Your Ultimate Guide to Sourcing Japan Used Underwear

Guide to Japan Used Underwear Vending Machines

- Introduction: Navigating the Global Market for japan used underwear vending machines

- Understanding japan used underwear vending machines Types and Variations

- Key Industrial Applications of japan used underwear vending machines

- Strategic Material Selection Guide for japan used underwear vending machines

- In-depth Look: Manufacturing Processes and Quality Assurance for japan used underwear vending machines

- Comprehensive Cost and Pricing Analysis for japan used underwear vending machines Sourcing

- Spotlight on Potential japan used underwear vending machines Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for japan used underwear vending machines

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the japan used underwear vending machines Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of japan used underwear vending machines

- Strategic Sourcing Conclusion and Outlook for japan used underwear vending machines

Introduction: Navigating the Global Market for japan used underwear vending machines

In recent years, the market for Japan used underwear vending machines has gained remarkable traction, presenting a unique opportunity for B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. These vending machines not only cater to niche markets but also capitalize on the growing trend of unconventional retail experiences. As urbanization continues to rise globally, the demand for innovative products like used underwear vending machines reflects changing consumer behaviors and interests.

This guide offers a comprehensive overview of the essentials involved in sourcing these vending machines. It delves into various types of machines available, the materials used in their construction, and the manufacturing and quality control processes that ensure product reliability. Additionally, it highlights key suppliers, discusses cost factors, and analyzes the current market landscape.

By equipping international B2B buyers with actionable insights and answers to frequently asked questions, this guide empowers informed sourcing decisions. Whether you are a distributor looking to expand your product line or a retailer seeking unique offerings to attract customers, understanding the intricacies of the Japan used underwear vending machine market can position your business for success in an evolving global marketplace.

Understanding japan used underwear vending machines Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Vending Machines | Offers a variety of used underwear types and sizes | Retail outlets, novelty shops | Pros: Wide selection; Cons: May face regulatory scrutiny. |

| Luxury Vending Machines | High-end models featuring designer brands and premium options | Upscale boutiques, exclusive events | Pros: Attracts affluent customers; Cons: High initial investment. |

| Customizable Vending Machines | Allows for branding and tailored product offerings | Marketing campaigns, promotional events | Pros: Enhances brand visibility; Cons: More complex setup. |

| Automated Quality Control Units | Equipped with sensors to ensure product quality and hygiene | Health and wellness stores | Pros: Ensures quality; Cons: Higher maintenance costs. |

| Themed Vending Machines | Focused on specific themes or niches (e.g., anime, cosplay) | Niche markets, themed events | Pros: Appeals to specific demographics; Cons: Limited market reach. |

Standard Vending Machines

Standard vending machines are the most common type, offering a variety of used underwear in different sizes and styles. These machines are suitable for retail outlets and novelty shops, catering to a broad audience. When considering a purchase, buyers should evaluate the machine’s capacity, ease of restocking, and the potential for regulatory compliance, especially regarding hygiene standards.

Luxury Vending Machines

Luxury vending machines provide a premium experience, featuring high-end brands and designer underwear. These are often placed in upscale boutiques or at exclusive events where affluent customers are present. Buyers must consider the initial investment and ongoing maintenance costs, as these machines require a more sophisticated setup and stock management to maintain brand prestige.

Customizable Vending Machines

Customizable vending machines allow businesses to brand their machines and tailor the product offerings to specific customer preferences. This flexibility is particularly beneficial for marketing campaigns and promotional events, enabling brands to create a unique customer experience. Buyers should weigh the advantages of enhanced brand visibility against the complexity and costs associated with setup and maintenance.

Automated Quality Control Units

Automated quality control units come equipped with sensors that ensure the products’ quality and hygiene. This type of machine is particularly suitable for health and wellness stores, where customer trust is paramount. While these machines provide a significant advantage in ensuring product integrity, buyers need to factor in higher maintenance costs and the potential need for technical support.

Themed Vending Machines

Themed vending machines cater to specific niches, such as anime or cosplay, making them ideal for niche markets and themed events. These machines can attract dedicated customer segments, but their appeal may be limited to specific demographics. Buyers should consider the machine’s location and target audience to maximize sales potential while also accounting for the costs associated with stocking specialized products.

Related Video: Used Panties? Mystery Box? | Trying the WEIRDEST VENDING MACHINES in AKIHABARA, TOKYO, Japan

Key Industrial Applications of japan used underwear vending machines

| Industry/Sector | Specific Application of Japan Used Underwear Vending Machines | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Niche retail outlets for adult products | Attracts specific consumer demographics, enhancing foot traffic | Compliance with local regulations, customer privacy measures |

| Hospitality | Hotels and motels offering unique amenities | Differentiates services, enhances guest experience | Maintenance and hygiene standards, discreet installation |

| Entertainment Venues | Nightclubs and adult entertainment venues | Increases revenue through unique offerings | Target market analysis, inventory management |

| E-commerce | Online platforms for subscription services | Expands product range, caters to niche markets | Logistics for inventory, international shipping regulations |

| Event Management | Trade shows and exhibitions for adult-themed products | Engages attendees, boosts brand visibility | Custom branding options, ease of setup and dismantling |

Detailed Appl

Related Video: USED PANTY VENDING MACHINES in JAPAN?!

Strategic Material Selection Guide for japan used underwear vending machines

When selecting materials for Japan’s used underwear vending machines, international B2B buyers must consider various factors, including the properties of materials, their advantages and disadvantages, and how they impact the overall functionality and compliance with local standards. Below is an analysis of four common materials used in these machines, tailored to the needs of buyers from Africa, South America, the Middle East, and Europe.

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand varying temperatures. It typically has a temperature rating of up to 800°C and can handle high-pressure applications.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust, making it ideal for vending machines exposed to moisture. However, it is more expensive than other metals and can be complex to manufacture due to its hardness, which may lead to higher production costs.

Impact on Application: Stainless steel is suitable for environments where hygiene is paramount, such as in vending machines for used underwear. It is compatible with various cleaning agents used in maintenance.

Considerations for Buyers: Buyers should ensure that the stainless steel used complies with international standards, such as ASTM A240. Furthermore, they should verify that suppliers can provide the necessary certifications for quality assurance.

2. Mild Steel

Key Properties: Mild steel is characterized by its good weldability and machinability. It has a lower tensile strength compared to stainless steel but is still suitable for many applications.

Pros & Cons: The main advantage of mild steel is its cost-effectiveness and ease of manufacturing. However, it is prone to corrosion if not properly coated or treated, which can limit its lifespan in humid environments.

Impact on Application: While mild steel can be used for structural components of vending machines, it requires protective coatings to enhance corrosion resistance. This material is less suited for areas that come into direct contact with moisture.

Considerations for Buyers: Buyers should consider the local climate and ensure that any mild steel components are treated with appropriate coatings, such as galvanization, to meet durability requirements. Compliance with local standards like DIN EN 10025 is also essential.

3. Polycarbonate

Key Properties: Polycarbonate is a high-performance plastic known for its impact resistance and transparency. It can withstand temperatures up to 120°C and is lightweight compared to metals.

Pros & Cons: The key advantage of polycarbonate is its excellent impact resistance, making it ideal for the outer casing of vending machines. However, it may not offer the same level of durability as metals and can be susceptible to scratching.

Impact on Application: Polycarbonate is suitable for transparent sections of vending machines, allowing visibility of the products inside. It is also compatible with various cleaning agents, which is crucial for hygiene.

Considerations for Buyers: Buyers should ensure that the polycarbonate used complies with standards such as JIS K 6900 for plastic materials. Additionally, they should verify the UV resistance of the material if the machines are to be placed outdoors.

4. Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It typically has a melting point of around 660°C.

Pros & Cons: The main advantage of aluminum is its lightweight nature, which can reduce shipping costs and ease installation. However, it can be more expensive than mild steel and may require additional treatments for enhanced corrosion resistance.

Impact on Application: Aluminum is suitable for components that require a balance of strength and weight, such as frames and panels in vending machines. It is also non-magnetic, which can be beneficial in specific applications.

Considerations for Buyers: Buyers should check for compliance with standards like ASTM B221 for aluminum extrusions. They should also consider the environmental impact of aluminum production and recycling options.

Summary Table

| Material | Typical Use Case for japan used underwear vending machines | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, outer casing | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Mild Steel | Structural framework | Cost-effective, easy to fabricate | Prone to corrosion without treatment | Low |

| Polycarbonate | Transparent panels | High impact resistance | Susceptible to scratching | Medium |

| Aluminum | Lightweight frames and panels | Lightweight, good corrosion resistance | Higher cost than mild steel, needs treatment | Medium |

This strategic material selection guide provides insights that can help international buyers make informed decisions when sourcing components for Japan’s used underwear vending machines. Understanding the properties and implications of each material will ensure compliance with local standards and enhance the overall performance of the machines.

In-depth Look: Manufacturing Processes and Quality Assurance for japan used underwear vending machines

The manufacturing processes and quality assurance protocols for Japan’s used underwear vending machines are essential for ensuring product safety, reliability, and compliance with international standards. This section outlines the key stages of manufacturing, quality control measures, and practical insights for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe.

Manufacturing Process

1. Material Preparation

The first stage involves selecting high-quality materials suitable for the vending machines. This includes:

- Metal Components: Typically, stainless steel is used for durability and corrosion resistance.

- Plastic Parts: High-grade plastics are chosen for components that require flexibility and impact resistance.

- Electronic Components: These include payment systems and vending mechanisms, which must meet specific electrical standards.

Key Techniques:

– Material Sourcing: Establish partnerships with reliable suppliers who can provide certified materials.

– Material Inspection: Conduct incoming quality checks (IQC) to ensure materials meet specifications before production begins.

2. Forming

Once materials are prepared, they undergo various forming processes:

- Sheet Metal Fabrication: This involves cutting, bending, and shaping metal sheets into the required forms for the machine’s casing.

- Injection Molding: Used for producing plastic components, ensuring high precision and uniformity.

Key Techniques:

– CNC Machining: Computer Numerical Control (CNC) machines are often utilized for precise cutting and shaping of components.

– Heat Treatment: Certain metal parts may undergo heat treatment to enhance strength and wear resistance.

3. Assembly

The assembly stage is critical for integrating all components into a functional vending machine.

- Sub-Assembly: Various components, such as electronic parts and mechanical systems, are pre-assembled.

- Final Assembly: The complete machine is assembled, integrating all parts and systems.

Key Techniques:

– Automated Assembly Lines: Use of robotics to increase efficiency and reduce human error during assembly.

– Manual Assembly: Skilled technicians perform final adjustments and quality checks during assembly.

4. Finishing

After assembly, the machines undergo finishing processes to enhance aesthetics and protect against environmental factors.

- Surface Treatment: Techniques such as powder coating or painting are applied to improve durability and appearance.

- Quality Inspection: Each machine is thoroughly inspected for functionality and defects before packaging.

Key Techniques:

– Electrostatic Painting: Ensures an even coating and is environmentally friendly.

– Final Quality Control (FQC): A comprehensive check that includes testing all machine functions.

Quality Assurance

Quality assurance in the manufacturing of used underwear vending machines is paramount to ensure compliance with international standards and customer satisfaction.

International Standards

- ISO 9001: This standard outlines the requirements for a quality management system (QMS), ensuring consistent quality in products and services.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: Relevant for ensuring the reliability of electronic components.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Conducted on raw materials to verify they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product to ensure functionality and safety.

Common Testing Methods

- Functional Testing: Verifies that all machine components work as intended.

- Durability Testing: Simulates long-term use to assess wear and tear.

- Safety Testing: Ensures compliance with electrical safety standards.

Verifying Supplier Quality Control

For international B2B buyers, especially those from diverse regions, verifying a supplier’s quality control processes is crucial. Here are actionable strategies:

-

Supplier Audits: Conduct regular audits of potential suppliers to review their manufacturing processes and quality control systems. This can help ensure adherence to international standards.

-

Request Quality Reports: Ask for detailed quality assurance reports, including IQC, IPQC, and FQC documentation, to understand their quality metrics.

-

Third-Party Inspections: Engage third-party inspection services to conduct independent assessments of the manufacturing processes and final products.

-

Certifications: Verify that suppliers hold relevant certifications such as ISO 9001 and CE marking. Request copies of these certifications to ensure authenticity.

-

Feedback from Previous Buyers: Seek testimonials or case studies from other international buyers who have worked with the supplier to gauge their reliability and product quality.

Conclusion

The manufacturing processes and quality assurance protocols for Japan’s used underwear vending machines are designed to meet high international standards. By understanding these processes and actively verifying supplier quality, international B2B buyers can make informed decisions, ensuring they partner with manufacturers that prioritize quality and compliance. This diligence is particularly important for buyers from diverse regions such as Africa, South America, the Middle East, and Europe, where varying standards and expectations may exist.

Related Video: Amazing Garment Manufacturing Process from Fabric to Finished Product Inside the Factory

Comprehensive Cost and Pricing Analysis for japan used underwear vending machines Sourcing

When sourcing used underwear vending machines from Japan, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This section outlines the key cost components, price influencers, and practical tips for navigating the sourcing process effectively.

Cost Components

-

Materials: The primary materials involved in the manufacturing of vending machines include metal casing, electronic components, and coin mechanisms. Sourcing high-quality materials is vital for durability and functionality, and prices can vary based on global market fluctuations.

-

Labor: Labor costs in Japan can be higher compared to other manufacturing countries. Skilled labor is required for assembly, programming, and quality control. Buyers should factor in these costs, especially if considering custom features.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and administrative expenses. Overhead costs can significantly affect the final pricing, so understanding the manufacturer’s operational efficiencies is beneficial.

-

Tooling: Tooling costs are relevant if the machines require custom molds or specific adaptations. This can be a significant upfront investment and should be negotiated upfront to avoid surprises.

-

Quality Control (QC): Ensuring that the machines meet the required standards involves additional costs. Buyers should inquire about the QC processes in place, as rigorous standards can lead to increased costs but ultimately better product quality.

-

Logistics: Shipping and handling are crucial, particularly for international orders. Costs can fluctuate based on distance, shipping method, and current fuel prices. Buyers should evaluate different logistics providers to find the most cost-effective solution.

-

Margin: Manufacturers typically include a profit margin that can vary based on competition and demand. Understanding the market context can help buyers negotiate better terms.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly influence pricing. Larger orders often lead to discounts, so buyers should assess their demand forecasts to optimize order sizes.

-

Specifications/Customization: Customized machines may incur additional costs. Buyers should clearly define their specifications upfront to avoid unexpected charges.

-

Materials and Quality: Premium materials and certifications (like ISO standards) can raise the price. Buyers should weigh the importance of these factors against their budget.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers may charge more but offer better quality and service.

-

Incoterms: Understanding the Incoterms agreed upon in the contract is essential. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect overall costs.

Buyer Tips

-

Negotiation: Effective negotiation can lead to better pricing. Buyers should prepare to discuss volumes, payment terms, and delivery schedules to find mutually beneficial agreements.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the initial purchase price. This includes maintenance, operational costs, and potential downtime.

-

Pricing Nuances: Be aware of currency fluctuations and economic conditions in Japan that may impact pricing. Engaging with local experts or consultants can provide valuable insights.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers can help in benchmarking prices and understanding market rates. This also provides leverage during negotiations.

Disclaimer

Prices for used underwear vending machines can vary widely based on the factors outlined above. This analysis serves as a guide and should be supplemented with direct inquiries to suppliers for accurate and current pricing information.

Spotlight on Potential japan used underwear vending machines Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘japan used underwear vending machines’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for japan used underwear vending machines

Key Technical Properties of Japan Used Underwear Vending Machines

When considering the procurement of used underwear vending machines from Japan, it is essential to understand several technical properties that can impact both functionality and compliance with local regulations. Here are some critical specifications:

-

Material Grade

– Definition: The quality of materials used in the machine’s construction, typically stainless steel or high-grade plastic.

– Importance: Higher-grade materials ensure durability and resistance to corrosion, which is crucial for machines placed in various environments, especially in humid or high-traffic areas. -

Temperature Tolerance

– Definition: The operational temperature range within which the vending machine functions optimally, often between -10°C to 50°C.

– Importance: Ensures the machine can operate effectively in different climates, important for buyers in regions with extreme temperatures. -

Power Consumption

– Definition: The amount of electricity the vending machine uses, usually measured in watts.

– Importance: Lower power consumption can lead to significant cost savings over time, making it attractive for buyers focused on operational efficiency. -

Capacity

– Definition: The number of items the vending machine can hold, typically ranging from 50 to 200 units.

– Importance: Understanding capacity helps in assessing the potential revenue generation and the frequency of restocking required, crucial for managing inventory effectively. -

Payment System Compatibility

– Definition: The types of payment methods the machine accepts, including cash, credit cards, and mobile payments.

– Importance: A flexible payment system increases customer convenience and can enhance sales, making it a vital consideration for international buyers. -

Security Features

– Definition: Measures implemented to prevent theft or vandalism, such as reinforced locks and alarm systems.

– Importance: Enhanced security features protect the investment and ensure that the machines remain operational and profitable.

Common Trade Terminology

Understanding industry jargon is crucial for effective communication and negotiation in the procurement process. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Buyers should consider whether they are dealing with OEMs for quality assurance and brand reputation. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units a supplier is willing to sell.

– Relevance: Knowing the MOQ is essential for budgeting and inventory planning, especially for startups or smaller businesses. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to request price quotes from suppliers for specific goods or services.

– Relevance: This is a critical step in sourcing, helping buyers compare prices and terms from different vendors. -

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law.

– Relevance: Understanding Incoterms is vital for clarifying the responsibilities of buyers and sellers in international shipping, including who pays for shipping and insurance. -

Lead Time

– Definition: The time it takes from placing an order until it is received.

– Relevance: Awareness of lead time is crucial for inventory management and ensuring timely availability of products. -

Warranty

– Definition: A guarantee provided by the manufacturer regarding the condition of the machine and its parts over a specified period.

– Relevance: A robust warranty can provide peace of mind and reduce total cost of ownership, making it an essential factor in decision-making.

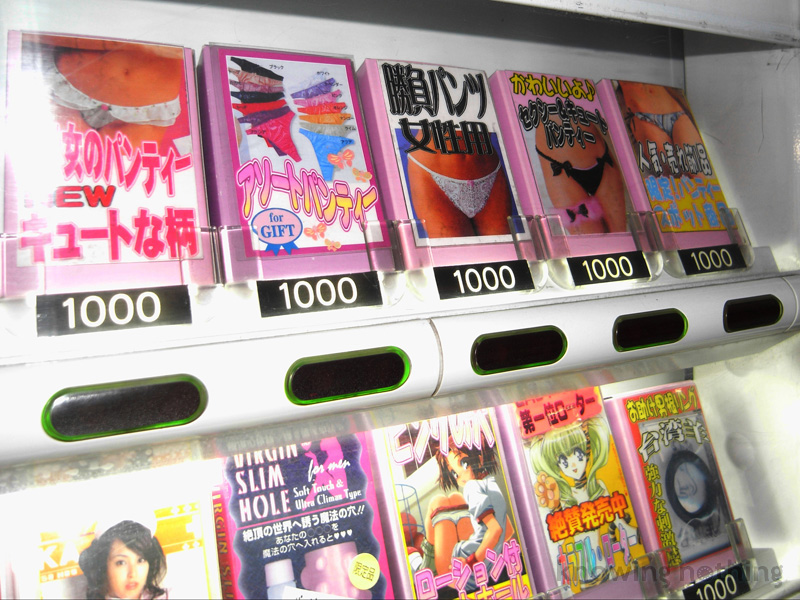

Illustrative Image (Source: Google Search)

By understanding these technical specifications and trade terms, international B2B buyers can make informed decisions when sourcing used underwear vending machines from Japan, ensuring that their investments are sound and aligned with their operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the japan used underwear vending machines Sector

Market Overview & Key Trends

The market for used underwear vending machines in Japan is shaped by unique cultural nuances and evolving consumer behaviors. Globally, there is a growing interest in alternative vending solutions, driven by a surge in e-commerce and the demand for unique, niche products. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial.

One significant trend is the integration of technology in vending machines. Innovations such as cashless payment systems, mobile app connectivity, and real-time inventory management are becoming standard. This transition not only enhances the consumer experience but also offers operational efficiencies for vending operators. Additionally, the increasing popularity of pop culture and subcultures in Japan has created a niche market that foreign buyers can tap into.

Emerging trends also include the rise of eco-conscious consumerism. As global awareness regarding sustainability grows, there is a demand for ethically sourced and environmentally friendly products, even in unconventional markets. International buyers should be prepared to adapt to these trends by sourcing machines that align with contemporary consumer values, which can lead to better market penetration and brand loyalty.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly becoming a critical factor for businesses in the used underwear vending machine sector. The environmental impact of textile waste is significant, and buyers are encouraged to prioritize suppliers who demonstrate a commitment to sustainable practices. This includes using recycled materials for packaging, energy-efficient vending machines, and responsible disposal methods for unsold items.

Furthermore, ethical sourcing is essential in building a reputable brand image. Buyers should seek partnerships with suppliers who can provide transparency in their supply chains, ensuring that all products are sourced responsibly. Certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX® can be indicators of a supplier’s commitment to sustainability.

By focusing on sustainability and ethical sourcing, international B2B buyers not only comply with increasing regulations but also cater to a consumer base that values environmentally friendly products. This approach can enhance brand loyalty and open new markets, particularly in regions where consumers are becoming more environmentally conscious.

Brief Evolution/History

The concept of vending machines in Japan dates back to the early 20th century, primarily serving beverages and snacks. However, the introduction of used underwear vending machines in the late 1990s marked a distinct cultural shift, catering to niche consumer interests and the unique aspects of Japanese subculture. Over the years, these machines have evolved from simple vending solutions to sophisticated, technology-driven units that incorporate user-friendly features and cater to a diverse clientele.

For international B2B buyers, understanding this evolution provides insight into the cultural context and potential market strategies that can be employed when entering the Japanese market. The fusion of technology and unique cultural offerings continues to shape the landscape, presenting both challenges and opportunities for overseas investors.

Related Video: THE TRUTH BEHIND JAPANS USED PANTY VENDING MACHINES

Frequently Asked Questions (FAQs) for B2B Buyers of japan used underwear vending machines

-

What should I consider when vetting suppliers for used underwear vending machines?

When vetting suppliers, prioritize their reputation, experience, and compliance with local regulations. Request references from past clients and check online reviews. Ensure they have a clear understanding of the market and are willing to provide documentation proving their manufacturing standards. Certifications like ISO or other quality assurance credentials can also indicate reliability. Establishing communication is vital; gauge their responsiveness and willingness to address your concerns. -

Can I customize the vending machines to fit my market needs?

Yes, many suppliers offer customization options for their vending machines. This can include modifications to design, size, product selection, and branding elements. Discuss your specific requirements upfront and request samples or prototypes to evaluate the proposed changes. Be clear about your target demographic and market trends to ensure that the customization aligns with local preferences. -

What is the typical minimum order quantity (MOQ) and lead time for these machines?

MOQs can vary significantly by supplier but typically range from 10 to 50 units, depending on the manufacturer’s capacity and your customization requests. Lead times generally range from 4 to 12 weeks, factoring in production schedules and shipping logistics. Always clarify these details during negotiations to align expectations and ensure timely delivery. -

What payment methods are commonly accepted by suppliers?

Most suppliers accept various payment methods, including bank transfers, letters of credit, and secure online payment platforms. It’s advisable to negotiate terms upfront, considering options such as partial payments upon order confirmation and the balance upon delivery. Ensure to use secure payment methods that provide some level of buyer protection to mitigate risks. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers will have a robust quality assurance (QA) process in place. Request details about their QA protocols, including inspections during production, pre-shipment checks, and any relevant certifications. Suppliers should be willing to provide warranties or guarantees for their machines, demonstrating their confidence in product quality. -

How should I handle logistics and shipping for international orders?

Logistics can be complex for international orders. Coordinate with your supplier to understand shipping options, including air freight for faster delivery or sea freight for cost-effectiveness. Ensure that all customs documentation is prepared to avoid delays at the border. Consider partnering with a freight forwarder experienced in handling machinery to streamline the process. -

What steps should I take if there is a dispute with the supplier?

In the event of a dispute, maintain clear and documented communication with the supplier. Attempt to resolve issues amicably through direct negotiation. If resolution fails, refer to the terms outlined in your contract regarding dispute resolution, such as mediation or arbitration. Legal recourse should be a last resort, and consulting a legal expert familiar with international trade laws is advisable. -

Are there specific regulations I need to comply with when importing these machines?

Yes, compliance with local regulations is crucial when importing used underwear vending machines. Research import restrictions, customs duties, and health regulations in your country. Some regions may require specific certifications or inspections for imported goods, especially those related to hygiene. Collaborating with a local expert or customs broker can help ensure compliance and smooth the import process.

Strategic Sourcing Conclusion and Outlook for japan used underwear vending machines

In conclusion, the strategic sourcing of used underwear vending machines from Japan presents a unique opportunity for international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe. As demand for innovative consumer products grows, understanding the nuances of this niche market is essential. Buyers should focus on building relationships with reputable suppliers, ensuring compliance with local regulations, and leveraging insights into consumer preferences to drive sales.

Illustrative Image (Source: Google Search)

Furthermore, strategic sourcing enables businesses to optimize their supply chains, reduce costs, and enhance product offerings. By prioritizing quality and authenticity, companies can differentiate themselves in competitive markets and tap into the cultural intrigue surrounding these vending machines.

Looking ahead, we encourage international buyers to actively explore partnerships with Japanese manufacturers and distributors. This proactive approach will not only facilitate access to unique products but also foster collaboration and innovation in an evolving market landscape. Seize this opportunity to enhance your portfolio and meet the growing consumer demand for distinctive products.