Your Ultimate Guide to Sourcing Shoe Vending Machine

Guide to Shoe Vending Machine

- Introduction: Navigating the Global Market for shoe vending machine

- Understanding shoe vending machine Types and Variations

- Key Industrial Applications of shoe vending machine

- Strategic Material Selection Guide for shoe vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for shoe vending machine

- Comprehensive Cost and Pricing Analysis for shoe vending machine Sourcing

- Spotlight on Potential shoe vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for shoe vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the shoe vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of shoe vending machine

- Strategic Sourcing Conclusion and Outlook for shoe vending machine

Introduction: Navigating the Global Market for shoe vending machine

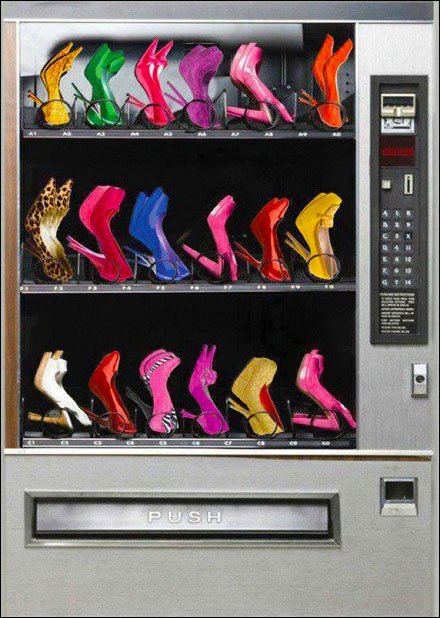

In today’s fast-paced retail environment, shoe vending machines are revolutionizing the way consumers access footwear. These automated retail solutions offer convenience, speed, and a unique shopping experience, making them increasingly vital for businesses aiming to capture the attention of on-the-go customers. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the market dynamics and sourcing strategies associated with shoe vending machines is essential for informed decision-making.

This comprehensive guide covers everything you need to know about shoe vending machines, including various types available in the market, the materials used in their construction, and the manufacturing and quality control processes that ensure reliability and durability. We will also delve into the profiles of reputable suppliers, analyze cost structures, and explore the market trends shaping the future of automated footwear retail.

Equipped with this knowledge, B2B buyers can confidently navigate the complexities of sourcing shoe vending machines. Whether you’re looking to enhance your retail offering or expand into new markets, this guide empowers you with actionable insights and answers to frequently asked questions. By leveraging the information provided, businesses can make strategic decisions that align with their operational goals and consumer demands, ultimately enhancing their competitive edge in the global marketplace.

Understanding shoe vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Shoe Vending | Mechanical dispensing, coin-operated | Retail stores, airports | Pros: Simple operation, low maintenance. Cons: Limited payment options, slower transaction times. |

| Smart Shoe Vending | Digital interface, cashless payments, app integration | Shopping malls, gyms | Pros: Enhanced user experience, data analytics. Cons: Higher initial investment, reliance on technology. |

| Customizable Shoe Vending | Modular design, customizable branding | Events, pop-up shops | Pros: Flexible marketing, unique customer engagement. Cons: Potentially higher costs for customization. |

| Eco-Friendly Shoe Vending | Made from sustainable materials, energy-efficient | Eco-conscious brands, festivals | Pros: Attracts eco-minded consumers, aligns with CSR goals. Cons: May have limited stock options. |

| High-End Luxury Vending | Premium products, enhanced security features | Luxury retail, airports | Pros: Targets affluent consumers, exclusive offerings. Cons: High operational costs, niche market appeal. |

Traditional Shoe Vending

Traditional shoe vending machines are characterized by their mechanical dispensing systems and coin-operated functionalities. They are commonly found in retail environments such as convenience stores and airports, providing a straightforward solution for customers needing footwear on-the-go. From a B2B perspective, these machines are attractive due to their simplicity and low maintenance requirements. However, their limitations in payment options and slower transaction speeds may deter some buyers seeking a more modern solution.

Smart Shoe Vending

Smart shoe vending machines integrate digital interfaces and cashless payment options, often allowing transactions via mobile apps. These machines are increasingly popular in shopping malls and gyms, offering an enhanced user experience through personalized marketing and data collection. For B2B buyers, the investment in smart vending machines can yield significant returns through improved customer engagement and operational efficiency, though the higher upfront costs and reliance on technology can be a consideration.

Customizable Shoe Vending

Customizable shoe vending machines feature a modular design that allows for branding and product selection tailored to specific events or locations. Ideal for pop-up shops or events, these machines can create unique customer experiences that stand out in a crowded marketplace. B2B buyers should consider the flexibility these machines offer for marketing purposes, although customization can lead to higher costs that may affect budget constraints.

Eco-Friendly Shoe Vending

Eco-friendly shoe vending machines are constructed from sustainable materials and designed for energy efficiency. They cater to businesses aiming to appeal to environmentally conscious consumers, particularly at festivals or eco-centric events. While these machines can enhance a brand’s corporate social responsibility (CSR) profile, buyers should be aware that they may offer a limited selection of stock, which could affect sales performance.

High-End Luxury Vending

High-end luxury vending machines focus on offering premium products with advanced security features, often found in luxury retail spaces or airports. These machines target affluent consumers seeking exclusive footwear options. For B2B buyers, investing in luxury vending machines can elevate brand perception and attract high-value customers. However, the operational costs associated with maintaining such machines and the niche market appeal should be carefully evaluated before purchase.

Related Video: Machine Learning in 2024 – Beginner’s Course

Key Industrial Applications of shoe vending machine

| Industry/Sector | Specific Application of Shoe Vending Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Shopping Malls and Retail Stores | Increased foot traffic, 24/7 availability, and convenience | Machine durability, payment processing options, and product range |

| Sports & Fitness | Gyms and Sports Complexes | Quick access to footwear for workouts and events | Size and type of shoes offered, machine size, and maintenance support |

| Transportation | Airports and Train Stations | Immediate shoe replacement for travelers in need | Security features, payment methods, and product variety |

| Education | Universities and Colleges | Easy access to footwear for students and staff | Custom branding options, machine capacity, and service agreements |

| Events & Festivals | Concerts, Festivals, and Trade Shows | On-the-go shoe sales for attendees | Flexibility in product offerings, machine mobility, and payment options |

Retail

In retail environments such as shopping malls and stores, shoe vending machines offer a unique solution by providing customers with immediate access to footwear. This caters to spontaneous purchases and enhances the shopping experience by offering convenience, especially for shoppers who may need a quick change. For international buyers, considerations should include the durability of the machine in high-traffic areas, various payment processing options to accommodate diverse customer preferences, and a wide range of shoe styles to attract different demographics.

Sports & Fitness

In gyms and sports complexes, shoe vending machines serve athletes and fitness enthusiasts by offering immediate access to specialized footwear. This application solves the problem of inadequate footwear during workouts or events, ensuring that users have the right shoes for performance. Buyers from regions like South Africa or Brazil should focus on the variety of shoe sizes and types available, as well as the machine’s size and maintenance support to ensure it meets the demands of busy facilities.

Transportation

Airports and train stations benefit significantly from shoe vending machines by providing travelers with quick shoe replacements. This is particularly useful for those who may have experienced discomfort during travel or need suitable footwear for their destination. For international buyers, key sourcing considerations include robust security features to protect against theft, flexible payment methods that cater to a diverse clientele, and a variety of shoe options to accommodate different travel needs.

Education

Universities and colleges can utilize shoe vending machines to provide students and staff with easy access to footwear. This application is especially beneficial during events or sports days when individuals may need to change shoes quickly. Buyers in the educational sector should consider custom branding options for the vending machines, ensuring that they align with the institution’s identity, alongside machine capacity and potential service agreements for maintenance and support.

Events & Festivals

At concerts, festivals, and trade shows, shoe vending machines offer a practical solution for attendees needing on-the-go footwear. This application enhances the visitor experience by providing quick access to shoes that match their needs, whether for comfort or style. International buyers should focus on the flexibility of product offerings to cater to diverse crowds, the mobility of the machines for easy relocation, and various payment options to ensure a seamless transaction experience.

Related Video: DIY Vending Machine – Arduino based Mechatronics Project

Strategic Material Selection Guide for shoe vending machine

When selecting materials for shoe vending machines, it is crucial to consider various properties that affect performance, durability, and overall cost. Below are analyses of four common materials used in the construction of shoe vending machines, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high tensile strength, and ability to withstand a wide range of temperatures. It typically has a temperature rating up to 800°F (427°C) and can endure high-pressure environments.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust, making it suitable for outdoor or humid environments. However, it is more expensive than other materials and can be challenging to manufacture due to its hardness, which may increase production costs.

Impact on Application: Stainless steel is ideal for components exposed to moisture or corrosive substances, ensuring longevity and reliability in various climates.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A240 for stainless steel products. In regions like Europe and the Middle East, stainless steel grades must meet specific corrosion resistance requirements.

2. High-Density Polyethylene (HDPE)

Key Properties: HDPE is a lightweight, flexible plastic with good impact resistance and a temperature rating of around 120°F (49°C). It is also resistant to a variety of chemicals and UV radiation.

Pros & Cons: The advantages of HDPE include its low cost and ease of manufacturing, allowing for complex shapes and designs. However, it may not be as durable as metals and can deform under high temperatures or heavy loads.

Impact on Application: HDPE is suitable for non-structural components of vending machines, such as internal trays or covers, where weight savings are essential.

Considerations for International Buyers: Buyers should check for compliance with regulations regarding plastic materials, especially in Europe, where restrictions on certain chemicals in plastics are stringent.

3. Aluminum

Key Properties: Aluminum offers a good balance of strength and weight, with a temperature rating of up to 400°F (204°C). It is also resistant to corrosion when anodized.

Pros & Cons: The key advantage of aluminum is its lightweight nature, which simplifies transport and installation. However, it can be more expensive than other non-metal alternatives and may require protective coatings to enhance its corrosion resistance.

Impact on Application: Aluminum is often used for structural components and exterior panels of vending machines, providing a sleek appearance while reducing overall weight.

Considerations for International Buyers: Compliance with standards such as ASTM B221 for aluminum extrusions is essential. Buyers should also consider the environmental impact of aluminum production and recycling options available in their region.

4. Mild Steel

Key Properties: Mild steel is known for its excellent strength and weldability, with a temperature rating of around 300°F (149°C). However, it is susceptible to corrosion if not properly coated.

Pros & Cons: The main advantage of mild steel is its low cost and ease of machining, making it a popular choice for structural components. The downside is its vulnerability to rust, which necessitates protective coatings or regular maintenance.

Impact on Application: Mild steel is often used for the frame and internal structures of vending machines, where strength is critical, and exposure to harsh environments is limited.

Considerations for International Buyers: Buyers must ensure that mild steel products meet relevant standards, such as ASTM A36. In regions like Africa and South America, where humidity levels can be high, additional protective measures may be necessary.

Summary Table

| Material | Typical Use Case for shoe vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Exterior panels, structural components | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| High-Density Polyethylene (HDPE) | Internal trays, non-structural components | Low cost and easy to manufacture | Less durable under heavy loads | Low |

| Aluminum | Structural components, exterior panels | Lightweight and corrosion-resistant | Higher cost and potential need for coatings | Medium |

| Mild Steel | Frame and internal structures | Low cost and good strength | Susceptible to corrosion without protection | Low |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions based on performance, cost, and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for shoe vending machine

The manufacturing process of shoe vending machines is a complex interplay of technology, engineering, and quality control. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these processes is crucial for ensuring they select reliable suppliers and high-quality products.

Manufacturing Processes

1. Material Preparation

The first stage in manufacturing a shoe vending machine involves sourcing and preparing materials. This typically includes:

- Metal Components: Steel or aluminum is often used for the frame due to its strength and durability. Suppliers should provide certifications for the materials used, ensuring they meet international standards.

- Plastic Parts: High-density polyethylene (HDPE) or polycarbonate is used for the external casing. Buyers should verify the quality of these plastics to ensure resistance to wear and environmental conditions.

- Electronic Components: This includes payment systems (like card readers), sensors, and displays. It’s essential to source from reputable manufacturers with proven reliability.

2. Forming

In this stage, materials are shaped and molded into the components of the vending machine. Key techniques include:

- CNC Machining: This technology allows for precise cutting and shaping of metal parts, ensuring they fit together seamlessly.

- Injection Molding: Used for plastic components, this process creates uniform shapes and sizes, crucial for aesthetic and functional consistency.

- Laser Cutting: This method is often used for intricate designs and ensures high precision, especially for the machine’s interface and branding.

3. Assembly

The assembly phase is where the machine comes together. This includes:

- Sub-Assembly: Components like the payment system, control panel, and storage compartments are assembled separately before being integrated into the main body.

- Main Assembly: All sub-assemblies are combined, with careful attention to wiring and connections for electronic components.

- Integration Testing: Initial tests are conducted to ensure that all systems work together properly before final assembly.

4. Finishing

The final stage of manufacturing involves:

- Surface Treatment: Processes such as powder coating or painting enhance durability and aesthetics. Buyers should inquire about the types of treatments used, as this impacts the machine’s lifespan.

- Quality Checks: Before the machines are packaged and shipped, they undergo rigorous testing to ensure they meet performance standards.

Quality Assurance

International Standards

For B2B buyers, compliance with international quality standards is essential. Key certifications to look for include:

- ISO 9001: This standard ensures that the manufacturing processes meet consistent quality management principles.

- CE Marking: Required in Europe, it indicates that the product complies with EU safety, health, and environmental protection legislation.

- API Standards: Particularly relevant for electronic components, ensuring they meet performance and safety requirements.

Quality Control Checkpoints

Quality control (QC) is a critical aspect of the manufacturing process, involving various checkpoints:

- Incoming Quality Control (IQC): This initial stage checks the quality of raw materials before they enter the manufacturing process. Buyers should request IQC reports to ensure materials meet their specifications.

- In-Process Quality Control (IPQC): During manufacturing, random samples are tested to monitor quality throughout the assembly process. B2B buyers can ask for IPQC documentation to verify these checks.

- Final Quality Control (FQC): Before shipping, machines undergo comprehensive testing to ensure they meet functional and safety standards. Buyers should request FQC results as part of their procurement process.

Common Testing Methods

Several testing methods are employed to ensure the quality of shoe vending machines:

- Functional Testing: Verifying that all electronic components work as intended, including payment systems and user interfaces.

- Durability Testing: Simulating long-term use to ensure that the machine can withstand wear and tear.

- Safety Testing: Ensuring that all components comply with safety standards to prevent hazards during operation.

Verifying Supplier Quality Control

For international B2B buyers, verifying the quality control processes of suppliers is paramount. Here are actionable insights:

- Supplier Audits: Conducting regular audits of suppliers helps ensure compliance with quality standards. This could involve on-site visits or third-party inspections.

- Quality Reports: Request detailed quality reports that outline testing methods and results. This transparency builds trust and confidence in the supplier’s capabilities.

- Third-Party Inspections: Engaging third-party inspection agencies can provide unbiased assessments of the manufacturing process and product quality.

Quality Control Nuances for International Buyers

Buyers from different regions may encounter unique challenges in quality assurance:

- Cultural Differences: Understanding local manufacturing practices and quality perceptions is crucial. For example, quality expectations may differ between European and African suppliers.

- Regulatory Compliance: Buyers must ensure that products comply with local regulations in their respective markets, which may require additional certifications or testing.

- Supply Chain Transparency: With complex supply chains, buyers should seek suppliers who maintain transparency about their sourcing and manufacturing practices.

By understanding the manufacturing processes and quality assurance practices associated with shoe vending machines, B2B buyers can make informed decisions that align with their operational needs and quality expectations. This knowledge not only enhances procurement effectiveness but also fosters long-term partnerships with reliable suppliers.

Related Video: “Plastic Slipper Manufacturing Process 🏭 | Factory Production Explained|#@HeavenMakingProcess

Comprehensive Cost and Pricing Analysis for shoe vending machine Sourcing

When sourcing shoe vending machines, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis will cover the key cost components, price influencers, and provide actionable insights for buyers, particularly those from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary cost driver, materials can include metals, plastics, electronic components, and display screens. Quality and sourcing location significantly impact prices. For instance, sourcing from local suppliers may reduce costs compared to importing materials.

-

Labor: Labor costs vary widely based on geographical location and local wage standards. In countries with lower labor costs, such as those in parts of Africa and South America, manufacturers can offer competitive pricing. However, consider potential quality differences when labor costs are low.

-

Manufacturing Overhead: This includes factory rent, utilities, equipment depreciation, and administrative expenses. Buyers should inquire about the overhead rate applied by manufacturers, as it can affect overall pricing.

-

Tooling: Initial tooling costs can be substantial, especially for customized machines. Buyers should assess whether the supplier includes tooling costs in the quoted price or if these are extra, as this can significantly influence the total cost.

-

Quality Control (QC): Implementing robust QC processes incurs costs but is essential for ensuring product reliability. Suppliers with stringent QC processes may charge higher prices, but this can lead to reduced long-term costs due to fewer defects and returns.

Illustrative Image (Source: Google Search)

-

Logistics: Shipping and handling costs can vary significantly based on the destination, shipping method, and Incoterms. International buyers should consider these costs when evaluating total pricing.

-

Margin: Suppliers will typically add a markup to cover their costs and desired profit margin. Understanding the typical industry margin can help buyers gauge if a price is fair.

Price Influencers

Several factors influence the pricing of shoe vending machines:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) to maximize cost efficiency.

-

Specifications/Customization: Custom features can increase both the base price and the tooling costs. Buyers should clearly define their specifications to avoid unexpected costs.

-

Materials: The choice of materials (e.g., standard vs. high-quality components) can affect both initial costs and long-term durability.

-

Quality/Certifications: Machines that meet international standards or possess certain certifications may command higher prices but ensure compliance and reliability, which can reduce liability risks.

-

Supplier Factors: The supplier’s reputation, experience, and location can impact pricing. Established suppliers may charge more due to their reliability and service quality.

-

Incoterms: The chosen Incoterms will determine who bears the cost and risk at various points during shipping. This can significantly affect the total landed cost for international buyers.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers about pricing structures. Understanding their cost components can provide leverage in negotiations.

-

Cost-Efficiency: Consider the total cost of ownership (TCO) rather than just the initial purchase price. Factors like maintenance, energy consumption, and potential downtime should be factored into the decision-making process.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, prices may vary significantly between Europe and Africa due to differences in logistics and material availability.

-

Local Partnerships: Forming partnerships with local distributors can reduce logistics costs and improve service levels. This is particularly beneficial in regions with challenging supply chains.

-

Market Research: Conduct thorough market research to understand prevailing prices and industry standards. This will empower buyers to make informed decisions and avoid overpaying.

Disclaimer

Prices mentioned in discussions and negotiations are indicative and subject to change based on market conditions, currency fluctuations, and evolving supplier capabilities. Always seek updated quotes and detailed breakdowns from suppliers to ensure clarity and budget alignment.

Spotlight on Potential shoe vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘shoe vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for shoe vending machine

Critical Technical Properties of Shoe Vending Machines

-

Material Grade

– The material used in the construction of shoe vending machines typically includes high-grade steel or aluminum for durability and resistance to vandalism. This is crucial for machines located in high-traffic public areas, ensuring longevity and reduced maintenance costs. -

Capacity

– Capacity refers to the number of shoes the vending machine can hold at one time. A typical machine might accommodate between 30 to 100 pairs, depending on the design. Higher capacity machines can cater to larger crowds, making them ideal for events or busy urban locations.

Illustrative Image (Source: Google Search)

-

Temperature Tolerance

– Shoe vending machines should be designed to operate within a specific temperature range, often between -10°C to 50°C. This tolerance is important for maintaining the integrity of the footwear, especially in regions with extreme weather conditions. -

Power Supply Options

– Vending machines may operate on standard AC power or solar energy. Offering both options can enhance flexibility in deployment, particularly in remote areas where electricity may be unreliable. -

User Interface Technology

– The interface includes touchscreen displays and payment systems (credit card, mobile payment). A user-friendly interface is essential for a positive customer experience, encouraging repeat use and enhancing sales. -

Security Features

– Integrated security systems such as tamper-proof locks and surveillance cameras are vital. These features protect the machine’s contents and deter theft, making the investment more secure for business owners.

Common Trade Terminology in the Shoe Vending Machine Industry

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that manufacture products based on specifications provided by another company. In the context of shoe vending machines, buyers may source machines from OEMs that can customize features to meet specific market demands, ensuring a competitive edge. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory effectively and negotiate better pricing, particularly when launching new products. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting a price quote for specific products or services. This process is crucial for buyers to gather competitive pricing data, which aids in budget planning and supplier selection. -

Incoterms (International Commercial Terms)

– These are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers. Familiarity with Incoterms is vital for international transactions, as they define aspects such as delivery responsibilities and risk management during shipping. -

Lead Time

– Lead time refers to the time taken from placing an order to its delivery. For B2B buyers, understanding lead times helps in planning stock levels and meeting customer demand without delays, which is particularly important in fast-paced markets. -

Warranty

– A warranty is a guarantee provided by the manufacturer regarding the condition of the machine. Knowing the warranty terms is essential for B2B buyers to assess the risk of potential failures and associated costs in maintenance or replacement.

Understanding these technical properties and trade terminologies is essential for B2B buyers in the shoe vending machine market. This knowledge not only aids in making informed purchasing decisions but also helps in navigating the complexities of international trade, ultimately leading to successful business operations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the shoe vending machine Sector

Market Overview & Key Trends

The shoe vending machine sector is experiencing significant transformation, driven by the convergence of technology, consumer behavior, and urbanization. Global drivers such as increasing urban populations and the demand for convenience are propelling the growth of vending solutions, particularly in high-traffic areas like airports, malls, and public transit stations. In regions such as Africa and South America, the rise of e-commerce and mobile payment systems is influencing how businesses approach sourcing and distribution, making vending machines a viable option for rapid market penetration.

Current and emerging B2B tech trends include the integration of IoT technology for real-time inventory management and data analytics to understand consumer preferences. This technology allows operators to optimize product offerings based on regional demand, which is particularly beneficial for international buyers looking to cater to diverse markets. Furthermore, the shift towards cashless transactions is reshaping the vending landscape, with contactless payment options becoming standard.

Market dynamics are also influenced by sustainability concerns. As global awareness of environmental issues grows, companies are seeking suppliers who prioritize eco-friendly practices. This trend is particularly pronounced in Europe and the Middle East, where regulations and consumer expectations are driving businesses to adopt greener operational models. For B2B buyers, understanding these dynamics is crucial for strategic sourcing and staying competitive in an evolving marketplace.

Sustainability & Ethical Sourcing in B2B

Incorporating sustainability into the shoe vending machine sector is not merely a trend but a necessity for long-term viability. The environmental impact of traditional manufacturing and supply chains can be substantial, leading to increased scrutiny from consumers and regulators alike. B2B buyers must prioritize partnerships with manufacturers who are committed to reducing their carbon footprint through energy-efficient production methods and sustainable material sourcing.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly evaluating their suppliers based on their labor practices, sourcing materials responsibly, and ensuring fair treatment of workers. This is particularly relevant for international buyers from Africa and South America, where local labor laws and practices may vary significantly.

Green certifications and the use of sustainable materials in the production of vending machines and the shoes they dispense are becoming essential factors in sourcing decisions. Buyers should look for vendors who utilize recycled materials or offer products certified by recognized sustainability standards, as these attributes not only enhance brand reputation but also align with the growing consumer preference for environmentally conscious products.

Brief Evolution/History

The evolution of the shoe vending machine sector can be traced back to the early 2000s when vending machines primarily offered snacks and beverages. With advances in technology, the concept expanded to include more diverse products, including footwear. The introduction of smart vending machines, equipped with touchscreen interfaces and mobile payment options, marked a significant shift towards consumer-centric solutions.

As urbanization increased and lifestyles became more fast-paced, the demand for convenient, on-the-go shopping options grew. This led to the proliferation of shoe vending machines in strategic locations, catering to both impulse buyers and those in need of quick replacements. Today, the sector is not only about convenience but also about providing tailored experiences that align with sustainability and ethical practices, reflecting broader societal shifts towards responsible consumption.

In conclusion, international B2B buyers must remain attuned to these trends and dynamics to effectively navigate the evolving shoe vending machine market, ensuring that their sourcing strategies align with consumer expectations and sustainability goals.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of shoe vending machine

-

What should I consider when vetting suppliers for shoe vending machines?

When vetting suppliers, prioritize their experience in the vending machine industry, particularly with shoe vending machines. Check for customer reviews and case studies that showcase their product quality and reliability. Ensure they have a solid track record of fulfilling orders on time. Evaluate their certifications, such as ISO or CE, which indicate adherence to international quality standards. Additionally, consider their ability to provide after-sales support and maintenance services, as this can significantly impact your operational efficiency. -

Can I customize the shoe vending machines to fit my brand?

Yes, many manufacturers offer customization options for shoe vending machines. You can request specific branding, color schemes, and even unique features tailored to your market’s preferences. Discuss your customization needs upfront with potential suppliers, as this may affect lead times and costs. Ensure that any modifications maintain compliance with safety and operational standards, as failure to do so could result in regulatory issues. -

What is the minimum order quantity (MOQ) for shoe vending machines, and how long is the lead time?

MOQs for shoe vending machines can vary significantly by supplier and the complexity of the order. Generally, you might expect MOQs ranging from 5 to 50 units. Lead times also differ based on production capacity, customization requirements, and shipping logistics. Standard lead times can range from 4 to 12 weeks. Always confirm these details in advance to align your procurement strategy with your business needs. -

What payment methods are typically accepted by suppliers?

Payment methods can vary by supplier, but common options include wire transfers, letters of credit, and online payment platforms. For international transactions, using a letter of credit may provide added security, as it guarantees payment upon meeting specific conditions. Always clarify payment terms, including deposits and payment schedules, before finalizing the order to avoid any misunderstandings. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers of shoe vending machines should implement rigorous quality assurance (QA) processes. This includes inspections at various production stages, testing of final products, and adherence to international quality standards. Request documentation of their QA protocols and any certifications that demonstrate their commitment to quality. Additionally, inquire about their warranty and return policy, which can provide further assurance regarding product reliability. -

How do logistics and shipping work for international orders of shoe vending machines?

Logistics for international orders typically involve coordination between the supplier and a freight forwarder. Suppliers should provide options for shipping methods, such as sea freight or air freight, depending on your urgency and budget. It’s essential to discuss responsibilities for customs clearance and duties upfront. Ensure you receive a detailed shipping timeline and track the shipment to avoid delays upon arrival at your destination. -

What steps should I take if there is a dispute with my supplier?

In the event of a dispute, first, attempt to resolve the issue directly with the supplier through clear communication. Document all correspondences and agreements. If a resolution cannot be reached, refer to the terms outlined in your contract, which may include mediation or arbitration clauses. Be aware of the legal framework governing international trade in your agreement, as this can affect your options for dispute resolution. -

What certifications should I look for in shoe vending machines?

When sourcing shoe vending machines, look for certifications that ensure compliance with safety and operational standards. Common certifications include CE (Conformité Européenne) for European markets, ISO (International Organization for Standardization) for quality management systems, and RoHS (Restriction of Hazardous Substances) for environmental compliance. These certifications indicate that the machines meet specific regulatory requirements and can enhance your credibility when marketing them in your region.

Strategic Sourcing Conclusion and Outlook for shoe vending machine

In conclusion, the strategic sourcing of shoe vending machines presents an array of opportunities for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. By leveraging data-driven insights and understanding regional market dynamics, businesses can make informed decisions that optimize supply chain efficiencies and enhance customer experiences.

Key takeaways include the importance of selecting reliable suppliers, understanding local consumer preferences, and integrating advanced technology for seamless operations. Additionally, fostering strong relationships with vendors can lead to better pricing strategies and enhanced service support.

As the demand for innovative retail solutions continues to grow, investing in shoe vending machines can position your business at the forefront of the retail evolution. Looking ahead, it is essential for B2B buyers to stay agile and responsive to market trends while exploring collaborations that align with their strategic objectives.

Take action today—assess your sourcing strategies and engage with suppliers who share your vision for growth and innovation. Together, we can redefine retail experiences and meet the evolving needs of consumers across diverse markets.