Your Ultimate Guide to Sourcing Some Vending Machines On

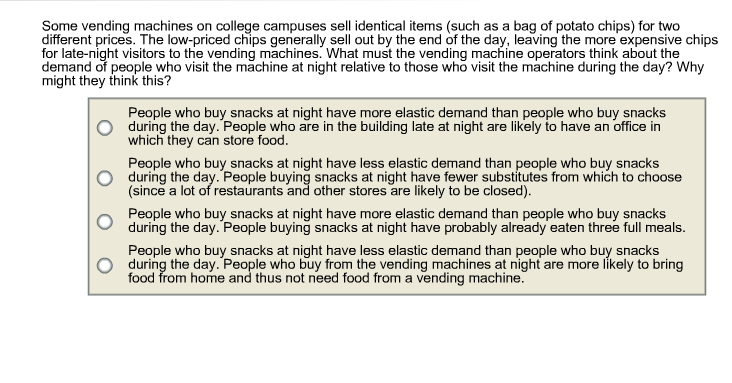

Guide to Some Vending Machines On College Campuses

- Introduction: Navigating the Global Market for some vending machines on college campuses

- Understanding some vending machines on college campuses Types and Variations

- Key Industrial Applications of some vending machines on college campuses

- Strategic Material Selection Guide for some vending machines on college campuses

- In-depth Look: Manufacturing Processes and Quality Assurance for some vending machines on college campuses

- Comprehensive Cost and Pricing Analysis for some vending machines on college campuses Sourcing

- Spotlight on Potential some vending machines on college campuses Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for some vending machines on college campuses

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the some vending machines on college campuses Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of some vending machines on college campuses

- Strategic Sourcing Conclusion and Outlook for some vending machines on college campuses

Introduction: Navigating the Global Market for some vending machines on college campuses

In the rapidly evolving landscape of higher education, vending machines on college campuses have emerged as a critical component of student life, catering to the demand for convenience and accessibility. These machines are no longer limited to snacks and beverages; they now offer a diverse range of products, including healthy food options, technology accessories, and even personal care items. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding this market is essential for making informed sourcing decisions.

This comprehensive guide delves into various aspects of vending machines tailored for college environments. It covers the types of vending machines, highlighting innovations such as cashless payment systems and smart vending solutions. We explore the materials and manufacturing processes that ensure durability and sustainability, as well as the quality control measures that protect against supply chain disruptions.

Key insights into supplier networks will help buyers identify reliable partners, while cost analysis provides a framework for budgeting and investment planning. Additionally, the guide addresses prevalent market trends shaping the vending landscape, including consumer preferences and technological advancements.

By equipping B2B buyers with the necessary knowledge and tools, this guide empowers them to navigate the global market effectively, ensuring they meet the unique needs of their target demographics while optimizing profitability. Whether you are a seasoned investor or new to this niche, understanding these dynamics is crucial for successful engagement in the college vending machine market.

Understanding some vending machines on college campuses Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Snack Vending Machines | Standard design with a variety of snacks and beverages | Campus dining services, student convenience | Pros: Low maintenance, easy to restock. Cons: Limited product variety may not cater to dietary preferences. |

| Healthy Food Vending Machines | Focus on nutritious options, often featuring fresh items | Wellness programs, health initiatives | Pros: Appeals to health-conscious students. Cons: Higher initial investment and potential spoilage of fresh items. |

| Tech-Integrated Vending Machines | Equipped with touch screens, cashless payment options | Innovative campus experiences, tech-savvy environments | Pros: Enhanced user experience, real-time inventory tracking. Cons: Higher cost and requires technical support. |

| Customized Product Vending Machines | Tailored offerings based on campus preferences, including local brands | Branding opportunities, niche markets | Pros: Increases student engagement, supports local businesses. Cons: Requires market research and ongoing adjustments. |

| Automated Retail Kiosks | Larger machines resembling small stores, offering diverse products | 24/7 service, extended product range | Pros: Greater variety and accessibility. Cons: Higher upfront costs and maintenance challenges. |

Traditional Snack Vending Machines

These machines typically offer a range of snacks and beverages, catering to the basic needs of students. They are suitable for high-traffic areas on campus, such as dormitories, libraries, and student unions. For B2B buyers, the primary considerations include the machine’s reliability, ease of restocking, and maintenance requirements. While these machines are cost-effective and easy to manage, they may not meet the diverse dietary preferences of a modern student body, which is an essential factor to consider.

Healthy Food Vending Machines

These machines prioritize nutritious options, often including salads, fruits, and low-calorie snacks. They align with growing wellness trends among students and can be strategically placed in gyms or health centers. B2B buyers should assess factors such as product shelf life, supplier partnerships for fresh items, and the potential for higher pricing. Although they cater to health-conscious consumers, the initial investment can be higher, and there is a risk of spoilage if not managed correctly.

Tech-Integrated Vending Machines

Incorporating advanced technology, these machines offer features like touch screens and cashless payment systems. They are ideal for tech-savvy campuses looking to enhance the student experience. Buyers should consider the cost of technology integration and the need for ongoing technical support. While they provide a modern user experience and real-time inventory management, the initial investment and potential technical issues could pose challenges for some institutions.

Customized Product Vending Machines

These machines can be tailored to reflect the preferences and tastes of the student population, including local snacks and beverages. They are effective in creating a unique campus experience and supporting local businesses. For B2B buyers, understanding student preferences through market research is crucial. While they foster engagement and loyalty, they require continuous adjustments to inventory and could involve higher operational costs.

Automated Retail Kiosks

Resembling small convenience stores, these kiosks provide a wider variety of products, including electronics and personal care items, and can operate 24/7. They are suitable for locations with high foot traffic and extended hours, such as near dorms or libraries. Buyers should consider the initial investment and ongoing maintenance costs. Although they offer greater accessibility and product variety, managing inventory and ensuring machine functionality can be more complex than traditional vending solutions.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of some vending machines on college campuses

| Industry/Sector | Specific Application of some vending machines on college campuses | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Snack and beverage vending machines in student lounges | Increased student satisfaction and engagement | Reliability, product variety, and maintenance support |

| Health and Wellness | Healthy food vending machines in gym facilities | Promotes healthier lifestyle choices | Nutritional compliance, sourcing local products |

| Technology | Tech gadget vending machines for student needs | Immediate access to essential tech products | Inventory management, payment system integration |

| Hospitality | Vending machines offering meal options during late hours | Enhances campus life and convenience | Food safety standards, variety of cuisine options |

| Retail | Merchandise vending machines for college-branded products | Boosts school spirit and revenue generation | Custom branding options, inventory turnover rates |

Education

Vending machines in educational settings serve as convenient access points for snacks and beverages, particularly in high-traffic areas like student lounges. They solve the problem of limited food options during busy schedules, catering to student needs for quick and affordable sustenance. Buyers in this sector should prioritize reliability and product variety, ensuring machines are stocked with popular items and maintained properly to minimize downtime.

Health and Wellness

Healthy food vending machines positioned in gym facilities provide students with nutritious options post-workout. This application addresses the growing demand for healthier lifestyle choices among the student population. International buyers, particularly from regions like Africa and South America, should focus on nutritional compliance and the sourcing of local products to cater to diverse dietary preferences and cultural considerations.

Technology

In an increasingly tech-driven world, vending machines that dispense gadgets such as chargers, headphones, or even laptops meet the urgent needs of students. These machines provide immediate access to essential products, especially during exam periods. For international buyers, key considerations include inventory management systems that can track sales and ensure popular items are always available, as well as seamless payment system integration to accommodate various payment methods.

Hospitality

Vending machines offering meal options during late hours enhance campus life by catering to students’ late-night cravings. This application is particularly beneficial in areas with limited dining options during off-hours. Buyers in the hospitality sector should ensure compliance with food safety standards and consider a variety of cuisine options to appeal to a diverse student body, which can enhance overall satisfaction and campus experience.

Retail

Merchandise vending machines that offer college-branded products, such as apparel and accessories, can significantly boost school spirit while generating additional revenue. This application meets students’ desires for branded items conveniently located on campus. Key sourcing considerations include custom branding options and the ability to manage inventory turnover rates effectively, ensuring that popular items remain available while minimizing unsold stock.

Related Video: DIY Vending Machine – Arduino based Mechatronics Project

Strategic Material Selection Guide for some vending machines on college campuses

When selecting materials for vending machines on college campuses, it is crucial to consider the unique demands of the environment and the specific needs of the target market. The materials used not only affect the durability and functionality of the machines but also influence maintenance costs and compliance with local regulations. Below is an analysis of several common materials used in vending machine construction, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

Stainless Steel

Key Properties:

Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. It is often rated for high-pressure applications, making it suitable for vending machines that may experience fluctuations in temperature and humidity.

Pros & Cons:

The primary advantage of stainless steel is its durability and long lifespan, which can reduce replacement costs over time. However, it is more expensive than other materials, which can impact initial investment. Manufacturing complexity can also be higher due to the need for specialized tools and processes.

Impact on Application:

Stainless steel is compatible with various media, including beverages and snacks, and is easy to clean, making it ideal for high-traffic college environments.

Considerations for International Buyers:

Buyers from regions like Europe, particularly Germany and France, will find that stainless steel meets stringent EU regulations regarding food safety and hygiene. Compliance with standards such as DIN and EN is essential.

Polycarbonate

Key Properties:

Polycarbonate is a thermoplastic known for its high impact resistance and transparency. It can withstand moderate temperature variations and is often used in areas where visibility of products is essential.

Pros & Cons:

The key advantage of polycarbonate is its lightweight nature and excellent shatter resistance, which can reduce shipping costs and the risk of breakage. However, it is less durable than metals and can be prone to scratching, which may affect aesthetics over time.

Impact on Application:

Polycarbonate is suitable for vending machines that require clear panels for product visibility, enhancing consumer engagement. However, it is less suitable for environments with extreme temperatures.

Considerations for International Buyers:

In regions like Africa and South America, where UV exposure can be intense, UV-resistant grades of polycarbonate are recommended to prevent degradation. Compliance with local safety standards should also be verified.

Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has a good strength-to-weight ratio. It can handle moderate temperatures and is often used in structural components of vending machines.

Pros & Cons:

Aluminum is cost-effective and easy to fabricate, making it a popular choice for manufacturers. However, it may not be as durable as stainless steel in high-stress applications and can be susceptible to denting.

Impact on Application:

Aluminum is suitable for exterior panels and frames, providing a balance of strength and weight. Its corrosion resistance makes it ideal for outdoor installations.

Considerations for International Buyers:

Buyers in the Middle East should consider the effects of high temperatures and humidity on aluminum. Compliance with ASTM standards is essential to ensure material quality and performance.

Glass

Key Properties:

Glass is known for its aesthetic appeal and can be treated for increased strength and thermal resistance. It is often used in vending machines for product display.

Pros & Cons:

The primary advantage of glass is its visual appeal, which can enhance the consumer experience. However, it is fragile and can shatter easily, leading to safety concerns and higher replacement costs.

Impact on Application:

Glass is ideal for showcasing products but may require additional safety features, such as tempered or laminated glass, to ensure durability.

Considerations for International Buyers:

In Europe, glass must meet specific safety standards, such as EN 12150 for tempered glass. Buyers should ensure compliance with local regulations to avoid legal issues.

Summary Table

| Material | Typical Use Case for some vending machines on college campuses | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Exterior panels and structural components | Excellent durability and hygiene | Higher initial cost | High |

| Polycarbonate | Clear product display panels | Lightweight and impact-resistant | Prone to scratches | Medium |

| Aluminum | Frames and structural elements | Cost-effective and easy to fabricate | Less durable under stress | Low |

| Glass | Product display areas | Aesthetic appeal | Fragile and higher replacement cost | Medium |

This guide provides actionable insights for international B2B buyers, helping them make informed decisions on material selection for vending machines on college campuses.

In-depth Look: Manufacturing Processes and Quality Assurance for some vending machines on college campuses

Manufacturing vending machines for college campuses involves a meticulous process that ensures the final product is reliable, user-friendly, and meets the diverse needs of students and faculty. Understanding the manufacturing processes and quality assurance measures is crucial for international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe. This section explores the key stages in manufacturing and the standards of quality control that ensure vending machines meet the highest operational standards.

Manufacturing Processes

The manufacturing of vending machines typically encompasses four main stages: material preparation, forming, assembly, and finishing. Each stage incorporates specific techniques and considerations relevant to the end-user environment.

1. Material Preparation

This initial stage involves selecting high-quality materials that can withstand the rigors of outdoor and indoor environments. Common materials include:

- Steel and Aluminum: These metals are favored for their durability and resistance to wear and tear.

- Plastics: Used for internal components and touchpoints, these materials should be UV-resistant and easy to clean.

During this phase, suppliers often conduct material inspections to ensure compliance with international standards, which is critical for maintaining product integrity.

2. Forming

The forming stage involves shaping the prepared materials into the components of the vending machine. This can include:

- Cutting: Using laser cutters or CNC machines for precision.

- Bending and Welding: Techniques such as press braking or MIG welding are employed to create robust structures.

Key considerations include ensuring that the forming processes minimize waste and maintain uniformity across batches, which is particularly important for large orders.

3. Assembly

Once the components are formed, they are assembled into the final product. This stage typically involves:

- Integration of Mechanical and Electronic Systems: Ensuring seamless operation of the dispensing mechanism, payment systems, and user interfaces.

- Quality Checks: Throughout the assembly process, inspections are conducted to catch any defects early.

Automation is increasingly utilized in assembly lines to enhance efficiency and reduce human error, which is essential for maintaining a consistent quality standard.

4. Finishing

The final stage involves applying coatings, decals, and any other aesthetic elements. This not only enhances the visual appeal but also adds protective layers to combat environmental factors. Techniques such as powder coating or electroplating are commonly used to ensure durability.

Quality Assurance

Quality assurance (QA) is integral to the manufacturing of vending machines, and it encompasses various international standards and industry-specific certifications. B2B buyers should be well-versed in these to make informed purchasing decisions.

International Standards

-

ISO 9001: This standard focuses on quality management systems and is crucial for manufacturers aiming to enhance customer satisfaction through effective quality management practices. It ensures that processes are standardized and continually improved.

-

CE Marking: For machines sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards. This is especially relevant for buyers in Europe, ensuring that products meet necessary regulatory requirements.

-

API Standards: These standards apply particularly to mechanical components and ensure that the machinery operates efficiently and safely.

Quality Control Checkpoints

Quality control (QC) checkpoints are essential throughout the manufacturing process to ensure that products meet specified standards. Common checkpoints include:

- Incoming Quality Control (IQC): Inspections of raw materials upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to catch defects early.

- Final Quality Control (FQC): A thorough examination of the finished product before it is shipped to ensure it meets all quality standards.

Common Testing Methods

Various testing methods are employed to validate the performance and safety of vending machines:

- Functional Testing: Ensures that all mechanical and electronic systems operate correctly.

- Durability Testing: Simulates real-world usage to assess the machine’s resilience.

- Safety Testing: Verifies compliance with safety regulations, particularly electrical safety.

Verifying Supplier Quality Control

For international B2B buyers, verifying the quality control practices of suppliers is crucial. Here are actionable steps:

-

Conduct Supplier Audits: Regular audits help assess compliance with quality standards and identify areas for improvement. Look for manufacturers that welcome third-party audits as a sign of confidence in their processes.

-

Request Quality Reports: Suppliers should provide detailed quality reports that outline their QC processes, test results, and any certifications they hold. This transparency is essential for building trust.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and product quality. This is particularly beneficial for buyers in regions with less stringent local regulations.

QC Certification Nuances for International Buyers

When dealing with suppliers from different regions, B2B buyers should be aware of potential nuances in quality certifications. For instance:

-

Regional Regulations: Different regions may have varying standards and compliance requirements. Buyers from Africa or South America should be particularly mindful of local regulations that might affect the usability of vending machines.

-

Language and Documentation: Ensure that all quality documentation is available in a language that is easily understandable. Misinterpretation can lead to compliance issues.

-

Cultural Considerations: Understanding the business culture of suppliers can help in navigating quality expectations and establishing effective communication.

Conclusion

A comprehensive understanding of the manufacturing processes and quality assurance measures for vending machines is vital for international B2B buyers. By focusing on material selection, manufacturing techniques, and rigorous quality control practices, buyers can ensure that they source high-quality vending machines that meet the needs of college campuses. Engaging in thorough supplier evaluation and maintaining a proactive approach to quality assurance will ultimately lead to successful partnerships and satisfied end-users.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for some vending machines on college campuses Sourcing

Understanding the Cost Structure of Vending Machines

When sourcing vending machines for college campuses, it’s crucial to understand the comprehensive cost structure involved. The primary cost components include:

-

Materials: This encompasses the raw materials used in manufacturing the vending machines, such as metal, plastic, and electronic components. The choice of materials can significantly affect both durability and cost.

-

Labor: Labor costs vary by region and can be influenced by local wage standards. In countries with higher labor costs, consider suppliers that employ automation to reduce these expenses.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient operations can help minimize these costs.

-

Tooling: The investment in molds and tools necessary for production can be substantial. Customizations that require specialized tooling will increase initial costs but may offer better market differentiation.

-

Quality Control (QC): Ensuring the machines meet quality standards can incur additional costs. Implementing stringent QC processes is essential to minimize defects and maintain brand reputation.

-

Logistics: Shipping costs can vary significantly based on distance, mode of transport, and freight terms. Understanding the logistics landscape is crucial for accurate pricing.

-

Margin: Suppliers typically add a margin to cover their costs and generate profit. This can vary based on market conditions and competition.

Key Price Influencers

Several factors can influence the pricing of vending machines:

-

Volume/MOQ: Bulk purchases often lead to discounts. Understanding the Minimum Order Quantity (MOQ) can help in negotiating better prices.

-

Specifications/Customization: Machines that are customized to meet specific campus needs may incur higher costs. Balance the need for customization against budget constraints.

-

Materials: Premium materials may enhance machine durability and aesthetics but will increase costs. Evaluate the trade-offs between cost and quality.

-

Quality/Certifications: Machines that comply with international safety and quality standards may cost more upfront but can lead to long-term savings through reduced maintenance and higher user satisfaction.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) is essential as they determine who is responsible for costs and risks at various stages of the shipping process.

Buyer Tips for Cost-Efficiency

To ensure a cost-effective purchasing process, consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially if placing large orders. Leverage your position as a potential long-term partner to negotiate better terms.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, energy efficiency, and potential downtime when evaluating overall costs.

-

Pricing Nuances: Be aware that pricing may vary significantly across regions due to local economic conditions, currency fluctuations, and demand. Conduct market research to understand these nuances.

-

Supplier Diversity: Engage with multiple suppliers to compare offerings and prices. This can also provide insights into market trends and innovations.

-

Long-term Relationships: Establishing a long-term relationship with suppliers can lead to better pricing and service terms. Consider signing contracts that ensure stable pricing over time.

Disclaimer

The prices and insights provided in this analysis are indicative and can vary based on specific supplier negotiations, regional market conditions, and evolving economic factors. Always conduct thorough market research and obtain multiple quotes to ensure competitive pricing for your vending machine sourcing needs.

Spotlight on Potential some vending machines on college campuses Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘some vending machines on college campuses’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for some vending machines on college campuses

Key Technical Properties

When considering vending machines for college campuses, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some essential properties to evaluate:

-

Material Grade: The material used in vending machines significantly impacts durability and maintenance. Common materials include stainless steel, which is resistant to corrosion and easy to clean, and high-impact plastics that can withstand rough handling. For international buyers, selecting the right material ensures longevity and reduces replacement costs.

-

Energy Efficiency Rating: Vending machines equipped with energy-efficient technologies can reduce operational costs. Look for machines with ENERGY STAR certifications or similar ratings. Energy efficiency not only lowers expenses but also appeals to environmentally conscious consumers and institutions.

-

Capacity and Dimensions: The size and capacity of the vending machine are critical for meeting demand. College campuses often have high foot traffic, necessitating machines that can hold a larger inventory. Standard dimensions should be considered to ensure the machine fits designated spaces without obstructing walkways.

-

Payment Options: Modern vending machines should support multiple payment methods, including cash, credit/debit cards, and mobile payments. This flexibility is essential for catering to diverse student populations and enhancing user experience.

-

Connectivity Features: Advanced vending machines may offer connectivity options such as IoT capabilities for real-time inventory management and remote monitoring. This feature is invaluable for ensuring that popular items are always stocked, optimizing operational efficiency, and enhancing the overall service quality.

-

Temperature Control: For machines dispensing perishable items, effective temperature control is vital. Ensure that the machine maintains appropriate temperatures for food safety and quality. This is particularly important for compliance with health regulations in various regions.

Common Trade Terminology

Familiarity with industry jargon can facilitate smoother negotiations and purchasing processes. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers assess quality and reliability, as well as negotiate better pricing by sourcing directly from manufacturers.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This is particularly important for buyers in regions with varying demand, as it impacts inventory management and cash flow. Negotiating MOQs can lead to more favorable terms and lower upfront costs.

-

RFQ (Request for Quotation): An RFQ is a formal document that solicits price offers from suppliers for specific goods or services. For international buyers, issuing an RFQ can help in gathering competitive bids and ensuring transparency in pricing. It’s a critical step in the procurement process.

-

Incoterms (International Commercial Terms): These are predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is essential for clarifying who is responsible for shipping, insurance, and tariffs, minimizing potential disputes.

-

Lead Time: This refers to the time taken from placing an order to receiving the goods. For B2B buyers, understanding lead times is crucial for planning and inventory management, especially in the academic calendar where demand may fluctuate.

-

Warranty: A warranty is a guarantee from the manufacturer regarding the condition of the product and the manufacturer’s responsibility for repairs or replacements. A strong warranty can provide peace of mind for buyers, ensuring that they are covered in case of defects or malfunctions.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of vending machine procurement more effectively, ensuring they make choices that align with their operational needs and market dynamics.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the some vending machines on college campuses Sector

Market Overview & Key Trends

The vending machine sector on college campuses is experiencing notable transformations driven by several global factors. Increased health consciousness among students has led to a demand for healthier snack options, pushing vendors to diversify their offerings beyond traditional snacks and beverages. Moreover, the integration of technology into vending machines, such as cashless payment systems and IoT-enabled inventory management, is becoming a standard expectation. This trend is particularly relevant for international B2B buyers looking to enhance user experience and operational efficiency.

In regions like Africa and South America, where mobile payment systems are gaining traction, the ability to accept various payment methods is critical. Meanwhile, European countries, such as France and Germany, are witnessing an increased focus on automation and smart vending solutions that provide real-time data analytics. This capability allows institutions to optimize product offerings based on consumption patterns, reducing waste and improving profitability.

Additionally, there is a growing emphasis on local sourcing and partnerships with regional suppliers. This trend not only supports local economies but also aligns with the increasing demand for fresh, locally-produced goods among students. B2B buyers should be aware of these dynamics as they seek to establish connections with suppliers who can provide innovative, tech-savvy solutions tailored to the specific needs of campus environments.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of business strategy in the vending machine sector, particularly within college campuses. The environmental impact of vending operations, from energy consumption to waste generation, is under scrutiny. Buyers must prioritize suppliers who implement energy-efficient machines and utilize sustainable packaging materials. The adoption of eco-friendly practices not only minimizes carbon footprints but also resonates with the values of the student demographic, who increasingly favor brands committed to sustainability.

Ethical sourcing is another critical consideration for B2B buyers. Establishing supply chains that prioritize fair labor practices and responsible sourcing ensures compliance with international standards and enhances brand reputation. Certifications such as Fair Trade and organic labels are becoming essential in the decision-making process for buyers looking to align with ethical practices.

Illustrative Image (Source: Google Search)

Investing in ‘green’ certified materials for vending machines, such as recyclable plastics or sustainable wood, can significantly impact the overall environmental footprint. B2B buyers should actively seek partnerships with manufacturers that prioritize sustainability in their production processes, as this will not only fulfill corporate social responsibility goals but also attract eco-conscious consumers.

Brief Evolution/History

The vending machine industry has undergone significant changes since its inception in the early 20th century. Initially focused on dispensing simple snacks and drinks, the sector has evolved into a technology-driven marketplace that emphasizes convenience and customer experience. In recent decades, the introduction of cashless payment systems and smart technology has revolutionized how vending machines operate, particularly in educational settings.

As college campuses adapt to the needs of a tech-savvy generation, the evolution of vending machines has shifted towards more sophisticated, user-friendly solutions. This ongoing transformation presents ample opportunities for international B2B buyers to engage with innovative suppliers who are reshaping the landscape of vending services on campuses worldwide.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of some vending machines on college campuses

-

What criteria should I use to vet suppliers of vending machines for college campuses?

When vetting suppliers, consider their experience in the vending machine industry, particularly in the educational sector. Look for suppliers with a proven track record of reliability and customer satisfaction. Check for certifications that demonstrate compliance with safety and quality standards, such as ISO 9001 or CE marking. Request references from other educational institutions to gauge their performance. Finally, assess their capacity to provide ongoing support and maintenance services, which is crucial for long-term partnerships. -

Can vending machines be customized to meet specific needs?

Yes, many suppliers offer customization options for vending machines to cater to the unique preferences of college campuses. You can customize product selections, branding elements, and payment systems (including mobile payment options). It’s essential to communicate your specific needs during the procurement process. Ensure that the supplier has experience with customization projects and can provide examples of previous work. This will help you understand the potential for aligning the machines with your institution’s branding and student preferences. -

What are the typical minimum order quantities (MOQ) and lead times for vending machines?

Minimum order quantities can vary widely by supplier and machine type, but generally, expect MOQs of 10 to 50 units for bulk orders. Lead times typically range from 4 to 12 weeks, depending on customization and production schedules. It is advisable to discuss your requirements early in the negotiation process to avoid delays. Additionally, inquire about the supplier’s capacity to handle urgent orders, especially if you are working with tight timelines for installation on campus. -

What payment terms should I expect when sourcing vending machines internationally?

Payment terms can differ significantly based on the supplier and your geographic location. Common arrangements include a deposit upfront (usually 30-50%) with the balance due upon delivery or installation. For international transactions, consider utilizing letters of credit or escrow services to mitigate risk. Ensure that the payment terms are clearly outlined in the contract, including any provisions for currency fluctuations and transaction fees, which can impact the overall cost. -

How can I ensure quality assurance and compliance with certifications?

To ensure quality assurance, verify that the supplier adheres to international quality standards. Request copies of relevant certifications, such as ISO or safety compliance certifications. Conduct a factory audit if possible, or ask for third-party inspection reports before shipment. Additionally, inquire about the supplier’s warranty policy and post-sale support to ensure that any potential issues can be resolved quickly. Establishing clear quality expectations in the contract will also provide a basis for accountability. -

What logistics considerations should I keep in mind when importing vending machines?

Logistics is a critical factor when importing vending machines. Assess the supplier’s experience with international shipping, including handling customs clearance and local regulations. Work with logistics partners who specialize in transporting large equipment to minimize delays. Consider the cost implications of shipping, insurance, and potential tariffs. Also, plan for installation logistics on campus, including any necessary infrastructure or electrical requirements, to ensure a smooth deployment. -

What steps should I take in case of disputes with a supplier?

To effectively manage disputes, establish a clear dispute resolution process in your contract, including mediation or arbitration clauses. Keep detailed records of all communications and transactions with the supplier. If a dispute arises, attempt to resolve it amicably through direct communication first. Should this fail, engage a third-party mediator or arbitrator familiar with international trade laws. Understanding the legal frameworks governing your contracts will also empower you to act decisively in protecting your interests. -

How can I stay updated on market trends and innovations in vending machines?

Staying informed about market trends requires a proactive approach. Subscribe to industry publications and attend trade shows or conferences focused on vending and retail technology. Join relevant professional associations or online forums where industry experts share insights and best practices. Networking with other B2B buyers and suppliers can also provide valuable information on emerging technologies, consumer preferences, and competitive products that can enhance your offering on college campuses.

Strategic Sourcing Conclusion and Outlook for some vending machines on college campuses

In conclusion, strategic sourcing for vending machines on college campuses presents a unique opportunity for international B2B buyers to tap into a growing market. By prioritizing supplier partnerships that emphasize quality, sustainability, and innovation, organizations can enhance their product offerings while meeting the evolving needs of students.

Key takeaways include:

- Market Awareness: Understanding regional preferences and dietary trends is crucial. For instance, offering healthier snack options can significantly increase vending machine usage among health-conscious students.

- Technology Integration: Leveraging smart vending technology can streamline operations and provide valuable data analytics, enhancing inventory management and customer experience.

- Sustainability Practices: Sourcing from suppliers who prioritize eco-friendly products will not only align with global sustainability goals but also attract environmentally conscious consumers.

As we look to the future, international B2B buyers are encouraged to adopt a forward-thinking approach in their sourcing strategies. By embracing innovation and sustainability, companies can not only improve their competitive edge but also contribute positively to the communities they serve. Engage with local suppliers and explore collaborative opportunities to maximize your impact in the vibrant college marketplace.

Illustrative Image (Source: Google Search)