Your Ultimate Guide to Sourcing Live Fish Vending Machine

Guide to Live Fish Vending Machine Near Me

- Introduction: Navigating the Global Market for live fish vending machine near me

- Understanding live fish vending machine near me Types and Variations

- Key Industrial Applications of live fish vending machine near me

- Strategic Material Selection Guide for live fish vending machine near me

- In-depth Look: Manufacturing Processes and Quality Assurance for live fish vending machine near me

- Comprehensive Cost and Pricing Analysis for live fish vending machine near me Sourcing

- Spotlight on Potential live fish vending machine near me Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for live fish vending machine near me

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the live fish vending machine near me Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of live fish vending machine near me

- Strategic Sourcing Conclusion and Outlook for live fish vending machine near me

Introduction: Navigating the Global Market for live fish vending machine near me

In today’s fast-evolving marketplace, the demand for fresh, live seafood has surged, prompting innovative solutions like live fish vending machines. These machines not only cater to the growing consumer preference for quality and freshness but also present a lucrative opportunity for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. Understanding the intricacies of sourcing these machines is critical for businesses looking to capitalize on this trend.

This guide offers a comprehensive overview of the live fish vending machine market, addressing crucial aspects such as the various types available, the materials used in their construction, manufacturing standards, and quality control practices. Additionally, it will delve into supplier options, cost considerations, and market dynamics that influence purchasing decisions.

B2B buyers will find value in the detailed FAQs section, which addresses common queries and challenges faced when sourcing these machines. By empowering buyers with actionable insights and clear sourcing strategies, this guide aims to facilitate informed decision-making, ensuring that businesses can navigate the complexities of the global market effectively. Whether you’re a retailer in Saudi Arabia, a distributor in the UK, or a startup in South America, understanding the live fish vending machine landscape will enable you to leverage this innovative solution to meet consumer demands and enhance your business offerings.

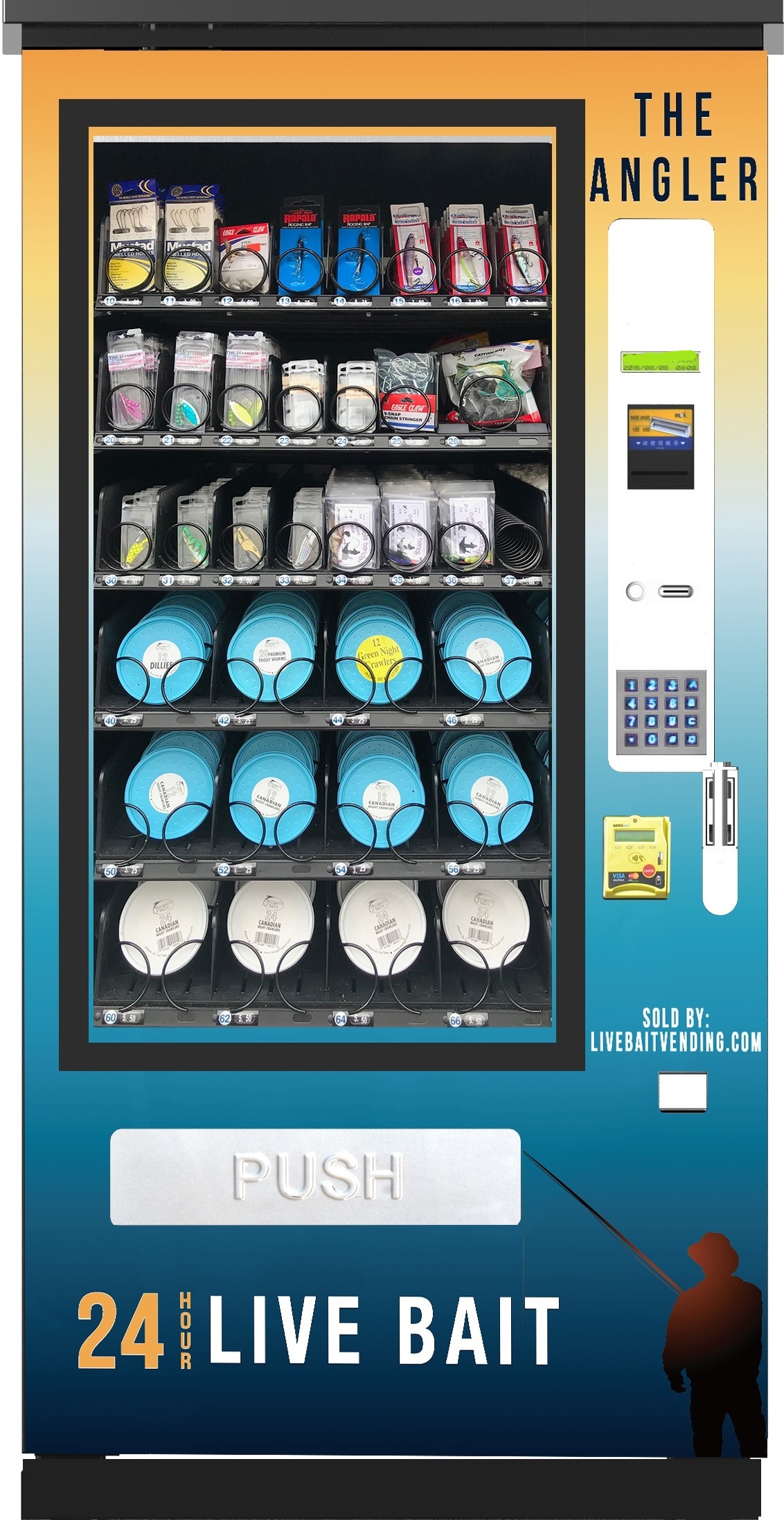

Illustrative Image (Source: Google Search)

Understanding live fish vending machine near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Fish Vending Machine | Standard unit with refrigerated tanks for live fish | Retail fish markets, supermarkets | Pros: Familiarity, easy maintenance. Cons: Limited species variety. |

| Automated Smart Fish Dispenser | High-tech, touchscreen interface, and real-time inventory tracking | Restaurants, seafood delivery services | Pros: Enhanced customer experience, efficient inventory management. Cons: Higher initial investment. |

| Mobile Fish Vending Unit | Compact, portable design for various locations | Food trucks, pop-up markets | Pros: Flexibility in location, lower startup costs. Cons: Limited capacity. |

| Eco-friendly Fish Vending Machine | Utilizes sustainable materials and energy-efficient technology | Eco-conscious retailers, specialty markets | Pros: Appeals to environmentally aware consumers. Cons: Potentially higher operational costs. |

| Customized Fish Vending Solutions | Tailored designs to fit specific business needs | Large retail chains, aquaculture businesses | Pros: Meets unique requirements, maximizes space utilization. Cons: Longer lead time for production. |

Traditional Fish Vending Machine

The traditional fish vending machine is characterized by its refrigerated tanks designed to keep live fish at optimal temperatures. These machines are commonly found in retail fish markets and supermarkets, providing a reliable source of fresh seafood. B2B buyers should consider factors such as machine capacity, maintenance requirements, and the range of fish species offered. While these machines are familiar and easy to maintain, they may lack the variety that some businesses seek.

Automated Smart Fish Dispenser

Automated smart fish dispensers feature advanced technology, including touchscreen interfaces and real-time inventory tracking. These machines are ideal for restaurants and seafood delivery services, where efficiency and customer engagement are critical. B2B buyers should evaluate the initial investment against potential increases in sales and customer satisfaction. The enhanced experience and inventory management capabilities are significant advantages, although the upfront costs may deter some smaller businesses.

Mobile Fish Vending Unit

The mobile fish vending unit offers a compact and portable solution, making it suitable for food trucks and pop-up markets. This flexibility allows businesses to reach diverse customer bases at various locations. Buyers should assess the capacity and operational costs associated with these units. While they provide lower startup costs and location flexibility, the limited capacity may restrict sales volume during peak times.

Eco-friendly Fish Vending Machine

Eco-friendly fish vending machines are designed with sustainability in mind, utilizing energy-efficient technologies and sustainable materials. These machines cater to eco-conscious retailers and specialty markets that prioritize environmental responsibility. B2B buyers should consider the operational costs and the potential for attracting environmentally aware consumers. While they may incur higher initial costs, the long-term benefits of appealing to a niche market can be significant.

Customized Fish Vending Solutions

Customized fish vending solutions are tailored to meet the specific needs of larger retail chains and aquaculture businesses. These machines can be designed to maximize space utilization and accommodate unique operational requirements. Buyers should evaluate the lead time for production and the potential for long-term cost savings. While the customization offers significant advantages in terms of fit and function, it may also result in longer waiting periods for delivery and installation.

Related Video: Buying Every Fish From the Live Fish Vending Machine… deadly fish

Key Industrial Applications of live fish vending machine near me

| Industry/Sector | Specific Application of live fish vending machine near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aquaculture | Retail sales of live fish directly to consumers | Increased sales opportunities, reduced overhead costs | Compliance with health regulations, machine durability |

| Hospitality | On-site fish vending for restaurants and hotels | Freshness of seafood, unique dining experience | Supply chain reliability, machine maintenance and service support |

| Education | Educational institutions for aquaculture programs | Hands-on learning for students, promoting sustainable practices | Customization options, training for staff |

| Retail | Supermarkets and grocery stores selling live fish | Diversification of product offerings, attracting more customers | Location suitability, machine size and capacity |

| Food Processing | Integration in processing plants for immediate sales | Streamlined supply chain, reduced spoilage | Equipment compatibility, ease of integration with existing systems |

Aquaculture

In the aquaculture industry, live fish vending machines serve as an innovative retail solution, allowing producers to sell fish directly to consumers. This approach not only increases sales opportunities but also reduces overhead costs associated with traditional retail setups. International buyers must consider compliance with health regulations specific to their regions, ensuring that machines are durable and capable of maintaining optimal water conditions for fish health.

Hospitality

For the hospitality sector, live fish vending machines can be installed in restaurants and hotels to provide guests with the freshest seafood options. This unique offering enhances the dining experience and emphasizes the establishment’s commitment to quality. B2B buyers in this sector should focus on supply chain reliability to ensure consistent fish availability, as well as the importance of machine maintenance and service support to minimize downtime.

Education

Educational institutions, particularly those with aquaculture programs, can utilize live fish vending machines to provide students with hands-on learning experiences. This application promotes sustainable practices and helps students understand the complexities of fish farming and retail. Buyers in this sector should seek customization options for the machines to fit their specific educational needs, along with appropriate training for staff to operate the equipment effectively.

Retail

In the retail sector, supermarkets and grocery stores can leverage live fish vending machines to diversify their product offerings. By providing live fish, these businesses can attract more customers looking for fresh seafood options. Key considerations for international buyers include the suitability of machine locations within stores and the size and capacity of the machines to meet customer demand effectively.

Food Processing

Live fish vending machines can also find applications in food processing plants, allowing for immediate sales of fresh fish post-processing. This integration streamlines the supply chain and reduces spoilage by providing a direct sales channel. Buyers in this industry should prioritize equipment compatibility with existing systems and the ease of integration to enhance operational efficiency.

Strategic Material Selection Guide for live fish vending machine near me

When selecting materials for live fish vending machines, it is crucial to consider their properties, durability, and compatibility with the specific requirements of the application. Here, we analyze four common materials that are often used in the construction of these machines, focusing on their key properties, advantages and disadvantages, and considerations for international buyers.

1. Stainless Steel (e.g., AISI 304/316)

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, particularly in environments exposed to moisture and saline conditions. It has a high-temperature rating and can withstand significant pressure, making it suitable for various operational conditions.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust and corrosion, which is vital for maintaining hygiene in live fish vending applications. However, it is more expensive than other materials, and its manufacturing process can be complex, potentially leading to higher costs for international buyers.

Impact on Application: Stainless steel is compatible with various media, including water and ice, which are commonly used in live fish vending machines. Its non-reactive nature ensures that it does not alter the quality of the fish.

Specific Considerations: Buyers from regions like the Middle East and Europe should ensure compliance with local food safety standards and regulations regarding materials in contact with food products. Common standards include ASTM and DIN.

2. Polycarbonate

Key Properties: Polycarbonate is a lightweight, high-impact-resistant plastic that can withstand a wide range of temperatures. It is also transparent, allowing for visibility of the fish inside the vending machine.

Pros & Cons: The main advantage of polycarbonate is its impact resistance and lower weight compared to metals, making it easier to handle and install. However, it has lower temperature and pressure ratings than metals and can be prone to scratching.

Impact on Application: Polycarbonate is suitable for the viewing panels of vending machines, as it allows customers to see the live fish. However, it may not be suitable for parts that require high durability or exposure to extreme temperatures.

Specific Considerations: Buyers should check for compliance with international safety standards, especially in regions with stringent regulations on food contact materials. The compatibility of polycarbonate with cleaning agents used in maintenance should also be considered.

3. Aluminum

Key Properties: Aluminum is lightweight and has good corrosion resistance, especially when anodized. It has a moderate strength-to-weight ratio and can be easily machined.

Pros & Cons: The key advantage of aluminum is its lightweight nature, which can reduce shipping costs and ease installation. However, it is less durable than stainless steel and can be susceptible to corrosion in highly saline environments unless properly treated.

Impact on Application: Aluminum is often used for structural components of vending machines, where weight savings are critical. Its corrosion resistance makes it suitable for humid environments, but it may not be ideal for direct contact with seawater.

Specific Considerations: B2B buyers should be aware of the specific grades of aluminum used, as this can affect performance. Compliance with local standards, such as those in Europe (EN standards), is also essential.

4. Glass Reinforced Plastic (GRP)

Key Properties: GRP is a composite material known for its high strength-to-weight ratio and excellent corrosion resistance. It can be molded into complex shapes, making it versatile for various applications.

Pros & Cons: The primary advantage of GRP is its resistance to corrosion and chemicals, making it suitable for aquatic environments. However, it can be more expensive than traditional plastics and may require specialized manufacturing techniques.

Impact on Application: GRP is ideal for the body of the vending machine, providing durability and resistance to harsh conditions. Its lightweight nature allows for easy transport and installation.

Specific Considerations: International buyers should consider the manufacturing standards for GRP, as different regions may have varying regulations regarding its use in food-related applications. Compliance with ASTM standards is often necessary.

Summary Table

| Material | Typical Use Case for live fish vending machine near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel (e.g., AISI 304/316) | Structural components, tanks, and piping | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Polycarbonate | Viewing panels and lightweight components | Impact-resistant, lightweight | Lower temperature rating, scratches easily | Medium |

| Aluminum | Structural components and frames | Lightweight, good corrosion resistance | Less durable than stainless steel | Medium |

| Glass Reinforced Plastic (GRP) | Body of the vending machine | Corrosion resistant, versatile molding | Higher cost, specialized manufacturing needed | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for live fish vending machine near me

Manufacturing Processes of Live Fish Vending Machines

The production of live fish vending machines involves several critical stages that ensure both functionality and quality. Understanding these processes can significantly aid international B2B buyers in making informed purchasing decisions.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Materials: The first step involves selecting high-quality materials that meet safety and durability standards. Common materials include stainless steel for the body and food-grade plastics for internal components.

– Sourcing: It is crucial to source materials from reputable suppliers who comply with international standards, such as ISO 9001, to ensure consistency and reliability. -

Forming

– Cutting and Shaping: Advanced machinery is used to cut and shape the materials into the required dimensions. Techniques such as laser cutting and CNC machining are commonly employed for precision.

– Molding: Plastic components are often produced through injection molding, allowing for complex shapes and designs that can enhance the machine’s functionality. -

Assembly

– Component Integration: After forming, components are assembled. This includes integrating refrigeration systems, water filtration units, and electronic controls.

– Wiring and Testing: Electrical components are wired, and initial functionality tests are performed to ensure all systems operate correctly. -

Finishing

– Surface Treatment: To enhance durability and aesthetics, machines undergo surface treatments such as polishing or powder coating. This not only improves appearance but also provides corrosion resistance.

– Final Assembly and Packaging: The final assembly takes place, followed by thorough cleaning and packaging, ensuring the machine is ready for shipping.

Quality Assurance in Manufacturing

Quality assurance is paramount in the production of live fish vending machines, as it directly impacts user satisfaction and safety.

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently meet customer requirements and enhance satisfaction.

- CE Marking: In Europe, machines must meet specific health, safety, and environmental protection standards. CE marking signifies compliance with these regulations.

- API Standards: For machines using pumps or other fluid systems, adherence to American Petroleum Institute (API) standards may be relevant, particularly in ensuring the safe handling of aquatic life.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– At this stage, all incoming materials are inspected for quality and conformity to specifications. This includes checking for defects and ensuring that materials meet the required certifications. -

In-Process Quality Control (IPQC)

– Throughout the manufacturing process, regular inspections are conducted to ensure each stage meets quality standards. This includes monitoring assembly practices and verifying that components function as intended. -

Final Quality Control (FQC)

– Before packaging and shipping, a final inspection is performed to assess the overall quality of the machine. This includes testing all functionalities, ensuring that the vending machine operates smoothly and safely.

Common Testing Methods

- Functional Testing: This assesses the machine’s performance under normal operating conditions, including checks on refrigeration, water circulation, and user interface responsiveness.

- Durability Testing: Machines are subjected to various stress tests to evaluate their longevity and resistance to wear and tear.

- Safety Testing: This includes electrical safety tests to ensure compliance with international safety standards, especially important for machines operating in public spaces.

Verifying Supplier Quality Control

For B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are actionable steps to consider:

-

Supplier Audits

– Conduct regular audits of suppliers to ensure they adhere to quality standards. This can include reviewing their manufacturing processes, quality control practices, and compliance with international standards. -

Requesting Reports

– Ask suppliers for detailed quality control reports, including data from IQC, IPQC, and FQC stages. This documentation can provide insights into the supplier’s commitment to quality. -

Third-Party Inspections

– Engage third-party inspection agencies to assess the quality of machines before shipment. This can provide an unbiased evaluation of the manufacturing and quality assurance processes. -

Certification Verification

– Ensure that suppliers possess relevant certifications (e.g., ISO 9001, CE) and verify these credentials through official channels. This adds an additional layer of assurance regarding their manufacturing practices.

Quality Control and Certification Nuances for International Buyers

When sourcing live fish vending machines, international buyers should be mindful of specific nuances related to quality control and certification:

- Regulatory Compliance: Different regions may have varying regulations regarding food safety and machine operation. Buyers should familiarize themselves with local regulations and ensure that the machines comply with these standards.

- Cultural Considerations: In regions like the Middle East and Africa, local preferences and cultural practices may influence the design and functionality of vending machines. This should be taken into account during the manufacturing process.

- Post-Purchase Support: Ensure that suppliers offer adequate after-sales support, including maintenance and parts availability. This is crucial for ensuring the longevity and reliability of the machines in diverse operating environments.

By comprehensively understanding the manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions that align with their operational needs and quality expectations.

Comprehensive Cost and Pricing Analysis for live fish vending machine near me Sourcing

Cost Structure for Live Fish Vending Machines

When sourcing live fish vending machines, understanding the comprehensive cost structure is vital for B2B buyers. Here are the key components that influence the overall cost:

-

Materials: The primary materials include stainless steel for the machine body, high-quality pumps for water circulation, and refrigeration units. The choice of materials impacts durability and maintenance costs. For instance, using higher-grade materials may result in a higher upfront cost but lower long-term maintenance expenses.

-

Labor: Labor costs vary based on the complexity of manufacturing and the region. In countries with higher labor rates, such as those in Europe, the manufacturing costs will be significantly impacted. Buyers should also consider the labor involved in installation and maintenance.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overheads, making it essential to evaluate suppliers’ operational efficiency.

-

Tooling: Tooling costs can be substantial, particularly for custom machines tailored to specific requirements. Buyers should factor in these costs when assessing the total price, especially if they require unique features.

-

Quality Control (QC): Investing in quality assurance processes ensures that the machines meet international standards. This may increase upfront costs but can prevent future issues and costs related to machine failures or recalls.

-

Logistics: Shipping costs vary based on the distance and method of transportation. For international buyers, understanding Incoterms (International Commercial Terms) is crucial to determine who bears the shipping risks and costs.

-

Margin: Suppliers typically include a margin that reflects their business costs and desired profit. Understanding market standards for margins can provide leverage in negotiations.

Price Influencers

Several factors can influence the pricing of live fish vending machines:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often lead to discounts. Negotiating for larger quantities can reduce per-unit costs significantly.

-

Specifications and Customization: Custom features can increase costs. Buyers should clearly define their specifications to avoid unexpected costs during the manufacturing phase.

-

Materials and Quality Certifications: Machines made from higher-quality materials or those that meet specific quality certifications (like ISO) may cost more but offer better performance and reliability.

-

Supplier Factors: The reputation, reliability, and history of the supplier can influence pricing. Well-established suppliers may charge a premium but offer better service and quality assurance.

-

Incoterms: Understanding the terms of shipping can affect the total cost. For example, choosing Ex-Works (EXW) means the buyer is responsible for all shipping costs, while Delivered Duty Paid (DDP) includes shipping and duties in the price.

Buyer Tips for Cost-Efficiency

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, here are actionable insights:

-

Negotiation: Always negotiate terms and pricing. Suppliers may have some flexibility, especially for larger orders or repeat business.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, operating costs, and potential resale value. A cheaper machine may have higher long-term costs.

-

Pricing Nuances: Be aware of currency fluctuations and tariffs that can affect costs when importing machines. Budget accordingly and factor these into negotiations.

-

Supplier Evaluation: Conduct thorough research on potential suppliers. Look for reviews, case studies, and client testimonials to gauge reliability and quality.

Disclaimer

The prices and cost structures discussed are indicative and may vary based on specific configurations, supplier negotiations, and market conditions. Always conduct thorough research and obtain multiple quotes to ensure competitive pricing tailored to your needs.

Spotlight on Potential live fish vending machine near me Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘live fish vending machine near me’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for live fish vending machine near me

Key Technical Properties of Live Fish Vending Machines

When considering the procurement of live fish vending machines, international B2B buyers should pay attention to several essential technical properties that ensure reliability, efficiency, and compliance with local regulations. Here are the critical specifications to consider:

-

Material Grade

The material used in the construction of vending machines is crucial for durability and hygiene. Stainless steel is often preferred due to its resistance to corrosion and ease of cleaning. Buyers should ensure that materials comply with food safety standards in their respective countries, which can vary significantly between regions. -

Temperature Control Range

Maintaining optimal water temperature is vital for the health of live fish. Vending machines should have adjustable temperature controls with a range typically between 4°C to 20°C (39°F to 68°F). This specification is essential for ensuring fish remain in good condition until they are sold, which directly impacts customer satisfaction and sales. -

Water Filtration System

A robust water filtration system is necessary to keep the water clean and oxygenated. Machines should include multi-stage filtration processes that can remove impurities while ensuring the water is suitable for various species of fish. This system not only protects the fish but also minimizes maintenance needs, which can be a significant operational cost. -

Capacity and Size

The capacity of the vending machine, often measured in liters or gallons, determines how many fish it can hold at any given time. Buyers should assess their expected volume of sales to choose an appropriately sized machine. Additionally, the overall dimensions should fit the intended location, whether it’s a retail space or a public area. -

Energy Efficiency

Energy consumption is a significant factor, especially in regions where electricity costs are high. Look for machines that are energy-efficient and have eco-friendly certifications. This not only reduces operational costs but also aligns with global sustainability initiatives, appealing to environmentally conscious consumers. -

User Interface and Payment Options

The ease of use for both operators and customers is critical. Machines should have intuitive interfaces and multiple payment options, including cash, credit/debit cards, and mobile payments. This flexibility can enhance customer experience and increase sales opportunities.

Common Trade Terminology

Understanding industry terminology is equally essential for effective communication and negotiation in the B2B space. Here are some common terms relevant to live fish vending machines:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce equipment that may be marketed by another manufacturer. When sourcing vending machines, knowing the OEM can help buyers assess the quality and reliability of the product. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For live fish vending machines, this can affect inventory planning and cash flow. Buyers should negotiate MOQs that align with their business needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for a specific quantity of goods. Issuing an RFQ for live fish vending machines allows buyers to compare options and negotiate better deals. -

Incoterms

These are international commercial terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is crucial for international transactions to avoid misunderstandings about who bears the risk and costs during transportation. -

Lead Time

This term refers to the amount of time it takes from placing an order until it is delivered. In the context of live fish vending machines, shorter lead times can be critical for meeting market demands, especially in regions with fluctuating fish availability. -

Warranty and Service Agreement

A warranty provides assurance regarding the quality of the product and outlines the manufacturer’s responsibilities in case of defects. A service agreement ensures ongoing maintenance and support, which is essential for minimizing downtime and ensuring operational efficiency.

By focusing on these technical properties and understanding the relevant trade terminology, B2B buyers can make informed decisions that enhance their investment in live fish vending machines.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the live fish vending machine near me Sector

Market Overview & Key Trends

The live fish vending machine sector is witnessing a notable transformation driven by several global trends. Urbanization and convenience are key factors propelling the demand for automated vending solutions, particularly in densely populated regions across Africa, South America, the Middle East, and Europe. As consumers increasingly seek fresh seafood, the ability to provide live fish in easily accessible locations through vending machines is gaining traction.

Moreover, advancements in technology are shaping the market dynamics. The integration of IoT (Internet of Things) capabilities in vending machines allows for real-time monitoring of fish health and water quality, which enhances operational efficiency and consumer confidence. Additionally, blockchain technology is emerging as a solution for transparency in supply chains, enabling buyers to verify the provenance and quality of the fish sold.

International B2B buyers should also be aware of regional variations in consumer preferences and regulatory landscapes. For example, countries in the Middle East may have specific requirements regarding the types of fish offered, while European markets are increasingly leaning towards eco-friendly and sustainable solutions. Understanding these nuances will be crucial for successful market entry and product positioning.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of the live fish vending machine sector. As consumers become more environmentally conscious, B2B buyers must prioritize ethical sourcing practices. This involves ensuring that fish are sourced from sustainable fisheries or aquaculture operations that adhere to responsible practices.

The environmental impact of sourcing practices is significant. Overfishing and habitat destruction are pressing issues that can tarnish a brand’s reputation. Therefore, obtaining green certifications such as the Marine Stewardship Council (MSC) or the Aquaculture Stewardship Council (ASC) can bolster credibility and appeal to eco-conscious consumers.

Additionally, the use of sustainable materials in the construction of vending machines—such as recyclable plastics or energy-efficient components—can enhance a company’s commitment to sustainability. This not only meets consumer demand for responsible products but also aligns with regulatory frameworks aimed at reducing environmental footprints.

Brief Evolution/History

The concept of vending machines has evolved significantly over the past few decades. Initially, these machines primarily dispensed snacks and beverages. However, as consumer needs shifted towards convenience and freshness, the introduction of live fish vending machines began in Japan during the early 2000s.

This innovation quickly spread to other parts of Asia and is now gaining momentum in Western markets. The evolution reflects a broader trend towards automation in food retail, where technology meets consumer demand for fresh, high-quality products. As the market matures, international B2B buyers must stay ahead of the curve by embracing technological advancements and sustainability practices to remain competitive.

Frequently Asked Questions (FAQs) for B2B Buyers of live fish vending machine near me

-

What criteria should I use to vet suppliers of live fish vending machines?

When sourcing suppliers, prioritize those with a proven track record in international trade. Verify their certifications, such as ISO 9001 for quality management and any relevant fish farming certifications. Request references from previous international clients and assess their production capabilities. Additionally, check for compliance with local regulations in your target market to avoid future legal complications. -

Can I customize the live fish vending machine to suit my market needs?

Yes, many suppliers offer customization options. Discuss your specific requirements, such as size, design, fish species, and technology integration (e.g., payment systems, monitoring features). Ensure that the supplier has experience with similar customizations and can provide examples of past projects. Customization may affect lead times and pricing, so clarify these aspects upfront. -

What are the typical minimum order quantities (MOQ) and lead times for live fish vending machines?

MOQs can vary significantly by supplier, typically ranging from 1 to 10 units for custom orders. Standard models may have lower MOQs. Lead times depend on the complexity of the order and the supplier’s production capacity, often ranging from 4 to 12 weeks. Discuss these details early in negotiations to align expectations and plan your inventory accordingly. -

What payment methods are commonly accepted for international purchases?

Most suppliers accept various payment methods, including bank transfers, letters of credit, and online payment platforms. It’s advisable to negotiate favorable terms, such as partial upfront payments and balance upon delivery. Ensure that the payment method you choose provides adequate protection against fraud and disputes, particularly in international transactions. -

How can I ensure the quality of the live fish vending machines I purchase?

Request detailed quality assurance (QA) processes from potential suppliers, including pre-shipment inspections and testing protocols. Ask for certifications that verify the machines’ compliance with international standards. Consider hiring a third-party inspection service to conduct on-site evaluations before shipment, especially if you are ordering large quantities or customized models. -

What certifications should I look for in live fish vending machines?

Look for certifications that demonstrate compliance with both local and international standards. Common certifications include CE marking (for European markets), RoHS (Restriction of Hazardous Substances), and any specific food safety certifications relevant to your market. These certifications indicate that the machines meet safety and environmental standards, which is crucial for building trust with your customers. -

What logistics considerations should I keep in mind when importing live fish vending machines?

Plan your logistics carefully, including shipping methods, customs clearance, and local delivery. Consider using a freight forwarder who specializes in handling machinery to facilitate the process. Be aware of import duties and taxes in your country, and ensure that the supplier provides all necessary documentation to avoid delays in customs. Additionally, factor in the machine’s installation and setup requirements. -

How should I handle disputes with suppliers?

Establish clear terms and conditions in your contract, including dispute resolution mechanisms such as arbitration or mediation. Maintain open communication with the supplier to address issues as they arise. If a dispute escalates, having documentation of all transactions, communications, and agreements will be crucial. Consider consulting legal experts familiar with international trade laws to guide you through the resolution process.

Strategic Sourcing Conclusion and Outlook for live fish vending machine near me

As the live fish vending machine market continues to evolve, strategic sourcing remains crucial for international B2B buyers looking to capitalize on this innovative retail solution. Key takeaways highlight the importance of understanding local market dynamics, compliance with health and safety regulations, and the integration of technology to enhance user experience. Buyers should prioritize suppliers who demonstrate reliability, quality assurance, and a commitment to sustainability, as these factors will influence consumer trust and brand loyalty.

Investing in live fish vending machines not only meets the growing demand for fresh seafood but also aligns with the trend towards convenience and sustainability in food retail. By establishing strong supplier partnerships and leveraging regional insights, businesses can effectively navigate challenges and seize opportunities in diverse markets across Africa, South America, the Middle East, and Europe.

Looking ahead, the potential for growth in this sector is significant. International B2B buyers are encouraged to explore collaborative ventures, innovative technologies, and customer engagement strategies to stay ahead in this competitive landscape. Embrace the future of retail by integrating live fish vending machines into your business model, ensuring you meet the evolving needs of consumers while driving profitability.