Your Ultimate Guide to Sourcing Live Bait And Tackle

Guide to Live Bait And Tackle Vending Machines

- Introduction: Navigating the Global Market for live bait and tackle vending machines

- Understanding live bait and tackle vending machines Types and Variations

- Key Industrial Applications of live bait and tackle vending machines

- Strategic Material Selection Guide for live bait and tackle vending machines

- In-depth Look: Manufacturing Processes and Quality Assurance for live bait and tackle vending machines

- Comprehensive Cost and Pricing Analysis for live bait and tackle vending machines Sourcing

- Spotlight on Potential live bait and tackle vending machines Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for live bait and tackle vending machines

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the live bait and tackle vending machines Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of live bait and tackle vending machines

- Strategic Sourcing Conclusion and Outlook for live bait and tackle vending machines

Introduction: Navigating the Global Market for live bait and tackle vending machines

In today’s competitive fishing industry, live bait and tackle vending machines are revolutionizing the way businesses cater to anglers’ needs. These innovative machines not only streamline the purchasing process but also enhance customer convenience by providing quick access to essential fishing supplies. As the demand for automated solutions grows, understanding the various types of vending machines, their materials, manufacturing standards, and quality control processes becomes crucial for B2B buyers seeking to capitalize on this trend.

This comprehensive guide will delve into the intricacies of live bait and tackle vending machines, offering insights into the different types available, the materials used in their construction, and the best practices for manufacturing and quality assurance. Furthermore, we will explore the landscape of suppliers, pricing structures, and market dynamics, ensuring you are well-equipped to make informed sourcing decisions.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, this guide serves as an invaluable resource. By addressing common questions and providing actionable insights, it empowers businesses to navigate the global market with confidence, ultimately facilitating successful partnerships and enhanced profitability in the burgeoning fishing equipment sector. Embrace this opportunity to stay ahead of the curve and meet the evolving demands of your customers.

Understanding live bait and tackle vending machines Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Live Bait Vending Machine | Dispenses live bait such as worms and minnows; often refrigerated | Fishing shops, bait and tackle stores | Pros: Easy to use, reliable supply; Cons: Limited to specific bait types. |

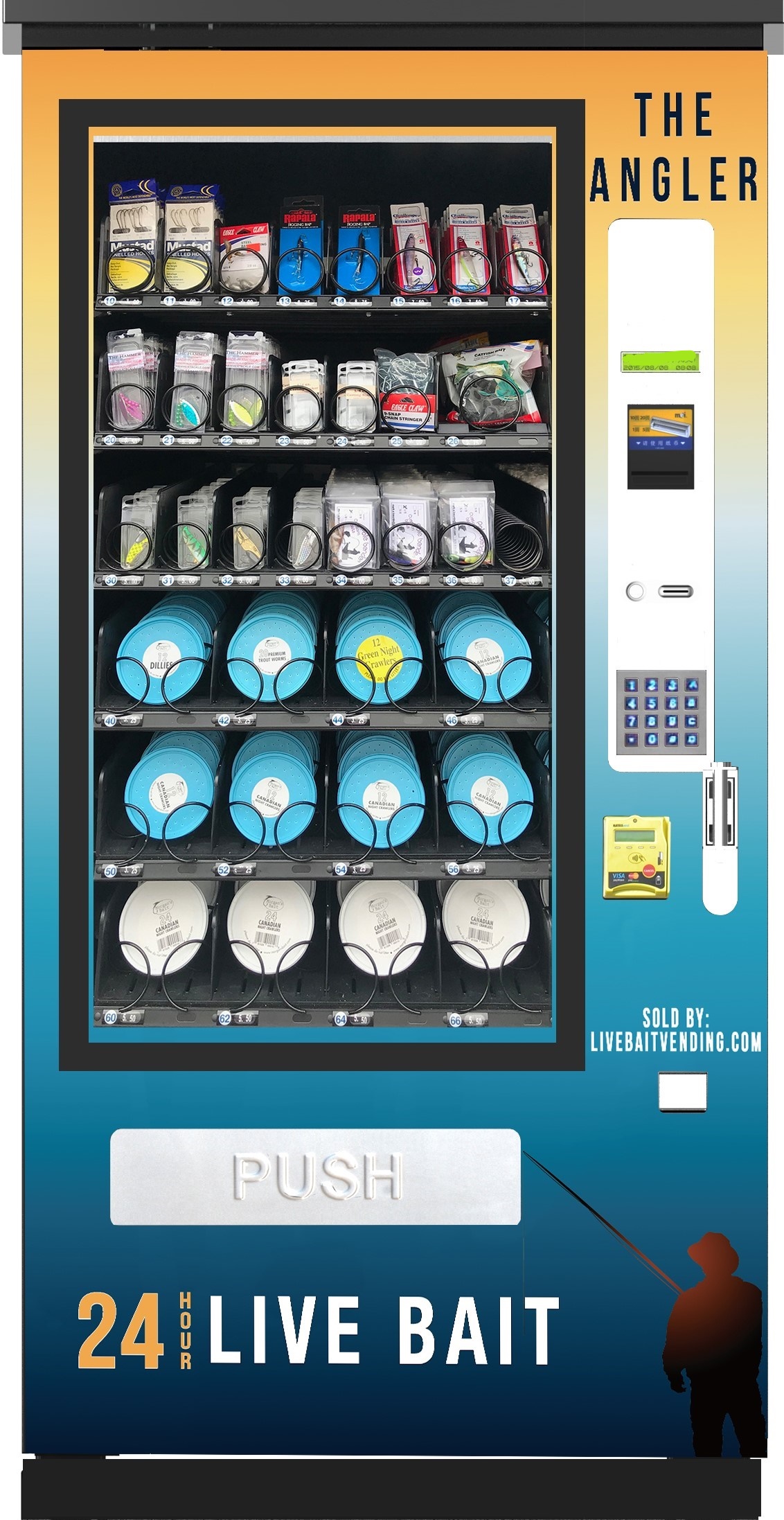

| Multi-Product Tackle Vending Machine | Offers a variety of bait and tackle products; customizable compartments | Retail environments, outdoor sports stores | Pros: Versatile, attracts diverse customer base; Cons: Higher initial investment. |

| Mobile Live Bait Vending Unit | Portable design; can be moved to different locations; battery-operated | Fishing tournaments, outdoor events | Pros: Flexibility in location; Cons: May require regular maintenance and charging. |

| Automated Tackle Kiosk | Integrated payment systems; touchscreen interface; provides product information | Urban areas, parks, and recreational sites | Pros: User-friendly, attracts tech-savvy customers; Cons: Higher operational costs due to technology. |

| Eco-Friendly Bait Machine | Uses sustainable practices; offers organic bait options; energy-efficient | Eco-conscious retailers, specialty shops | Pros: Appeals to environmentally aware consumers; Cons: May have limited product range. |

Standard Live Bait Vending Machine

Standard live bait vending machines are designed specifically for dispensing live bait such as worms and minnows. These machines typically feature refrigeration to maintain bait freshness, making them ideal for fishing shops and bait stores. When considering a purchase, B2B buyers should evaluate the machine’s capacity, ease of maintenance, and reliability of supply to ensure they meet customer demand effectively.

Multi-Product Tackle Vending Machine

These machines offer a wide range of fishing tackle products alongside live bait, with customizable compartments for various items. They are particularly useful in retail environments where a diverse customer base seeks different fishing supplies. Buyers should consider the initial investment and the potential for increased sales through product variety, as well as the machine’s ability to adapt to changing inventory needs.

Mobile Live Bait Vending Unit

Portable live bait vending units are designed for flexibility, allowing operators to transport them to fishing tournaments or outdoor events. These battery-operated machines can cater to transient customer bases, making them a popular choice for businesses seeking to capitalize on high-traffic events. B2B buyers should assess the unit’s battery life and maintenance requirements to ensure consistent operation.

Automated Tackle Kiosk

Automated tackle kiosks feature integrated payment systems and touchscreen interfaces, providing customers with product information and a seamless purchasing experience. These kiosks are especially effective in urban areas and parks, where convenience is key. Buyers should weigh the benefits of attracting tech-savvy customers against the higher operational costs associated with such technology.

Eco-Friendly Bait Machine

Eco-friendly bait machines focus on sustainability, offering organic bait options and utilizing energy-efficient practices. They cater to a growing market of environmentally conscious consumers and can be positioned in specialty shops. B2B buyers should consider the machine’s product range and the potential for attracting eco-aware customers, balancing it against the limited product offerings that may arise from focusing on sustainability.

Related Video: Buying Every Fish From the Live Fish Vending Machine… creepy fish

Key Industrial Applications of live bait and tackle vending machines

| Industry/Sector | Specific Application of live bait and tackle vending machines | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Recreational Fishing | Automated vending at popular fishing spots | Increased sales through convenience and accessibility | Machine durability for outdoor use, payment integration options |

| Marine Tourism | Bait vending at marinas and tourist destinations | Enhances customer experience and boosts local economy | Compliance with local regulations, bait freshness standards |

| Aquaculture | Supply of live bait for fish farming operations | Streamlines supply chain and reduces handling costs | Quality of bait, sourcing from sustainable suppliers |

| Sporting Goods Retail | Integration in retail outlets selling fishing gear | Attracts customers and diversifies product offerings | Space requirements, machine size, and design aesthetics |

| Environmental Research | Provision of bait for ecological studies and monitoring | Supports research initiatives and enhances data collection | Customization for specific bait types, tracking capabilities |

Recreational Fishing

Live bait and tackle vending machines are increasingly used at popular fishing locations to cater to the needs of anglers. By placing these machines at strategic spots such as lakes, rivers, and coastal areas, businesses can provide immediate access to live bait, which is often a critical component for successful fishing. This not only enhances the convenience for customers but also drives additional sales during peak fishing seasons. International buyers should consider the machine’s durability to withstand various weather conditions and the ease of payment processing to accommodate diverse customer preferences.

Marine Tourism

In regions with significant marine tourism, live bait vending machines can be a valuable addition to marinas and tourist hotspots. These machines allow tourists to quickly purchase bait for fishing excursions, thereby enriching their experience and encouraging longer stays. For businesses, this translates into increased foot traffic and sales. Buyers should be mindful of local regulations regarding the sale of live bait and ensure that the vending machines maintain the necessary standards for bait freshness to satisfy health and safety requirements.

Aquaculture

In the aquaculture sector, live bait vending machines can streamline the supply process for fish farmers. By providing a consistent source of live bait, these machines reduce the need for manual handling and transportation, which can be costly and time-consuming. This application is particularly beneficial for farms that require specific types of bait to optimize fish growth. Buyers in this sector should focus on sourcing high-quality bait and consider the logistical aspects of machine placement near aquaculture facilities to minimize supply chain disruptions.

Sporting Goods Retail

Retailers specializing in fishing gear can enhance their offerings by integrating live bait vending machines into their stores. This not only attracts fishing enthusiasts but also provides a comprehensive shopping experience where customers can find everything they need in one location. For B2B buyers, considerations should include the machine’s design to fit retail aesthetics and the amount of space available for installation. Additionally, understanding customer traffic patterns can help optimize placement for maximum visibility and sales.

Environmental Research

Live bait vending machines can also play a crucial role in environmental research, particularly in ecological studies that require specific bait for monitoring fish populations and aquatic ecosystems. By providing researchers with easy access to the necessary bait, these machines support various scientific initiatives aimed at preserving marine life. Buyers in this field should look for machines that can be customized to dispense different types of bait and potentially include tracking features to monitor usage for data collection purposes.

Related Video: Introduction to Industrial Automation | Introduction and History

Strategic Material Selection Guide for live bait and tackle vending machines

When selecting materials for live bait and tackle vending machines, international B2B buyers must consider various factors including durability, corrosion resistance, and cost-effectiveness. Below is an analysis of four common materials used in the construction of these machines, focusing on their properties, advantages, disadvantages, and specific considerations for buyers in diverse regions such as Africa, South America, the Middle East, and Europe.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. It typically has a temperature rating of up to 500°F (260°C) and can handle high-pressure environments.

Pros & Cons:

The advantages of stainless steel include its durability, aesthetic appeal, and low maintenance requirements. However, it can be more expensive than other materials and may require specialized manufacturing processes, which can increase lead times.

Impact on Application:

Stainless steel is highly compatible with a variety of media, making it suitable for environments where moisture and exposure to corrosive substances are prevalent.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A240 for stainless steel grades. In regions with high humidity or saline environments, selecting a higher grade of stainless steel (e.g., 316) is advisable.

2. Polypropylene

Key Properties:

Polypropylene is a thermoplastic polymer known for its chemical resistance and lightweight nature. It can withstand temperatures up to 180°F (82°C) and is resistant to many solvents.

Pros & Cons:

The main advantages of polypropylene include its low cost and ease of manufacturing, which allows for quicker production times. However, it is less durable than metals and may not withstand extreme temperatures or heavy loads.

Impact on Application:

Polypropylene is ideal for applications involving water or non-corrosive liquids but may not be suitable for environments with high mechanical stress or temperature fluctuations.

Considerations for International Buyers:

Buyers should verify compliance with local regulations regarding plastics, such as REACH in Europe. The cost-effectiveness of polypropylene can vary significantly depending on local availability and import tariffs.

3. Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, particularly when anodized. It can handle temperatures up to 400°F (204°C) and is often used in applications requiring a balance of strength and weight.

Pros & Cons:

Aluminum is cost-effective and easier to machine than stainless steel, making it a popular choice. However, it is less durable under extreme conditions and can be prone to scratching and denting.

Impact on Application:

Aluminum is suitable for applications where weight savings are critical, but its lower strength compared to stainless steel may limit its use in high-load scenarios.

Considerations for International Buyers:

International buyers should consider the availability of aluminum grades that meet specific strength and corrosion resistance requirements, such as 6061 or 7075. Compliance with standards like ASTM B221 is essential.

4. Galvanized Steel

Key Properties:

Galvanized steel is carbon steel coated with zinc to enhance corrosion resistance. It can typically withstand temperatures up to 300°F (149°C) and offers good mechanical strength.

Pros & Cons:

This material is relatively inexpensive and provides decent corrosion protection, making it suitable for outdoor applications. However, it can be less durable than stainless steel and may require periodic maintenance to prevent rust.

Impact on Application:

Galvanized steel is effective in environments where exposure to moisture is common, but it may not be suitable for highly corrosive conditions.

Considerations for International Buyers:

Buyers should ensure that the galvanization process meets local standards, such as ASTM A123. In regions with high humidity, additional protective coatings may be necessary to extend the lifespan of galvanized components.

Summary Table

| Material | Typical Use Case for live bait and tackle vending machines | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-end, moisture-prone environments | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Polypropylene | Low-cost applications, non-corrosive environments | Cost-effective, lightweight | Less durable, temperature sensitive | Low |

| Aluminum | Lightweight designs, moderate load applications | Good strength-to-weight ratio | Prone to scratching, lower durability | Medium |

| Galvanized Steel | Outdoor applications, moderate corrosion resistance | Inexpensive, decent corrosion protection | Requires maintenance, less durable | Low |

This strategic material selection guide provides B2B buyers with essential insights into the materials used for live bait and tackle vending machines, enabling informed decisions tailored to specific regional needs and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for live bait and tackle vending machines

Manufacturing Processes for Live Bait and Tackle Vending Machines

Manufacturing live bait and tackle vending machines involves several critical stages, each contributing to the overall quality and functionality of the final product. Understanding these stages can aid B2B buyers in evaluating suppliers effectively.

1. Material Preparation

The first step in the manufacturing process is material preparation. This includes sourcing high-quality raw materials such as metal for the frame, plastic for the vending compartments, and electronic components for the machine’s operational systems. Suppliers should ensure that materials meet relevant standards to enhance durability and resistance to environmental factors such as moisture and temperature fluctuations, which are crucial for outdoor use.

- Sourcing: Identify suppliers who provide materials that comply with international standards.

- Inspection: Conduct incoming quality control (IQC) checks to verify that materials meet specifications before they enter the production line.

2. Forming

Once materials are prepared, the next step is forming, where raw materials are shaped into specific components of the vending machine. This process typically involves techniques like:

- CNC Machining: Computer Numerical Control (CNC) machines are used for precise cutting and shaping of metal and plastic parts.

- Injection Molding: This technique is essential for producing plastic components, allowing for intricate designs that can accommodate various bait sizes.

Buyers should seek out manufacturers who utilize advanced forming technologies to ensure high precision and quality in the components.

3. Assembly

Following forming, the assembly stage involves putting together all components into a complete vending machine. This phase includes:

- Component Integration: Integrating electronic systems, including payment processing units and user interfaces, with the physical structure of the machine.

- Testing During Assembly: Implementing in-process quality control (IPQC) to test critical functionalities, such as the mechanical operation of doors and the accuracy of dispensing mechanisms.

Effective assembly practices are vital for ensuring that the machine operates seamlessly once installed in the field.

4. Finishing

The finishing stage enhances both the aesthetic and protective qualities of the vending machine. This includes:

- Surface Treatment: Applying coatings such as powder coating or galvanization to protect against rust and wear, which is particularly important in humid environments.

- Final Assembly and Testing: Conducting final quality checks (FQC) to ensure all components are functioning correctly and that the machine meets the required specifications.

A well-finished product not only looks appealing but also has a longer lifespan, which is a significant selling point for buyers.

Quality Assurance Standards

To ensure the highest quality in manufacturing live bait and tackle vending machines, adherence to international quality standards is crucial. Here are some relevant standards and practices:

International Standards

- ISO 9001: This standard focuses on quality management systems and is essential for manufacturers aiming to enhance customer satisfaction and meet regulatory requirements.

- CE Marking: For European buyers, CE marking indicates that the product complies with EU safety, health, and environmental protection legislation.

Industry-Specific Standards

- API Standards: For machines using specific materials or processes related to the petroleum and natural gas industries, compliance with American Petroleum Institute (API) standards may be necessary.

Quality Control Checkpoints

B2B buyers should be aware of the various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Ensures that all materials meet specified quality requirements before production.

- In-Process Quality Control (IPQC): Regular inspections during assembly to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product to validate performance and compliance with standards.

Common Testing Methods

Several testing methods are commonly employed to ensure quality:

- Functional Testing: Verifying that all machine features, such as payment processing and bait dispensing, operate correctly.

- Durability Testing: Assessing the machine’s resilience to environmental factors, particularly for outdoor installations.

- Safety Testing: Ensuring that the machine meets safety regulations, such as electrical safety standards.

Verifying Supplier Quality Control

B2B buyers can verify a supplier’s quality control measures through several approaches:

- Audits: Conduct on-site audits to review manufacturing processes, quality control practices, and compliance with standards.

- Reports: Request detailed quality control reports that outline testing methods, results, and any corrective actions taken.

- Third-Party Inspections: Engage independent inspection agencies to assess the manufacturing process and product quality, providing an unbiased evaluation.

Quality Assurance Nuances for International Buyers

When sourcing live bait and tackle vending machines, international buyers, especially from Africa, South America, the Middle East, and Europe, should consider:

- Local Regulations: Understand any specific regulations in the target market that may affect product compliance.

- Cultural Factors: Recognize variations in quality expectations and customer preferences across different regions, which may influence product design and functionality.

- Logistics and Supply Chain: Ensure that the supplier has robust logistics capabilities to manage shipping and delivery effectively, minimizing delays and ensuring product integrity upon arrival.

By thoroughly understanding the manufacturing processes and quality assurance standards, B2B buyers can make informed decisions when sourcing live bait and tackle vending machines, ultimately leading to successful partnerships and customer satisfaction.

Related Video: Most Satisfying Factory Production Processes And Heavy-Duty Factory Machines!

Comprehensive Cost and Pricing Analysis for live bait and tackle vending machines Sourcing

Cost Structure for Live Bait and Tackle Vending Machines

When sourcing live bait and tackle vending machines, understanding the cost components is crucial for making informed purchasing decisions. The main cost components include:

-

Materials: This includes the cost of the machine’s casing, internal mechanisms, electronic components, and any refrigeration systems necessary for live bait preservation. The choice of materials significantly impacts durability and price.

-

Labor: Labor costs cover the workforce involved in assembling the machines. This varies by region, with countries in Africa and South America often having lower labor costs compared to Europe, potentially affecting the overall pricing.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, including utilities, maintenance, and administrative costs. Efficient manufacturing processes can help minimize overhead, which is a critical factor in competitive pricing.

-

Tooling: Investment in tooling and equipment necessary for production can be substantial. Custom tooling for specialized machines can increase initial costs but may offer better long-term value if high-quality production is achieved.

-

Quality Control (QC): Ensuring the machines meet safety and performance standards incurs additional costs. Investing in robust QC processes can prevent future issues, leading to lower warranty claims and improved customer satisfaction.

-

Logistics: Transportation and shipping costs must be factored in, especially for international buyers. Import duties, taxes, and freight charges can significantly affect the final price.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and risks. Understanding the typical margin in the industry can help in evaluating price competitiveness.

Price Influencers

Several factors influence the pricing of live bait and tackle vending machines:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often yield lower per-unit costs due to economies of scale. Negotiating for bulk purchases can be beneficial for businesses looking to expand their offerings.

-

Specifications/Customization: Custom features such as branding, specific bait types, or enhanced technology can increase costs. Buyers should assess whether these features provide sufficient value to justify the additional expense.

-

Materials: The choice of materials directly impacts durability and maintenance needs. Higher-quality materials may lead to a higher upfront cost but can result in lower total cost of ownership over time.

-

Quality and Certifications: Machines with certifications for safety and efficiency may come at a premium. However, these certifications can enhance marketability and reduce liability risks.

-

Supplier Factors: Supplier reliability, reputation, and service levels can affect pricing. Established suppliers may charge higher prices but offer better support and warranties.

-

Incoterms: The agreed-upon shipping terms (Incoterms) can influence costs. Understanding responsibilities for shipping, insurance, and import duties is essential for accurate cost estimation.

Buyer Tips

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, consider the following tips:

-

Negotiation: Always be prepared to negotiate prices. Establishing a good relationship with suppliers can lead to better deals and terms.

-

Cost-Efficiency: Analyze the total cost of ownership, including maintenance and operational costs, rather than focusing solely on the purchase price.

-

Pricing Nuances: Be aware of pricing fluctuations due to currency exchange rates, local economic conditions, and regional demand. Conduct market research to compare prices across different suppliers.

-

Supplier Evaluation: Assess potential suppliers based on their track record, quality assurance processes, and customer service. A reliable supplier can save costs in the long run.

Disclaimer

Prices and cost estimates provided in this analysis are indicative and may vary based on specific requirements, supplier negotiations, and market conditions. Always seek detailed quotes from multiple suppliers to ensure competitive pricing.

Spotlight on Potential live bait and tackle vending machines Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘live bait and tackle vending machines’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for live bait and tackle vending machines

Key Technical Properties of Live Bait and Tackle Vending Machines

When considering live bait and tackle vending machines for international markets, several critical technical specifications must be understood to ensure optimal performance and compliance with local regulations. Here are the key properties:

- Material Grade

– The choice of materials, such as stainless steel or high-grade plastic, is essential for durability and corrosion resistance, especially in humid or wet environments. This affects the longevity of the machine and its ability to withstand harsh conditions, which is crucial for regions like Africa and South America where weather can be unpredictable.

Illustrative Image (Source: Google Search)

-

Temperature Control Range

– Live bait requires specific temperature conditions to remain viable. Vending machines should have a temperature control range (typically between 4°C and 10°C) to maintain the quality of the bait. Buyers should assess the effectiveness of the refrigeration system to ensure it meets local environmental conditions. -

Capacity and Size Tolerance

– Machines come in various sizes and capacities, often measured in liters for storage space. Understanding size tolerance is critical for compatibility with installation sites. For instance, a larger capacity might be necessary for areas with high fishing traffic, while smaller units may suffice in less frequented locations. -

Power Supply Specifications

– The power requirements of the vending machine, including voltage and amperage, should align with local electrical standards. This is particularly important for buyers in regions with inconsistent power supply, as machines may require specific configurations or backup systems to ensure reliability. -

User Interface

– A user-friendly interface, often featuring touch screens or mobile app connectivity, can enhance customer experience. It is vital for machines operating in diverse markets where customers may have varying levels of technological familiarity. -

Safety Standards Compliance

– Compliance with international safety standards (like CE, UL, or local equivalents) is essential for legal operation and customer safety. Buyers should ensure that machines are certified for electrical safety and food handling, particularly in markets with stringent regulations.

Common Trade Terminology

Understanding trade terminology is crucial for effective communication and negotiation in the B2B landscape. Here are some common terms related to live bait and tackle vending machines:

-

OEM (Original Equipment Manufacturer)

– Refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, partnering with an OEM can ensure high-quality components tailored to specific needs. -

MOQ (Minimum Order Quantity)

– The smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for budgeting and inventory management, especially for smaller businesses or new entrants in the market. -

RFQ (Request for Quotation)

– A document issued by a buyer to solicit price offers from suppliers for specific products or services. This process helps buyers compare prices and terms before making purchasing decisions. -

Incoterms (International Commercial Terms)

– A series of pre-defined commercial terms published by the International Chamber of Commerce, used in international trade contracts. These terms clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which is particularly relevant for cross-border transactions. -

Lead Time

– The amount of time that passes from the initiation of a process until its completion. In the context of vending machines, understanding lead time is crucial for planning inventory and ensuring timely delivery to meet customer demands. -

Warranty Period

– The duration for which a manufacturer guarantees the performance of their product. Buyers should evaluate warranty terms as they can impact long-term maintenance costs and the overall investment in vending machines.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing live bait and tackle vending machines, ensuring they meet both operational needs and market regulations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the live bait and tackle vending machines Sector

Market Overview & Key Trends

The live bait and tackle vending machine sector is experiencing significant transformation driven by technological advancements and changing consumer behaviors. Global drivers include increased interest in outdoor recreational activities, particularly fishing, which has surged during recent years as individuals seek safe outdoor experiences. This trend is particularly strong in regions like Africa, South America, the Middle East, and Europe, where local economies are increasingly dependent on sustainable fishing practices.

Current and emerging B2B technology trends are reshaping the market landscape. Innovations such as IoT-enabled vending machines allow for real-time inventory management, ensuring that stock levels are optimized and reducing waste. Additionally, mobile payment systems and user-friendly interfaces are enhancing customer experience, making it easier for anglers to access bait and tackle products conveniently.

Market dynamics are also influenced by the rise of eco-conscious consumers who demand sustainable products. B2B buyers must be aware of regional regulations regarding fishing practices and bait sourcing, which can vary significantly across countries. For instance, in Europe, stricter regulations on the use of certain live baits are prompting suppliers to offer alternatives that meet sustainability criteria, creating opportunities for businesses that prioritize eco-friendly solutions.

Sustainability & Ethical Sourcing in B2B

Sustainability is a critical consideration in the live bait and tackle vending machine industry. The environmental impact of sourcing live bait can be substantial, including overfishing and habitat destruction. Therefore, ethical supply chains are becoming increasingly important for B2B buyers. Companies that can demonstrate sustainable practices not only comply with regulations but also enhance their brand reputation among environmentally conscious consumers.

Green certifications and materials play a vital role in this sector. Buyers should look for vendors that offer products certified by recognized environmental organizations, such as the Marine Stewardship Council (MSC) or similar bodies relevant to their region. These certifications ensure that the bait sourced is harvested sustainably, helping to preserve aquatic ecosystems. Furthermore, using biodegradable or recyclable packaging for tackle products can significantly reduce environmental footprints, aligning with global sustainability goals.

Brief Evolution/History

The live bait and tackle vending machine market has evolved significantly since its inception. Initially, these machines were simple dispensers of basic fishing supplies, often located in remote areas with limited access to retail outlets. Over the decades, technological advancements have transformed these machines into sophisticated retail platforms capable of offering a wide variety of products, including live bait, tackle, and even fishing licenses. This evolution reflects broader changes in consumer expectations and technological capabilities, positioning vending machines as a convenient and efficient solution for anglers in diverse regions, including emerging markets in Africa and South America.

By understanding these dynamics, international B2B buyers can make informed decisions that align with current trends and sustainability practices, ensuring their investments are not only profitable but also responsible.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of live bait and tackle vending machines

-

What should I consider when vetting suppliers of live bait and tackle vending machines?

When vetting suppliers, prioritize their experience in the industry, customer reviews, and their track record for timely delivery. Request references from other international buyers, and verify their business licenses and certifications. Additionally, consider suppliers’ compliance with local regulations regarding the sale of live bait, as this can vary significantly across regions, particularly in Africa and South America. -

Can I customize the vending machines to fit my specific needs?

Yes, many suppliers offer customization options for their vending machines. This may include modifications in size, design, and the types of bait or tackle offered. Discuss your specific requirements upfront and ensure that the supplier can accommodate these changes. It’s also wise to request prototypes or samples before committing to a larger order. -

What are the typical minimum order quantities (MOQ) and lead times for these machines?

MOQs can vary widely depending on the supplier and the level of customization. Standard orders may start at 5-10 units, while customized machines could have higher MOQs. Lead times generally range from 4-12 weeks, depending on production schedules and shipping logistics. Always confirm these details in your initial discussions to avoid misunderstandings later. -

What payment methods are commonly accepted, and are there any recommended practices?

Most suppliers accept various payment methods, including bank transfers, letters of credit, and online payment platforms. For larger transactions, using a letter of credit can provide additional security. It’s advisable to negotiate payment terms that are favorable to both parties, such as partial payments upfront and the balance upon delivery. -

How can I ensure quality assurance and necessary certifications for the machines?

Request detailed information about the quality assurance processes the supplier employs. Look for certifications relevant to your market, such as ISO standards or specific certifications for equipment handling live bait. It’s beneficial to conduct a factory audit or request third-party inspections to verify compliance with these standards before shipment.

-

What logistics should I plan for when importing these machines?

Logistics planning is crucial when importing vending machines. Evaluate shipping options (air vs. sea freight) based on cost and urgency. Ensure you understand customs regulations in your country, including any import duties and taxes applicable to live bait and tackle. Collaborating with a logistics provider experienced in international shipping can streamline this process. -

What steps should I take if a dispute arises with the supplier?

In the event of a dispute, maintain clear communication with the supplier to resolve issues amicably. Document all correspondence and agreements. If necessary, refer to the contract terms regarding dispute resolution processes, which may include mediation or arbitration. Engaging a legal advisor familiar with international trade can also provide valuable guidance. -

How can I assess the long-term reliability of a supplier?

To assess a supplier’s long-term reliability, consider their financial stability, the longevity of their business, and their capacity for scaling operations. Regularly communicate with them and monitor their responsiveness and willingness to adapt to your changing needs. Building a relationship over time can provide insights into their reliability and commitment to quality service.

Strategic Sourcing Conclusion and Outlook for live bait and tackle vending machines

In conclusion, the strategic sourcing of live bait and tackle vending machines presents a unique opportunity for international B2B buyers. By leveraging the growing demand for convenient fishing solutions, businesses can tap into a lucrative market while enhancing customer satisfaction. Key takeaways include the importance of understanding local regulations, selecting reliable suppliers, and ensuring the machines are equipped with high-quality bait and tackle to meet consumer needs.

Investing in quality vending machines not only increases revenue but also strengthens brand loyalty among fishing enthusiasts. Buyers should prioritize suppliers that offer robust support and maintenance services, ensuring optimal performance and longevity of the machines.

Looking ahead, the integration of technology in vending machines—such as cashless payment options and real-time inventory tracking—will be crucial in meeting the evolving expectations of customers. As markets in Africa, South America, the Middle East, and Europe continue to expand, now is the time for B2B buyers to act strategically. Engage with suppliers, innovate your offerings, and position your business at the forefront of the fishing retail landscape.