Your Ultimate Guide to Sourcing Moet Vending Machine

Guide to Moet Vending Machine

- Introduction: Navigating the Global Market for moet vending machine

- Understanding moet vending machine Types and Variations

- Key Industrial Applications of moet vending machine

- Strategic Material Selection Guide for moet vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for moet vending machine

- Comprehensive Cost and Pricing Analysis for moet vending machine Sourcing

- Spotlight on Potential moet vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for moet vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the moet vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of moet vending machine

- Strategic Sourcing Conclusion and Outlook for moet vending machine

Introduction: Navigating the Global Market for moet vending machine

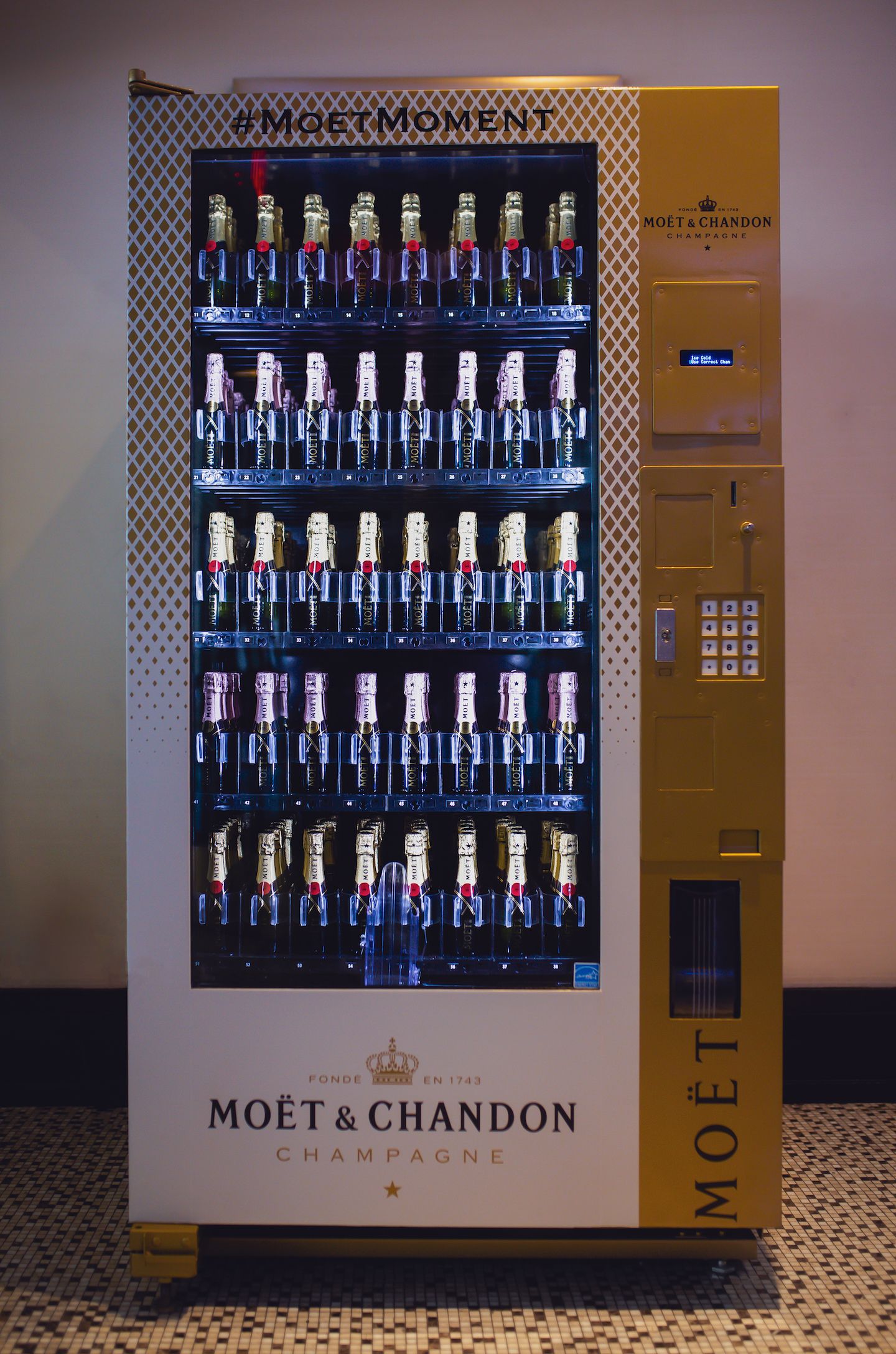

In an increasingly competitive global market, the Moët vending machine stands out as a transformative solution for businesses aiming to enhance customer experience and drive sales. These innovative machines not only offer convenience but also elevate the luxury retail experience, making premium products like Moët & Chandon champagne accessible in unique environments, from upscale venues to events. For B2B buyers across Africa, South America, the Middle East, and Europe, understanding the value and functionality of these machines is crucial for informed sourcing decisions.

This comprehensive guide delves into various aspects of the Moët vending machine, including the different types available, materials used in construction, manufacturing and quality control standards, and potential suppliers. It will also cover cost considerations and market trends, equipping international buyers with the knowledge needed to navigate this niche market effectively.

Moreover, the guide addresses frequently asked questions, demystifying common concerns and providing insights into best practices for integration and operation. By empowering B2B buyers with actionable insights and authoritative information, this resource facilitates strategic decision-making, ensuring that investments in Moët vending machines yield maximum returns while enhancing brand presence and consumer engagement in diverse markets.

Understanding moet vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Moët Vending Machine | Classic design, glass display, and manual selection | Restaurants, upscale bars, event venues | Pros: Elegant appearance, enhances customer experience. Cons: Higher maintenance costs, limited product variety. |

| Smart Moët Vending Machine | Touchscreen interface, cashless payment options | Nightclubs, luxury hotels, high-end events | Pros: Modern technology, real-time inventory tracking. Cons: Higher initial investment, requires tech support. |

| Mobile Moët Vending Unit | Portable, compact design for events and festivals | Outdoor events, weddings, corporate gatherings | Pros: Versatile usage, easy to transport. Cons: Limited capacity, may require additional setup time. |

| Multi-Product Moët Vending Machine | Offers a variety of Moët products and accessories | Retail stores, duty-free shops, supermarkets | Pros: Attracts diverse clientele, maximizes sales opportunities. Cons: Complex inventory management, higher upfront cost. |

| Luxury Moët Experience Kiosk | Interactive experience with tasting options and pairings | Wine exhibitions, luxury brand pop-ups | Pros: Unique customer engagement, enhances brand perception. Cons: Requires trained staff, higher operational costs. |

Traditional Moët Vending Machine

The Traditional Moët Vending Machine features a classic design with a glass display that showcases the products. It typically operates with a manual selection process, making it ideal for environments like upscale restaurants and bars. Buyers should consider the elegance it brings to customer interactions, enhancing the overall dining experience. However, it may incur higher maintenance costs and offer limited product variety, which could affect sales in a competitive market.

Smart Moët Vending Machine

Smart Moët Vending Machines incorporate modern technology, including touchscreen interfaces and cashless payment systems. They are particularly suited for high-traffic venues like nightclubs and luxury hotels. These machines allow for real-time inventory tracking and can significantly streamline the purchasing process for consumers. However, they require a higher initial investment and ongoing technical support, which buyers must factor into their purchasing decisions.

Mobile Moët Vending Unit

The Mobile Moët Vending Unit is designed for portability, making it a perfect choice for outdoor events, weddings, and corporate gatherings. Its compact design allows for easy transport and setup, appealing to event organizers looking for flexible solutions. While this type provides versatility, it has limited capacity and may require additional time for setup, which can impact service speed at busy events.

Multi-Product Moët Vending Machine

This variant offers a diverse range of Moët products and accessories, making it suitable for retail environments such as duty-free shops and supermarkets. By attracting a broader clientele, it maximizes sales opportunities. However, the complexity of inventory management can pose challenges for buyers, alongside a higher upfront cost that necessitates careful financial planning.

Luxury Moët Experience Kiosk

The Luxury Moët Experience Kiosk provides an interactive customer experience, often featuring tasting options and food pairings. This type is ideal for wine exhibitions and luxury brand pop-ups, enhancing brand perception and customer engagement. However, it requires trained staff to operate effectively, which can lead to higher operational costs. Buyers should weigh the potential for unique customer experiences against the investment in staff and training.

Related Video: AI, Machine Learning, Deep Learning and Generative AI Explained

Key Industrial Applications of moet vending machine

| Industry/Sector | Specific Application of moet vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Automated champagne dispensing in hotels | Enhances guest experience and increases sales | Compliance with health regulations, maintenance support, and reliability |

| Retail | Luxury champagne vending in upscale shops | Attracts high-end clientele and boosts impulse buys | Quality of service, product range, and payment system integration |

| Event Management | On-site champagne sales at events and festivals | Streamlines sales process and improves customer access | Portability, ease of setup, and user-friendly interface |

| Corporate Events | Champagne vending for corporate gatherings | Elevates brand image and offers unique experiences | Custom branding options, capacity, and service agreements |

| Nightlife & Bars | Self-service champagne dispensing in nightclubs | Increases efficiency and reduces wait times | Security features, product freshness, and inventory management |

Hospitality

In the hospitality sector, the moet vending machine serves as an innovative solution for hotels looking to enhance the guest experience. By offering automated champagne dispensing, hotels can provide a luxurious touch that appeals to guests celebrating special occasions. This not only boosts sales but also streamlines the service process, allowing staff to focus on other guest needs. International buyers should consider compliance with local health regulations and the reliability of the machine to ensure consistent service.

Retail

Upscale retail environments can benefit significantly from installing a moet vending machine, which allows for luxury champagne sales. This application attracts high-end clientele, encouraging impulse purchases while providing a unique shopping experience. Retailers must evaluate the quality of service the machine offers, the range of products available, and how well it integrates with existing payment systems to maximize sales potential.

Event Management

For event management companies, the moet vending machine facilitates on-site champagne sales at various events and festivals. This solution streamlines the sales process, making it easier for attendees to access premium beverages without long wait times. Buyers in this sector should prioritize portability and ease of setup, along with a user-friendly interface that can cater to large crowds efficiently.

Corporate Events

At corporate gatherings, a moet vending machine can elevate the brand image and provide guests with a unique experience. By offering champagne in a self-service format, companies can create an upscale atmosphere that reflects positively on their brand. When sourcing for this application, businesses should consider custom branding options, the machine’s capacity to serve large groups, and service agreements that ensure maintenance and support.

Nightlife & Bars

In the nightlife and bar industry, the moet vending machine can significantly enhance operational efficiency by reducing wait times during peak hours. By allowing patrons to serve themselves, bars can improve customer satisfaction while increasing sales volume. Key considerations for international buyers include the security features of the machine, ensuring product freshness, and effective inventory management to avoid stockouts during busy nights.

Related Video: How to Start a Vending Machine Business, Cost, Tips, How Much You Make

Strategic Material Selection Guide for moet vending machine

When selecting materials for a Moët vending machine, it is crucial to consider the specific requirements of the application, including durability, aesthetics, and compliance with international standards. Below is an analysis of four common materials used in the construction of Moët vending machines, focusing on their properties, pros and cons, and considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. It is often rated for various environments, making it suitable for both indoor and outdoor applications.

Pros & Cons:

Stainless steel is highly durable and resistant to rust and staining, which is essential for maintaining a clean appearance in a vending environment. However, it can be more expensive than other materials and may require specialized manufacturing techniques, which could increase production costs.

Impact on Application:

Stainless steel is compatible with a wide range of beverages and is easy to clean, making it ideal for vending machines that dispense luxury products like Moët. Its non-reactive nature ensures that the taste and quality of the beverages are preserved.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM A240 for stainless steel grades. Preferences for stainless steel grades may vary by region, with some markets favoring specific finishes or grades for aesthetic reasons.

2. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It is often used in applications where weight savings are critical.

Pros & Cons:

Aluminum is generally less expensive than stainless steel and is easier to machine, which can reduce manufacturing complexity. However, it is less durable than stainless steel and may not withstand heavy impacts as well.

Impact on Application:

Aluminum’s lightweight nature makes it suitable for portable vending machines, while its corrosion resistance allows it to be used in various environments. However, it may not be suitable for high-pressure applications.

Considerations for International Buyers:

Compliance with standards such as ASTM B221 for aluminum extrusions is essential. Buyers should also consider regional preferences for aluminum finishes, as some markets may prefer anodized or powder-coated surfaces for aesthetic purposes.

3. Glass

Key Properties:

Glass offers excellent visibility and aesthetic appeal, making it an attractive option for displaying luxury products like Moët. It can be treated for enhanced strength and thermal resistance.

Pros & Cons:

The primary advantage of glass is its visual appeal, which can enhance the consumer experience. However, it is fragile and can be susceptible to breakage, which may lead to increased maintenance costs.

Impact on Application:

Glass is ideal for showcasing products, allowing customers to see the high-end offerings. However, its fragility limits its use in high-traffic or outdoor environments.

Considerations for International Buyers:

Buyers should be aware of glass safety standards, such as those set by ASTM C1036, and consider local regulations regarding glass usage in vending machines. Preferences for tempered or laminated glass may vary by region.

4. Polycarbonate

Key Properties:

Polycarbonate is a strong, impact-resistant plastic that is lightweight and has good clarity. It is often used as a substitute for glass due to its durability.

Illustrative Image (Source: Google Search)

Pros & Cons:

Polycarbonate is less expensive than glass and is highly resistant to impact, making it a safer option for vending machines. However, it may scratch more easily and can degrade under UV exposure unless treated.

Impact on Application:

Polycarbonate is suitable for environments where safety and durability are paramount. Its clarity allows for product visibility, but care should be taken to ensure that UV-treated options are used for outdoor applications.

Considerations for International Buyers:

Buyers should check compliance with standards such as ASTM D5767 for polycarbonate materials. Additionally, preferences for UV-resistant treatments may vary by region, particularly in areas with high sun exposure.

Summary Table

| Material | Typical Use Case for moet vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components and exterior panels | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Aluminum | Frame and lightweight components | Lightweight and cost-effective | Less durable than stainless steel | Medium |

| Glass | Display panels for product visibility | Aesthetic appeal | Fragile, prone to breakage | Medium |

| Polycarbonate | Protective covers and display panels | Impact-resistant and lightweight | Scratches easily, UV degradation risk | Low |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decisions that align with regional preferences and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for moet vending machine

Manufacturing Processes for Moët Vending Machines

The manufacturing of Moët vending machines is a multi-stage process that requires precision and adherence to industry standards. Below are the main stages involved in the production of these machines, along with key techniques employed in each phase.

1. Material Preparation

Selection of Materials: The initial step involves sourcing high-quality materials, typically stainless steel for the chassis and food-grade plastics for internal components. Suppliers should provide certification of material quality to ensure compliance with safety and durability standards.

Pre-Treatment: Materials undergo pre-treatment processes such as cleaning and coating to enhance corrosion resistance. This step is crucial for longevity, especially in humid environments typical of many regions in Africa and South America.

2. Forming

Fabrication Techniques: Various fabrication methods are employed, including laser cutting and CNC machining. These techniques ensure precise dimensions and high-quality finishes for components such as doors and internal shelving.

Welding and Joining: Automated welding is commonly used to assemble the chassis, ensuring structural integrity. This phase might also include the use of adhesives or mechanical fasteners depending on the design specifications.

3. Assembly

Sub-Assembly: Components like refrigeration units, electronic displays, and payment systems are assembled in sub-groups. Each group is tested independently to ensure functionality.

Final Assembly: The final assembly involves integrating all sub-assemblies into the main vending machine structure. Attention to detail in this phase is crucial as it impacts the overall performance and user experience.

4. Finishing

Surface Treatments: After assembly, the machine undergoes surface treatments such as powder coating or painting. These treatments not only enhance aesthetics but also provide additional protection against environmental factors.

Quality Checks: At this stage, machines are subject to visual inspections and functional tests to ensure that all parts are correctly installed and operational.

Quality Assurance for Moët Vending Machines

Quality assurance is critical in the manufacturing process of Moët vending machines, ensuring that they meet international standards and customer expectations. Below are the key aspects of quality assurance relevant to B2B buyers.

International Standards

ISO 9001: This standard outlines the requirements for a quality management system (QMS). Manufacturers should be certified to ISO 9001 to ensure that their processes consistently meet customer and regulatory requirements.

CE Marking: For machines sold in Europe, obtaining a CE mark demonstrates compliance with EU safety and health standards. This is particularly important for international buyers from Europe.

API Standards: Depending on the market, adherence to American Petroleum Institute (API) standards may be necessary, particularly if the vending machines are designed to dispense beverages containing alcohol.

QC Checkpoints

Quality control checkpoints are critical in the manufacturing process. Below are the typical checkpoints employed:

-

Incoming Quality Control (IQC): Incoming materials are inspected for quality and specifications before they enter production.

-

In-Process Quality Control (IPQC): During production, regular checks are made at various stages to identify defects early and reduce waste.

-

Final Quality Control (FQC): Before shipping, each machine undergoes a comprehensive inspection and testing to ensure it operates as intended.

Common Testing Methods

Testing methods commonly used in the QC process include:

-

Functional Testing: Verifying that all electronic and mechanical components operate correctly.

-

Durability Testing: Machines are subjected to stress tests to assess their performance under various environmental conditions.

-

Safety Testing: Ensuring all safety features function correctly to protect users.

Verifying Supplier Quality Control

B2B buyers should take proactive steps to verify the quality control practices of suppliers. Here are some actionable insights:

Supplier Audits

Conducting audits of potential suppliers can reveal a lot about their manufacturing practices and quality control processes. Buyers should look for suppliers that welcome third-party audits and can provide documentation of previous audits.

Quality Reports

Requesting quality reports that detail the results of previous inspections and tests can provide insights into the supplier’s commitment to quality. Look for trends in defect rates and how they have addressed any issues.

Third-Party Inspections

Engaging independent inspection agencies can add an additional layer of assurance. These agencies can conduct checks at various stages of production and provide unbiased reports on compliance with specifications and standards.

QC and Certification Nuances for International Buyers

International buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification processes:

-

Regional Regulations: Each region may have unique regulatory requirements. For instance, machines sold in the EU must comply with CE regulations, while those in the Middle East may need to meet local safety standards.

-

Cultural Considerations: Understanding the cultural context in which the machines will be used can inform quality expectations. For example, in hotter climates, the refrigeration components must be especially robust.

-

Documentation and Traceability: Ensure that suppliers provide comprehensive documentation for all materials and processes. This is crucial for traceability in case of recalls or quality issues.

By understanding the manufacturing processes and quality assurance practices associated with Moët vending machines, B2B buyers can make informed decisions and ensure that they are partnering with reliable suppliers committed to delivering high-quality products.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for moet vending machine Sourcing

In sourcing Moët vending machines, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis focuses on the key cost components, price influencers, and actionable tips that can guide buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary cost driver in manufacturing Moët vending machines includes high-quality materials such as stainless steel, glass, and electronics. The choice of materials impacts durability and aesthetics, which are critical for luxury brands like Moët.

-

Labor: Labor costs encompass the wages of skilled workers involved in the assembly and quality control of the machines. Regions with higher labor costs may affect the overall pricing, while sourcing from countries with lower wages can lead to significant savings.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs, impacting the final price.

-

Tooling: Investment in specialized tooling for customization or high-volume production can be significant. Buyers should consider whether they need custom features, as this will influence tooling costs.

-

Quality Control (QC): Ensuring that each machine meets stringent quality standards incurs costs. Robust QC processes are essential, especially for luxury products, and may vary by supplier.

-

Logistics: Shipping, handling, and warehousing costs are critical, particularly for international buyers. Factors such as distance, shipping mode, and local regulations can greatly affect logistics expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding the margin expectations of suppliers can help in negotiating better pricing.

Price Influencers

-

Volume/MOQ: The minimum order quantity (MOQ) can significantly influence the price per unit. Higher volumes often lead to lower prices due to economies of scale.

-

Specifications/Customization: Custom features can increase costs. Buyers must weigh the benefits of customization against potential price increases.

-

Materials and Quality/Certifications: The choice of materials directly impacts both cost and quality. Additionally, certifications (e.g., ISO, CE) may be necessary for compliance in certain markets, adding to costs.

-

Supplier Factors: Reliability and reputation of suppliers can affect pricing. Established suppliers may offer premium prices due to their proven track record.

-

Incoterms: Understanding Incoterms is vital for cost estimation, as they define the responsibilities of buyers and sellers in shipping. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can shift costs significantly.

Buyer Tips

-

Negotiation: Effective negotiation can lead to better pricing and terms. Buyers should prepare by understanding their supplier’s cost structure and market conditions.

-

Cost-Efficiency: Conduct a total cost of ownership analysis, which includes not just purchase price but also maintenance, operational costs, and potential resale value.

-

Pricing Nuances: Be aware of fluctuations in raw material prices and currency exchange rates, especially for international transactions. These factors can lead to unexpected cost changes.

-

Strategic Sourcing: Consider diversifying suppliers to mitigate risks and leverage competition for better pricing.

-

Local Market Knowledge: Understanding local regulations and market conditions in the target region (e.g., Africa, South America) can provide advantages in negotiations and sourcing decisions.

Disclaimer

Prices for Moët vending machines can vary widely based on the above factors and are indicative only. Buyers should conduct thorough market research and supplier evaluations to obtain accurate pricing specific to their needs and circumstances.

Spotlight on Potential moet vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘moet vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for moet vending machine

Critical Specifications for Moët Vending Machines

When considering the procurement of Moët vending machines, understanding the technical specifications is crucial for ensuring quality, reliability, and compliance with operational needs. Here are some essential specifications to consider:

-

Material Grade

The construction material of the vending machine is pivotal. Stainless steel is commonly used due to its durability, resistance to corrosion, and aesthetic appeal. For international buyers, especially from humid regions in Africa or coastal areas in Europe, selecting high-grade materials can significantly impact the machine’s longevity and maintenance costs. -

Temperature Control Range

Moët vending machines must maintain optimal temperature conditions for champagne storage and dispensing. A typical operational range is between 4°C to 10°C. This specification is vital for preserving the quality of the beverage and ensuring compliance with industry standards, thus protecting your investment. -

Power Consumption

Efficiency in power usage is critical, especially for businesses looking to minimize operational costs. Vending machines with energy-efficient ratings can reduce electricity bills and carbon footprint, aligning with sustainability goals. Look for machines that comply with international energy standards (like ENERGY STAR certification). -

Dispensing Mechanism

The technology used for dispensing champagne can vary. Advanced machines may feature touchless dispensing or automated pouring systems that enhance user experience and minimize waste. Understanding the mechanics helps in evaluating the machine’s reliability and ease of maintenance. -

User Interface

The interface should be intuitive and user-friendly. A touchscreen display with multilingual options can cater to diverse customer bases, particularly in multicultural regions such as Europe and the Middle East. A good interface enhances customer satisfaction and can lead to increased sales. -

Capacity and Size

The machine’s capacity, often measured in the number of bottles it can hold, is crucial for operational efficiency. Buyers need to assess their expected foot traffic and sales volume to select a machine that meets their needs without overstocking or understocking.

Common Trade Terminology

Understanding industry jargon can facilitate smoother transactions and negotiations. Here are some essential terms to familiarize yourself with:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. For buyers, knowing the OEM can provide insights into quality and warranty support. -

MOQ (Minimum Order Quantity)

This is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is critical for budgeting and inventory management, particularly for smaller businesses or those just entering the market. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to invite them to submit price quotations for specific goods or services. It is an essential step in the procurement process, allowing buyers to compare prices and negotiate better terms. -

Incoterms (International Commercial Terms)

These are a set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and insurance responsibilities, which is crucial for budgeting and logistics planning.

Illustrative Image (Source: Google Search)

-

Lead Time

This term refers to the time taken from placing an order until the goods are delivered. Knowing the lead time helps businesses plan their inventory and manage customer expectations effectively. -

Warranty Period

The warranty period is the time during which a product is guaranteed to be free from defects. Understanding the warranty terms helps buyers assess the risk associated with their investment and the level of after-sales support they can expect.

By grasping these specifications and terminology, international B2B buyers can make informed decisions regarding the procurement of Moët vending machines, ensuring both operational efficiency and product integrity.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the moet vending machine Sector

Market Overview & Key Trends

The moet vending machine sector is experiencing dynamic shifts driven by multiple global factors. One of the primary drivers is the growing demand for convenience and on-the-go consumption, particularly in urbanized areas across Africa, South America, the Middle East, and Europe. As consumers increasingly seek unique experiences, the integration of premium products, such as Moët & Chandon, into vending machines is gaining traction, aligning with trends in the luxury segment.

Technological advancements are also influencing the market landscape. The rise of smart vending machines equipped with cashless payment systems, touchless interfaces, and IoT capabilities is reshaping consumer interactions. These innovations enhance user experience, improve operational efficiency, and allow for real-time inventory management, making them appealing to B2B buyers looking to invest in modern vending solutions.

Additionally, the shift towards personalization is significant. Machines that offer tailored recommendations based on consumer preferences are emerging, and this trend is expected to grow. B2B buyers should pay attention to partnerships with tech firms that can provide advanced analytics and machine learning capabilities to optimize product offerings.

Emerging markets, particularly in Africa and South America, present substantial growth opportunities. As urban centers expand and disposable incomes rise, there is a burgeoning appetite for luxury items in non-traditional retail formats. Buyers should consider local partnerships that understand these markets’ unique cultural and economic landscapes to successfully penetrate these regions.

Sustainability & Ethical Sourcing in B2B

In today’s market, sustainability is not just a trend but a requirement for responsible business practices. The environmental impact of manufacturing and operating vending machines is under scrutiny, compelling B2B buyers to prioritize sustainable sourcing.

To align with global sustainability goals, companies are increasingly seeking eco-friendly materials for their vending machines. This includes using recycled plastics, biodegradable components, and energy-efficient technologies. Investing in machines with a lower carbon footprint not only meets consumer demand for sustainability but also enhances brand reputation.

Moreover, ethical supply chains are crucial. Buyers should ensure that their vendors adhere to fair labor practices and transparency in sourcing. Certifications such as Fair Trade and ISO 14001 can serve as benchmarks for evaluating suppliers. By prioritizing ethical sourcing, companies can mitigate risks associated with supply chain disruptions and enhance their corporate social responsibility (CSR) profiles.

Investing in sustainable practices can also lead to long-term cost savings. For instance, energy-efficient machines can reduce operational costs and appeal to environmentally conscious consumers, thus driving sales.

Brief Evolution/History

The concept of vending machines has evolved significantly since their inception in the late 19th century. Originally designed to dispense simple items like postcards and candy, the industry has transformed dramatically with advancements in technology and changing consumer behaviors. The introduction of premium products, particularly in the beverage sector, marked a turning point, with luxury brands like Moët & Chandon entering the space to cater to sophisticated consumers.

In recent years, the integration of technology has further revolutionized the sector, with smart machines becoming a standard. This evolution reflects a broader trend towards convenience and personalization, making the vending machine a relevant player in the modern retail landscape. For B2B buyers, understanding this evolution is key to making informed decisions about future investments in the sector.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of moet vending machine

-

What should I consider when vetting suppliers for moet vending machines?

When vetting suppliers, prioritize those with a proven track record in manufacturing vending machines, especially those that specialize in luxury products like Moët. Check for certifications such as ISO 9001 to ensure quality management. Look for suppliers with strong references from international clients, and consider conducting site visits or virtual inspections to assess their production capabilities. Additionally, inquire about their after-sales support and warranty policies to ensure they can meet your ongoing service needs. -

Can I customize the moet vending machine to reflect my brand?

Yes, many suppliers offer customization options for moet vending machines. You can typically request branding elements such as logos, colors, and designs that align with your corporate identity. Ensure to discuss your customization needs upfront, as this may affect production timelines and costs. Request prototypes or mock-ups to visualize the final product before committing to large orders, ensuring the design meets your expectations. -

What are the typical minimum order quantities (MOQ) and lead times?

Minimum order quantities for moet vending machines can vary significantly by supplier and the complexity of your order. Generally, MOQs may range from 5 to 20 units for custom designs, while standard models may have lower MOQs. Lead times can range from 4 to 12 weeks, depending on the customization level and supplier capacity. Always confirm these details during negotiations to align with your project timelines. -

What payment methods are typically accepted for international orders?

Most suppliers accept various payment methods, including bank transfers, letters of credit, and secure online payment platforms. For larger orders, letters of credit are preferred as they provide security for both parties. Ensure to negotiate payment terms that are favorable, such as partial upfront payments and the balance upon delivery. Always verify the supplier’s payment policies and consider using escrow services for additional security. -

What quality assurance processes should I expect from suppliers?

Reputable suppliers will have stringent quality assurance (QA) processes in place. Expect to see documentation of their QA protocols, including pre-production inspections, in-process checks, and final product testing. Request certificates of compliance with international standards, such as CE or RoHS, to ensure the machines meet safety and regulatory requirements in your market. Some suppliers may also offer third-party inspection services for added assurance. -

How should I handle logistics and shipping for my order?

Logistics can be complex for international shipments. Discuss shipping terms (Incoterms) with your supplier to understand who is responsible for shipping costs, insurance, and customs clearance. Consider using a freight forwarder experienced in handling machinery to streamline the shipping process. It’s crucial to factor in potential delays due to customs procedures and to ensure that your supplier provides all necessary shipping documents, such as bills of lading and customs declarations. -

What steps can I take if I encounter a dispute with my supplier?

In the event of a dispute, first try to resolve the issue directly with the supplier through clear communication. Document all correspondence and agreements to support your case. If direct negotiations fail, review the terms of your contract regarding dispute resolution mechanisms, such as mediation or arbitration. Engaging a legal professional familiar with international trade laws may be necessary to navigate complex disputes effectively. -

Are there any specific certifications I should look for in a moet vending machine?

Yes, look for certifications that ensure the vending machine complies with safety and quality standards relevant to your market. Common certifications include CE marking for European markets, UL certification for the U.S., and ISO 9001 for quality management systems. Additionally, check for any local certifications required in your country to ensure compliance with regional regulations, especially concerning electrical safety and food handling standards.

Strategic Sourcing Conclusion and Outlook for moet vending machine

In conclusion, the moet vending machine represents a unique opportunity for international B2B buyers to enhance their product offerings and cater to evolving consumer preferences. Strategic sourcing is essential in this context; it enables businesses to identify reliable suppliers, assess market conditions, and leverage competitive pricing. By focusing on quality and innovation, buyers can ensure they are investing in machines that not only meet operational requirements but also resonate with luxury-conscious consumers.

For buyers in Africa, South America, the Middle East, and Europe, the potential for growth in the vending sector is significant. The integration of technology, such as cashless payment systems and smart inventory management, can further enhance the consumer experience.

As you consider the addition of moet vending machines to your portfolio, remember to conduct thorough market research, evaluate supplier capabilities, and remain adaptable to changing market dynamics. Now is the time to act—embrace the future of automated luxury retail and position your business at the forefront of this exciting trend.