanding sports card vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Vending Machine | Standard design with a glass front and coils | Retail stores, sports events | Pros: Widely recognized, easy to stock. Cons: Limited to physical locations. |

| Digital Touchscreen Machine | Interactive display with card selection | Shopping malls, trade shows | Pros: Engaging user experience, customizable. Cons: Higher initial investment. |

| Mobile Vending Unit | Compact, transportable design | Festivals, pop-up events | Pros: Flexibility in location, lower overhead. Cons: Limited inventory. |

| Automated Card Grading Machine | Integrated grading system for cards | Collectors’ fairs, specialty shops | Pros: Adds value through grading, attracts serious collectors. Cons: Complex maintenance. |

| NFT-Integrated Vending Machine | Combines physical cards with digital assets | Tech-savvy markets, online events | Pros: Appeals to digital collectors, innovative. Cons: Requires tech infrastructure. |

Traditional Vending Machine

Traditional vending machines are the most common type found in retail environments. They typically feature a glass front and mechanical coils that dispense sports cards when selected. B2B buyers in retail stores or sports events may find these machines appealing due to their straightforward operation and low maintenance costs. However, they are limited to physical locations and may not cater to the growing demand for digital interactions.

Digital Touchscreen Machine

Digital touchscreen machines offer an interactive experience, allowing users to browse a catalog of available sports cards on a digital display. This type is particularly suitable for shopping malls and trade shows, where engagement is key. B2B buyers should consider the initial investment, as these machines tend to cost more than traditional models. Nonetheless, the ability to customize offerings and enhance user experience makes them a compelling choice for businesses aiming to attract a younger, tech-savvy audience.

Mobile Vending Unit

The mobile vending unit is designed for flexibility and ease of transport, making it ideal for festivals and pop-up events. This type of machine allows businesses to reach customers in various locations without the need for a permanent setup. B2B buyers should weigh the advantages of lower overhead against the limitations of inventory size, as these units typically hold fewer cards than stationary machines. This could affect sales potential if demand is high.

Automated Card Grading Machine

Automated card grading machines integrate a grading system that evaluates the condition of sports cards. This is particularly appealing to collectors and can be a significant draw at collectors’ fairs and specialty shops. Buyers should be aware of the complexity involved in maintaining these machines. While they can add substantial value and attract serious collectors, the upkeep and technical support required could be a deterrent for some businesses.

NFT-Integrated Vending Machine

The NFT-integrated vending machine represents a cutting-edge approach to sports card vending, combining physical cards with digital assets. This type is especially relevant in tech-savvy markets and online events, appealing to a demographic that values both physical collectibles and digital ownership. B2B buyers must consider the necessary technological infrastructure and the evolving market for NFTs. While this innovation can attract a niche audience, it also poses challenges in terms of consumer education and market volatility.

Related Video: DIY Card Vending Machine – Easy Cardboard Craft

Key Industrial Applications of sports card vending machine

| Industry/Sector | Specific Application of sports card vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | In-store sports card sales | Increased foot traffic, convenience for collectors | Location analysis, machine size, payment integration |

| Sports Venues | Event-based card sales | Enhanced fan experience, immediate availability of products | Product variety, machine durability, promotional partnerships |

| E-commerce | Automated fulfillment kiosks | Streamlined order processing, reduced labor costs | Inventory management, software integration, security features |

| Educational Institutions | Learning tools for sports management programs | Engaging students, practical applications in sports marketing | Customization options, educational content integration |

| Entertainment & Gaming | Gaming lounges and arcades | Diversified revenue streams, attracting a niche audience | Brand partnerships, machine aesthetics, maintenance support |

In the retail sector, sports card vending machines can be strategically placed in high-traffic areas such as shopping malls or convenience stores. They cater to collectors and casual buyers alike, providing a convenient purchasing option. This application not only boosts foot traffic but also enhances customer satisfaction by offering a wide range of products. International buyers should consider location analysis and payment integration options to maximize sales potential.

For sports venues, these machines serve as a unique opportunity to sell sports cards during events. They enhance the fan experience by providing immediate access to collectible items, which can be a valuable revenue stream for teams and event organizers. Key considerations for sourcing include the durability of the machines to withstand high usage and the ability to feature promotional partnerships that align with the venue’s branding.

In the e-commerce industry, sports card vending machines can act as automated fulfillment kiosks that streamline the order processing for online purchases. This application reduces labor costs and improves efficiency, making it easier for businesses to manage inventory and fulfill customer orders. Buyers should focus on software integration for seamless operation and robust security features to protect valuable inventory.

Educational institutions can leverage sports card vending machines as engaging tools for sports management programs. By providing students with practical applications in sports marketing, these machines can enhance learning experiences. Customization options for branding and educational content can make these machines more appealing to schools and universities, allowing them to support their educational goals while also generating revenue.

Lastly, in the entertainment and gaming sector, sports card vending machines can be integrated into gaming lounges and arcades, providing a unique attraction for visitors. This application diversifies revenue streams and attracts niche audiences who share a passion for sports collectibles. International buyers should consider brand partnerships and machine aesthetics to enhance the overall experience and ensure long-term engagement.

Related Video: How to Start a Vending Machine Business, Cost, Tips, How Much You Make

Strategic Material Selection Guide for sports card vending machine

When selecting materials for sports card vending machines, several factors must be considered to ensure optimal performance, durability, and compliance with international standards. Below is an analysis of four common materials used in the construction of these machines, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. It typically has a temperature rating of up to 800°C and can endure considerable mechanical stress.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust, making it ideal for outdoor installations. However, it can be more expensive than other materials and may require specialized manufacturing processes, which can increase overall costs.

Impact on Application: Stainless steel is compatible with various media, including moisture and dust, which are common in outdoor environments. Its durability ensures a long lifespan, reducing maintenance costs.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local corrosion resistance standards. In Europe, adherence to ASTM and DIN standards is essential for quality assurance.

2. Aluminum

Key Properties: Aluminum is lightweight, has good corrosion resistance, and can withstand moderate temperatures. Its thermal conductivity is higher than that of steel, making it suitable for applications where heat dissipation is necessary.

Pros & Cons: The lightweight nature of aluminum makes it easier to transport and install, reducing logistics costs. However, it is less durable than stainless steel and can be prone to denting and scratching, which may affect the aesthetic appeal.

Impact on Application: Aluminum is suitable for indoor machines or environments with minimal exposure to harsh elements. Its lightweight nature can be advantageous for portable vending solutions.

Considerations for International Buyers: Buyers should check for compliance with local standards, particularly in the Middle East, where heat resistance is crucial. The choice of aluminum grade can significantly affect performance and cost.

3. Polycarbonate

Key Properties: Polycarbonate is a high-performance plastic known for its impact resistance and clarity. It can withstand temperatures ranging from -40°C to 120°C, making it suitable for various environments.

Pros & Cons: The primary advantage of polycarbonate is its lightweight and shatter-resistant properties, which enhance safety. However, it may not be as durable as metals in high-stress environments and can be susceptible to scratching.

Impact on Application: This material is ideal for transparent sections of vending machines, allowing visibility of the cards inside. It is also resistant to UV light, making it suitable for outdoor use.

Considerations for International Buyers: Compliance with safety standards is critical, especially in Europe, where regulations regarding plastic materials are stringent. Buyers should also consider the environmental impact and recyclability of polycarbonate.

4. Mild Steel

Key Properties: Mild steel is characterized by its ductility and weldability, with a temperature rating of around 250°C. It is less corrosion-resistant than stainless steel but can be treated for enhanced durability.

Pros & Cons: Mild steel is cost-effective and easy to manufacture, making it a popular choice for many applications. However, its susceptibility to rust and corrosion can lead to higher maintenance costs if not properly treated.

Impact on Application: While suitable for indoor environments, mild steel requires protective coatings for outdoor use to prevent corrosion. This treatment can impact the overall cost and manufacturing complexity.

Considerations for International Buyers: Buyers in humid regions like parts of Africa and South America should prioritize corrosion-resistant coatings. Compliance with local standards for steel grades is also essential to ensure product longevity and safety.

Summary Table

| Material | Typical Use Case for sports card vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor machines in harsh environments | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Indoor and portable vending machines | Lightweight and easy to install | Less durable, prone to dents | Medium |

| Polycarbonate | Transparent sections of machines | Shatter-resistant and lightweight | Susceptible to scratching | Medium |

| Mild Steel | Indoor machines with protective coatings | Cost-effective and easy to manufacture | Susceptible to corrosion | Low |

This strategic material selection guide provides crucial insights for B2B buyers, enabling informed decisions that align with operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for sports card vending machine

Manufacturing Processes for Sports Card Vending Machines

When considering the procurement of sports card vending machines, understanding the manufacturing processes is crucial for ensuring both quality and reliability. The production of these machines typically involves several key stages, including material preparation, forming, assembly, and finishing. Each stage employs specific techniques that contribute to the overall functionality and durability of the final product.

1. Material Preparation

The first step in manufacturing a sports card vending machine involves selecting appropriate materials. Common materials include:

- Metal: Often used for the frame and internal mechanism due to its strength and durability.

- Plastic: Utilized for exterior panels and components that require lightweight properties.

- Electronics: Components such as circuit boards, sensors, and displays are essential for the machine’s operation.

Once materials are selected, they undergo processing, which may include cutting, shaping, and treating to enhance durability and resistance to wear and tear.

2. Forming

In the forming stage, the prepared materials are shaped into specific components of the vending machine. Key techniques include:

- Sheet Metal Fabrication: This involves cutting and bending metal sheets to create the machine’s framework and internal parts.

- Injection Molding: Used for producing plastic components, this technique allows for the efficient mass production of complex shapes.

- 3D Printing: An emerging technique that may be used for creating prototypes or custom parts, ensuring precision and reducing waste.

These techniques ensure that each part meets design specifications and is produced to the required standards.

3. Assembly

The assembly stage is critical, as it combines all manufactured components into a functional vending machine. This process typically involves:

- Mechanical Assembly: Joining metal and plastic parts using screws, bolts, and fasteners.

- Electrical Assembly: Integrating electrical components, including wiring and circuit boards, ensuring that all electronic parts work cohesively.

- Software Installation: Loading the necessary software that controls the machine’s operations, including payment processing and inventory management.

Attention to detail during assembly is crucial, as any errors can lead to operational failures.

4. Finishing

The finishing stage enhances both the appearance and functionality of the vending machine. Key activities include:

- Painting and Coating: Applying protective finishes to prevent corrosion and enhance aesthetics.

- Quality Control Checks: Conducting initial quality assessments to identify any defects before the machines are shipped.

This stage ensures that the machines are not only visually appealing but also ready for long-term use in various environments.

Quality Assurance in Manufacturing

Quality assurance (QA) is vital in ensuring that sports card vending machines meet international standards and customer expectations. It encompasses a series of checkpoints and testing methods throughout the manufacturing process.

Relevant International Standards

To maintain high quality, manufacturers often adhere to international standards such as:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent quality across processes.

- CE Marking: Required for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- API Standards: Important for components that involve electrical safety and performance.

B2B buyers should ensure that their suppliers are compliant with these standards to mitigate risks associated with product quality.

Quality Control Checkpoints

The QC process typically involves several key checkpoints, including:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing to detect defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product to ensure it meets all operational requirements.

These checkpoints help identify potential issues at various stages of production, allowing for timely corrections.

Common Testing Methods

Testing methods used in quality assurance include:

- Functional Testing: Verifying that the vending machine operates as intended under various scenarios.

- Durability Testing: Assessing the machine’s resilience to physical stress, environmental conditions, and long-term usage.

- Safety Testing: Ensuring that electrical components meet safety standards to prevent hazards.

B2B buyers should inquire about the specific testing methods used by suppliers to ensure thorough quality checks.

Verifying Supplier Quality Control

For international B2B buyers, verifying the quality control practices of suppliers is essential. Here are actionable strategies:

- Conduct Audits: Regularly audit suppliers to assess their manufacturing processes and quality assurance measures. This can be done through onsite visits or remote assessments.

- Request Quality Reports: Suppliers should provide documentation of their quality control processes, including test results and compliance certifications.

- Engage Third-Party Inspectors: Utilizing independent inspectors can provide an unbiased evaluation of the supplier’s quality practices and products.

QC Certification Nuances for International Buyers

Buyers from regions such as Africa, South America, the Middle East, and Europe may encounter unique challenges regarding quality certification. Considerations include:

- Local Regulations: Ensure that suppliers are aware of and compliant with local regulations and standards, which may differ significantly across regions.

- Cultural Differences: Understanding cultural attitudes towards quality and compliance can impact negotiations and relationships with suppliers.

- Logistics and Supply Chain: Assess the supplier’s ability to maintain quality standards throughout the supply chain, especially in regions with varying infrastructure and regulatory environments.

By focusing on these aspects, international B2B buyers can make informed decisions and establish reliable partnerships in the procurement of sports card vending machines.

Related Video: From Factory to Table: Inside the Production Process of Poker Cards

Comprehensive Cost and Pricing Analysis for sports card vending machine Sourcing

Understanding the Cost Structure of Sports Card Vending Machines

When sourcing sports card vending machines, international B2B buyers must consider various cost components to make informed purchasing decisions. The primary cost components include:

-

Materials: The quality and type of materials used in manufacturing the machines significantly impact the overall cost. Common materials include high-quality plastics for casing, electronic components for functionality, and mechanical parts for vending operations. Sourcing materials locally can sometimes reduce costs but may affect quality.

-

Labor: Labor costs vary widely across regions. In countries with lower labor costs, such as some parts of Africa and South America, production expenses may be reduced. However, this can be a trade-off with potential quality and delivery times.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, rent, and administrative expenses. Understanding the manufacturing environment of the supplier can provide insights into these costs.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. Buyers should assess whether the supplier has existing tooling or if new investment will be required, impacting overall pricing.

-

Quality Control (QC): Implementing rigorous QC processes can increase costs but is essential for ensuring product reliability. Suppliers with strong QC protocols may charge a premium, but this often leads to better long-term performance and customer satisfaction.

-

Logistics: Shipping costs can vary significantly based on the origin and destination of the machines, as well as the chosen mode of transport. Incoterms will dictate responsibilities and costs, which is crucial for budgeting.

-

Margin: Suppliers will typically add a margin over the total costs to ensure profitability. Understanding the market dynamics can provide leverage in negotiations.

Price Influencers to Consider

Several factors can influence the pricing of sports card vending machines:

-

Volume/MOQ: Bulk purchasing often results in lower per-unit costs. Buyers should inquire about minimum order quantities (MOQ) and explore potential discounts for larger orders.

-

Specifications/Customization: Custom features such as branding, size adjustments, or enhanced functionality can lead to increased costs. Clearly defining requirements early in discussions can help manage expectations around pricing.

-

Material Quality/Certifications: Higher-quality materials and certifications (e.g., safety, environmental standards) can add to costs but might be necessary for compliance in certain markets.

-

Supplier Factors: The reputation and experience of the supplier can affect pricing. Established suppliers may charge more due to perceived reliability and quality assurance.

-

Incoterms: Understand the terms of trade that dictate shipping responsibilities and costs. Choosing the right Incoterms can lead to significant savings.

Buyer Tips for Effective Sourcing

-

Negotiate: Leverage volume purchases and long-term relationships to negotiate better pricing and terms. Building rapport with suppliers can lead to more favorable conditions.

-

Focus on Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), including maintenance, potential downtime, and replacement parts, rather than just the purchase price.

-

Pricing Nuances: Be aware of regional pricing trends and fluctuations. For instance, suppliers in Europe may have higher base prices due to stricter regulations, while those in Africa may offer lower base prices but could come with longer lead times.

-

Local Partnerships: Consider partnering with local distributors or agents who understand the regional market dynamics and can assist in navigating costs and logistics.

-

Research and Benchmark: Conduct market research to benchmark pricing across different suppliers. This can provide leverage in negotiations and help uncover competitive pricing strategies.

Disclaimer

Prices and cost components mentioned are indicative and can vary significantly based on specific supplier agreements, regional factors, and market conditions. Buyers are encouraged to conduct thorough due diligence and engage in comprehensive discussions with potential suppliers to obtain accurate and current pricing information.

Spotlight on Potential sports card vending machine Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for sports card vending machine.)*

Essential Technical Properties and Trade Terminology for sports card vending machine

Key Technical Properties of Sports Card Vending Machines

When evaluating sports card vending machines, international B2B buyers should consider several critical technical properties that influence performance, durability, and overall value. Here are some essential specifications to keep in mind:

Illustrative Image (Source: Google Search)

-

Material Grade

– Definition: This refers to the quality of materials used in the construction of the vending machine, typically encompassing metals, plastics, and electronic components.

– Importance: Higher-grade materials ensure longevity and resistance to wear and tear, which is vital for machines deployed in high-traffic areas. For buyers in regions with varying climates, such as Africa and the Middle East, selecting machines with rust-resistant or UV-protected materials can significantly reduce maintenance costs. -

Dimensions and Footprint

– Definition: This encompasses the size and layout of the vending machine, including height, width, and depth.

– Importance: Understanding the dimensions is crucial for ensuring the machine fits within designated spaces in retail environments. For buyers in urban areas or those with limited floor space, compact models may be more beneficial. -

Capacity

– Definition: The total number of cards the vending machine can hold at any given time.

– Importance: A higher capacity can lead to longer intervals between restocking, which is particularly advantageous for busy locations. Buyers should assess local demand to determine the appropriate capacity to maximize sales without frequent interruptions. -

Power Requirements

– Definition: This indicates the electrical specifications necessary for the machine to operate, including voltage and power consumption.

– Importance: Different regions may have varying electrical standards. Ensuring compatibility with local power supplies is essential for seamless operation and preventing electrical issues, especially in areas with inconsistent power availability. -

User Interface

– Definition: This refers to the design and functionality of the machine’s display and interaction systems, including touchscreens and card selection mechanisms.

– Importance: A user-friendly interface enhances customer experience and can lead to higher sales. Buyers should consider machines with multilingual support to cater to diverse customer bases in regions like South America and Europe. -

Security Features

– Definition: This includes measures like lock systems, surveillance cameras, and anti-theft designs.

– Importance: Ensuring the security of both the machine and the inventory is crucial, especially in areas with high theft rates. Investing in machines with robust security features can protect assets and reduce insurance costs.

Common Trade Terminology in the Sports Card Vending Machine Industry

Understanding industry jargon is essential for effective communication and negotiations. Here are some key terms that B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

– Definition: Refers to a company that produces parts and equipment that may be marketed by another manufacturer.

– Relevance: Buyers should identify the OEM of the vending machines to ensure they are sourcing from reputable manufacturers known for quality and reliability. -

MOQ (Minimum Order Quantity)

– Definition: The smallest amount of a product that a supplier is willing to sell.

– Relevance: Understanding MOQ is crucial for budget planning and inventory management. Buyers should negotiate MOQs that align with their sales forecasts to avoid overstocking or understocking. -

RFQ (Request for Quotation)

– Definition: A document that solicits price proposals from suppliers for specified goods or services.

– Relevance: An RFQ helps buyers compare pricing and terms from different suppliers, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of sellers and buyers in the shipping process.

– Relevance: Familiarity with Incoterms is essential for understanding shipping costs, risks, and responsibilities. Buyers should negotiate terms that minimize their liabilities while ensuring timely delivery. -

Lead Time

– Definition: The amount of time it takes from placing an order until the goods are delivered.

– Relevance: Knowing the lead time helps buyers plan their inventory and sales strategies effectively, ensuring they meet customer demand without delays.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions when procuring sports card vending machines, ultimately enhancing their operational efficiency and market competitiveness.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the sports card vending machine Sector

Market Overview & Key Trends

The sports card vending machine sector is experiencing a notable transformation driven by several global trends. The resurgence of interest in collectible cards, fueled by social media and online marketplaces, is propelling demand. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of the rising popularity of trading cards among younger demographics. This shift not only increases sales potential but also necessitates a keen eye for trending card types, such as NFTs and limited editions.

Another significant trend is the integration of technology into vending machines. Smart vending machines equipped with cashless payment systems, real-time inventory tracking, and user-friendly interfaces are becoming the norm. Buyers should consider sourcing machines that utilize advanced technologies, as they enhance customer experiences and streamline operations. Additionally, the rise of e-commerce platforms is encouraging manufacturers to explore hybrid models that combine online sales with physical vending locations.

Market dynamics also reflect a growing emphasis on customization and localization. B2B buyers are encouraged to collaborate with suppliers who offer customizable vending solutions that cater to local tastes and preferences. This can include localized branding, card collections, and even bilingual interfaces, particularly in multilingual regions like South America and Europe.

Sustainability & Ethical Sourcing in B2B

As the demand for sports card vending machines grows, so does the importance of sustainability and ethical sourcing. The environmental impact of manufacturing processes and materials used in vending machines is under scrutiny. B2B buyers should prioritize suppliers that utilize eco-friendly materials, such as recycled plastics and sustainably sourced wood, for machine construction.

Moreover, advocating for ethical supply chains is crucial. This means working with manufacturers that ensure fair labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 for environmental management and Fair Trade certification for labor practices can serve as indicators of a supplier’s commitment to sustainability.

Investing in sustainable vending solutions not only aligns with global sustainability goals but also enhances brand reputation among environmentally conscious consumers. This is particularly relevant in regions like Europe, where regulatory frameworks are increasingly favoring sustainable practices.

Brief Evolution/History

The concept of vending machines has evolved significantly since their introduction in the late 19th century. Initially used for dispensing simple items, vending machines have transformed dramatically over the decades, adapting to consumer trends and technological advancements. The sports card vending machine emerged as a niche product in the 1980s, gaining momentum as the collectible card market expanded.

Today, these machines offer a diverse range of products, from traditional sports cards to modern collectibles like gaming cards and NFTs. This evolution reflects broader trends in consumer behavior and technological innovation, making the sports card vending machine sector an exciting space for international B2B buyers to explore. Understanding this history can provide valuable insights into current market dynamics and future opportunities.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of sports card vending machine

-

What should I consider when vetting suppliers for sports card vending machines?

When vetting suppliers, assess their experience in the industry, reputation, and customer reviews. Verify their compliance with international standards and regulations, particularly in your target market. Request references from previous clients and check their ability to provide after-sales support. Engage in direct communication to gauge their responsiveness and willingness to customize products according to your specifications. It’s also prudent to visit their manufacturing facility if possible, or utilize third-party inspection services to ensure quality. -

Can I customize the sports card vending machines to fit my brand?

Yes, most manufacturers offer customization options for sports card vending machines. You can tailor the machine’s exterior design, color schemes, and branding elements to align with your company’s identity. Additionally, inquire about the ability to program specific card offerings or features that cater to your target audience. Be sure to discuss these requirements during the initial negotiation phase to avoid misunderstandings later in the process. -

What are the typical minimum order quantities (MOQs) and lead times for these machines?

Minimum order quantities can vary significantly by supplier, often ranging from 10 to 100 units for sports card vending machines. Lead times also depend on the complexity of the order and current demand; expect anywhere from 4 to 12 weeks for production. It’s advisable to discuss these details upfront to ensure you can meet your market demand without excessive inventory costs. Additionally, consider potential delays in logistics, especially if importing from overseas suppliers.

Illustrative Image (Source: Google Search)

-

What payment terms should I expect when ordering sports card vending machines?

Payment terms can differ by supplier but typically include a deposit (often 30-50%) upon order confirmation, with the balance due prior to shipping. Some suppliers may offer flexible payment options, such as letters of credit or installment payments based on delivery milestones. Always clarify these terms in the contract and consider using escrow services for large transactions to protect your investment and ensure that goods meet specifications before final payment. -

How do I ensure quality assurance and certifications for the machines?

Request detailed information on the quality assurance processes employed by the manufacturer, including any certifications such as ISO 9001, CE, or other relevant standards. Ask for documentation that proves compliance with safety regulations in your region. Conducting third-party quality audits can be beneficial, especially if you are sourcing from international suppliers. Establishing a clear quality control plan in your contract will help mitigate risks associated with defects or non-compliance. -

What logistics considerations should I keep in mind when importing these machines?

Logistics plays a crucial role in the successful importation of sports card vending machines. Factor in shipping costs, customs duties, and potential delays at ports. Choose a reliable freight forwarder who understands the complexities of international shipping, especially in regions like Africa and South America where logistics infrastructure may vary. Ensure you have all necessary documentation ready for customs clearance, including invoices, packing lists, and certificates of origin. -

How should disputes regarding orders or product quality be handled?

Establish a clear dispute resolution process in your contract, including preferred methods such as mediation or arbitration. Maintain open lines of communication with your supplier to address any issues promptly. Document all correspondence and agreements related to the transaction, including product specifications and quality expectations. In case of product defects or discrepancies, approach the supplier with evidence and a proposed solution to facilitate swift resolution. -

What are the best practices for maintaining the sports card vending machines post-purchase?

Regular maintenance is essential for ensuring the longevity and efficiency of your vending machines. Implement a routine check-up schedule that includes cleaning, software updates, and inventory management. Train your staff on troubleshooting common issues and provide them with a manual or access to customer support from the supplier. Keeping abreast of the latest trends in sports cards can help you adjust your inventory and offerings, enhancing customer satisfaction and sales.

Strategic Sourcing Conclusion and Outlook for sports card vending machine

The sports card vending machine market presents a unique opportunity for international B2B buyers looking to tap into a growing segment of the collectibles industry. As demand for sports cards surges across diverse regions such as Africa, South America, the Middle East, and Europe, strategic sourcing becomes essential. Buyers should prioritize partnerships with reliable manufacturers that offer customizable solutions, ensuring that the vending machines cater to local preferences and market trends.

Adopting a strategic sourcing approach not only enhances supply chain efficiency but also mitigates risks associated with currency fluctuations and geopolitical uncertainties. By leveraging data analytics and market research, businesses can make informed decisions that align with their operational goals and customer demands.

Looking ahead, the sports card vending machine industry is poised for significant growth, driven by technological advancements and increased consumer engagement. International buyers are encouraged to explore collaborative ventures, attend industry expos, and engage with local distributors to stay ahead of emerging trends. By embracing a strategic sourcing mindset, businesses can optimize their investments and successfully navigate this evolving market landscape.