Your Ultimate Guide to Sourcing Juice Vending Machine

Guide to Juice Vending Machine

- Introduction: Navigating the Global Market for juice vending machine

- Understanding juice vending machine Types and Variations

- Key Industrial Applications of juice vending machine

- Strategic Material Selection Guide for juice vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for juice vending machine

- Comprehensive Cost and Pricing Analysis for juice vending machine Sourcing

- Spotlight on Potential juice vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for juice vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the juice vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of juice vending machine

- Strategic Sourcing Conclusion and Outlook for juice vending machine

Introduction: Navigating the Global Market for juice vending machine

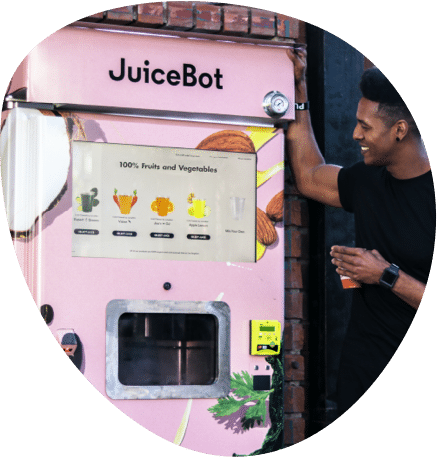

Juice vending machines are revolutionizing the way consumers access fresh beverages, offering a convenient and healthy alternative in various settings such as offices, schools, and public spaces. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe increasingly seek innovative solutions to meet evolving consumer demands, understanding the juice vending machine market becomes crucial.

This comprehensive guide delves into the diverse types of juice vending machines available, ranging from traditional models to advanced automated systems that use cutting-edge technology to deliver fresh juice on demand. It also explores the materials used in manufacturing these machines, ensuring durability and compliance with health standards. Quality control processes are highlighted to reassure buyers about the reliability and safety of their purchases.

Moreover, this guide provides insights into sourcing reputable suppliers and evaluating costs effectively, empowering B2B buyers to make informed decisions. By addressing common questions and concerns through a dedicated FAQ section, the guide facilitates a deeper understanding of market dynamics and operational considerations.

In essence, this resource is designed to equip international B2B buyers with the knowledge and insights needed to navigate the global juice vending machine market successfully, ensuring they can meet customer demands while optimizing their investment.

Understanding juice vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fresh Juice Vending Machine | Uses fresh ingredients, often equipped with a juicing mechanism | Airports, gyms, health clubs | Pros: High-quality, fresh product; attracts health-conscious consumers. Cons: Higher maintenance and ingredient sourcing costs. |

| Pre-Packaged Juice Vending Machine | Dispenses bottled or canned juices, often with a variety of brands | Office buildings, schools, retail stores | Pros: Lower maintenance; consistent supply. Cons: Limited freshness; may not appeal to health-focused customers. |

| Smoothie Vending Machine | Blends fruit and other ingredients on demand | Colleges, cafes, events | Pros: Customizable options; appeals to younger demographics. Cons: Requires more complex machinery; higher energy consumption. |

| Automated Juice Dispenser | Dispenses juice from large containers with minimal user interaction | Restaurants, catering services | Pros: Efficient for high-volume sales; easy to use. Cons: Limited product variety; potential for wastage if not managed properly. |

| Eco-Friendly Juice Machine | Focuses on sustainability, using biodegradable packaging and organic ingredients | Eco-conscious businesses, wellness centers | Pros: Attracts environmentally aware consumers; promotes a sustainable image. Cons: Potentially higher costs; may require specialized suppliers. |

Fresh Juice Vending Machine

Fresh juice vending machines are designed to extract juice from whole fruits and vegetables, offering customers a nutritious option on the go. These machines often feature advanced juicing technology that ensures minimal oxidation, preserving the flavor and nutrients of the juice. They are particularly suitable for high-traffic areas like airports, gyms, and health clubs, where customers seek healthy and fresh beverage options. When considering a purchase, B2B buyers should evaluate the machine’s maintenance requirements, the availability of fresh produce, and the potential return on investment based on customer demand.

Pre-Packaged Juice Vending Machine

Pre-packaged juice vending machines dispense bottled or canned juices from various brands. They are a popular choice for businesses that prioritize ease of operation, as they require minimal maintenance and can be stocked quickly. These machines are commonly found in office buildings, schools, and retail stores, making them accessible to a broad audience. Buyers should consider the selection of brands and flavors offered, as well as shelf life and storage requirements, to ensure they meet the preferences of their target market.

Smoothie Vending Machine

Smoothie vending machines offer a unique selling proposition by blending fruits and other ingredients on demand. These machines can cater to customization, allowing customers to create their own smoothies based on personal preferences. They are ideal for locations like colleges, cafes, and events, where younger demographics are likely to seek refreshing and healthy options. Buyers should assess the machine’s blending capabilities, ingredient sourcing, and energy efficiency, as these factors can significantly impact operational costs and customer satisfaction.

Automated Juice Dispenser

Automated juice dispensers are designed to provide quick and efficient service, dispensing juice from large containers with minimal user interaction. This type of machine is well-suited for restaurants and catering services that require high-volume sales. The efficiency of these machines can lead to increased sales, but buyers must consider the potential for product wastage if the machine is not managed properly, as well as the limitations in product variety compared to fresh juice machines.

Eco-Friendly Juice Machine

Eco-friendly juice machines focus on sustainability, utilizing biodegradable packaging and organic ingredients to appeal to environmentally conscious consumers. They are becoming increasingly popular in wellness centers and eco-conscious businesses that want to promote a green image. While they attract a niche market, buyers should be aware of potentially higher costs associated with sourcing sustainable ingredients and materials, as well as the need for specialized suppliers to maintain product quality.

Related Video: Fresh Apple Juice Vending Machine

Key Industrial Applications of juice vending machine

| Industry/Sector | Specific Application of Juice Vending Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Hotel Lobbies and Cafés | Enhances guest experience with fresh juice options | Size and design suitability, ease of maintenance, payment integration |

| Corporate Offices | Employee Wellness Initiatives | Promotes healthy lifestyle among employees | Nutritional variety, energy efficiency, and user-friendly interface |

| Educational Institutions | School Cafeterias and University Campuses | Provides healthy beverage choices for students | Compliance with health regulations, durability, and refill frequency |

| Retail | Supermarkets and Shopping Malls | Attracts health-conscious consumers | Product variety, vending machine placement, and payment options |

| Events & Festivals | Outdoor Events and Trade Shows | Offers convenience and refreshment to attendees | Portability, ease of setup, and ability to handle high foot traffic |

Hospitality

In the hospitality sector, juice vending machines are increasingly deployed in hotel lobbies and cafés. These machines serve as an attractive feature for guests, offering a variety of fresh juices that enhance the overall guest experience. For international buyers, particularly in regions like Africa and Europe, sourcing machines that are aesthetically pleasing and easy to maintain is crucial. Additionally, the ability to integrate cashless payment systems can significantly improve customer convenience.

Corporate Offices

Juice vending machines in corporate offices are integral to employee wellness initiatives. They provide a healthy alternative to sugary snacks and beverages, thereby promoting a healthier workplace culture. For buyers in South America and the Middle East, it’s important to consider the nutritional variety offered by these machines. Moreover, energy-efficient models can help reduce operational costs while encouraging employees to make healthier choices.

Illustrative Image (Source: Google Search)

Educational Institutions

In educational institutions, such as schools and universities, juice vending machines can be a vital part of cafeterias. They offer students nutritious drink options that support their health and learning. Buyers in these sectors should ensure that the machines comply with local health regulations and are designed for durability. Additionally, the frequency of refills is a key consideration, as high foot traffic can lead to rapid depletion of stock.

Retail

Retail environments, including supermarkets and shopping malls, benefit from the installation of juice vending machines by attracting health-conscious consumers. These machines serve as a convenient option for shoppers looking for quick and healthy refreshments. For international B2B buyers, key sourcing considerations include the variety of products offered and the optimal placement of machines to maximize visibility and sales.

Events & Festivals

At outdoor events and trade shows, juice vending machines provide a quick and refreshing beverage option for attendees. Their convenience makes them an attractive addition to any event. Buyers should prioritize models that are portable and easy to set up, as well as those capable of handling high foot traffic. Ensuring that the machines can accommodate various payment methods will also enhance the overall attendee experience.

Related Video: IJOOZ Smart Juicer | The Most Advanced Smart Juice Vending

Strategic Material Selection Guide for juice vending machine

When selecting materials for juice vending machines, it is crucial to consider factors such as durability, cost, and compatibility with the various juices and cleaning agents used. Below is an analysis of four common materials used in the construction of juice vending machines, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It typically has a temperature rating of up to 800°F (427°C) and is resistant to many chemicals, making it suitable for food and beverage applications.

Pros & Cons:

Stainless steel is highly durable and easy to clean, which is essential in maintaining hygiene standards in food service equipment. However, it is more expensive than other materials like carbon steel, and its manufacturing process can be complex, requiring specialized equipment.

Impact on Application:

The corrosion resistance of stainless steel makes it ideal for juice vending machines, which frequently come into contact with acidic juices. This prevents leaching and ensures product integrity.

Considerations for International Buyers:

Buyers must ensure compliance with food safety regulations in their respective regions, such as the FDA in the United States or EFSA in Europe. Common standards for stainless steel include ASTM A240 and DIN 1.4301.

2. Polycarbonate

Key Properties:

Polycarbonate is a strong, lightweight plastic that can withstand impacts and has a high-temperature resistance of around 240°F (115°C). It is also transparent, allowing for visibility of the juice within the machine.

Pros & Cons:

The primary advantage of polycarbonate is its lightweight nature and impact resistance, making it easy to transport and install. However, it can be less durable than metals and may scratch or discolor over time, especially when exposed to UV light.

Impact on Application:

Polycarbonate is often used for the front panels or containers in juice vending machines, providing visibility while protecting the contents. Its chemical resistance is generally good, but it may not be suitable for all cleaning agents.

Considerations for International Buyers:

Buyers should verify that the polycarbonate used is food-grade and complies with relevant regulations, such as those set by REACH in Europe. Standards like ASTM D635 may also apply.

3. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has a melting point of around 1220°F (660°C). It is also an excellent conductor of heat, which can be beneficial in certain applications.

Pros & Cons:

Aluminum is cost-effective and easy to machine, making it a popular choice for various components in vending machines. However, it is softer than stainless steel and may not be as durable in high-impact situations.

Impact on Application:

Aluminum is often used for frames or structural components in juice vending machines. Its resistance to corrosion helps maintain the machine’s appearance and functionality over time.

Considerations for International Buyers:

When sourcing aluminum, buyers should ensure it meets standards such as ASTM B221 or EN AW-6060. Additionally, they should be aware of any import regulations regarding aluminum products in their regions.

4. Glass

Key Properties:

Glass is non-reactive and can withstand high temperatures, making it suitable for juice vending machines. It typically has a temperature rating of up to 300°F (149°C) and is available in various thicknesses.

Pros & Cons:

The primary advantage of glass is its aesthetic appeal and ability to provide a clear view of the product. However, it is heavy and can be prone to breakage, which may lead to higher replacement costs.

Impact on Application:

Glass is often used for juice containers or display panels, allowing customers to see the product. Its non-reactive nature ensures that the juice’s flavor remains unaffected.

Considerations for International Buyers:

Buyers should ensure that the glass used is tempered or laminated to enhance safety and durability. Compliance with safety standards such as ASTM C1036 is essential.

| Material | Typical Use Case for juice vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Machine body and components | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Polycarbonate | Front panels and containers | Lightweight and impact-resistant | Scratches and UV sensitivity | Medium |

| Aluminum | Structural components | Cost-effective and easy to machine | Softer and less durable | Low |

| Glass | Juice containers and display panels | Aesthetic appeal and non-reactive | Heavy and prone to breakage | Medium |

This analysis provides a comprehensive overview of material options for juice vending machines, enabling international B2B buyers to make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for juice vending machine

Manufacturing Processes for Juice Vending Machines

The manufacturing of juice vending machines involves several critical stages, each contributing to the machine’s functionality, durability, and overall quality. Understanding these processes can empower B2B buyers to make informed purchasing decisions and ensure they select suppliers who adhere to high manufacturing standards.

1. Material Preparation

The initial phase involves sourcing high-quality materials that meet specific industry standards. Common materials used in juice vending machines include:

- Stainless Steel: For the machine’s frame and components, offering durability and resistance to corrosion.

- Plastic: Used in parts such as dispensers and panels, which need to be lightweight yet sturdy.

- Electronic Components: These include sensors, control systems, and payment processing units, all of which must comply with international safety standards.

Buyers should ensure that suppliers utilize materials with certifications (e.g., NSF for food safety) to guarantee hygiene and safety.

2. Forming

Once materials are prepared, they undergo various forming processes, which may include:

- Sheet Metal Fabrication: Using techniques such as laser cutting and bending to create the frame and outer shell of the vending machine.

- Injection Molding: Often used for producing plastic parts like buttons and dispensers, ensuring precision and consistency in design.

- Assembly of Electrical Components: Integrating wiring, sensors, and control boards into the machine’s structure.

It’s essential for buyers to verify that the forming processes employed are efficient and can produce parts that meet their specifications.

3. Assembly

The assembly phase is crucial, as it involves combining all the components into a cohesive unit. Key aspects include:

- Modular Assembly Lines: Utilizing a systematic approach to streamline production, reduce errors, and enhance speed.

- Quality Checks During Assembly: Regular inspections at this stage can catch defects early, preventing them from progressing to later stages.

Buyers should inquire about the assembly line’s setup and whether it incorporates lean manufacturing principles to minimize waste and improve efficiency.

4. Finishing

Finishing processes enhance the aesthetic appeal and functionality of the juice vending machines. This includes:

- Surface Treatment: Applying coatings (e.g., powder coating) to protect surfaces and improve appearance.

- Final Assembly and Testing: Ensuring all components function correctly and meet design specifications before the machine is packaged for shipping.

Buyers should request detailed reports on the finishing processes to ensure that the machines not only look good but also perform reliably.

Quality Assurance

Quality assurance (QA) is vital in ensuring that juice vending machines meet international standards and customer expectations. Various QA measures are implemented throughout the manufacturing process.

International Standards

B2B buyers should be aware of the following relevant standards:

- ISO 9001: A widely recognized quality management standard, ensuring that manufacturers have robust processes in place.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA).

- API Standards: Particularly important for machines that incorporate hydraulic or pneumatic systems.

Buyers should ask suppliers for documentation proving compliance with these standards.

QC Checkpoints

Quality control (QC) typically involves several checkpoints:

- Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing checks during manufacturing to identify and rectify defects early in the process.

- Final Quality Control (FQC): Comprehensive testing of the finished product to verify functionality and safety.

Common Testing Methods

Various testing methods are employed to ensure product quality:

- Functional Testing: Verifying that all components operate as intended.

- Safety Testing: Ensuring compliance with electrical and mechanical safety standards.

- Durability Testing: Assessing the machine’s performance under various environmental conditions.

Buyers should request access to testing protocols and results to validate the efficacy of the QC processes.

Verification of Supplier QC

B2B buyers can take several steps to verify a supplier’s quality control measures:

- Supplier Audits: Conducting on-site audits to assess manufacturing capabilities, quality processes, and adherence to standards.

- Quality Reports: Requesting detailed reports that outline QC processes, testing methodologies, and results.

- Third-Party Inspections: Engaging independent inspection agencies to evaluate the manufacturing process and product quality before shipment.

QC and Certification Nuances for International Buyers

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is crucial:

- Regional Compliance: Be aware of local regulations and standards that may differ from international ones, especially regarding food safety and electrical equipment.

- Supply Chain Transparency: Demand transparency in the supply chain to ensure that all components meet the required standards.

- Cultural Considerations: Recognize that communication styles and negotiation practices may vary, which can impact the buying process.

By being informed about these aspects, buyers can effectively navigate the complexities of sourcing juice vending machines from global suppliers, ensuring they receive high-quality products that meet their operational needs.

Related Video: Juice filling machine,juice factory,juice production line,beverage machine,juice bottling

Comprehensive Cost and Pricing Analysis for juice vending machine Sourcing

In the sourcing of juice vending machines, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe. Here’s a detailed breakdown of the key components involved.

Cost Components

-

Materials: The primary materials for juice vending machines include stainless steel for durability, high-quality plastic for components, refrigeration units, and electronic parts. Prices can fluctuate based on global market trends and raw material availability.

-

Labor: Labor costs vary significantly by region. In countries with lower labor costs, such as those in parts of Africa and South America, manufacturers may offer more competitive pricing. However, skilled labor for assembling high-tech components might still necessitate higher wages.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes and advanced technologies can help reduce these costs.

-

Tooling: Initial investments in specialized tools and molds for producing vending machines can be substantial. Custom designs or specific features will increase tooling costs, which should be considered in the total pricing analysis.

-

Quality Control (QC): Ensuring that the machines meet international standards requires rigorous testing and quality assurance processes. The costs associated with QC can vary based on the complexity of the machine and the certifications required.

-

Logistics: Shipping and handling costs, including customs duties and insurance, can significantly impact the final price. Factors such as distance, shipping method, and the choice of Incoterms will influence these expenses.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on competition, market demand, and the perceived value of the machine’s features.

Price Influencers

Several factors can influence the pricing of juice vending machines:

-

Volume/MOQ: Bulk purchases often lead to discounts. Buyers should negotiate minimum order quantities (MOQs) to secure better rates.

-

Specifications/Customization: Custom features, such as unique branding or added functionalities, can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials: The choice of materials directly affects pricing. Higher-quality materials may lead to higher upfront costs but can offer better durability and lower maintenance expenses.

-

Quality/Certifications: Machines that comply with international safety and quality standards might carry a premium price. Buyers should assess the value of certifications relative to their market needs.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers might charge more but offer better after-sales support and warranty services.

-

Incoterms: Understanding the terms of shipment and delivery is crucial. Different Incoterms (e.g., FOB, CIF) can lead to variations in the total cost due to responsibilities in shipping and insurance.

Buyer Tips

-

Negotiation: Always negotiate terms with suppliers. Leverage your purchasing power, especially for larger orders, to secure better pricing.

-

Cost Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. A higher initial investment in a quality machine may yield savings over time through reduced maintenance and energy efficiency.

-

Pricing Nuances: Be aware of the regional pricing dynamics. For example, suppliers may adjust their pricing strategies based on local economic conditions and competitive pressures.

-

Market Research: Conduct thorough market research to understand prevailing prices and supplier options. This knowledge can empower buyers during negotiations and help in making informed decisions.

Disclaimer

Prices for juice vending machines can vary widely based on the aforementioned factors, and this analysis serves as a general guideline. Buyers should request detailed quotes and consider all components to accurately assess the total cost before making purchasing decisions.

Spotlight on Potential juice vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘juice vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for juice vending machine

Key Technical Properties of Juice Vending Machines

When considering the procurement of juice vending machines, understanding their technical specifications is crucial for making informed decisions. Here are some essential properties to evaluate:

-

Material Grade

– Definition: The quality of materials used in the construction of the vending machine, typically stainless steel or high-grade plastics.

– Importance: High-quality materials ensure durability and resistance to corrosion and wear, which is vital for machines operating in various climates, particularly in regions like Africa and South America where humidity can be high. -

Cooling System Efficiency

– Definition: The effectiveness of the refrigeration unit in maintaining optimal juice temperature.

– Importance: An efficient cooling system prolongs the shelf life of the juice and enhances customer satisfaction. Buyers should look for energy-efficient models to reduce operational costs. -

Capacity and Size

– Definition: The number of juice containers the machine can hold and the overall dimensions of the unit.

– Importance: Understanding capacity is essential for matching the machine to the expected volume of sales. Larger units may be necessary in high-traffic areas, while compact models are ideal for smaller venues. -

Payment Systems Compatibility

– Definition: The ability of the vending machine to accept various payment methods, including cash, credit/debit cards, and mobile payments.

– Importance: A diverse payment system increases sales opportunities and caters to customer preferences, particularly in urban areas where cashless transactions are common. -

Power Consumption

– Definition: The amount of energy the machine requires for operation.

– Importance: Low power consumption is crucial for reducing operational expenses. Buyers should consider machines with energy-saving features, especially in regions where electricity costs are high. -

Temperature Control Range

– Definition: The range of temperatures that the machine can maintain for the juices.

– Importance: Precise temperature control is essential for preserving the quality and freshness of juice, which can vary widely depending on the juice type and local climate conditions.

Common Trade Terminology in Juice Vending Machines

Familiarity with industry jargon is important for effective communication and negotiations. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Context: Understanding whether a vending machine is OEM can impact quality assurance and after-sales support. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Context: This is crucial for budgeting, especially for smaller businesses or startups that may want to test market demand before larger investments. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price bids from suppliers.

– Context: An RFQ is essential for comparing prices and terms from different manufacturers, ensuring competitive pricing. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms published by the International Chamber of Commerce.

– Context: Understanding Incoterms helps clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which is critical for international transactions. -

Lead Time

– Definition: The amount of time from placing an order to receiving the product.

– Context: Knowing the lead time helps in inventory planning and ensures that machines are available when needed, particularly for seasonal sales peaks. -

Warranty Period

– Definition: The duration for which a manufacturer guarantees the performance of the machine.

– Context: A longer warranty period can indicate confidence in product quality and reduce potential long-term costs for repairs and maintenance.

Understanding these technical specifications and trade terms can empower B2B buyers to make informed purchasing decisions for juice vending machines, ensuring that they meet operational needs and customer expectations effectively.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the juice vending machine Sector

Market Overview & Key Trends

The juice vending machine sector is experiencing robust growth driven by several global factors. Increasing health consciousness among consumers, particularly in regions like Africa, South America, the Middle East, and Europe, is propelling demand for fresh and nutritious beverages. This trend is supported by a shift towards healthier lifestyle choices, with many consumers preferring natural juices over sugary drinks. Additionally, urbanization and busy lifestyles are encouraging the proliferation of vending machines in public spaces, workplaces, and educational institutions.

Emerging technologies are reshaping the sourcing landscape in this sector. Innovations such as IoT-enabled vending machines allow for real-time inventory tracking and data analytics, enhancing operational efficiency and customer experience. Moreover, contactless payment systems are becoming standard, catering to the growing preference for hygiene and convenience. International B2B buyers should keep an eye on suppliers who are integrating these technologies into their offerings, as this can significantly impact sales performance and customer satisfaction.

Market dynamics are also influenced by regional preferences and regulations. For instance, buyers in Europe may face stricter health and safety regulations compared to those in Africa or South America. Understanding these regional differences is crucial for international buyers to navigate sourcing effectively and ensure compliance. Establishing partnerships with local distributors can facilitate market entry and help adapt to local consumer preferences.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of the juice vending machine industry, driven by both consumer demand and regulatory pressures. The environmental impact of sourcing materials and manufacturing processes is under scrutiny, prompting businesses to adopt sustainable practices. For international B2B buyers, prioritizing suppliers with a commitment to environmental stewardship is essential. This includes sourcing machines made from recycled materials, utilizing energy-efficient technology, and minimizing waste during production.

Ethical supply chains are equally important. Buyers should seek vendors who ensure fair labor practices and contribute positively to the communities where they operate. Certifications such as Fair Trade and organic labels can serve as indicators of a supplier’s commitment to ethical sourcing. Implementing a thorough vetting process for suppliers can mitigate risks associated with unethical practices and enhance brand reputation.

Illustrative Image (Source: Google Search)

Investing in ‘green’ certifications not only aligns with consumer values but can also open doors to new market segments. As more consumers actively seek out eco-friendly options, having a sustainability-focused product line can differentiate a business in a competitive marketplace.

Brief Evolution/History

The evolution of juice vending machines has been marked by technological advancements and changing consumer preferences. Initially, vending machines offered canned or bottled juices, which limited freshness and nutritional value. However, the introduction of fresh juice vending machines in the late 2000s transformed the market, allowing consumers to enjoy freshly squeezed options on-the-go.

In recent years, the integration of smart technology has further revolutionized the sector. Features such as touchless interfaces, real-time inventory management, and personalized marketing through data analytics have made these machines more appealing to both consumers and business operators. As health trends continue to shape consumer behavior, the juice vending machine industry is poised for ongoing innovation and growth, making it a lucrative opportunity for international B2B buyers.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of juice vending machine

-

What key factors should I consider when vetting suppliers of juice vending machines?

When vetting suppliers, prioritize their experience in the industry, customer reviews, and certifications. Check for quality assurance protocols and whether they comply with international standards. Request references from previous clients to gauge reliability. Additionally, assess their production capacity and responsiveness to inquiries to ensure they can meet your demands efficiently. -

Can juice vending machines be customized to fit my brand’s requirements?

Yes, many manufacturers offer customization options for juice vending machines. You can typically request alterations in design, size, functionality, and branding elements such as logos and color schemes. When discussing customization, ensure you provide clear specifications and confirm any additional costs associated with these changes to avoid misunderstandings. -

What is the typical minimum order quantity (MOQ) for juice vending machines?

MOQs can vary significantly by supplier, generally ranging from 5 to 50 units. Smaller manufacturers may accommodate lower MOQs, while larger companies might have stricter requirements. Always inquire about MOQs upfront and consider negotiating terms based on your business’s scale and needs, especially if you’re new to the market. -

What are the usual lead times for receiving juice vending machines after placing an order?

Lead times can depend on several factors, including the complexity of the order and the supplier’s location. Typically, expect anywhere from 4 to 12 weeks for standard orders. For customized machines, this may extend to 12 to 20 weeks. Always confirm lead times in writing and plan accordingly to ensure your supply chain remains uninterrupted. -

What payment methods are commonly accepted by suppliers of juice vending machines?

Most suppliers accept various payment methods, including bank transfers, letters of credit, and payment platforms like PayPal. It’s essential to discuss and agree on payment terms before finalizing your order. For larger transactions, consider negotiating payment in installments based on production milestones to mitigate risk. -

How can I ensure the quality of the juice vending machines I purchase?

To ensure quality, request detailed product specifications and certifications, such as ISO or CE marking. Ask about the supplier’s quality control processes and whether they provide warranties or guarantees for their machines. Additionally, consider arranging for a factory visit or requesting samples to assess the product firsthand before making a bulk purchase. -

What logistics should I consider when importing juice vending machines?

Logistics for importing machines can be complex. Factor in shipping costs, customs duties, and potential delays at the port. Collaborate with experienced freight forwarders who understand international regulations and can assist with documentation. Ensure that your supply chain is equipped to handle delivery to your final destination, including installation requirements. -

How should I handle disputes with suppliers regarding juice vending machines?

Effective communication is crucial in resolving disputes. Document all agreements and communications clearly to refer back to them if issues arise. If a dispute occurs, attempt to resolve it directly with the supplier first. If that fails, consider mediation or arbitration as outlined in your contract. Always ensure you understand the legal framework governing international trade in your contract to protect your interests.

Strategic Sourcing Conclusion and Outlook for juice vending machine

In summary, the strategic sourcing of juice vending machines presents a unique opportunity for international B2B buyers to tap into a growing market. Key takeaways include the importance of understanding local consumer preferences, evaluating supplier reliability, and ensuring compliance with regional regulations. By leveraging strategic sourcing, businesses can enhance their competitive advantage, reduce operational risks, and maximize profitability.

For buyers in regions such as Africa, South America, the Middle East, and Europe, the shift towards health-conscious products makes juice vending machines an attractive investment. Engaging with reputable suppliers who can offer innovative technology and sustainable practices will be crucial in meeting consumer demands and expectations.

Looking ahead, the juice vending machine market is set for expansion, driven by technological advancements and a growing emphasis on convenience. International B2B buyers are encouraged to act decisively, explore partnerships, and invest in high-quality solutions that align with their business goals. Embracing these opportunities will not only foster growth but also contribute to a healthier future for consumers worldwide.