Your Ultimate Guide to Sourcing Market Research Vending

Guide to Market Research Vending Machine Business

- Introduction: Navigating the Global Market for market research vending machine business

- Understanding market research vending machine business Types and Variations

- Key Industrial Applications of market research vending machine business

- Strategic Material Selection Guide for market research vending machine business

- In-depth Look: Manufacturing Processes and Quality Assurance for market research vending machine business

- Comprehensive Cost and Pricing Analysis for market research vending machine business Sourcing

- Spotlight on Potential market research vending machine business Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for market research vending machine business

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the market research vending machine business Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of market research vending machine business

- Strategic Sourcing Conclusion and Outlook for market research vending machine business

Introduction: Navigating the Global Market for market research vending machine business

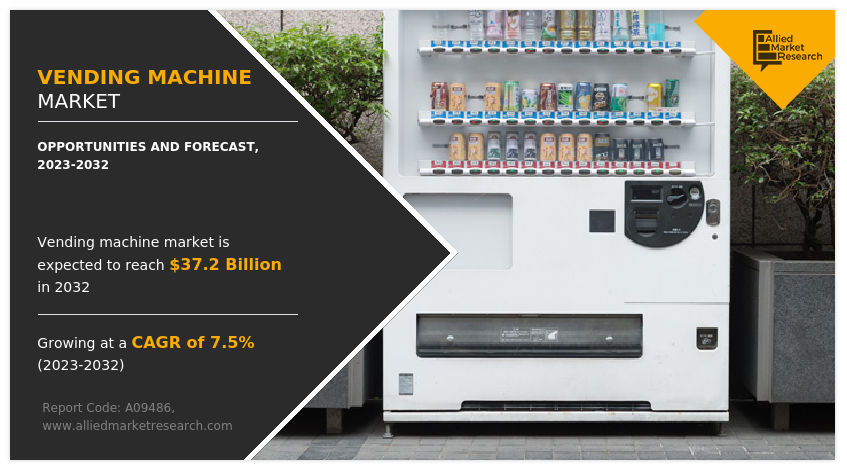

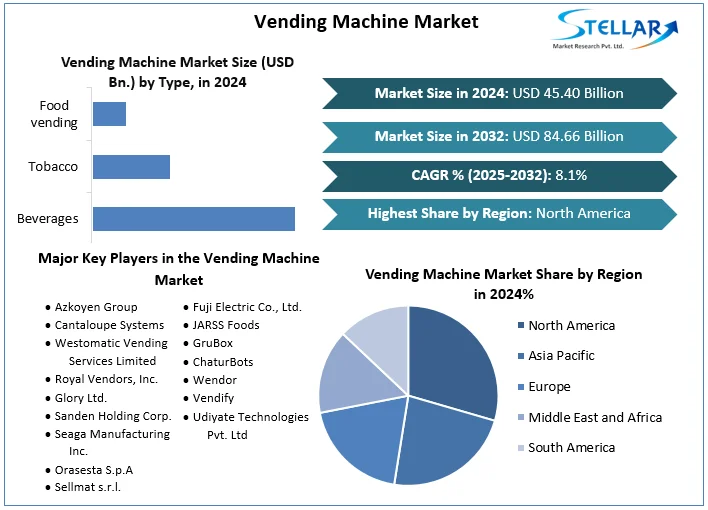

In today’s rapidly evolving business landscape, the market research vending machine business stands out as a pivotal solution for enterprises seeking to harness consumer insights effectively. This innovative approach not only streamlines data collection but also enhances the accuracy of market analysis, enabling businesses to make informed decisions that drive growth. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the nuances of this market is crucial for strategic sourcing and competitive advantage.

This comprehensive guide delves into various aspects of the market research vending machine business. It covers essential topics such as types of machines, materials used, manufacturing and quality control processes, and key suppliers. Additionally, it examines the cost factors associated with these machines and provides an overview of the current market landscape, including emerging trends and consumer preferences.

By exploring frequently asked questions, this guide empowers B2B buyers to navigate the complexities of sourcing market research vending machines confidently. It equips them with actionable insights and best practices, ensuring they can make choices that align with their business objectives and market demands. With a focus on delivering value, this resource is designed to facilitate informed sourcing decisions, ultimately fostering successful partnerships and driving sustainable growth in diverse markets.

Understanding market research vending machine business Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Vending Machines | Dispenses products directly, often cash-based | Retail, office break rooms | Pros: Easy to set up, low initial investment. Cons: Limited data collection, maintenance required. |

| Smart Vending Machines | Equipped with IoT technology, real-time data | Market research, consumer behavior | Pros: Advanced analytics, remote monitoring. Cons: Higher cost, requires tech support. |

| Interactive Kiosks | Touchscreen interfaces, multimedia content | Customer feedback, surveys | Pros: Engaging user experience, versatile applications. Cons: Higher complexity, may require training for users. |

| Mobile Vending Units | Portable, can be relocated easily | Event marketing, pop-up research | Pros: Flexibility, can reach diverse audiences. Cons: Limited product range, potential logistical challenges. |

| Automated Survey Stations | Focused on data collection via surveys | Research studies, academic research | Pros: Streamlined data collection, anonymity for respondents. Cons: May deter users if not user-friendly. |

Traditional Vending Machines

Traditional vending machines are the most recognizable form of vending technology. They typically dispense snacks, beverages, or other retail products in exchange for cash or card payments. These machines are commonly used in workplaces and public spaces. For B2B buyers, the primary consideration is the low initial investment and ease of setup. However, the lack of data collection capabilities limits their effectiveness in market research applications.

Smart Vending Machines

Smart vending machines integrate IoT technology, allowing for real-time data collection and monitoring. These machines can track inventory levels, customer preferences, and sales patterns, making them ideal for businesses looking to gather actionable insights. B2B buyers should consider the higher upfront costs and the need for ongoing technical support, but the potential for advanced analytics makes them a valuable asset for market research.

Interactive Kiosks

Interactive kiosks offer a more engaging experience through touchscreen interfaces that can display multimedia content. These machines are commonly used for customer feedback and surveys, making them suitable for businesses looking to enhance customer interaction. While they provide a versatile platform for data collection, B2B buyers must weigh the higher complexity and potential training requirements against the benefits of improved user engagement.

Mobile Vending Units

Mobile vending units are designed for flexibility, allowing businesses to relocate them easily for events or pop-up marketing campaigns. They can be used effectively for market research by reaching diverse audiences in various locations. The main advantages include flexibility and the ability to target specific demographics. However, buyers should consider the limited product range and potential logistical challenges associated with mobile operations.

Automated Survey Stations

Automated survey stations focus on gathering data through surveys and questionnaires. These machines can provide anonymity to respondents, encouraging honest feedback. They are particularly useful in research studies and academic settings. B2B buyers should consider the streamlined data collection process and the potential for high-quality insights. However, the user-friendliness of the interface is crucial, as a complicated system may deter participation.

Related Video: Business Model Canvas Explained with Examples

Key Industrial Applications of market research vending machine business

| Industry/Sector | Specific Application of market research vending machine business | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Consumer behavior analysis through product sampling | Enhanced understanding of customer preferences and trends | Machine reliability, data analytics capabilities, and user interface design |

| Education | Student feedback collection via interactive kiosks | Improved curriculum development based on real-time feedback | Compliance with educational standards, ease of use for students, and data privacy measures |

| Hospitality | Guest satisfaction surveys in hotels and restaurants | Increased customer loyalty and service improvement | Customization options, multilingual support, and data reporting features |

| Market Research Firms | Automated data collection for market analysis | Cost-effective and timely insights for strategic decisions | Integration with existing data systems, scalability, and maintenance support |

| Transportation & Logistics | Route optimization feedback from drivers | Enhanced operational efficiency and reduced costs | Robustness for outdoor use, real-time data transmission, and GPS integration |

Detailed Applications

Retail: In the retail sector, market research vending machines can be employed to gather consumer behavior insights through product sampling and feedback collection. These machines allow customers to sample products in exchange for their opinions, providing retailers with valuable data on preferences and purchasing behavior. For international B2B buyers, sourcing machines that are reliable and equipped with advanced data analytics capabilities is crucial, especially in diverse markets like Africa and South America, where consumer preferences may vary significantly.

Education: Educational institutions can utilize market research vending machines to collect real-time feedback from students on courses, teaching methods, and facilities. This feedback can be instrumental in refining curricula and improving student satisfaction. Buyers in this sector must consider compliance with educational standards and ensure that the machines are user-friendly, particularly for younger students. Additionally, data privacy is a critical factor to address in regions like Europe, where regulations are stringent.

Hospitality: In the hospitality industry, these vending machines can facilitate guest satisfaction surveys, allowing hotels and restaurants to gauge customer experiences efficiently. By collecting feedback directly from guests, businesses can identify areas for improvement and enhance service quality, ultimately leading to increased customer loyalty. Key considerations for buyers include the customization of survey questions and features like multilingual support to cater to diverse clientele, particularly in tourist-heavy regions.

Market Research Firms: Market research firms can leverage automated data collection through vending machines to conduct surveys and gather insights for various clients. This application offers a cost-effective solution for obtaining timely market intelligence, which is essential for strategic decision-making. Buyers should focus on sourcing machines that can seamlessly integrate with existing data systems and offer scalability to accommodate varying project sizes, especially in fast-growing markets across the Middle East and Asia.

Transportation & Logistics: In the transportation sector, vending machines can be used to collect feedback from drivers regarding route optimization and logistical challenges. This data can lead to improved operational efficiency and reduced transportation costs. Buyers should prioritize sourcing robust machines that can withstand outdoor environments, ensure real-time data transmission, and integrate GPS functionalities to enhance the effectiveness of the feedback collected.

Related Video: How to Start a Vending Machine Business, Cost, Tips, How Much You Make

Strategic Material Selection Guide for market research vending machine business

When selecting materials for market research vending machines, it is essential to consider the performance characteristics, cost implications, and regional compliance standards. Below is an analysis of four common materials used in the construction of these machines, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 800°F (427°C) and can endure various environmental conditions.

Pros & Cons:

The primary advantage of stainless steel is its durability and resistance to rust and corrosion, making it suitable for both indoor and outdoor installations. However, it is relatively expensive compared to other materials and can be challenging to machine, which may increase manufacturing complexity.

Impact on Application:

Stainless steel is compatible with a wide range of media, including water, soft drinks, and various food products, ensuring hygiene and safety in vending applications.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with local food safety standards, such as the European Food Safety Authority (EFSA) regulations. Additionally, understanding the grades of stainless steel (e.g., 304 vs. 316) is crucial for selecting the right material based on environmental exposure.

2. Carbon Steel

Key Properties:

Carbon steel is a strong material with good tensile strength and can handle a variety of pressures. However, it is susceptible to corrosion without proper treatment and typically has a temperature rating of around 400°F (204°C).

Pros & Cons:

The main advantage of carbon steel is its cost-effectiveness, making it a popular choice for budget-sensitive projects. Its primary drawback is the need for protective coatings to prevent rust, which can add to maintenance costs over time.

Impact on Application:

Carbon steel is suitable for non-corrosive environments and can be used for structural components of vending machines. However, it is not ideal for applications involving moisture or corrosive substances.

Considerations for International Buyers:

Buyers in Africa and South America should be aware of the need for protective coatings and maintenance schedules. Compliance with local standards, such as ASTM for materials, is also essential to ensure product safety and longevity.

3. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has a good strength-to-weight ratio. It generally has a temperature rating of around 300°F (149°C) and is easy to machine.

Pros & Cons:

The key advantage of aluminum is its lightweight nature, which facilitates easier transport and installation. However, it is less durable than stainless steel and can be prone to scratching and denting.

Impact on Application:

Aluminum is suitable for housing and structural components of vending machines, especially in environments where weight is a concern. Its corrosion resistance makes it ideal for outdoor applications.

Considerations for International Buyers:

International buyers should consider the specific aluminum alloy used, as different alloys have varying properties. Compliance with standards like JIS in Japan or EN in Europe is important for ensuring material quality and performance.

4. Plastic (Polycarbonate)

Key Properties:

Polycarbonate is a strong, lightweight plastic with excellent impact resistance and a temperature rating of about 240°F (116°C). It is also transparent, allowing for visibility of the products inside vending machines.

Pros & Cons:

The main advantage of polycarbonate is its impact resistance and lower weight, making it easy to handle and install. However, it can be less durable under extreme temperatures and may degrade over time when exposed to UV light.

Impact on Application:

Polycarbonate is commonly used for transparent panels in vending machines, providing visibility while protecting the contents. It is suitable for environments where safety and visibility are priorities.

Considerations for International Buyers:

Buyers should ensure that the selected polycarbonate meets relevant safety standards, especially in regions with strict regulations on materials used in consumer products. Understanding the UV resistance of the material is also crucial for outdoor applications.

Summary Table

| Material | Typical Use Case for market research vending machine business | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, housing for outdoor machines | Excellent corrosion resistance | Higher cost, manufacturing complexity | High |

| Carbon Steel | Non-corrosive structural components | Cost-effective | Susceptible to rust, requires coating | Low |

| Aluminum | Housing and structural components | Lightweight, easy to machine | Less durable, prone to scratching | Medium |

| Plastic (Polycarbonate) | Transparent panels for visibility | Impact resistant, lightweight | Less durable under extreme conditions | Medium |

This strategic material selection guide provides actionable insights for international B2B buyers, ensuring that they make informed decisions based on performance, cost, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for market research vending machine business

Manufacturing Processes for Market Research Vending Machines

The manufacturing of market research vending machines involves several key stages that ensure the final product meets industry demands for functionality, durability, and quality. Understanding these processes can help B2B buyers make informed decisions when sourcing from international suppliers.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Materials: The first step is choosing high-quality raw materials, including metals (for structural components), plastics (for casings), and electronic components (for payment systems and user interfaces).

– Processing: Materials are often cut, shaped, and treated to meet specifications. This can involve processes like laser cutting for precision or injection molding for plastic components. -

Forming

– Shaping Components: Techniques such as stamping, bending, and machining are employed to form the metal parts of the vending machine. This stage is crucial for ensuring the structural integrity of the machine.

– Integration of Electronics: The assembly of electronic components, including circuit boards and sensors, occurs at this stage. Ensuring compatibility and functionality is critical to the operation of the vending machine. -

Assembly

– Component Assembly: After forming, components are assembled into a complete unit. This may include the integration of the vending mechanism, user interface, and payment systems.

– Quality Control Checks: During assembly, initial quality checks are conducted to catch defects early. This can include visual inspections and functional tests of individual components. -

Finishing

– Surface Treatment: The final stage often involves painting, coating, or applying finishes to protect the machine from environmental factors and enhance aesthetics.

– Final Assembly and Testing: The complete unit undergoes rigorous testing to ensure all systems function correctly. This includes operational tests for vending mechanisms, payment processing, and user interfaces.

Quality Assurance in Manufacturing

Quality assurance is critical in the manufacturing of vending machines, particularly for international B2B buyers who require reliability and compliance with various standards.

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems (QMS) and is vital for ensuring consistent quality in manufacturing processes. Manufacturers certified under ISO 9001 demonstrate their ability to meet customer and regulatory requirements.

Illustrative Image (Source: Google Search)

-

CE Marking: For machines sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards. It is essential for market entry in the European Union.

-

API Standards: Depending on the specific applications of the vending machine (e.g., dispensing pharmaceuticals), adherence to API standards may be necessary. These standards ensure the safety and efficacy of products dispensed by the machines.

Quality Control Checkpoints

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components upon arrival. Suppliers should provide documentation proving compliance with specifications.

-

In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process help identify defects early. This can include measurements, visual inspections, and functional tests of components before they are assembled.

-

Final Quality Control (FQC): After assembly, the entire unit undergoes comprehensive testing, including functionality tests for all systems. This ensures that the final product meets all operational standards.

Common Testing Methods

- Functional Testing: Verifies that all components operate as intended under various conditions.

- Durability Testing: Assesses the machine’s resilience to wear and tear, particularly for components that experience frequent use.

- Environmental Testing: Ensures the machine can withstand temperature fluctuations, humidity, and dust, especially important for outdoor installations.

Verifying Supplier Quality Control

B2B buyers must conduct due diligence when selecting suppliers, particularly in international markets. Here are actionable steps to ensure robust quality control:

-

Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes and quality control measures. This can include on-site visits to evaluate equipment, processes, and compliance with standards.

-

Request Quality Reports: Suppliers should provide detailed quality assurance reports, including results from IQC, IPQC, and FQC stages. This transparency helps in assessing the supplier’s commitment to quality.

-

Third-Party Inspections: Engage third-party inspection services to conduct independent quality assessments. These inspections can be particularly useful for verifying compliance with international standards.

-

Certification Verification: Ensure that suppliers have valid certifications (e.g., ISO 9001, CE) by checking with the issuing bodies. This adds a layer of assurance regarding their quality management practices.

Quality Control Nuances for International Buyers

For buyers from Africa, South America, the Middle East, and Europe, understanding regional regulations and compliance standards is crucial. Here are some nuances to consider:

- Cultural Differences: Different regions may have varying approaches to quality assurance. Familiarize yourself with local practices and expectations.

- Regulatory Compliance: Ensure that the supplier is aware of and compliant with both local and international regulations. This includes understanding import/export regulations that may affect product compliance.

- Supply Chain Considerations: Assess the entire supply chain for potential risks that may affect product quality. This includes evaluating logistics, storage conditions, and handling practices.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions, ensuring they source high-quality market research vending machines that meet their operational needs.

Related Video: Business English Vocabulary : VV 47 – Manufacturing & Production Process (1) | English Vocabulary

Comprehensive Cost and Pricing Analysis for market research vending machine business Sourcing

When considering the sourcing of vending machines for market research purposes, B2B buyers must navigate a complex landscape of costs and pricing strategies. Understanding the cost components and price influencers can significantly enhance negotiation leverage and overall purchasing strategy.

Cost Components

-

Materials: The primary cost driver in vending machine production is the materials used, which typically include metal, plastic, electronic components, and refrigeration units. High-quality materials that ensure durability and functionality often come at a premium, but they can reduce long-term maintenance costs.

-

Labor: Labor costs can vary significantly depending on the region. For instance, manufacturing in regions with higher labor costs, such as Europe, may lead to increased overall pricing. Conversely, sourcing from countries with lower labor costs, such as some parts of South America or Africa, may yield cost savings.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses. Efficient factories with streamlined operations can minimize these overheads, allowing for more competitive pricing.

-

Tooling: Initial tooling costs for custom designs can be substantial. Buyers should consider whether the vending machines will require unique specifications or custom branding, as this can significantly increase upfront costs.

-

Quality Control (QC): Implementing robust quality control processes is vital to ensure the machines function as intended. This may involve additional costs, but it’s an investment in reducing future operational issues and increasing customer satisfaction.

-

Logistics: Transportation costs depend on the shipping method, distance, and volume. Buyers should evaluate the total logistics costs, including shipping insurance and tariffs, particularly when importing from regions like Europe or the Middle East to Africa or South America.

-

Margin: Suppliers typically include a profit margin in their pricing structure, which can vary based on the competitive landscape and the value-added services offered.

Price Influencers

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for discounts, making it advantageous for buyers with greater demand. Understanding the MOQ can help in negotiating better terms.

-

Specifications and Customization: Custom features can increase costs significantly. Buyers should weigh the necessity of these features against potential savings from standardized models.

-

Materials and Quality Certifications: Machines built with certified materials (e.g., ISO certifications) may command higher prices but ensure compliance and reliability, which are crucial for long-term operations.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium but offer better service and reliability.

-

Incoterms: Different Incoterms (International Commercial Terms) can affect the overall pricing structure by determining who bears the cost at various stages of shipping and delivery.

Buyer Tips

-

Negotiation: Leverage bulk purchasing to negotiate better prices and terms. Establishing long-term relationships with suppliers can also lead to better pricing over time.

-

Cost Efficiency: Conduct a Total Cost of Ownership (TCO) analysis that includes purchase price, maintenance, and operational costs. This approach helps in making informed decisions that go beyond the initial purchase price.

-

Pricing Nuances: Be aware of currency fluctuations and economic conditions that may impact pricing, especially when dealing with international suppliers. Additionally, consider the impact of local regulations and taxes on total costs.

Disclaimer

Prices can vary widely based on several factors, including market conditions, supplier negotiations, and regional economic factors. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

By understanding these cost components and price influencers, B2B buyers can make more informed decisions that align with their strategic goals while maximizing value in their sourcing of market research vending machines.

Spotlight on Potential market research vending machine business Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘market research vending machine business’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for market research vending machine business

Key Technical Properties

When engaging in the market research vending machine business, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some critical specifications:

-

Material Grade

The material grade refers to the quality and type of materials used in the construction of vending machines, such as stainless steel or high-grade plastics. Selecting the right material is important for durability, maintenance, and aesthetic appeal. For B2B buyers, choosing machines made from corrosion-resistant materials is vital, especially in humid or outdoor environments. -

Dimensions and Footprint

This specification includes the overall size and layout of the vending machine. Buyers must consider the space available for installation and the accessibility for users. A well-planned dimension can optimize foot traffic and sales. Understanding the footprint helps in ensuring compliance with local regulations regarding public space usage. -

Power Consumption

Power consumption indicates the amount of electricity required to operate the vending machine. Machines with lower energy consumption are not only environmentally friendly but also lead to reduced operational costs. B2B buyers should assess the energy efficiency ratings to ensure long-term savings and compliance with energy regulations. -

Capacity and Product Variety

This property refers to the number of items a vending machine can hold and the variety of products it can offer. A higher capacity allows for a broader range of products, which can attract more customers. Buyers should evaluate their target market’s preferences to select machines that can accommodate the desired product mix. -

User Interface Technology

The technology used for the user interface, such as touch screens or mobile payment options, significantly affects customer interaction and sales. Advanced interfaces can improve user experience and streamline transactions. B2B buyers must consider the technological capabilities of vending machines to ensure they meet consumer expectations.

Common Trade Terminology

Familiarizing oneself with industry jargon can facilitate smoother transactions and negotiations. Here are some common terms in the vending machine business:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts and equipment that may be marketed by another manufacturer. For buyers, working with OEMs can ensure that they receive high-quality machines and components tailored to their specifications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it impacts inventory management and cash flow. Buyers should negotiate MOQs to align with their business strategy and demand forecasts. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers. This process is essential for comparing pricing and terms across different vendors. B2B buyers should provide detailed specifications in their RFQs to receive accurate and competitive quotes. -

Incoterms (International Commercial Terms)

These are predefined international rules that outline the responsibilities of buyers and sellers in shipping goods. Understanding Incoterms is vital for B2B transactions, as they clarify costs, risks, and obligations, helping to avoid misunderstandings during the shipping process. -

Lead Time

Lead time refers to the amount of time between placing an order and receiving the product. For buyers, understanding lead times is critical for inventory planning and ensuring that vending machines are available when needed. Buyers should discuss lead times with suppliers to synchronize their operations effectively.

Illustrative Image (Source: Google Search)

- Warranty and Service Agreement

A warranty is a guarantee provided by the manufacturer regarding the condition of the product, while a service agreement outlines the terms for maintenance and repairs. B2B buyers should thoroughly review these documents to ensure they are protected against potential defects and have access to ongoing support.

By understanding these properties and terms, international B2B buyers can make more informed decisions, ultimately leading to successful investments in the vending machine market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the market research vending machine business Sector

Market Overview & Key Trends

The market research vending machine business is experiencing transformative changes driven by technological advancements and evolving consumer preferences. Key global drivers include the increasing demand for data-driven insights, the rise of automation, and the integration of artificial intelligence (AI) in data collection. For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, understanding these trends is crucial for making informed sourcing decisions.

Emerging B2B tech trends such as cloud-based data analytics and real-time reporting are reshaping how market research is conducted. These technologies facilitate faster data collection and analysis, allowing businesses to respond swiftly to market changes. Moreover, the demand for user-friendly interfaces and mobile accessibility is pushing manufacturers to innovate, leading to more interactive and engaging vending machines.

International buyers should also consider regional market dynamics. For example, in Africa and South America, there is a growing emphasis on localized data collection to cater to diverse consumer behaviors. Meanwhile, European buyers may prioritize compliance with stringent data protection regulations, such as GDPR. Understanding these nuances will enable B2B buyers to select the right vendors and technologies that align with their operational needs.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a focal point for businesses across sectors, and the market research vending machine industry is no exception. The environmental impact of manufacturing processes and product lifecycle management is under scrutiny, compelling companies to adopt sustainable practices. For B2B buyers, this means prioritizing vendors that demonstrate a commitment to sustainability through responsible sourcing and eco-friendly materials.

Ethical supply chains are increasingly important, particularly as consumers demand transparency and corporate accountability. Buyers should seek suppliers that provide certifications for sustainable practices, such as ISO 14001 for environmental management or the Forest Stewardship Council (FSC) certification for materials. Additionally, exploring options for energy-efficient vending machines can significantly reduce operational costs and carbon footprints.

Investing in sustainable solutions not only enhances brand reputation but also aligns with the growing regulatory pressures to minimize environmental impact. Buyers should engage with manufacturers who prioritize sustainable design and production methods, ensuring that their sourcing decisions contribute positively to the environment.

Brief Evolution/History

The market research vending machine business has evolved significantly since its inception in the late 20th century. Initially, these machines served as simple data collection points, primarily for consumer feedback in retail settings. However, technological advancements have transformed them into sophisticated data-gathering tools capable of integrating with digital platforms and offering real-time analytics.

In the past decade, the proliferation of mobile technology and the internet of things (IoT) has further revolutionized the sector. Modern vending machines are now equipped with features such as touchscreens, biometric sensors, and connectivity options that facilitate seamless data collection and consumer interaction. This evolution reflects the broader trend towards automation and data-driven decision-making in the B2B landscape, making it essential for international buyers to stay informed about the latest innovations and sourcing opportunities.

Related Video: Global Trends Tutorial: Chapter 3: IPE

Frequently Asked Questions (FAQs) for B2B Buyers of market research vending machine business

-

How can I vet potential suppliers for market research vending machines?

When sourcing suppliers, start by checking their business credentials, including registration and any industry certifications. Request references from previous clients, and look for reviews or testimonials. It’s also wise to conduct a site visit if possible, or utilize third-party inspection services to ensure their manufacturing capabilities align with your needs. Furthermore, leveraging platforms like Alibaba or Global Sources can provide insights into supplier ratings and transaction histories. -

Can I customize the vending machines to fit my brand?

Yes, most manufacturers offer customization options for their vending machines. This can include branding through color schemes, logos, and specific functionalities tailored to your target market’s needs. When discussing customization, ensure you clarify the extent of changes possible and any additional costs associated with these modifications. It’s advisable to get prototypes or samples to evaluate the quality of customization before placing large orders. -

What are the minimum order quantities (MOQ) and lead times for production?

MOQs can vary significantly between suppliers, often ranging from 50 to several hundred units depending on the customization and complexity of the machines. Lead times also depend on production schedules, typically ranging from 4 to 12 weeks after the order is confirmed. Always confirm these details upfront to align your purchasing strategy with your operational timelines. -

What payment terms should I expect when dealing with international suppliers?

Payment terms can vary, but common practices include a deposit (usually 30-50%) before production and the balance upon completion or prior to shipment. Some suppliers may accept letters of credit, which can provide additional security. Ensure to discuss and agree on payment methods that are comfortable for both parties, considering any transaction fees associated with international payments. -

How can I ensure quality assurance and certification compliance?

Request copies of relevant quality assurance certifications such as ISO 9001 or specific safety standards applicable to vending machines in your region. Consider implementing a Quality Assurance plan that includes regular inspections during the production process. Additionally, hiring third-party inspection agencies can help verify that the machines meet your quality and compliance standards before shipment. -

What logistics options are available for shipping the vending machines?

Shipping options include sea freight, air freight, and express couriers, with sea freight being the most cost-effective for large orders. Discuss logistics with your supplier to understand their shipping capabilities and whether they offer FOB (Free on Board) or CIF (Cost, Insurance, and Freight) terms. Ensure to factor in customs clearance and duties, as these can significantly impact overall costs and delivery timelines. -

How should I handle disputes with suppliers?

Establish clear communication channels and a dispute resolution process before entering into any agreements. If issues arise, document all communications and agreements in writing. It’s advisable to include mediation or arbitration clauses in contracts, as these methods can be less costly and time-consuming than litigation. If necessary, consult legal professionals familiar with international trade laws to guide you through the resolution process. -

What are the best practices for maintaining a long-term supplier relationship?

Building a strong relationship with your supplier can yield benefits like better pricing, priority production, and enhanced cooperation. Regular communication is key; provide feedback on product quality and service. Consider visiting their facilities to foster goodwill and understanding. Additionally, being transparent about your business needs and challenges can help suppliers better support your operations and adapt to changing market demands.

Strategic Sourcing Conclusion and Outlook for market research vending machine business

In summary, strategic sourcing is essential for B2B buyers in the market research vending machine business, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. By focusing on building strong supplier relationships, leveraging data analytics, and embracing innovative technologies, businesses can optimize their procurement processes and gain a competitive edge.

Key Takeaways:

– Supplier Relationships: Cultivating partnerships with reliable suppliers ensures quality and consistency in product offerings.

– Cost Efficiency: Strategic sourcing enables businesses to identify cost-effective solutions without compromising on quality.

– Market Insights: Utilizing data-driven insights from the vending machine market can guide purchasing decisions and enhance operational efficiency.

Looking ahead, international B2B buyers should proactively engage with emerging trends and adapt to the evolving landscape of the market research vending machine industry. By prioritizing strategic sourcing practices, businesses can not only enhance their procurement strategies but also position themselves for sustainable growth in an increasingly competitive market. Now is the time to take action—evaluate your sourcing strategies and explore opportunities that align with your business goals for the future.