Your Ultimate Guide to Sourcing Japanese Panty Vending

Guide to Japanese Panty Vending Machine

- Introduction: Navigating the Global Market for japanese panty vending machine

- Understanding japanese panty vending machine Types and Variations

- Key Industrial Applications of japanese panty vending machine

- Strategic Material Selection Guide for japanese panty vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for japanese panty vending machine

- Comprehensive Cost and Pricing Analysis for japanese panty vending machine Sourcing

- Spotlight on Potential japanese panty vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for japanese panty vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the japanese panty vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of japanese panty vending machine

- Strategic Sourcing Conclusion and Outlook for japanese panty vending machine

Introduction: Navigating the Global Market for japanese panty vending machine

In the realm of unconventional merchandise, Japanese panty vending machines stand out as a unique business opportunity that has garnered attention worldwide. These machines cater to niche markets, offering products that blend novelty with cultural significance. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding this market can lead to lucrative ventures and diversification of product offerings.

This guide serves as a comprehensive resource for sourcing Japanese panty vending machines. We delve into various types and materials used in these machines, ensuring buyers can choose options that align with their market demands. Insights into manufacturing processes and quality control measures provide a framework for evaluating potential suppliers, helping buyers make informed decisions.

Additionally, we address the cost structures associated with these machines and explore the market landscape, including consumer trends and regional preferences. A dedicated FAQ section will clarify common queries, equipping buyers with the knowledge needed to navigate this unique sector.

By leveraging the insights presented in this guide, international B2B buyers can empower their sourcing strategies, capitalize on emerging trends, and ultimately enhance their competitive edge in the global marketplace. Whether you’re based in Mexico or Kenya, this guide will facilitate informed decisions, paving the way for successful business ventures in this intriguing niche.

Understanding japanese panty vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Panty Vending Machine | Offers a range of new panties in various sizes and styles | Retail stores, adult novelty shops | Pros: Simple inventory management; Cons: Limited variety may not cater to niche markets. |

| Used Panty Vending Machine | Dispenses second-hand panties, often marketed as unique items | Specialty boutiques, online marketplaces | Pros: Unique selling point; Cons: Regulatory concerns and potential hygiene issues. |

| Customizable Panty Vending Machine | Allows customers to select styles, sizes, and colors | High-end retail outlets, pop-up shops | Pros: Personalized customer experience; Cons: Higher initial investment and complexity. |

| Subscription Panty Vending Machine | Offers recurring delivery of panties based on customer preferences | Subscription box services, e-commerce | Pros: Steady revenue stream; Cons: Requires robust logistics and customer service. |

| Novelty Panty Vending Machine | Features quirky designs and themes, often with humor | Event venues, entertainment centers | Pros: Attracts attention and foot traffic; Cons: Seasonal demand may fluctuate. |

Standard Panty Vending Machine

Standard panty vending machines typically offer a selection of new panties, catering to a broad audience. These machines are ideal for retail stores and adult novelty shops, where they can provide a straightforward shopping experience. Buyers should consider the ease of inventory management and the potential for steady sales, but they may find that a limited variety might not appeal to niche markets.

Used Panty Vending Machine

These machines dispense second-hand panties, often marketed as unique or collector’s items. They are popular in specialty boutiques and online marketplaces where novelty and uniqueness are key selling points. While they can attract a dedicated clientele, buyers must navigate regulatory concerns and address potential hygiene issues, which can complicate operations.

Customizable Panty Vending Machine

Customizable panty vending machines allow customers to select their preferred styles, sizes, and colors. This type is particularly suitable for high-end retail outlets and pop-up shops looking to offer a personalized shopping experience. Although they can enhance customer satisfaction, buyers should be prepared for a higher initial investment and the complexities of managing a customizable inventory.

Subscription Panty Vending Machine

These machines facilitate a subscription model, offering recurring deliveries of panties tailored to customer preferences. They are well-suited for subscription box services and e-commerce platforms, providing a steady revenue stream. However, buyers should be aware of the logistical challenges and the need for robust customer service to maintain satisfaction and retention.

Novelty Panty Vending Machine

Novelty panty vending machines feature quirky designs and humorous themes, making them ideal for event venues and entertainment centers. They can attract significant foot traffic and generate interest, but buyers must consider that demand may fluctuate seasonally. The initial investment can be justified by the potential for high visibility and unique marketing opportunities.

Related Video: THE TRUTH BEHIND JAPANS USED PANTY VENDING MACHINES

Key Industrial Applications of japanese panty vending machine

| Industry/Sector | Specific Application of Japanese Panty Vending Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | In-room vending for guests | Enhances guest experience and privacy | Machine reliability, product variety, and discreet branding |

| Retail | Standalone vending in shopping districts | Attracts niche customers and increases foot traffic | Location selection, security features, and payment options |

| Entertainment Venues | Vending at events or nightclubs | Provides unique merchandise and boosts revenue | Stock management, machine aesthetics, and user accessibility |

| Adult Entertainment | Vending in adult-themed establishments | Offers convenience and aligns with brand image | Product sourcing, legal compliance, and customer privacy |

| Online Retail | Integration with e-commerce platforms | Expands product reach and enhances customer engagement | Logistics, payment integration, and inventory management |

Hospitality

In the hospitality industry, Japanese panty vending machines can be strategically placed in hotel rooms to offer guests a unique and discreet shopping experience. This application enhances guest satisfaction by providing convenience and privacy, particularly appealing to those looking for novelty items. International B2B buyers in this sector should focus on sourcing reliable machines that can accommodate various product offerings and maintain a discreet brand image that aligns with the hotel’s overall aesthetic.

Retail

Standalone vending machines in shopping districts serve as a compelling attraction for niche markets, particularly in urban areas. These machines can draw customers seeking unique items, thus increasing foot traffic and sales for nearby businesses. B2B buyers from the retail sector must consider location selection, security features, and the variety of products offered to maximize profitability. Effective marketing strategies that highlight the novelty of the vending experience can also enhance consumer interest.

Entertainment Venues

In entertainment venues such as nightclubs and concert halls, these vending machines can provide a unique merchandise option that aligns with the venue’s brand. By offering exclusive items, they can enhance the overall experience and generate additional revenue streams. For international buyers in this sector, considerations around stock management, machine aesthetics, and user accessibility are crucial to ensure a seamless integration into the venue’s existing operations.

Adult Entertainment

For adult-themed establishments, Japanese panty vending machines offer a convenient solution for patrons looking for discreet purchases. This application aligns with the brand image of such venues and caters to customer preferences for privacy. Buyers in this industry must focus on product sourcing, legal compliance, and maintaining customer privacy to build trust and ensure repeat business. Understanding local regulations regarding adult merchandise is also essential.

Online Retail

Integrating Japanese panty vending machines with e-commerce platforms presents a modern retail approach that expands product reach. This application allows businesses to engage customers both online and offline, enhancing their overall shopping experience. B2B buyers in this sector should prioritize logistics, payment integration, and inventory management to ensure smooth operations. Additionally, marketing strategies that promote the convenience of this dual-channel approach can significantly enhance customer engagement.

Strategic Material Selection Guide for japanese panty vending machine

When selecting materials for Japanese panty vending machines, it is crucial to consider their properties, performance, and suitability for specific applications. Below is an analysis of several common materials used in these machines, focusing on their key properties, advantages, disadvantages, and considerations for international buyers.

1. Stainless Steel

Key Properties: Stainless steel is highly resistant to corrosion and oxidation, making it ideal for environments where hygiene and durability are paramount. It can withstand high temperatures and pressures, ensuring reliable performance under various operating conditions.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to corrosion, which extends the lifespan of the vending machine. However, it tends to be more expensive than other materials, and its manufacturing complexity can lead to higher production costs.

Impact on Application: Stainless steel is compatible with a variety of media, including water and air, making it suitable for vending machines that may require cleaning or maintenance. Its non-porous surface helps maintain hygiene standards.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding food safety and hygiene. Common standards like ASTM A240 for stainless steel may apply, and preferences for specific grades (e.g., 304 or 316) can vary by region.

2. High-Density Polyethylene (HDPE)

Key Properties: HDPE is known for its excellent chemical resistance, lightweight nature, and impact resistance. It can operate effectively in a wide temperature range, making it suitable for various environments.

Pros & Cons: The key advantage of HDPE is its cost-effectiveness and ease of manufacturing, allowing for rapid production and customization. However, it may not be as durable as metals and can degrade under UV exposure unless treated.

Impact on Application: HDPE is compatible with many liquids and can be used in vending machines that dispense items requiring moisture protection. Its lightweight nature facilitates easier installation and maintenance.

Considerations for International Buyers: Buyers should check for compliance with environmental regulations, especially regarding recyclability. Standards like ASTM D3350 may be relevant, and preferences may differ based on local market trends.

3. Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can be anodized for enhanced durability and aesthetic appeal.

Pros & Cons: The main advantage of aluminum is its lightweight nature, which reduces shipping costs and installation efforts. However, it can be more susceptible to scratches and dents compared to stainless steel.

Impact on Application: Aluminum is suitable for applications where weight savings are critical, such as portable vending machines. Its corrosion resistance makes it a viable option for humid environments.

Considerations for International Buyers: Compliance with standards such as ASTM B221 for aluminum extrusions is important. Buyers should also consider the local market’s acceptance of aluminum in vending machine designs.

4. Polycarbonate

Key Properties: Polycarbonate is a strong, transparent thermoplastic known for its impact resistance and clarity. It can withstand a wide range of temperatures and is often used in applications requiring visibility.

Pros & Cons: The key advantage of polycarbonate is its high impact resistance, making it ideal for protective covers and panels. However, it can be more expensive than other plastics and may yellow over time with UV exposure.

Impact on Application: Polycarbonate is particularly useful for vending machines with transparent sections, allowing customers to view products. Its durability ensures that the machine remains functional in high-traffic areas.

Considerations for International Buyers: Buyers should verify compliance with safety standards, particularly regarding food contact. Standards like ASTM D3935 may be applicable, and regional preferences for transparency and UV resistance should be considered.

Summary Table

| Material | Typical Use Case for japanese panty vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, exterior casing | High durability, corrosion resistance | Higher cost, complex manufacturing | High |

| High-Density Polyethylene (HDPE) | Internal components, storage bins | Cost-effective, lightweight | Less durable, UV degradation | Low |

| Aluminum | Structural elements, lightweight designs | Lightweight, corrosion-resistant | Susceptible to scratches, dents | Medium |

| Polycarbonate | Transparent panels, protective covers | High impact resistance, visibility | Expensive, potential UV yellowing | Medium |

This guide provides a comprehensive overview of material selection for Japanese panty vending machines, aiding international B2B buyers in making informed decisions tailored to their specific regional needs and compliance requirements.

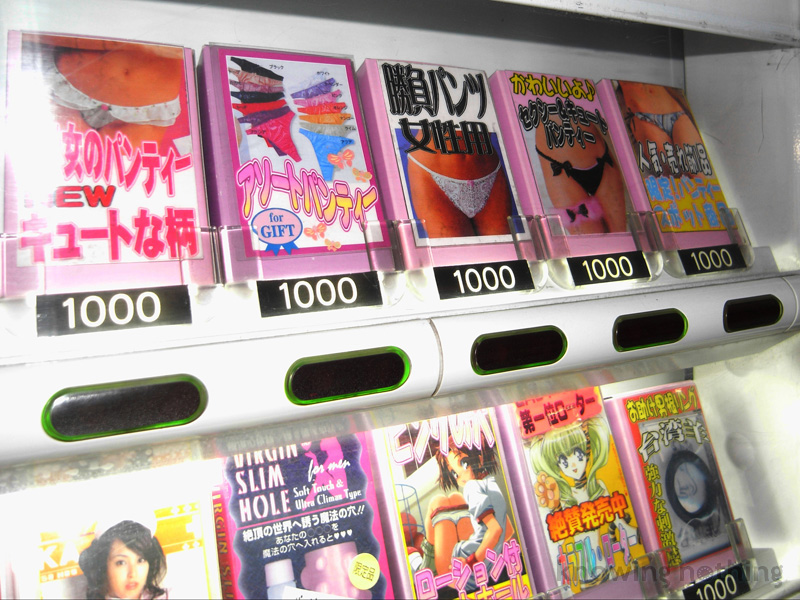

Illustrative Image (Source: Google Search)

In-depth Look: Manufacturing Processes and Quality Assurance for japanese panty vending machine

The manufacturing process of Japanese panty vending machines involves several key stages, each critical to ensuring the final product meets quality and functionality standards. Understanding these processes is essential for international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, where specific market demands and regulatory environments may influence purchasing decisions.

Manufacturing Process

1. Material Preparation

The first step in manufacturing involves sourcing high-quality materials. The primary components include:

– Metal Framework: Typically steel or aluminum for durability.

– Electronic Components: Including payment systems, sensors, and control boards.

– Plastic Parts: For housing and display components, often requiring specialized polymers that can withstand wear and tear.

Suppliers should ensure that materials comply with international standards, such as RoHS (Restriction of Hazardous Substances) for electronic components.

2. Forming

This stage involves shaping the metal and plastic components. Key techniques include:

– CNC Machining: Used for precise cuts and shapes in metal parts.

– Injection Molding: Commonly applied for plastic components, allowing for complex shapes and high-volume production.

– Laser Cutting: Enhances precision and reduces waste during the metal forming process.

B2B buyers should inquire about the machinery used and the technical capabilities of the supplier to ensure efficiency and quality in production.

3. Assembly

The assembly process combines all components into a functional unit. This typically involves:

– Mechanical Assembly: Attaching metal frames, installing electronic components, and securing plastic casings.

– Wiring: Connecting the electronic components for power and control.

– Quality Control Checks: Conducted at various stages to ensure components fit correctly and function as intended.

Buyers should ask about the assembly line’s organization and whether they employ lean manufacturing practices to reduce waste and enhance productivity.

4. Finishing

Finishing touches enhance aesthetics and durability. This includes:

– Painting and Coating: Applying protective and decorative finishes to metal parts.

– Quality Testing: Final checks on all electronic functions and mechanical integrity.

– Packaging: Ensuring machines are securely packaged for shipping to prevent damage during transport.

Quality Assurance

Quality assurance (QA) is crucial in manufacturing to meet both customer expectations and regulatory requirements. For Japanese panty vending machines, several standards and checkpoints are relevant.

International Standards

- ISO 9001: Focuses on quality management systems, ensuring manufacturers meet customer and regulatory requirements consistently.

- CE Marking: Indicates compliance with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: Particularly relevant for electronic components, ensuring they meet specific safety and performance criteria.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Inspects raw materials and components upon arrival to verify quality before production begins.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product to ensure it meets all specifications before shipment.

Common Testing Methods

- Functional Testing: Verifies that all electronic components operate correctly.

- Durability Testing: Assesses the machine’s ability to withstand regular use over time.

- Safety Testing: Ensures compliance with electrical safety standards, which is especially important for machines containing electronic parts.

Verifying Supplier Quality Control

B2B buyers can take several steps to ensure their suppliers maintain high quality standards:

-

Supplier Audits: Conducting regular audits to assess manufacturing processes and adherence to quality standards. This can include examining production facilities and reviewing documentation.

-

Quality Reports: Requesting detailed quality reports from suppliers, including data from IQC, IPQC, and FQC stages. This information can provide insight into the supplier’s quality control processes and historical performance.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of manufacturing quality. This is particularly valuable for buyers in regions where they cannot easily visit suppliers.

-

Certifications: Verifying that suppliers hold relevant certifications (e.g., ISO 9001, CE, API) that demonstrate their commitment to quality. Buyers should also inquire about the recertification process and any recent changes in compliance status.

Quality Control and Certification Nuances for International Buyers

International buyers, especially from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances regarding quality control and certification:

-

Regional Standards: Different regions may have varying regulatory requirements. For example, CE marking is mandatory for selling in Europe but may not be required in other regions. Understanding these distinctions can prevent compliance issues.

-

Cultural Factors: Communication styles and business practices can differ significantly across cultures. B2B buyers should be prepared to navigate these differences when discussing quality expectations and negotiations.

-

Market Expectations: Local market demands may influence product features and quality requirements. Buyers should conduct market research to understand consumer preferences and ensure the vending machines meet these expectations.

By comprehensively understanding the manufacturing processes and quality assurance standards for Japanese panty vending machines, international B2B buyers can make informed decisions that align with their business goals and market demands.

Related Video: Awesome Scene! Best Mass Production Factory Manufacturing Process

Comprehensive Cost and Pricing Analysis for japanese panty vending machine Sourcing

The cost structure of sourcing Japanese panty vending machines involves various components that significantly influence the total price. Understanding these components is essential for international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary materials used in manufacturing vending machines, such as metals, plastics, and electronic components, contribute significantly to the overall cost. High-quality materials ensure durability and compliance with safety standards, which may increase initial costs but can lead to lower maintenance expenses over time.

-

Labor: Labor costs vary by region, with countries like Japan having higher wage standards compared to emerging markets. When sourcing machines, consider the labor cost impact on the manufacturing process. This can include assembly, programming, and quality checks.

-

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, rent, and administrative expenses. Buyers should inquire about the supplier’s operational efficiency, as this can affect pricing.

-

Tooling: If customization is required, tooling costs can significantly impact the overall price. Custom molds or dies for specific designs or features may be necessary, which can lead to higher upfront costs.

-

Quality Control (QC): Ensuring that machines meet the necessary quality standards is vital, especially for products with specific certifications. Quality assurance processes can add to the cost but are essential for minimizing defects and ensuring customer satisfaction.

-

Logistics: Shipping costs can vary widely based on the origin of the machine, destination, and chosen Incoterms. International shipping, customs duties, and insurance should all be factored into the total cost.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market demand, competition, and the supplier’s reputation. Understanding the market landscape can help buyers negotiate better terms.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to reduced per-unit costs. Buyers should assess their market potential to determine optimal order sizes that can maximize savings.

-

Specifications/Customization: Custom features or specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality/Certifications: Higher quality materials and recognized certifications can enhance the machine’s longevity and reliability but come at a premium. Buyers should weigh the benefits of investing in quality against their budget constraints.

-

Supplier Factors: The supplier’s experience, reputation, and production capabilities can influence pricing. Establishing a relationship with reliable suppliers can lead to better pricing and service.

-

Incoterms: Understanding Incoterms is critical for international transactions. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of the machines.

Buyer Tips

-

Negotiation: Effective negotiation can lead to better pricing. Understanding the supplier’s cost structure can provide leverage during discussions.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes initial purchase price, maintenance, and operational costs. Investing in higher-quality machines may yield lower TCO in the long run.

-

Pricing Nuances: Be aware that prices may fluctuate due to currency exchange rates, geopolitical issues, and changes in material costs. Regular market research can help buyers stay informed.

Disclaimer

Prices for Japanese panty vending machines are indicative and can vary based on numerous factors, including market conditions, customization, and supplier negotiations. Buyers are encouraged to conduct thorough due diligence and obtain multiple quotes to ensure the best value for their investment.

Spotlight on Potential japanese panty vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘japanese panty vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for japanese panty vending machine

Key Technical Properties of Japanese Panty Vending Machines

Understanding the technical specifications of Japanese panty vending machines is crucial for international B2B buyers looking to enter this niche market. Below are some critical specifications to consider:

-

Material Grade: The machines are typically constructed from high-grade stainless steel or ABS plastic. Stainless steel provides durability and resistance to corrosion, while ABS plastic offers lightweight and cost-effective solutions. Selecting the right material affects longevity and maintenance costs.

-

Capacity: Most vending machines have a capacity of 50-100 items, depending on the model. This specification is important for inventory management and understanding customer demand, especially in high-traffic areas. Machines with larger capacities can reduce restocking frequency, optimizing operational efficiency.

-

Power Requirements: Vending machines generally operate on standard 220V electrical systems, with some models requiring specific power configurations. Understanding the power needs helps ensure compatibility with local infrastructure, avoiding potential installation issues.

-

Payment Systems: Advanced models incorporate cashless payment options, such as credit cards and mobile payments. This feature is essential for enhancing customer convenience and improving transaction security, especially in urban areas where cash usage is declining.

-

Dimensions: The physical size of the vending machine is critical for placement in retail spaces. Typical dimensions range from 1.5 to 2 meters in height and 0.6 to 1 meter in width. Ensuring the machine fits within designated spaces can prevent logistical challenges during installation.

-

Temperature Control: Some machines are equipped with temperature regulation features to maintain product quality. This is particularly important in regions with high ambient temperatures, as it preserves the condition of the items being sold.

Common Trade Terminology

Familiarity with industry-specific jargon can facilitate smoother negotiations and transactions. Below are key terms relevant to the vending machine sector:

-

OEM (Original Equipment Manufacturer): Refers to companies that manufacture products that are marketed under another company’s brand. For buyers, understanding OEM relationships can help identify reliable manufacturers and ensure product quality.

-

MOQ (Minimum Order Quantity): This term indicates the smallest quantity of goods that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory planning, as it can impact overall purchasing costs.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. Crafting a well-defined RFQ can help buyers receive accurate pricing and terms, which is crucial for cost analysis.

-

Incoterms (International Commercial Terms): These are standardized shipping terms that outline the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help buyers understand shipping costs, risk management, and delivery responsibilities.

-

Lead Time: This term refers to the time taken from placing an order to delivery. Understanding lead times helps buyers manage expectations and plan accordingly, especially in markets where demand can fluctuate rapidly.

-

Warranty Period: This indicates the duration for which the manufacturer guarantees the product against defects. A clear understanding of warranty terms can protect buyers from unforeseen repair costs and ensure product reliability.

By grasping these essential technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing Japanese panty vending machines, ultimately enhancing their market entry strategy and operational success.

Illustrative Image (Source: Google Search)

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the japanese panty vending machine Sector

The Japanese panty vending machine sector has witnessed significant evolution, driven by a confluence of cultural trends and technological advancements. As international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, engage with this unique market, understanding the underlying dynamics becomes crucial.

Market Overview & Key Trends

The global panty vending machine market is influenced by several key drivers, including rising interest in novelty products, increasing adult entertainment tourism, and a growing acceptance of unconventional merchandise. Notably, Japan remains at the forefront, where these machines have gained popularity not just as a product but as a cultural phenomenon.

Emerging B2B technology trends include the integration of advanced payment systems such as mobile wallets and contactless payments, catering to a tech-savvy consumer base. Additionally, vending machines are increasingly equipped with IoT capabilities, allowing for real-time inventory management and consumer analytics, enhancing operational efficiency for businesses.

For international buyers, understanding local regulations regarding adult products is essential. In regions like Africa and the Middle East, cultural sensitivities and legal frameworks may impact the market’s receptiveness. On the other hand, European markets tend to be more liberal, but buyers should still be aware of varying regulations across countries. Collaborating with local distributors who understand these dynamics can facilitate smoother market entry and compliance.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a paramount concern in the panty vending machine sector, as consumers increasingly demand transparency regarding the environmental impact of products. International buyers should prioritize partnerships with suppliers who adhere to sustainable practices. This includes the use of eco-friendly materials and responsible manufacturing processes.

Ethical sourcing is equally vital. Ensuring that products are sourced from manufacturers that uphold fair labor practices not only mitigates reputational risks but also appeals to a growing demographic of socially conscious consumers. Certifications such as Fair Trade or Global Organic Textile Standard (GOTS) can serve as benchmarks for quality and ethical standards.

Incorporating sustainable practices into the supply chain can also enhance brand loyalty among consumers who value environmental stewardship. B2B buyers should seek suppliers who offer ‘green’ certifications and engage in practices that minimize waste and carbon footprints throughout the production process.

Brief Evolution/History

The concept of panty vending machines originated in Japan during the late 20th century, primarily catering to a niche market. Initially perceived as a novelty, these machines have evolved into a symbol of Japan’s unique blend of technology and culture. Over the years, they have expanded in variety and sophistication, often featuring products that reflect the latest fashion trends and consumer preferences. This evolution has not only transformed the vending machine landscape in Japan but has also sparked interest among international buyers looking to explore innovative retail opportunities.

Related Video: ONESOURCE Global Trade: A Truly Global Solution

Frequently Asked Questions (FAQs) for B2B Buyers of japanese panty vending machine

-

What should I consider when vetting suppliers of Japanese panty vending machines?

When vetting suppliers, focus on their reputation, experience, and compliance with international standards. Request references and case studies to gauge their reliability. Additionally, confirm whether they have relevant certifications, such as ISO or CE, which indicate adherence to quality and safety standards. Conducting a factory visit or using third-party inspection services can also help ensure that the supplier meets your specifications and quality requirements. -

Can I customize my Japanese panty vending machines?

Yes, many suppliers offer customization options. This can include branding, size, color, and features of the machines. Discuss your specific needs with potential suppliers, including the types of products you intend to sell. Be clear about your target market, as this may influence the design and functionality of the machines. Ensure that the customization options align with both your brand image and customer preferences. -

What are the minimum order quantities (MOQ) and lead times for these machines?

MOQs can vary significantly between suppliers, often ranging from a few units to several dozen. Discuss MOQs upfront to ensure they fit your business model. Lead times for production can also vary; typically, expect 4 to 12 weeks depending on the supplier’s capacity and your customization requirements. Always confirm these details before finalizing your order to avoid unexpected delays. -

What payment options are available for purchasing these machines?

Payment options can include bank transfers, letters of credit, and escrow services, depending on the supplier’s terms. It’s advisable to negotiate favorable terms that mitigate risk, such as partial payment upfront and the balance upon delivery or installation. Ensure that the payment method you choose provides adequate protection for both parties in case of disputes.

-

How can I ensure quality assurance for my vending machines?

Quality assurance can be maintained by requiring suppliers to provide detailed quality control processes and inspection reports. Request samples of the machines before full-scale production to assess quality firsthand. Additionally, consider setting up a third-party quality inspection service to verify that the machines meet your specifications and international standards before shipping. -

What certifications should I look for in Japanese panty vending machines?

Key certifications to look for include ISO (International Organization for Standardization) and CE (Conformité Européenne) marking, which indicate compliance with international safety and quality standards. These certifications are essential for ensuring that the machines are safe for operation and meet regulatory requirements in your target market. Confirm that the supplier can provide documentation for these certifications. -

What logistics considerations should I be aware of when importing these machines?

When importing, consider shipping methods (air freight vs. sea freight), customs clearance, and tariffs that may apply to your shipment. Work with logistics providers experienced in handling machinery imports to ensure compliance with local regulations. Also, factor in insurance for your shipment to protect against potential damage or loss during transit. -

How should I handle disputes with suppliers?

To handle disputes effectively, establish clear terms in your contract, including clauses for conflict resolution and governing law. In case of a dispute, communicate directly with the supplier to resolve issues amicably. If necessary, consider mediation or arbitration as alternatives to legal proceedings, as these methods can be less costly and time-consuming. Keeping a detailed record of all communications and transactions can also aid in resolving disputes efficiently.

Strategic Sourcing Conclusion and Outlook for japanese panty vending machine

The exploration of the Japanese panty vending machine market offers significant insights for international B2B buyers. As demand for niche products grows, particularly in regions like Africa, South America, the Middle East, and Europe, strategic sourcing becomes essential. Buyers should focus on understanding local market preferences and cultural nuances to effectively position these machines.

Key Takeaways:

-

Market Research: Conduct thorough research to identify target demographics and preferences, ensuring that offerings align with local tastes and legal requirements.

-

Supplier Relationships: Establish strong partnerships with reliable manufacturers in Japan to secure quality products and favorable pricing structures. This will enhance supply chain efficiency and responsiveness to market changes.

-

Regulatory Compliance: Be aware of and comply with local regulations regarding vending machines and adult products to mitigate legal risks.

Looking ahead, the potential for growth in the Japanese panty vending machine market is promising. As consumer attitudes shift and acceptance of unique vending products rises, now is the time for international buyers to engage. By leveraging strategic sourcing practices, businesses can capitalize on this emerging trend and position themselves at the forefront of a lucrative market. Explore your options today and take the first step toward expanding your product offerings in this innovative sector.