Your Ultimate Guide to Sourcing Mobile Vending Machine

Guide to Mobile Vending Machine

- Introduction: Navigating the Global Market for mobile vending machine

- Understanding mobile vending machine Types and Variations

- Key Industrial Applications of mobile vending machine

- Strategic Material Selection Guide for mobile vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for mobile vending machine

- Comprehensive Cost and Pricing Analysis for mobile vending machine Sourcing

- Spotlight on Potential mobile vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for mobile vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the mobile vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of mobile vending machine

- Strategic Sourcing Conclusion and Outlook for mobile vending machine

Introduction: Navigating the Global Market for mobile vending machine

In an increasingly dynamic global marketplace, mobile vending machines have emerged as a transformative solution for businesses aiming to enhance their reach and customer engagement. These versatile units not only offer convenience but also cater to diverse consumer preferences, making them an essential investment for B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. As urbanization continues to rise and consumer behavior shifts towards on-the-go options, understanding the intricacies of mobile vending machines becomes crucial for success.

This comprehensive guide delves into the multifaceted world of mobile vending machines, covering various types, materials, manufacturing processes, quality control measures, and supplier options. Additionally, it addresses cost considerations, market trends, and frequently asked questions that can empower international buyers in their sourcing decisions. Whether you are in Mexico seeking to penetrate local markets or in the UK exploring innovative retail solutions, this guide is designed to equip you with the knowledge needed to navigate the complexities of mobile vending procurement.

By leveraging the insights presented herein, B2B buyers will not only make informed decisions but also capitalize on the growing opportunities presented by mobile vending machines. The aim is to provide a robust framework for understanding this sector, ensuring that your business can adapt and thrive in a competitive landscape.

Understanding mobile vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Snack Vending Machines | Compact, automated dispensing of snacks | Offices, schools, public spaces | Pros: Low maintenance, high demand; Cons: Limited product variety |

| Beverage Vending Machines | Specializes in drinks, including cold and hot options | Events, gyms, hotels | Pros: High turnover; Cons: Requires regular restocking and cleaning |

| Food Trucks | Mobile kitchens offering a variety of meals | Festivals, corporate events | Pros: Diverse menu options; Cons: Higher operational costs and regulations |

| Specialty Vending Machines | Customized for specific products (e.g., cosmetics, electronics) | Retail environments, airports | Pros: Unique offerings; Cons: Niche market appeal, potentially lower sales |

| Automated Retail Kiosks | Interactive and tech-driven, often with touchscreen interfaces | Malls, airports, transit stations | Pros: Engaging customer experience; Cons: Higher initial investment |

Snack Vending Machines

Snack vending machines are designed to dispense a variety of snacks, including chips, candies, and healthy options. Their compact size makes them suitable for placement in offices, schools, and public spaces where quick access to snacks is desired. When purchasing, consider the machine’s capacity, payment options (cash, card, mobile payments), and the variety of snacks it can hold. Regular maintenance is crucial to ensure product freshness and machine functionality.

Beverage Vending Machines

These machines focus on dispensing beverages, ranging from soft drinks to hot coffee. They are commonly found in gyms, hotels, and event venues, where high foot traffic can lead to significant sales. B2B buyers should evaluate the types of beverages offered, the machine’s energy efficiency, and its user interface. Regular restocking and cleaning are essential to maintain customer satisfaction and machine performance.

Food Trucks

Food trucks are mobile kitchens that provide a wide range of meal options, appealing to diverse customer preferences. They are particularly effective at festivals and corporate events, where catering needs vary. Buyers should consider local regulations, operational costs, and menu diversity when investing in a food truck. While they offer flexibility and a unique dining experience, the initial investment and potential regulatory hurdles can be significant.

Specialty Vending Machines

These machines cater to specific markets by offering niche products such as cosmetics, electronics, or gourmet foods. Placed in retail environments or airports, they attract customers looking for unique items. B2B buyers should assess the machine’s target demographic, product range, and marketing potential. While they can generate higher margins through unique offerings, their appeal may be limited to specific customer segments.

Automated Retail Kiosks

Automated retail kiosks are interactive vending solutions that often feature touchscreen interfaces, allowing customers to browse and select products easily. These kiosks are ideal for high-traffic areas like malls and transit stations. When considering an investment, buyers should focus on the technology used, customer engagement features, and maintenance requirements. Although they can enhance the shopping experience, the initial investment and ongoing operational costs may be higher than traditional vending options.

Related Video: Machine Learning in 2024 – Beginner’s Course

Key Industrial Applications of mobile vending machine

| Industry/Sector | Specific Application of mobile vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Automated snack and beverage dispensing | Increased sales through 24/7 availability; reduced staffing costs | Machine size, payment options, product storage capacity |

| Healthcare | Dispensing medical supplies and snacks | Immediate access to essential items; improved patient satisfaction | Compliance with health regulations, temperature control |

| Education | Campus-wide snack and beverage services | Enhances student experience; promotes healthy eating | Variety of products offered, payment systems, location accessibility |

| Events & Entertainment | On-the-go food and beverage sales during events | Maximizes revenue opportunities; reduces queue times | Mobility features, ease of setup, payment processing options |

| Retail | Mobile pop-up shops for seasonal products | Flexibility to capture sales in high-traffic areas; low overhead costs | Product variety, branding opportunities, local regulations |

Food & Beverage

In the food and beverage industry, mobile vending machines are revolutionizing how consumers access snacks and drinks. These machines can operate around the clock, providing a steady stream of revenue without the need for constant staffing. For international B2B buyers, it’s crucial to consider machine specifications such as product storage capacity and payment options to cater to diverse consumer preferences.

Healthcare

Mobile vending machines in healthcare settings can dispense medical supplies, snacks, and beverages, ensuring that patients and staff have quick access to essential items. This application significantly enhances patient satisfaction by reducing wait times for snacks and supplies. Buyers in this sector must ensure compliance with health regulations and consider features like temperature control to maintain product integrity.

Education

In educational institutions, mobile vending machines offer convenient snack and beverage options to students. This enhances the overall campus experience and encourages healthier eating habits among students. When sourcing these machines, buyers should focus on the variety of products offered and the accessibility of payment systems, ensuring that they meet the needs of a diverse student body.

Events & Entertainment

During events and festivals, mobile vending machines provide on-the-go food and beverage options, maximizing revenue while minimizing queue times. These machines can be strategically placed to capture high traffic and cater to large crowds. B2B buyers should prioritize mobility features and ease of setup, along with efficient payment processing options to streamline operations.

Retail

In the retail sector, mobile vending machines can serve as pop-up shops for seasonal or specialty products, allowing businesses to quickly adapt to changing consumer trends. This flexibility enables brands to capture sales in high-traffic areas with lower overhead costs compared to traditional retail spaces. Buyers should consider product variety, branding opportunities, and local regulations when sourcing these machines to ensure compliance and marketability.

Related Video: How to Start a Vending Machine Business, Cost, Tips, How Much You Make

Strategic Material Selection Guide for mobile vending machine

When selecting materials for mobile vending machines, international B2B buyers must consider various factors that influence performance, durability, and compliance with local regulations. Here, we analyze four common materials used in mobile vending machines: stainless steel, aluminum, high-density polyethylene (HDPE), and carbon steel.

Stainless Steel

Key Properties:

Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand elevated temperatures. The most common grades, such as 304 and 316, offer varying levels of resistance to oxidation and pitting.

Pros & Cons:

Stainless steel is highly durable and easy to clean, making it ideal for food applications. However, it tends to be more expensive than other materials, which can impact the overall cost of the vending machine. Manufacturing complexity is moderate, as it requires specialized tools for cutting and welding.

Impact on Application:

Due to its non-reactive nature, stainless steel is suitable for storing food and beverages without altering their taste or quality. It can withstand the rigors of outdoor use, making it a preferred choice in diverse climates.

Considerations for International Buyers:

Buyers should ensure compliance with food safety standards such as FDA regulations in the U.S. or EU food contact materials regulations. Common standards like ASTM A240 for stainless steel may also apply.

Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can be anodized to enhance its surface properties, making it more durable against wear and tear.

Pros & Cons:

The primary advantage of aluminum is its low weight, which facilitates easier transport and installation of vending machines. However, it may not be as strong as stainless steel and can be prone to dents and scratches. The manufacturing process is generally simpler, contributing to lower overall costs.

Impact on Application:

Aluminum is suitable for applications where weight is a critical factor, such as portable vending machines. Its resistance to corrosion makes it ideal for outdoor environments, but care must be taken with acidic or alkaline foods.

Considerations for International Buyers:

Buyers should verify that the aluminum used meets international standards such as ASTM B221. Additionally, they should consider local preferences for material aesthetics, as aluminum can be less visually appealing than stainless steel.

High-Density Polyethylene (HDPE)

Key Properties:

HDPE is a thermoplastic polymer known for its high strength-to-density ratio, excellent impact resistance, and good chemical resistance. It can operate effectively in a wide temperature range.

Pros & Cons:

HDPE is cost-effective and lightweight, making it easy to mold into various shapes for custom designs. However, it may not provide the same level of structural integrity as metals, which can limit its use in high-stress applications.

Impact on Application:

HDPE is particularly suited for components that require flexibility and resistance to moisture, such as storage bins and trays in vending machines. Its chemical resistance allows it to handle various food items without degradation.

Considerations for International Buyers:

Buyers should ensure that HDPE complies with food safety regulations, such as those set by the FDA or EU. Additionally, they should confirm that the material meets relevant standards like ASTM D638 for tensile properties.

Carbon Steel

Key Properties:

Carbon steel is known for its high strength and durability. It can be treated with coatings to enhance corrosion resistance, although it is inherently susceptible to rust.

Pros & Cons:

While carbon steel is often more affordable than stainless steel, its susceptibility to corrosion can be a significant drawback unless properly coated. The manufacturing process is straightforward, making it a popular choice for budget-conscious projects.

Impact on Application:

Carbon steel is suitable for structural components of vending machines that do not come into direct contact with food. It is often used in frames and supports where strength is paramount.

Considerations for International Buyers:

Buyers should consider local climate conditions, as carbon steel may require additional protective coatings in humid or coastal areas. Compliance with standards such as ASTM A36 is also essential for structural applications.

| Material | Typical Use Case for mobile vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel (e.g., 304, 316) | Food storage and dispensing components | Excellent corrosion resistance | Higher cost compared to other materials | High |

| Aluminum | Portable vending machines and lightweight components | Lightweight and easy to transport | Less strength than stainless steel | Medium |

| High-Density Polyethylene (HDPE) | Storage bins and trays | Cost-effective and moisture resistant | Limited structural integrity | Low |

| Carbon Steel (e.g., A36) | Structural components (frames, supports) | High strength and durability | Susceptible to corrosion without coating | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for mobile vending machine

Manufacturing Processes for Mobile Vending Machines

The manufacturing of mobile vending machines involves several critical stages that ensure the final product is durable, functional, and meets the diverse needs of operators across various markets. For B2B buyers, understanding these processes is essential for making informed purchasing decisions.

Main Stages of Manufacturing

-

Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Common materials used include stainless steel for the exterior, which provides durability and resistance to corrosion, and high-quality plastics for internal components. Suppliers often source materials that comply with international standards, ensuring that the raw materials are certified and suitable for food contact. -

Forming

This stage involves shaping the materials into the required forms. Techniques such as laser cutting, bending, and welding are commonly employed. For instance, laser cutting allows for precise dimensions and intricate designs, which are crucial for the aesthetic and functional aspects of the vending machine. -

Assembly

Once the components are formed, they are assembled. This step requires skilled labor to ensure that all parts fit correctly and function as intended. Automated assembly lines may be utilized for high-volume production, which helps maintain consistency and reduce labor costs.

- Finishing

The finishing stage includes surface treatment, painting, and application of protective coatings. This not only enhances the appearance of the vending machines but also provides additional protection against environmental factors. Techniques such as powder coating are popular due to their durability and resistance to chipping.

Quality Assurance in Manufacturing

Quality assurance (QA) is vital in the production of mobile vending machines, ensuring that each unit meets regulatory and customer standards. Key aspects of QA include adherence to international and industry-specific standards, as well as systematic quality checkpoints throughout the manufacturing process.

Relevant International Standards

- ISO 9001: This is a globally recognized standard for quality management systems. Compliance with ISO 9001 indicates that a manufacturer has established processes for consistent quality, customer satisfaction, and continual improvement.

- CE Marking: For products sold in Europe, CE marking signifies compliance with health, safety, and environmental protection standards. This is crucial for mobile vending machines to ensure they are safe for consumer use.

- API Standards: For vending machines that handle food or beverages, adherence to standards set by organizations such as the American Petroleum Institute (API) may be relevant, particularly for components that interact with consumables.

Quality Control Checkpoints

Quality control (QC) checkpoints are integrated into the manufacturing process to ensure that products meet established standards. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality criteria. It helps to catch any defects before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to monitor the quality of the assembly and production processes. This step is essential for identifying and rectifying issues in real-time.

-

Final Quality Control (FQC): Before shipment, the finished products undergo a comprehensive quality check. This includes functional testing, safety assessments, and visual inspections to ensure that all specifications are met.

Common Testing Methods

B2B buyers should be aware of common testing methods used during the QC process, including:

- Functional Testing: Verifies that all components of the vending machine operate as intended, including payment systems, refrigeration units, and dispensing mechanisms.

- Safety Testing: Assesses the machine for electrical safety, ensuring that it complies with regulations to prevent hazards.

- Durability Testing: Evaluates the machine’s performance under various conditions, simulating real-world usage to ensure longevity.

Verifying Supplier Quality Control

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s QC processes is crucial. Here are actionable strategies:

-

Conduct Audits: Request on-site audits of the manufacturing facilities. This allows buyers to assess the manufacturing environment, processes, and adherence to quality standards firsthand.

-

Review Quality Reports: Suppliers should provide comprehensive quality reports detailing the results of IQC, IPQC, and FQC. Analyzing these reports can reveal patterns in quality issues or improvements.

-

Engage Third-Party Inspectors: Utilizing independent third-party inspection services can provide an unbiased evaluation of product quality. These inspectors can conduct random checks and provide detailed reports.

-

Understand Certification Nuances: Different regions may have specific certification requirements. Buyers should ensure that suppliers possess all necessary certifications relevant to their market, such as local food safety regulations or electrical standards.

Conclusion

In summary, understanding the manufacturing processes and quality assurance practices for mobile vending machines is essential for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and rigorous quality control measures, buyers can ensure they procure reliable and compliant machines. Engaging with suppliers who maintain high standards of quality assurance not only mitigates risks but also enhances operational efficiency in diverse markets.

Related Video: Satisfying Factory Production #Machines & Ingenious Skilled #Workers #Manufacturing Best Tools Tips

Comprehensive Cost and Pricing Analysis for mobile vending machine Sourcing

Cost Structure of Mobile Vending Machines

When sourcing mobile vending machines, understanding the cost structure is essential for international B2B buyers. The primary cost components typically include:

-

Materials: This encompasses the raw materials used in manufacturing the machine, such as metals, plastics, and electronic components. High-quality materials often lead to increased durability and performance.

-

Labor: Labor costs vary significantly based on the manufacturing location. Regions with lower labor costs can provide competitive pricing, but it’s crucial to assess the skill level and experience of the workforce.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and administrative expenses. Efficient production facilities with optimized processes can help reduce overhead costs.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. Investing in efficient tooling can lead to lower per-unit costs in larger production runs.

-

Quality Control (QC): Ensuring product quality is vital, particularly for machines that will be used in public settings. QC processes add to overall costs but can prevent costly returns and dissatisfaction.

-

Logistics: Shipping costs, customs duties, and warehousing should be factored into the total cost. International shipping can significantly impact pricing, especially when considering the distance and mode of transport.

-

Margin: Suppliers will typically add a profit margin to cover their risks and business expenses. Understanding the market standard for margins in your region can aid in negotiations.

Price Influencers in Mobile Vending Machine Sourcing

Several factors influence the pricing of mobile vending machines, including:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often lead to lower prices per unit. Suppliers may offer discounts for larger orders, so it’s beneficial to assess your needs carefully.

-

Specifications and Customization: Custom features or specific designs can increase costs. Buyers should evaluate the necessity of customizations versus standard models.

-

Materials: The choice of materials directly affects pricing. Premium materials may enhance durability and aesthetics but can increase the initial investment.

-

Quality and Certifications: Machines that meet specific safety and quality standards may carry higher prices but provide reassurance of reliability and compliance with local regulations.

-

Supplier Factors: The supplier’s reputation, location, and operational efficiencies can impact pricing. Established suppliers may charge more due to their reliability and quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining who bears shipping costs, risks, and responsibilities. This can significantly affect the total landed cost of the equipment.

Buyer Tips for Cost Efficiency

To optimize sourcing strategies, international buyers should consider the following tips:

-

Negotiate Effectively: Leverage information about competitors and market rates during negotiations. Establish a clear understanding of your needs and budget constraints.

-

Evaluate Total Cost of Ownership (TCO): Beyond the purchase price, consider maintenance, operating costs, and potential downtime. A slightly higher upfront cost may lead to lower operating expenses in the long run.

-

Understand Pricing Nuances: Different regions may have varying pricing structures due to local economic conditions, tariffs, and market demand. For instance, buyers in Africa may face different import duties compared to those in Europe.

-

Research Local Suppliers: In regions such as South America and the Middle East, local suppliers may offer advantageous pricing and reduced shipping costs. Building relationships with local vendors can lead to better terms and support.

-

Stay Informed on Market Trends: Keeping abreast of industry trends and innovations can help buyers make informed decisions about which features and technologies to invest in, ensuring they remain competitive.

Disclaimer

Prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential mobile vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘mobile vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for mobile vending machine

Key Technical Properties of Mobile Vending Machines

When considering the procurement of mobile vending machines, B2B buyers should focus on several critical technical specifications that directly impact the performance, durability, and overall value of the equipment. Here are essential properties to evaluate:

-

Material Grade

– The material used in the construction of vending machines, typically stainless steel or high-grade plastics, determines durability and resistance to corrosion. Stainless steel, for example, is preferred for its longevity and ease of cleaning, making it suitable for food-related applications. Buyers should ensure that the material meets local health and safety regulations. -

Power Requirements

– Understanding the power consumption and electrical specifications is vital, especially in regions with varying power supply conditions. Machines should be rated for specific voltage and current requirements (e.g., 110V/220V) and may require compatibility with local electrical standards. This ensures reliable operation without risking damage or operational downtime. -

Capacity and Size

– The internal capacity (e.g., number of items it can hold) and the overall dimensions of the vending machine are crucial for fitting into specific locations. Buyers should consider their target market and expected foot traffic to select a machine that maximizes product offerings while fitting within spatial constraints. -

Temperature Control

– For machines selling perishable items, effective refrigeration or heating systems are essential. Specifications should include temperature range capabilities (e.g., 0°C to 5°C for refrigeration) and energy efficiency ratings. This not only maintains product quality but also aligns with sustainability practices, which are increasingly important to consumers. -

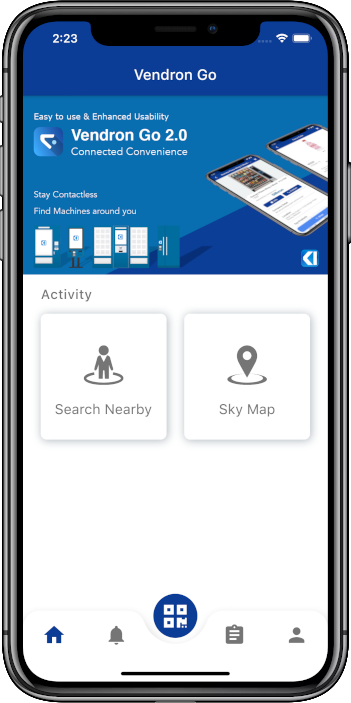

User Interface Technology

– Modern vending machines often feature touch screens or mobile payment systems. Buyers should assess the technology for user-friendliness and the ability to integrate with cashless payment systems, enhancing customer experience and increasing sales potential.

- Warranty and Support Services

– A comprehensive warranty and after-sales support are critical for minimizing operational disruptions. Buyers should inquire about the duration and coverage of the warranty, as well as the availability of technical support and spare parts.

Common Trade Terminology in the Mobile Vending Industry

Familiarity with industry jargon is essential for effective communication and negotiation in the procurement process. Here are key terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

– Refers to companies that produce parts or equipment that may be marketed by another manufacturer. When sourcing mobile vending machines, understanding whether a product is OEM can help ensure quality and compatibility. -

MOQ (Minimum Order Quantity)

– This term indicates the smallest number of units that a supplier is willing to sell. Knowing the MOQ is vital for budgeting and inventory management, particularly for smaller businesses looking to enter the vending market. -

RFQ (Request for Quotation)

– A formal process in which a buyer requests price quotations from suppliers for specific products or services. An effective RFQ can streamline procurement by ensuring that all vendors provide comparable pricing and specifications. -

Incoterms (International Commercial Terms)

– A set of predefined commercial terms used in international trade. Understanding Incoterms helps buyers clarify responsibilities regarding shipping, insurance, and tariffs, which is particularly important when sourcing from overseas suppliers. -

Lead Time

– The period from placing an order to the delivery of the product. Buyers should factor in lead times to ensure that they can meet market demands and avoid stockouts, especially in competitive environments. -

Customization

– Many vending machine suppliers offer customization options for branding and features. Understanding the extent of customization available allows buyers to tailor machines to their specific market needs, enhancing brand visibility and customer engagement.

By focusing on these essential technical properties and familiarizing themselves with industry terminology, international B2B buyers can make informed decisions that align with their operational goals and market demands.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the mobile vending machine Sector

Market Overview & Key Trends

The mobile vending machine sector is witnessing significant growth, driven by changing consumer behaviors, technological advancements, and urbanization trends. As consumers increasingly seek convenience and on-the-go options, international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are tapping into this demand. Key drivers include the rise of cashless payment systems, the integration of IoT technology for real-time inventory management, and the customization of vending solutions to cater to diverse markets.

Emerging trends in the B2B space include the adoption of eco-friendly machines that utilize sustainable materials and energy-efficient technologies. For instance, vending machines equipped with solar panels are becoming more prevalent, especially in regions with abundant sunlight. Furthermore, the use of data analytics to understand consumer preferences is reshaping product offerings, allowing businesses to adapt their inventory based on localized demand patterns.

Market dynamics are also influenced by regulatory frameworks aimed at promoting health and safety standards. Buyers need to stay informed about these regulations, especially in regions like Europe, where compliance can dictate product sourcing and operational practices. Additionally, partnerships with local suppliers and tech companies are becoming essential for navigating the complexities of distribution and logistics, ensuring that businesses can respond swiftly to market changes.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer just a trend but a necessity in the mobile vending machine sector. The environmental impact of manufacturing and operating vending machines requires a focused approach to minimize carbon footprints. B2B buyers are increasingly prioritizing suppliers that adopt sustainable practices, such as using recycled materials and reducing energy consumption.

Ethical sourcing is crucial for maintaining a responsible supply chain. Buyers should look for vendors that uphold fair labor practices and ensure that their materials are sourced from suppliers who comply with environmental and social governance (ESG) standards. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability.

Moreover, integrating ‘green’ certifications into product offerings not only enhances brand reputation but also appeals to a growing consumer base that values sustainability. Companies that invest in eco-friendly vending solutions can differentiate themselves in competitive markets, thereby attracting environmentally conscious consumers.

Brief Evolution/History

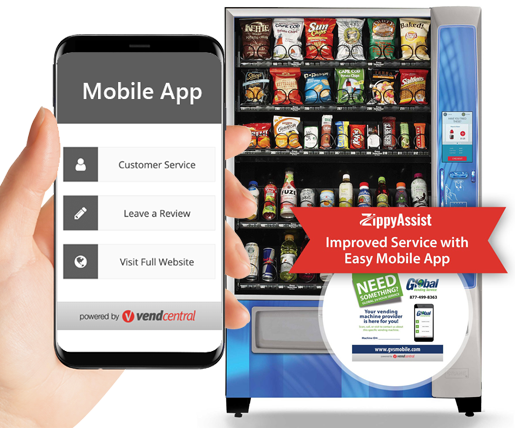

The mobile vending machine industry has evolved significantly over the decades. Originally designed for simple snack and beverage dispensing, these machines have transformed into sophisticated retail solutions. The 1990s saw the introduction of electronic payment systems, which revolutionized consumer interactions with vending machines.

In recent years, the integration of technology such as touchscreen interfaces, mobile app connectivity, and cashless payment options has expanded the functionality and appeal of vending machines. This evolution not only reflects technological advancements but also highlights a shift in consumer expectations towards convenience and personalization. As the market continues to innovate, B2B buyers must stay abreast of these developments to remain competitive and responsive to customer needs.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of mobile vending machine

-

What should I consider when vetting suppliers for mobile vending machines?

When vetting suppliers, prioritize their experience and reputation in the industry. Look for suppliers with a solid track record in manufacturing mobile vending machines, preferably with positive reviews from other B2B buyers. Request references and check their credentials, such as ISO certifications. Additionally, assess their ability to provide after-sales support, warranty terms, and responsiveness to inquiries, as these factors can significantly impact your long-term relationship. -

Can I customize mobile vending machines to fit my business needs?

Yes, many manufacturers offer customization options for mobile vending machines. You can request specific features, such as size, branding, and equipment configuration to align with your business model. It’s advisable to communicate your requirements clearly during initial discussions. However, keep in mind that extensive customization may affect production timelines and costs, so ensure you discuss these aspects upfront. -

What is the typical minimum order quantity (MOQ) and lead time for mobile vending machines?

MOQs can vary significantly among suppliers, often ranging from one unit for smaller manufacturers to larger quantities for established brands. Lead times also depend on customization and supplier capacity, generally ranging from 4 to 12 weeks. To avoid delays, it’s crucial to inquire about these details early in the negotiation process and factor them into your business planning. -

What payment methods are typically accepted for international orders?

Most suppliers accept various payment methods, including bank transfers, letters of credit, and online payment platforms. For international transactions, bank transfers are common due to their security and reliability. Always clarify payment terms and conditions, including deposits and payment schedules, before finalizing your order. Additionally, consider using an escrow service for large transactions to mitigate risks. -

What quality assurance measures should I look for in mobile vending machines?

Ensure that suppliers implement rigorous quality assurance (QA) processes. Request information about their QA protocols, including testing procedures and certifications. Look for compliance with international standards such as CE or ISO certifications, which indicate adherence to safety and quality benchmarks. Additionally, consider arranging for third-party inspections before shipment to verify that the machines meet your specifications. -

How can I ensure compliance with local regulations when importing mobile vending machines?

Familiarize yourself with local regulations regarding health, safety, and import requirements for mobile vending machines in your country. Engage with a local customs broker or legal advisor who can provide guidance on necessary certifications and documentation. Additionally, confirm that your supplier is knowledgeable about international shipping regulations and can assist in ensuring compliance during the import process. -

What logistics options should I consider for shipping mobile vending machines internationally?

Evaluate different logistics solutions based on cost, speed, and reliability. Common options include sea freight for bulk shipments and air freight for faster delivery. Discuss shipping terms with your supplier, including Incoterms, to clarify responsibilities for costs and risks during transit. Additionally, ensure that the machines are packaged securely to prevent damage during transport.

Illustrative Image (Source: Google Search)

- How should I handle disputes or issues with suppliers after placing an order?

Establish clear communication channels with your supplier from the outset. If disputes arise, refer to the terms outlined in your purchase agreement, including warranty and return policies. Document all correspondence and issues thoroughly. If resolution attempts fail, consider mediation or arbitration as a structured approach to resolving disputes. It’s beneficial to have a legal advisor familiar with international trade to assist if necessary.

Strategic Sourcing Conclusion and Outlook for mobile vending machine

In conclusion, effective strategic sourcing for mobile vending machines is essential for international B2B buyers seeking to capitalize on the growing demand for convenience and innovative retail solutions. Key takeaways include the importance of understanding regional market dynamics, such as consumer preferences and regulatory environments in Africa, South America, the Middle East, and Europe. Buyers should prioritize suppliers who offer customization options, robust after-sales support, and sustainable solutions, as these factors significantly impact customer satisfaction and operational efficiency.

Moreover, leveraging technology in the sourcing process can enhance transparency and foster stronger partnerships. By utilizing data analytics and digital platforms, businesses can make informed purchasing decisions that align with their strategic objectives.

Illustrative Image (Source: Google Search)

Looking ahead, the mobile vending machine market is poised for continued growth, driven by advancements in technology and shifting consumer behaviors. International B2B buyers are encouraged to engage with suppliers who not only understand these trends but also demonstrate a commitment to innovation and sustainability. By doing so, they can secure a competitive edge in this dynamic landscape. Embrace the future of retail—start exploring your options today to elevate your business offerings and meet evolving consumer demands.