Your Ultimate Guide to Sourcing Little Vending Machine

Guide to Little Vending Machine

- Introduction: Navigating the Global Market for little vending machine

- Understanding little vending machine Types and Variations

- Key Industrial Applications of little vending machine

- Strategic Material Selection Guide for little vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for little vending machine

- Comprehensive Cost and Pricing Analysis for little vending machine Sourcing

- Spotlight on Potential little vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for little vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the little vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of little vending machine

- Strategic Sourcing Conclusion and Outlook for little vending machine

Introduction: Navigating the Global Market for little vending machine

In today’s fast-paced global market, the demand for little vending machines is surging, making them a pivotal investment for businesses looking to enhance customer engagement and streamline sales processes. These compact machines not only offer convenience but also cater to diverse consumer preferences, making them a versatile addition to various environments—from offices to schools and public spaces. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the intricacies of the little vending machine market is essential for making informed sourcing decisions.

This comprehensive guide serves as an invaluable resource, detailing the different types of little vending machines available, the materials used in their construction, and the manufacturing and quality control processes that ensure reliability. It also highlights key suppliers, provides cost considerations, and analyzes market trends, enabling buyers to navigate the complexities of procurement with confidence.

By empowering buyers with actionable insights and answers to frequently asked questions, this guide not only simplifies the sourcing process but also enhances the potential for successful investments. Whether you’re in South Africa or Vietnam, understanding the nuances of little vending machines will position your business to capitalize on emerging opportunities in the vending industry.

Understanding little vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Snack Vending Machines | Designed for snacks; often compact and user-friendly | Office break rooms, schools | Pros: Easy to refill, high demand; Cons: Limited product range, may require frequent restocking. |

| Beverage Vending Machines | Specialize in drinks; can include hot and cold options | Gyms, events, hotels | Pros: Diverse product range, appealing to various demographics; Cons: Requires power source, maintenance can be complex. |

| Combo Vending Machines | Offer both snacks and beverages in one unit | Airports, shopping malls | Pros: Versatile, caters to diverse consumer needs; Cons: Higher upfront cost, potential for mechanical issues. |

| Healthy Vending Machines | Focus on nutritious snacks and drinks | Schools, corporate wellness programs | Pros: Increasing demand for healthy options, promotes brand image; Cons: Limited inventory, may require niche suppliers. |

| Specialty Vending Machines | Target specific markets (e.g., electronics, cosmetics) | Trade shows, specialized retail | Pros: Unique offerings, can attract niche markets; Cons: Higher operational costs, may have lower turnover rates. |

Snack Vending Machines

Snack vending machines are designed to dispense a variety of snacks, including chips, candy bars, and other quick bites. Their compact design makes them suitable for environments like office break rooms and schools, where quick access to snacks is essential. When purchasing, consider factors such as ease of refilling, the variety of products that can be offered, and the anticipated foot traffic in the location. While they are generally in high demand, buyers should be aware of the potential need for frequent restocking.

Beverage Vending Machines

Beverage vending machines can dispense a range of drinks, including sodas, bottled water, and even hot beverages like coffee or tea. Ideal for settings such as gyms, hotels, and event venues, these machines can cater to a wide audience. B2B buyers should evaluate power requirements and maintenance needs, as these machines often require a consistent power source and can be more complex to service than snack-only models. The diverse product range can significantly enhance customer satisfaction.

Combo Vending Machines

Combo vending machines combine the functionalities of snack and beverage dispensers, making them versatile choices for locations such as airports and shopping malls. They cater to a broad range of consumer preferences, allowing buyers to maximize their offerings. However, the initial investment is typically higher due to the dual functionality, and there may be a greater likelihood of mechanical issues due to the increased complexity. Buyers should consider the trade-off between variety and reliability.

Healthy Vending Machines

Healthy vending machines specialize in offering nutritious snacks and beverages, catering to a growing demand for health-conscious options. They are particularly popular in schools and corporate wellness programs, aligning with current trends toward healthier lifestyles. B2B buyers should assess the availability of suppliers for healthy products and the potential for limited inventory. While these machines can enhance a brand’s image, they may also require more specialized management.

Specialty Vending Machines

Specialty vending machines target niche markets, offering unique products such as electronics, cosmetics, or even local artisan goods. These machines are well-suited for trade shows and specialized retail environments, where they can attract specific consumer segments. B2B buyers should consider the higher operational costs associated with these machines and the potential for lower turnover rates compared to traditional vending options. Understanding the target market and product demand is crucial for success in this area.

Related Video: All Machine Learning Models Clearly Explained!

Key Industrial Applications of little vending machine

| Industry/Sector | Specific Application of little vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Automated retail for snacks and beverages | Increases sales through 24/7 availability and reduced labor costs | Size and capacity, payment options, product variety |

| Office Environments | On-site refreshment stations for employees | Enhances employee satisfaction and productivity | Energy efficiency, product selection, maintenance support |

| Healthcare | Dispensing of medical supplies and personal care items | Improves access to essential items, reduces waiting times | Compliance with health regulations, security features, reliability |

| Education | Snack and beverage stations in schools and universities | Promotes healthy eating habits and provides convenience | Nutritional standards, payment systems, user-friendly interface |

| Transportation Hubs | Vending solutions in airports and train stations | Meets passenger needs for quick snacks and drinks | Space constraints, product shelf-life, customer demographics |

Retail

In the retail sector, little vending machines serve as automated retail solutions for snacks and beverages. Positioned in high-traffic areas, they offer a wide range of products available 24/7, catering to consumers’ immediate cravings without the need for staff intervention. This not only increases sales but also reduces labor costs for retailers. International buyers should consider the machine’s size and capacity to fit their space, the variety of payment options to accommodate diverse customers, and the flexibility in product selection to meet local tastes.

Office Environments

In corporate settings, little vending machines act as on-site refreshment stations, providing employees with easy access to snacks and beverages. This convenience enhances employee satisfaction and boosts productivity by minimizing downtime during work hours. For international B2B buyers, sourcing machines that are energy-efficient can significantly reduce operational costs. Additionally, a well-curated product selection that aligns with health trends can foster a positive workplace culture.

Healthcare

In healthcare facilities, little vending machines can dispense medical supplies and personal care items, ensuring quick access for both staff and patients. This application addresses the critical need for immediate availability of essential items, thereby reducing waiting times for patients. When sourcing vending machines for healthcare, buyers must prioritize compliance with health regulations, incorporate security features to prevent tampering, and ensure reliability to maintain operational integrity.

Education

Little vending machines in educational institutions provide students with convenient access to snacks and beverages, promoting healthy eating habits. By placing these machines in schools and universities, institutions can cater to students’ needs while generating additional revenue. International buyers should ensure that the products offered meet nutritional standards and consider incorporating user-friendly interfaces that appeal to a younger demographic. Payment systems that accommodate various methods, including cashless options, can enhance user experience.

Transportation Hubs

In airports and train stations, little vending machines fulfill the demand for quick snacks and beverages among travelers. These machines can be strategically placed to maximize visibility and accessibility, providing a vital service in high-traffic areas. Buyers in this sector should consider space constraints and the shelf-life of products to ensure that offerings remain fresh. Understanding customer demographics can also guide product selection, helping to cater to the preferences of international travelers.

Related Video: How to Start a Vending Machine Business, Cost, Tips, How Much You Make

Strategic Material Selection Guide for little vending machine

When selecting materials for little vending machines, international B2B buyers must consider various factors including performance, durability, cost, and compliance with regional standards. Below is an analysis of four common materials used in the construction of little vending machines, highlighting their key properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Stainless Steel

Key Properties:

Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It typically has a temperature rating of up to 500°F (260°C) and can handle significant pressure, making it suitable for various environments.

Pros & Cons:

The durability of stainless steel is a significant advantage, as it resists rust and staining, ensuring longevity. However, it is more expensive than other materials, which can increase the overall cost of the vending machine. Manufacturing complexity can also be higher due to the need for specialized welding and finishing techniques.

Impact on Application:

Stainless steel is compatible with a wide range of media, including food and beverages, making it ideal for vending machines that dispense consumables.

Considerations for International Buyers:

Buyers should ensure compliance with food safety standards such as FDA regulations in the U.S. or EU regulations in Europe. Common grades like 304 and 316 are preferred, with 316 offering enhanced corrosion resistance for marine or humid environments.

2. Carbon Steel

Key Properties:

Carbon steel is known for its strength and toughness, with a typical temperature rating of around 400°F (204°C). However, it is prone to corrosion if not adequately protected.

Pros & Cons:

The primary advantage of carbon steel is its cost-effectiveness, making it an attractive option for budget-conscious buyers. However, its susceptibility to rust and corrosion limits its use in environments with high humidity or exposure to moisture, necessitating protective coatings.

Impact on Application:

Carbon steel is suitable for structural components of vending machines that do not come into direct contact with food or beverages.

Considerations for International Buyers:

Buyers should be aware of the need for protective coatings and may need to comply with local standards for material treatment. ASTM A36 is a commonly used standard for carbon steel.

3. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has a good strength-to-weight ratio. It can withstand temperatures up to 300°F (149°C) and is often used in applications where weight is a critical factor.

Pros & Cons:

The lightweight nature of aluminum makes it easy to transport and install, which is a significant advantage for vending machines. However, it is generally less durable than stainless steel and can be more expensive than carbon steel.

Impact on Application:

Aluminum is suitable for non-structural components and can be used in environments where weight reduction is necessary, such as portable vending machines.

Considerations for International Buyers:

Buyers should consider the specific alloy used, as different grades offer varying levels of strength and corrosion resistance. Compliance with standards such as ASTM B221 for aluminum extrusions is essential.

4. Plastic (Polycarbonate or ABS)

Key Properties:

Plastics like polycarbonate and ABS (Acrylonitrile Butadiene Styrene) are lightweight, impact-resistant, and can be molded into complex shapes. They generally have a temperature rating of around 200°F (93°C).

Pros & Cons:

The primary advantage of plastic is its cost-effectiveness and versatility in design. However, plastics may not withstand high temperatures or heavy loads as well as metals, limiting their use in certain applications.

Impact on Application:

Plastics are ideal for components such as display panels and internal mechanisms where weight and design flexibility are important.

Considerations for International Buyers:

Buyers should ensure that the plastic materials used comply with relevant safety standards, particularly for food contact applications. Common standards include FDA and EU regulations.

Summary Table

| Material | Typical Use Case for little vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, food contact surfaces | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Carbon Steel | Structural components not in contact with food | Cost-effective | Susceptible to corrosion | Low |

| Aluminum | Non-structural components, portable vending machines | Lightweight, easy to transport | Less durable than stainless steel | Medium |

| Plastic (PC/ABS) | Display panels, internal mechanisms | Cost-effective, design flexibility | Limited temperature and load capacity | Low |

This guide provides actionable insights for international B2B buyers, facilitating informed decisions in the strategic selection of materials for little vending machines.

In-depth Look: Manufacturing Processes and Quality Assurance for little vending machine

Manufacturing Processes for Little Vending Machines

The manufacturing of little vending machines involves a series of well-defined stages that ensure the final product meets the desired specifications and quality standards. Understanding these processes is crucial for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, where sourcing and quality assurance play significant roles in procurement decisions.

1. Material Preparation

The first stage in the manufacturing process is material preparation, where raw materials are selected based on the specifications of the vending machine. Common materials include:

- Metal Alloys: Steel and aluminum are widely used for the machine’s structure due to their durability.

- Plastics: Components like coin mechanisms and control panels often utilize high-quality plastics for lightweight and corrosion resistance.

- Electronic Components: Circuit boards, sensors, and display screens are sourced to ensure reliable operation.

B2B buyers should inquire about the suppliers’ sourcing practices and material certifications, as these factors significantly impact the durability and performance of the vending machines.

2. Forming

In the forming stage, raw materials are shaped into the necessary components. Key techniques include:

- CNC Machining: This technology is used to create precise metal parts, ensuring accuracy in dimensions and tolerances.

- Injection Molding: This is employed for plastic components, allowing for complex shapes and efficient mass production.

- Sheet Metal Fabrication: Used for creating the outer casing of the vending machine, this process involves cutting, bending, and assembling metal sheets.

B2B buyers should assess the machinery and technology used by suppliers, as modern equipment can lead to better product consistency and quality.

3. Assembly

The assembly stage integrates all components into the final product. This process typically involves:

- Sub-Assembly: Individual components like the control panel, payment systems, and refrigeration units are assembled separately before being integrated into the main machine.

- Main Assembly Line: The assembled components are put together on a production line, often utilizing automated systems for efficiency.

Buyers should consider the assembly techniques used and whether suppliers employ skilled labor or automation, as this can influence lead times and production costs.

4. Finishing

Finishing processes enhance the aesthetic and functional qualities of the vending machine. This stage may include:

- Painting and Coating: Protective coatings are applied to prevent rust and improve appearance.

- Quality Checks: Visual inspections and functional tests are conducted to ensure all components meet the required standards.

It is beneficial for buyers to verify if suppliers adhere to environmentally friendly finishing processes, as this can impact the machine’s lifecycle and compliance with regional regulations.

Quality Assurance (QA) in Manufacturing

Quality assurance is a critical aspect of manufacturing little vending machines, ensuring that each product meets international standards and customer expectations.

International Standards

For B2B buyers, familiarity with relevant international standards is essential. Key certifications include:

- ISO 9001: This standard outlines requirements for a quality management system, ensuring consistent product quality and continuous improvement.

- CE Marking: Required for products sold within the European Economic Area, indicating compliance with safety, health, and environmental protection standards.

- API Standards: Particularly relevant for electronic components, these standards ensure reliability and safety.

Understanding these standards helps buyers assess supplier credibility and the quality of their products.

QC Checkpoints

Quality control involves several checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): Verification of raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing checks during manufacturing to detect and correct defects early.

- Final Quality Control (FQC): Comprehensive inspections before shipment, including functional tests and compliance checks.

B2B buyers should request detailed QC reports from suppliers to verify that these checkpoints are effectively implemented.

Common Testing Methods

Testing methods are vital to ensure product functionality and safety. Common techniques include:

- Electrical Testing: Ensures all electronic components function correctly and safely.

- Durability Testing: Assesses the machine’s ability to withstand wear and tear in various environments.

- Performance Testing: Verifies that the vending machine operates according to specifications under real-world conditions.

Buyers should inquire about the specific testing methods used by suppliers to ensure thorough quality checks.

Verifying Supplier Quality Control

For international B2B buyers, verifying the quality control practices of suppliers is crucial. Here are actionable steps to ensure quality:

- Conduct Audits: Regularly audit suppliers’ facilities to assess their manufacturing processes and quality control measures.

- Request Documentation: Ask for quality assurance documentation, including ISO certifications and QC reports.

- Third-Party Inspections: Engage third-party inspection services to independently verify compliance with quality standards before shipment.

- Supplier Performance Metrics: Review metrics related to defect rates, return rates, and customer complaints to gauge supplier reliability.

Navigating QC/CERT Nuances

B2B buyers from Africa, South America, the Middle East, and Europe should be aware of regional nuances in quality certification and standards. For instance:

- Local Regulations: Ensure that suppliers comply with local regulations regarding safety and environmental impact.

- Cultural Considerations: Be mindful of cultural differences that may affect communication and expectations around quality.

- Trade Agreements: Leverage trade agreements that may facilitate smoother procurement processes and quality assurance.

By understanding these nuances, buyers can make informed decisions that align with their specific market needs and regulatory requirements.

In summary, a thorough understanding of the manufacturing processes and quality assurance practices for little vending machines can empower international B2B buyers to make informed decisions, ensuring they source reliable and high-quality products that meet their operational requirements.

Related Video: China’s Top 5 Manufacturing and Mass Production Videos | by @miracleprocess

Comprehensive Cost and Pricing Analysis for little vending machine Sourcing

Understanding the Cost Structure of Little Vending Machines

When sourcing little vending machines, understanding the comprehensive cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials, such as metal casings, electronic components, and display panels, significantly influences the final price. Suppliers often source these materials from various regions, impacting costs based on local market prices and availability.

-

Labor: Labor costs vary widely by region. Manufacturers in countries with lower labor costs may offer more competitive pricing, but this can also affect quality. Consider the skill level of the workforce in your sourcing region.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and indirect labor. Efficient production processes can help minimize these costs, making it essential to assess the manufacturing capabilities of potential suppliers.

-

Tooling: The initial investment in molds and tools required for production can be substantial, especially for custom machines. This cost is often amortized over large production runs, so minimum order quantities (MOQs) can significantly affect pricing.

-

Quality Control (QC): Implementing stringent quality control measures can increase costs but is vital for ensuring product reliability. Buyers should inquire about the QC processes to avoid unexpected failures in the field.

-

Logistics: Shipping costs, including freight, insurance, and customs duties, can add significantly to the total cost. Understanding Incoterms is crucial, as they dictate who bears the responsibility for shipping, insurance, and tariffs.

-

Margin: Suppliers will typically add a profit margin to their costs. This margin can vary based on market competition, product uniqueness, and the supplier’s negotiation power.

Key Price Influencers in Little Vending Machine Sourcing

Several factors influence the pricing of little vending machines:

-

Volume/MOQ: Larger orders often result in lower unit prices due to economies of scale. Establishing a good relationship with suppliers may lead to better pricing for smaller orders as well.

-

Specifications and Customization: Customized machines with specific features or branding requirements can lead to higher costs. Clearly define your specifications to avoid unexpected expenses.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (e.g., ISO) can affect both cost and buyer perception of value. Higher quality often commands a premium.

-

Supplier Factors: The reputation, reliability, and financial stability of the supplier play a crucial role in pricing. Suppliers with a proven track record may charge more but provide better assurance of quality and service.

Buyer Tips for Cost-Efficiency

To maximize value while minimizing costs, consider the following strategies:

-

Negotiate Terms: Engage in discussions regarding pricing, payment terms, and delivery schedules. Suppliers may be willing to offer discounts for prompt payment or larger orders.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance costs, potential downtime, and the lifespan of the vending machines to evaluate the true cost over time.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import tariffs, and regional pricing strategies that may affect overall costs.

-

Leverage Local Insights: Buyers from regions like Africa, South America, the Middle East, and Europe should utilize local market knowledge and networks to identify reliable suppliers and negotiate better terms.

Disclaimer

The prices and cost components discussed are indicative and can vary based on market conditions, supplier negotiations, and specific requirements. Always conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential little vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘little vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for little vending machine

Key Technical Properties of Little Vending Machines

When evaluating little vending machines for international B2B procurement, several technical properties are crucial for ensuring optimal performance, durability, and compatibility with local market requirements. Here are the essential specifications to consider:

-

Material Grade

The material used in the construction of vending machines significantly impacts their longevity and resistance to environmental factors. Common materials include stainless steel for the exterior, which offers corrosion resistance, and high-grade plastics for internal components. Selecting machines made from durable materials reduces maintenance costs and extends service life, which is vital for buyers focused on long-term investments. -

Size and Capacity

The dimensions and storage capacity of a vending machine determine its suitability for various locations and product offerings. Considerations include height, width, depth, and the number of product slots. For B2B buyers, understanding the size helps in space planning and inventory management, ensuring that the machines fit the intended environment while maximizing product turnover. -

Power Requirements

Understanding the power specifications, such as voltage and wattage, is essential for installation and operation. Many little vending machines operate on standard voltages (e.g., 110V or 220V), but variations exist. Buyers should ensure compatibility with local electrical systems to avoid operational issues and ensure safety compliance. -

Temperature Control

For machines that dispense perishable items, such as snacks or beverages, effective temperature control is critical. Look for machines with built-in refrigeration systems that maintain optimal temperatures to preserve product quality. This specification is particularly important in warmer climates, where temperature fluctuations can affect inventory integrity. -

User Interface and Payment Systems

The design of the user interface and the type of payment systems supported (e.g., cash, credit card, mobile payments) can significantly influence customer satisfaction. Machines with intuitive interfaces and multiple payment options are more likely to attract a diverse customer base, enhancing sales potential. -

Compliance and Certifications

Adherence to local and international standards (e.g., CE, UL) ensures that the vending machines meet safety and quality regulations. Certifications can provide buyers with peace of mind regarding product reliability and compliance with local laws, which is especially relevant in regulated markets.

Common Trade Terminology in Vending Machine Procurement

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Below are some common terms related to vending machines:

-

OEM (Original Equipment Manufacturer)

Refers to a company that produces equipment or components that are sold under another company’s brand name. Understanding OEM relationships can help buyers identify reliable manufacturers and ensure product quality. -

MOQ (Minimum Order Quantity)

The smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to determine if a supplier can meet their purchasing needs without exceeding budget constraints. -

RFQ (Request for Quotation)

A formal request issued by a buyer to potential suppliers to obtain pricing and terms for specific products or services. This process allows buyers to compare offers and negotiate favorable terms. -

Incoterms

International Commercial Terms that define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms such as FOB (Free On Board) and CIF (Cost, Insurance, and Freight) is essential for understanding shipping logistics and cost allocation. -

Warranty and Service Agreements

Contracts outlining the terms of product support and repairs after purchase. Buyers should carefully review warranty conditions to ensure adequate coverage for potential repairs or replacements, which can significantly impact total cost of ownership.

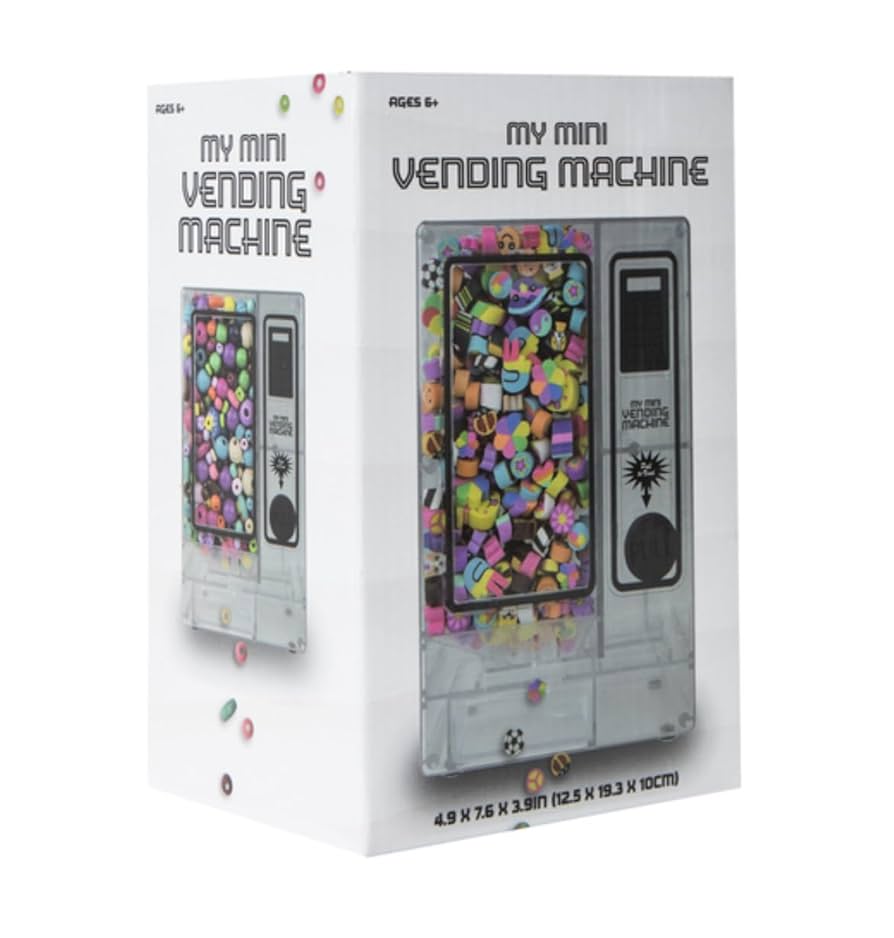

Illustrative Image (Source: Google Search)

- Lead Time

The time required from placing an order to delivery. Understanding lead times is essential for inventory management and planning, especially for businesses with tight schedules or specific launch dates.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing little vending machines, ensuring they choose the best solutions for their markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the little vending machine Sector

Market Overview & Key Trends

The little vending machine sector is experiencing significant growth driven by urbanization, changing consumer behaviors, and technological advancements. Globally, there is an increasing demand for convenience, particularly in urban areas where time-saving solutions are crucial. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, the integration of smart technology into vending machines is a notable trend. Features like cashless payment systems, remote inventory management, and real-time sales analytics are becoming essential for enhancing operational efficiency and improving customer experience.

Furthermore, the rise of e-commerce and digital payment platforms is reshaping how vending operators source and manage their inventory. B2B buyers should consider partnerships with tech providers specializing in IoT and machine learning to leverage data-driven insights for inventory optimization and customer engagement. Additionally, regional market dynamics show that local preferences and regulations significantly influence product offerings, necessitating a tailored approach when entering diverse markets. For instance, in South Africa, the demand for healthy snack options is surging, reflecting a broader global trend towards health-conscious consumerism.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical factor for buyers in the little vending machine sector. As environmental concerns grow, B2B buyers must prioritize suppliers who adopt sustainable practices. The environmental impact of vending machines, from energy consumption to waste generation, is under scrutiny. Therefore, sourcing from manufacturers that utilize energy-efficient technologies and recyclable materials is essential.

Ethical sourcing practices are also gaining traction, with buyers increasingly looking for suppliers who ensure fair labor practices and social responsibility within their supply chains. Certifications such as Fair Trade, Forest Stewardship Council (FSC), and ISO 14001 can serve as benchmarks for assessing supplier commitments to sustainability. Moreover, the incorporation of biodegradable packaging and refillable product options can enhance a brand’s reputation and appeal to environmentally conscious consumers. Buyers should actively seek out partners who are committed to transparency and sustainability to align with consumer expectations and regulatory standards.

Brief Evolution/History

The little vending machine sector has evolved significantly over the past few decades. Initially, vending machines primarily dispensed snacks and beverages, operating on a cash-only basis. However, the introduction of digital payment solutions and advanced vending technology has transformed these machines into smart retail solutions. Today, they offer a diverse range of products, including fresh food, personal care items, and electronics.

This evolution reflects broader trends in consumer behavior, emphasizing convenience and instant access to goods. As the market continues to innovate, international B2B buyers should remain vigilant about emerging technologies and consumer preferences to stay competitive in this dynamic landscape. Understanding this historical context can help buyers make informed decisions when selecting vending machine suppliers and technologies that align with future market demands.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of little vending machine

-

What should I consider when vetting suppliers for little vending machines?

When vetting suppliers, prioritize their experience in the industry and reputation among previous clients. Check for certifications such as ISO or other quality assurance standards relevant to vending machines. Request references and conduct background checks to verify their reliability. Additionally, evaluate their production capabilities and past projects to ensure they can meet your specific needs. -

Can I customize the little vending machines to fit my brand?

Yes, many manufacturers offer customization options for little vending machines. You can request specific colors, branding elements, and product configurations that align with your business’s identity. Discuss these requirements upfront during negotiations to ensure the supplier can accommodate your requests and to avoid additional costs later in the process. -

What are the typical minimum order quantities (MOQ) and lead times for little vending machines?

Minimum order quantities can vary significantly based on the supplier and machine specifications. Typically, MOQs range from 10 to 50 units. Lead times also depend on customization and production schedules, generally ranging from 4 to 12 weeks. Always confirm these details in advance to align with your inventory planning and market launch strategies. -

What payment terms should I expect when sourcing little vending machines?

Payment terms may vary between suppliers, but common practices include a 30% deposit upon order confirmation and the remaining balance before shipment. Some suppliers may offer flexible payment options, such as letters of credit or payment upon delivery. Ensure you negotiate terms that are favorable and secure for both parties, especially considering currency fluctuations. -

How can I ensure the quality of the little vending machines I purchase?

To ensure quality, request samples before placing bulk orders. Additionally, verify that the supplier conducts regular quality assurance tests and holds necessary certifications. Establish clear inspection criteria and consider third-party quality checks, especially if you are ordering from overseas. This proactive approach helps mitigate risks associated with product defects. -

What certifications should I look for in little vending machines?

Look for certifications that indicate compliance with safety and quality standards relevant to your market. Common certifications include CE (European Conformity), UL (Underwriters Laboratories), and ISO 9001. These certifications demonstrate that the machines meet industry standards and can help in gaining customer trust and regulatory compliance in your region. -

What logistics considerations should I keep in mind when importing little vending machines?

Logistics planning is crucial for importing vending machines. Consider shipping methods, customs regulations, and potential tariffs that may apply to your order. Work with a freight forwarder who understands the nuances of your specific markets to facilitate smooth customs clearance and timely delivery. Always plan for potential delays and additional costs in your budget. -

How should I handle disputes with suppliers of little vending machines?

To handle disputes effectively, maintain clear communication with your supplier and document all agreements and correspondence. If issues arise, attempt to resolve them amicably through negotiation. If necessary, refer to the contract terms regarding dispute resolution processes. Consider including arbitration clauses in your contracts to provide a structured path for resolving conflicts without resorting to litigation.

Strategic Sourcing Conclusion and Outlook for little vending machine

In conclusion, the strategic sourcing of little vending machines presents a unique opportunity for international B2B buyers, especially in emerging markets across Africa, South America, the Middle East, and Europe. By understanding local consumer preferences and aligning with suppliers that prioritize quality and innovation, businesses can enhance their competitive edge.

Key takeaways include the importance of assessing supplier reliability, negotiating favorable terms, and ensuring compliance with local regulations. As demand for convenient retail solutions continues to rise, investing in advanced vending technology can significantly enhance customer satisfaction and operational efficiency.

Illustrative Image (Source: Google Search)

Looking ahead, international buyers are encouraged to explore partnerships with manufacturers that emphasize sustainability and adaptability. The vending industry is poised for growth, and those who act strategically now will reap the benefits in the future. Consider leveraging data analytics to track performance and optimize product offerings, ensuring that your vending solutions meet the evolving needs of consumers. Engage actively in this dynamic market to position your business for success.