Your Ultimate Guide to Sourcing Seaga Sm16Sb Small Snack

Guide to Seaga Sm16Sb Small Snack Vending Machine

- Introduction: Navigating the Global Market for seaga sm16sb small snack vending machine

- Understanding seaga sm16sb small snack vending machine Types and Variations

- Key Industrial Applications of seaga sm16sb small snack vending machine

- Strategic Material Selection Guide for seaga sm16sb small snack vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for seaga sm16sb small snack vending machine

- Comprehensive Cost and Pricing Analysis for seaga sm16sb small snack vending machine Sourcing

- Spotlight on Potential seaga sm16sb small snack vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for seaga sm16sb small snack vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the seaga sm16sb small snack vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of seaga sm16sb small snack vending machine

- Strategic Sourcing Conclusion and Outlook for seaga sm16sb small snack vending machine

Introduction: Navigating the Global Market for seaga sm16sb small snack vending machine

The global demand for convenient and accessible snack options has surged, making the Seaga SM16SB Small Snack Vending Machine an essential asset for businesses looking to capitalize on this trend. This compact vending solution not only meets the growing consumer preference for on-the-go snacks but also presents a lucrative opportunity for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe.

This comprehensive guide will delve into the multifaceted aspects of the Seaga SM16SB, covering critical factors such as various types available, materials used in manufacturing, quality control processes, leading suppliers, cost considerations, and market insights. Additionally, it will address frequently asked questions to further empower buyers in their decision-making journey.

Understanding these elements is vital for international B2B buyers, as they navigate the complexities of sourcing vending machines tailored to their specific market needs. Whether you are in Mexico seeking to enhance your retail offerings or in Saudi Arabia aiming to diversify your snack distribution channels, this guide equips you with the knowledge to make informed purchasing decisions. By leveraging the insights provided, buyers can ensure they select the best vending solutions that not only meet consumer demands but also align with their business objectives.

Understanding seaga sm16sb small snack vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Configuration | Holds a variety of snacks, adjustable shelving | Offices, break rooms, schools | Pros: Versatile, easy to stock; Cons: Limited to standard snack sizes. |

| Healthy Snack Variant | Focuses on healthier options, organic choices | Gyms, health clubs, schools | Pros: Appeals to health-conscious consumers; Cons: Higher cost per item. |

| Cold Beverage Combo | Combines snacks with chilled beverages | Cafes, convenience stores | Pros: Increases sales opportunities; Cons: Requires additional maintenance. |

| Custom Branding Edition | Allows for personalized branding and graphics | Corporate offices, events | Pros: Enhances brand visibility; Cons: Higher initial investment. |

| Multi-Product Carousel | Rotating shelves for diverse product offerings | Airports, train stations | Pros: Maximizes product visibility; Cons: More complex to manage inventory. |

Standard Configuration

The Standard Configuration of the Seaga SM16SB vending machine is designed to accommodate a wide range of popular snacks. This model is particularly suitable for environments like offices, break rooms, and schools, where convenience is key. When purchasing, buyers should consider the machine’s capacity, ease of restocking, and the variety of snacks it can hold. While it offers versatility and is generally easy to maintain, it may not cater to specialized dietary preferences.

Healthy Snack Variant

For businesses targeting health-conscious consumers, the Healthy Snack Variant is an ideal choice. This version emphasizes organic and nutritious snack options, making it perfect for gyms, health clubs, and schools promoting wellness. Buyers should evaluate the range of products offered and the machine’s ability to keep items fresh. Although it appeals to a growing market segment, the higher cost of healthier snacks can be a drawback for some buyers.

Cold Beverage Combo

The Cold Beverage Combo vending machine integrates snacks with chilled beverages, making it a popular choice for cafes and convenience stores. This configuration not only enhances sales opportunities but also provides a comprehensive offering for customers on-the-go. Buyers should consider the additional maintenance required for cooling systems and the potential for increased energy costs. Despite these considerations, the convenience and variety offered can significantly boost customer satisfaction.

Custom Branding Edition

The Custom Branding Edition allows businesses to personalize their vending machines with specific branding and graphics. This is particularly beneficial for corporate offices and event venues looking to enhance brand visibility. When considering this option, buyers should assess the initial investment required for customization and the impact on marketing strategies. While the branding potential is a significant advantage, it may lead to higher upfront costs.

Multi-Product Carousel

The Multi-Product Carousel features rotating shelves that allow for a diverse array of product offerings. This machine is particularly effective in high-traffic areas like airports and train stations, where maximizing product visibility can drive sales. Buyers should focus on the complexity of inventory management and the potential need for more frequent restocking. While it offers a dynamic display and attracts attention, the operational intricacies may require additional training for staff.

Related Video: Machine Learning in 2024 – Beginner’s Course

Key Industrial Applications of seaga sm16sb small snack vending machine

| Industry/Sector | Specific Application of seaga sm16sb small snack vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Corporate Offices | Employee break rooms | Enhances employee satisfaction and productivity | Size constraints, product variety, payment options |

| Educational Institutions | Cafeterias and student lounges | Provides convenient access to snacks for students | Durability, energy efficiency, and product selection |

| Healthcare Facilities | Waiting rooms and staff lounges | Improves patient and staff comfort with on-site snacks | Hygiene standards, ease of cleaning, and reliable operation |

| Transportation Hubs | Airports and train stations | Offers travelers quick snack options | Security compliance, payment systems, and product freshness |

| Retail Environments | Shopping malls and retail stores | Increases impulse purchases and customer satisfaction | Location strategy, inventory management, and customer preferences |

Corporate Offices

In corporate settings, the Seaga SM16SB small snack vending machine is strategically placed in break rooms to provide employees with quick and convenient access to snacks. This not only enhances employee satisfaction but also boosts productivity by minimizing downtime during breaks. International buyers should consider the machine’s size to fit available space, the variety of snacks it can hold, and the payment options it supports, especially in regions like Africa and South America where cash transactions may be more common.

Educational Institutions

The vending machine serves as an essential amenity in educational institutions, particularly in cafeterias and student lounges, where it caters to the snacking needs of students. This convenience can significantly improve the overall campus experience by providing easy access to refreshments. Buyers in this sector should focus on the machine’s durability and energy efficiency, as well as the range of healthy snack options to meet the growing demand for nutritious choices among students in Europe and the Middle East.

Healthcare Facilities

In healthcare environments, the Seaga SM16SB vending machine can be placed in waiting rooms and staff lounges, offering snacks to patients and healthcare workers. This accessibility helps improve comfort during waiting times and provides staff with quick meal options. Buyers should prioritize hygiene standards, ease of cleaning, and the reliability of the machine’s operation to ensure it meets the stringent requirements of healthcare settings, particularly in countries with strict health regulations.

Transportation Hubs

Transportation hubs, such as airports and train stations, benefit from the presence of the Seaga SM16SB vending machine by offering travelers quick access to snacks during their journeys. This convenience can significantly enhance the travel experience, especially in regions where food options may be limited. Buyers should take into account security compliance, the types of payment systems supported (including cashless options), and the freshness of the products to cater to diverse traveler preferences.

Retail Environments

In retail settings like shopping malls and stores, the vending machine can stimulate impulse purchases by providing snacks in high-traffic areas. This not only increases customer satisfaction but also contributes to higher sales volumes. For B2B buyers, it is crucial to consider location strategy, effective inventory management, and understanding customer preferences to optimize the vending machine’s performance in various retail contexts across different regions.

Related Video: Electromagnets – Everyday Uses

Strategic Material Selection Guide for seaga sm16sb small snack vending machine

When selecting materials for the Seaga SM16SB small snack vending machine, it’s essential to consider various factors such as durability, cost, and compatibility with the intended use. Below is an analysis of common materials used in the construction of this vending machine, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high tensile strength, and ability to withstand high temperatures. It typically has a temperature rating of up to 800°F (427°C) and can handle moderate pressure, making it suitable for various environments.

Pros & Cons:

The primary advantage of stainless steel is its durability and resistance to rust and stains, which is crucial for vending machines that may be exposed to food and moisture. However, it is more expensive than other materials like carbon steel, and its manufacturing process can be complex due to the need for specialized welding techniques.

Impact on Application:

Stainless steel is compatible with food products, ensuring safety and hygiene. Its smooth surface is easy to clean, which is vital for maintaining the machine’s appearance and functionality.

Considerations for International Buyers:

Buyers from regions such as Europe and the Middle East should ensure compliance with food safety standards such as EN 10088 for stainless steel. In Africa and South America, local standards may vary, so it’s crucial to verify compliance with regional regulations.

2. Powder-Coated Steel

Key Properties:

Powder-coated steel provides a protective layer that enhances corrosion resistance and aesthetic appeal. The coating can withstand temperatures up to 200°F (93°C) and provides a durable finish.

Pros & Cons:

One of the main advantages of powder-coated steel is its cost-effectiveness compared to stainless steel while still offering decent durability and a variety of color options. However, the coating can chip or scratch, which may expose the underlying steel to corrosion over time.

Impact on Application:

This material is suitable for indoor applications where exposure to harsh environments is limited. It is not advisable for outdoor use or in areas with high humidity.

Considerations for International Buyers:

Buyers should check for compliance with local standards regarding coatings, as some regions may have restrictions on volatile organic compounds (VOCs) used in the powder-coating process.

3. Polycarbonate

Key Properties:

Polycarbonate is a high-impact plastic known for its transparency and strength. It can withstand temperatures from -40°F to 240°F (-40°C to 116°C) and has excellent UV resistance.

Pros & Cons:

The key advantage of polycarbonate is its lightweight nature and high impact resistance, making it ideal for transparent panels in vending machines. However, it is less resistant to scratching compared to glass and may yellow over time when exposed to UV light.

Impact on Application:

Polycarbonate is suitable for areas requiring visibility of the products inside the vending machine. Its lightweight nature makes it easier to handle during installation.

Considerations for International Buyers:

International buyers should ensure that the polycarbonate used complies with safety standards such as ASTM D256 for impact resistance. Additionally, they should consider the environmental impact of plastic materials in their purchasing decisions.

4. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has a temperature rating of up to 600°F (316°C). It is also a good conductor of heat, which can be beneficial in temperature-sensitive applications.

Pros & Cons:

Aluminum’s lightweight nature makes it easy to transport and install, and it is generally less expensive than stainless steel. However, it is softer than steel, making it more susceptible to dents and scratches.

Impact on Application:

Aluminum is suitable for structural components of vending machines where weight savings are important. Its corrosion resistance makes it a good choice for environments with high humidity.

Considerations for International Buyers:

Buyers should be aware of the specific aluminum grades being used, as they should comply with standards such as ASTM B221 for structural aluminum. Additionally, understanding local recycling regulations for aluminum can be beneficial.

Summary Table

| Material | Typical Use Case for seaga sm16sb small snack vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural and exterior components | Excellent durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Powder-Coated Steel | Exterior panels and frames | Cost-effective with aesthetic options | Can chip/scratch, exposing steel to corrosion | Medium |

| Polycarbonate | Transparent panels for product visibility | Lightweight and high impact resistance | Less scratch-resistant, may yellow over time | Medium |

| Aluminum | Structural components | Lightweight and corrosion-resistant | More susceptible to dents and scratches | Low |

This analysis provides a comprehensive overview of the materials used in the Seaga SM16SB small snack vending machine, enabling international B2B buyers to make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for seaga sm16sb small snack vending machine

The manufacturing process and quality assurance for the Seaga SM16SB small snack vending machine are critical aspects for B2B buyers, particularly those operating in diverse international markets such as Africa, South America, the Middle East, and Europe. Understanding these processes can significantly enhance buyer confidence and ensure that the machines meet their operational needs.

Manufacturing Process

1. Material Preparation

The manufacturing process begins with the careful selection and preparation of materials. The Seaga SM16SB typically utilizes high-quality metals and plastics that ensure durability and resistance to environmental factors. Raw materials undergo rigorous inspections to meet specified criteria before proceeding to the next stage.

- Key Techniques:

- Metal Treatment: Common techniques include galvanization or powder coating, which enhance the machine’s resistance to corrosion and wear.

- Plastic Molding: Injection molding is often employed to create complex plastic components efficiently.

2. Forming

In this stage, the prepared materials are shaped into the required components of the vending machine. This involves various forming techniques that ensure precision and compatibility.

- Key Techniques:

- CNC Machining: Computer Numerical Control (CNC) machining is used for precision cutting and shaping of metal parts.

- Press Forming: This technique is typically utilized for creating large, flat components that are integral to the machine’s structure.

3. Assembly

The assembly process is where the individual components come together to form the complete vending machine. This stage involves both manual and automated processes.

- Key Techniques:

- Automated Assembly Lines: These lines utilize robotics for tasks such as installing electronic components and securing parts together, ensuring consistent quality and efficiency.

- Manual Assembly: Skilled workers perform final assembly and quality checks, ensuring that each machine meets operational standards.

4. Finishing

The final touches are applied during the finishing stage. This includes aesthetic elements, such as painting and branding, as well as functional enhancements.

- Key Techniques:

- Surface Finishing: Techniques like sanding, polishing, and coating are employed to enhance the appearance and durability of the machine.

- Quality Checks: Each machine undergoes a series of inspections to ensure that it meets the required specifications and standards.

Quality Assurance

Quality assurance (QA) is an essential part of the manufacturing process for the Seaga SM16SB vending machine. Adherence to international and industry-specific standards ensures that the machines are safe, reliable, and efficient.

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems and ensures that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards, which is crucial for buyers in Europe.

- API Standards: Relevant for certain components, particularly those that interface with electrical systems.

QC Checkpoints

Quality control (QC) is implemented at various stages of the manufacturing process to identify defects and maintain high standards.

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help detect issues early, preventing defects from progressing further down the line.

- Final Quality Control (FQC): The completed machines undergo a final inspection to verify functionality, safety, and compliance with specifications.

Common Testing Methods

Testing is a critical component of QC, and it includes various methods to ensure the vending machines operate correctly and safely.

- Functional Testing: Each machine is tested to ensure that all features, such as payment systems and dispensing mechanisms, work as intended.

- Stress Testing: Machines are subjected to stress tests to evaluate their durability and functionality under various conditions.

- Safety Testing: Electrical components are tested to ensure compliance with safety standards, reducing the risk of malfunctions.

Verifying Supplier QC

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s QC practices is paramount.

- Audits: Conducting regular audits of the manufacturing facility can provide insights into the supplier’s adherence to quality standards and processes.

- Reports: Requesting detailed QC reports can help buyers understand the testing procedures and results for the machines they are purchasing.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s manufacturing and QC processes.

QC and Certification Nuances

Understanding the nuances of QC and certification is vital for international buyers. Different regions may have specific requirements and standards that must be met.

- Regulatory Compliance: Buyers should familiarize themselves with local regulations concerning vending machines, which may vary significantly from one country to another.

- Cultural Considerations: Some regions may prioritize certain features or certifications based on local preferences and market demands.

By grasping the intricacies of the manufacturing processes and quality assurance for the Seaga SM16SB small snack vending machine, B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their operational needs and quality expectations.

Related Video: Parle-G Biscuits Manufacturing process – Food Factory Tour- Modern Food factory, Mega Factory II

Comprehensive Cost and Pricing Analysis for seaga sm16sb small snack vending machine Sourcing

Understanding the Cost Structure of the Seaga SM16SB Small Snack Vending Machine

When sourcing the Seaga SM16SB small snack vending machine, it’s essential to understand its comprehensive cost structure. The primary components contributing to the total cost include:

-

Materials: The quality and type of materials used (e.g., metal, plastic, electronics) significantly impact the base cost. Higher quality components typically lead to higher initial costs but can improve durability and reduce maintenance expenses over time.

-

Labor: Labor costs vary based on the manufacturing location. Regions with higher labor rates will inflate costs, while locations with lower wages can provide more competitive pricing. It’s crucial to assess the skill level required for assembly and maintenance.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Understanding the overhead can help buyers evaluate supplier pricing strategies.

-

Tooling: Initial tooling costs can be substantial, especially for customized machines. If buyers require specific configurations or designs, they should factor in these costs, which can be amortized over larger orders.

-

Quality Control (QC): Investing in rigorous QC processes ensures that the machines meet specifications and standards. This can add to the upfront costs but is critical in reducing long-term warranty claims and customer dissatisfaction.

-

Logistics: Shipping costs can vary widely based on distance, mode of transportation, and the chosen Incoterms. For international buyers, understanding the full logistics cost—including duties, taxes, and insurance—is essential.

-

Margin: Suppliers will include a profit margin, which varies based on market conditions, competition, and perceived value. Buyers should be aware of typical margins within their region to negotiate effectively.

Price Influencers for the Seaga SM16SB

Several factors can influence the pricing of the Seaga SM16SB vending machine:

-

Volume/MOQ: Larger orders often attract discounts. Understanding the Minimum Order Quantity (MOQ) can help buyers negotiate better terms and reduce per-unit costs.

-

Specifications/Customization: Custom features may significantly increase costs. Buyers should weigh the benefits of customization against the added expense.

-

Materials and Quality Certifications: Machines built with premium materials or those that meet specific quality certifications (e.g., ISO, CE) typically command higher prices. Buyers should assess the value these certifications bring to their operations.

-

Supplier Factors: The reliability and reputation of the supplier can affect pricing. Established suppliers may charge more but provide better warranty support and service.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers, affecting shipping costs and risk management.

Buyer Tips for Cost-Efficiency

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider the following tips for effective sourcing:

-

Negotiation: Engage suppliers in discussions about pricing structures. Highlighting long-term relationships or potential larger orders can lead to better pricing.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, energy consumption, and potential downtime. A slightly higher initial cost may result in lower overall expenditures.

-

Understand Pricing Nuances: Different regions may have varying pricing strategies. For example, suppliers in Europe may include extensive service packages in their pricing, while those in Africa might offer lower upfront costs but less comprehensive support.

-

Research and Benchmarking: Gather pricing data from multiple suppliers and regions to establish a baseline. This will empower buyers to make informed decisions and negotiate effectively.

Disclaimer

Prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough due diligence and obtain multiple quotes to ensure the best value in sourcing the Seaga SM16SB vending machine.

Spotlight on Potential seaga sm16sb small snack vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘seaga sm16sb small snack vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for seaga sm16sb small snack vending machine

The Seaga SM16SB small snack vending machine is a popular choice for businesses looking to provide convenient snack options. Understanding its essential technical properties and trade terminology is crucial for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

Key Technical Properties

- Material Grade

– Definition: The Seaga SM16SB is typically constructed from high-grade steel and ABS plastic. These materials ensure durability and resistance to wear and tear.

– B2B Importance: High-quality materials reduce maintenance costs and increase the lifespan of the machine, making it a cost-effective investment for businesses.

Illustrative Image (Source: Google Search)

-

Dimensions

– Definition: The machine dimensions are approximately 30 inches wide, 20 inches deep, and 60 inches high.

– B2B Importance: Understanding the size is critical for placement in various environments, from small offices to larger retail spaces. Buyers must ensure that the machine fits within their intended location. -

Capacity

– Definition: The SM16SB can hold up to 16 different snack selections with a total capacity of approximately 300 items.

– B2B Importance: A higher capacity means less frequent refilling, which is essential for busy locations. It also allows businesses to offer a wider variety of products, appealing to diverse customer preferences. -

Power Requirements

– Definition: The machine operates on standard 110-120V electrical outlets.

– B2B Importance: Knowledge of power requirements is crucial for planning installation and ensuring compliance with local electrical standards, preventing operational disruptions. -

Temperature Control

– Definition: The machine includes adjustable temperature settings to maintain optimal snack freshness.

– B2B Importance: Effective temperature control is vital for product quality, particularly for items sensitive to heat or humidity. This feature can enhance customer satisfaction and reduce product waste. -

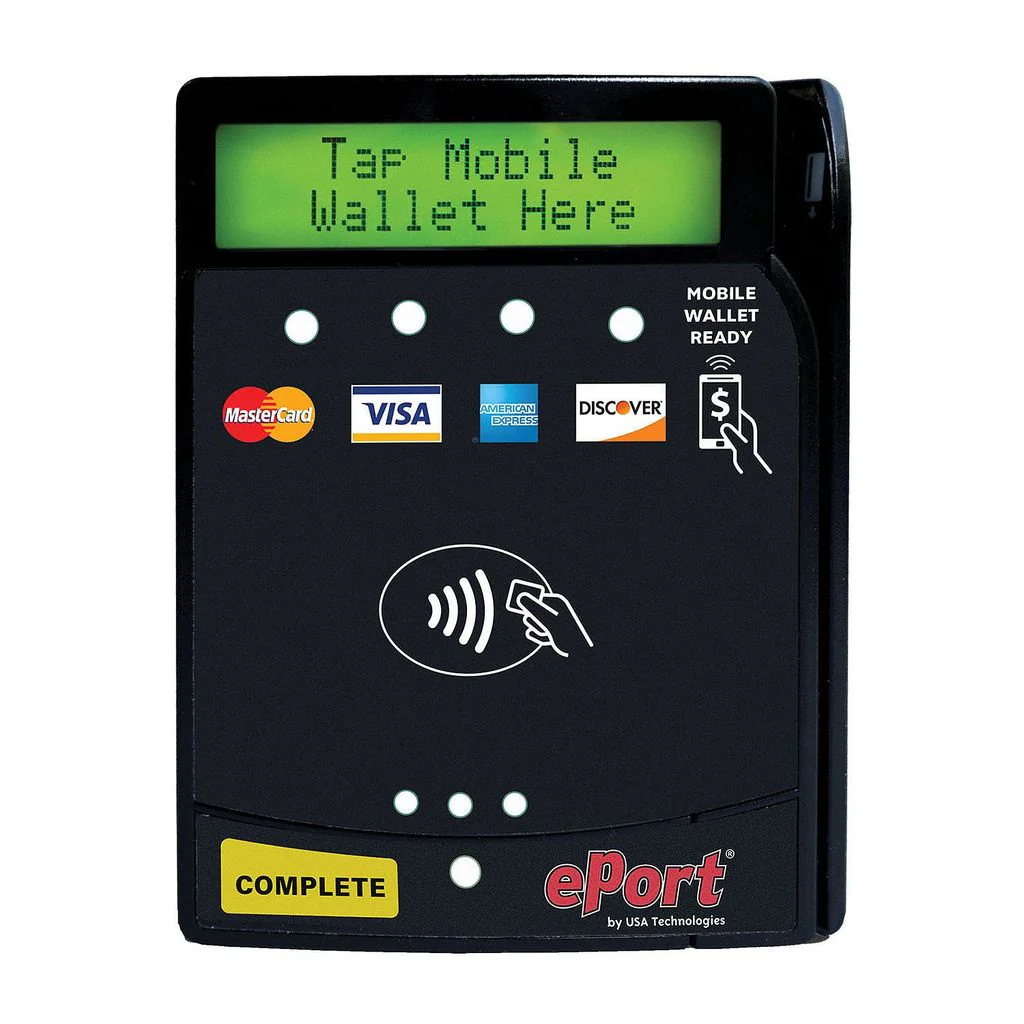

User Interface

– Definition: The Seaga SM16SB is equipped with a user-friendly digital interface and payment options, including cash, credit, and mobile payments.

– B2B Importance: A modern interface improves user experience, encouraging more transactions. Diverse payment options cater to various customer preferences, increasing sales potential.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: Refers to a company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers ensure they are sourcing high-quality machines and parts from reputable manufacturers. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is crucial for budgeting and inventory management, especially for smaller businesses that may not require large quantities. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and terms for a specific quantity of goods or services.

– Importance: Submitting an RFQ allows buyers to compare prices and terms from multiple suppliers, aiding in informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international rules that clarify the responsibilities of buyers and sellers for the delivery of goods.

– Importance: Familiarity with Incoterms is essential for understanding shipping costs, risk management, and logistics, particularly in international trade. -

Lead Time

– Definition: The amount of time that passes from the start of a process until its completion, particularly in manufacturing and supply chain contexts.

– Importance: Understanding lead times helps businesses plan for inventory and avoid stockouts, ensuring customer demand is met promptly. -

Warranty

– Definition: A guarantee provided by the manufacturer regarding the condition of the product and the terms under which repairs or replacements will be made.

– Importance: Warranties provide buyers with security regarding their investment, making it crucial to understand the terms and conditions associated with the vending machine.

By comprehensively understanding these technical properties and trade terminologies, international B2B buyers can make informed decisions when purchasing the Seaga SM16SB small snack vending machine, ensuring they meet their operational needs and customer expectations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the seaga sm16sb small snack vending machine Sector

Market Overview & Key Trends

The global market for vending machines, particularly the Seaga SM16SB small snack vending machine, is experiencing significant growth driven by several factors. The increasing demand for convenience and on-the-go snacks is propelling the adoption of vending solutions across various sectors, including education, healthcare, and corporate offices. In emerging markets in Africa and South America, urbanization and a growing middle class are further driving the demand for automated retail solutions.

Illustrative Image (Source: Google Search)

International B2B buyers should be aware of current technological trends such as cashless payment systems, mobile app integrations, and smart vending solutions that utilize IoT technology for inventory management and customer interaction. These advancements not only enhance user experience but also streamline operational efficiencies. Furthermore, sustainability is becoming a key driver in the vending machine sector, with businesses increasingly seeking machines that are energy-efficient and made from recyclable materials.

For buyers from regions like the Middle East and Europe, understanding local consumer preferences is crucial. In Europe, for instance, there is a growing trend towards healthier snack options, prompting vending machine suppliers to offer products that cater to dietary restrictions and preferences. Similarly, Middle Eastern markets are witnessing a rise in demand for locally sourced products, which can influence sourcing strategies for vending machine operators.

Sustainability & Ethical Sourcing in B2B

Sustainability has emerged as a core principle in the B2B landscape, particularly in the vending machine sector. The Seaga SM16SB small snack vending machine is designed with energy-efficient components, reducing its overall environmental footprint. International buyers should prioritize suppliers that not only adhere to energy-saving standards but also invest in sustainable manufacturing processes.

Ethical sourcing is another critical aspect for B2B buyers. Ensuring that the snacks provided in these vending machines are sourced from suppliers who practice fair labor standards and environmentally friendly farming methods is essential. Certifications such as Fair Trade, Organic, and Rainforest Alliance can serve as indicators of ethical sourcing practices.

Moreover, buyers should seek out vending machines that incorporate recyclable materials in their construction. This not only aligns with global sustainability goals but also appeals to increasingly environmentally conscious consumers. As regulations around sustainability tighten, investing in compliant and certified machines will not only mitigate risk but also enhance brand reputation.

Brief Evolution/History

The evolution of vending machines can be traced back to ancient Greece, where simple machines dispensed holy water. However, the modern vending machine began to take shape in the early 20th century, primarily offering cigarettes and soft drinks. The introduction of electronic vending machines in the 1980s marked a significant leap, allowing for cashless transactions and a wider variety of products.

Today, the Seaga SM16SB small snack vending machine exemplifies this evolution by integrating advanced technology and focusing on consumer convenience. The shift towards healthier and more diverse snack options reflects changing consumer preferences, while the incorporation of smart technology positions these machines as vital components of contemporary retail environments. For B2B buyers, understanding this evolution highlights the importance of adapting to market dynamics and consumer trends in order to remain competitive.

Related Video: Understanding the Global Trade Item Number (GTIN)

Frequently Asked Questions (FAQs) for B2B Buyers of seaga sm16sb small snack vending machine

-

What should I consider when vetting suppliers for the Seaga SM16SB vending machine?

When vetting suppliers, prioritize their reputation, experience, and customer feedback. Look for suppliers with a solid track record in international trade, especially in your region. Verify their certifications and compliance with local regulations. It’s also wise to request references from other businesses that have purchased similar machines. Additionally, assess their after-sales support and warranty policies, as these can be crucial for long-term satisfaction. -

Can the Seaga SM16SB vending machine be customized to meet my specific needs?

Yes, many suppliers offer customization options for the Seaga SM16SB vending machine. You can request modifications such as branding, color schemes, or specific configurations for snack selections. Discuss your requirements with potential suppliers to understand the extent of customization they can provide. Keep in mind that extensive modifications may impact lead times and costs, so plan accordingly. -

What are the minimum order quantities (MOQ) and lead times for purchasing the Seaga SM16SB?

MOQs can vary by supplier, but typically, they range from one to several units for the Seaga SM16SB. It’s crucial to confirm this with your chosen supplier. Lead times can also differ based on customization and supplier location, but generally, you should expect a timeframe of 4-8 weeks from order confirmation to delivery. Always inquire about potential delays and plan your inventory needs accordingly. -

What payment options are available when sourcing the Seaga SM16SB vending machine?

Most suppliers offer various payment methods, including bank transfers, credit cards, and letters of credit. For larger orders, consider negotiating favorable payment terms, such as partial upfront payments and the balance upon delivery. Always ensure that payment methods are secure and traceable. Additionally, be aware of currency fluctuations and any associated fees if dealing with international transactions. -

How can I ensure quality assurance and certifications for the Seaga SM16SB?

Request documentation for quality assurance processes and certifications such as ISO standards from your supplier. It’s important to verify that the machines meet safety and operational standards relevant to your market. Ask for product samples or test units to evaluate quality firsthand. Establish clear inspection criteria before shipment to mitigate risks associated with product quality. -

What logistics considerations should I keep in mind when importing the Seaga SM16SB?

Logistics are crucial when importing vending machines. Consider factors like shipping methods (air vs. sea), customs duties, and import regulations specific to your country. Work with a logistics partner experienced in international trade to navigate these complexities. Ensure that your supplier provides all necessary documentation for smooth customs clearance and plan for potential delays at the border.

-

How should I handle disputes with suppliers regarding the Seaga SM16SB?

Establish clear communication channels with your supplier to resolve issues promptly. If disputes arise, refer to the terms outlined in your purchase agreement, including warranties and return policies. Document all correspondence and agreements for reference. If necessary, consider mediation or arbitration to resolve conflicts, particularly in international trade, where legal frameworks can differ. -

What support can I expect after purchasing the Seaga SM16SB?

Post-purchase support typically includes installation guidance, user manuals, and troubleshooting assistance. Ensure your supplier offers comprehensive after-sales support, including warranty services and spare parts availability. Inquire about training for your staff on operating and maintaining the machine effectively. Good suppliers will also provide a contact for ongoing support and maintenance inquiries.

Strategic Sourcing Conclusion and Outlook for seaga sm16sb small snack vending machine

In conclusion, the Seaga SM16SB Small Snack Vending Machine represents a valuable investment for international B2B buyers, particularly in dynamic markets across Africa, South America, the Middle East, and Europe. Its compact design and diverse product offerings cater to various consumer preferences, making it an ideal solution for businesses aiming to enhance their service offerings and customer satisfaction.

Key takeaways include the importance of strategic sourcing to optimize procurement processes, ensuring that buyers can secure the best pricing and supply chain reliability. By partnering with reputable suppliers, businesses can leverage local insights and market trends to make informed decisions that align with their operational goals.

As you consider integrating the Seaga SM16SB into your product lineup, remember that this machine not only meets the growing demand for convenient snacking options but also positions your business to capitalize on the increasing consumer trend towards automated retail solutions.

Looking ahead, we encourage B2B buyers to explore the potential of the Seaga SM16SB to drive revenue growth and operational efficiency. Engage with suppliers, conduct thorough market research, and take the next step towards enhancing your vending solutions today. Your strategic sourcing decisions can pave the way for future success in the ever-evolving marketplace.