Your Ultimate Guide to Sourcing Japan Used Knickers Vending

Guide to Japan Used Knickers Vending Machine

- Introduction: Navigating the Global Market for japan used knickers vending machine

- Understanding japan used knickers vending machine Types and Variations

- Key Industrial Applications of japan used knickers vending machine

- Strategic Material Selection Guide for japan used knickers vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for japan used knickers vending machine

- Comprehensive Cost and Pricing Analysis for japan used knickers vending machine Sourcing

- Spotlight on Potential japan used knickers vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for japan used knickers vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the japan used knickers vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of japan used knickers vending machine

- Strategic Sourcing Conclusion and Outlook for japan used knickers vending machine

Introduction: Navigating the Global Market for japan used knickers vending machine

In today’s global marketplace, niche products like Japan’s used knickers vending machines are attracting attention from B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. These unique vending machines cater to a specific market segment, offering a blend of novelty and cultural intrigue that can enhance retail experiences and attract curious consumers. As a B2B buyer, understanding the intricacies of this product can open new avenues for profit and engagement.

This comprehensive guide delves into the critical aspects of sourcing Japan’s used knickers vending machines. It covers a variety of topics, including the different types of machines available, the materials used in their production, and the manufacturing and quality control processes that ensure product integrity. Additionally, we provide insights into potential suppliers, cost considerations, and market trends, equipping you with the knowledge needed to make informed purchasing decisions.

As you navigate this unique market, our guide aims to empower you with actionable insights and answers to frequently asked questions. Whether you’re looking to enter this niche or expand your current offerings, understanding the dynamics of Japan’s used knickers vending machines can be a strategic advantage in a competitive landscape. Embrace the opportunity to innovate in your market while capitalizing on the cultural allure of this unconventional product.

Understanding japan used knickers vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Used Knickers Vending Machine | Offers a variety of second-hand knickers in different sizes and styles. | Retail shops, novelty stores | Pros: Affordable, diverse stock; Cons: Quality may vary, potential legal concerns. |

| Premium Used Knickers Vending Machine | Features high-end, designer used knickers with brand labels. | Upscale boutiques, specialty shops | Pros: Higher quality, brand recognition; Cons: Higher price point, limited selection. |

| Customizable Used Knickers Vending Machine | Allows buyers to select styles and sizes based on customer preferences. | Custom retail setups, event-based sales | Pros: Tailored offerings, customer engagement; Cons: Higher operational costs, complex inventory management. |

| Themed Used Knickers Vending Machine | Focuses on specific themes (e.g., anime, pop culture) to attract niche markets. | Niche markets, pop culture events | Pros: Strong market appeal, unique offerings; Cons: Limited audience, potential stock challenges. |

| Automated Used Knickers Vending Machine | Incorporates advanced technology for contactless payments and inventory tracking. | Tech-savvy retail environments, urban centers | Pros: Enhanced user experience, efficient stock management; Cons: Higher initial investment, maintenance costs. |

Standard Used Knickers Vending Machine

This type is characterized by its broad selection of second-hand knickers available in various sizes and styles, catering to a wide audience. It is commonly found in retail shops and novelty stores where affordability and variety are key selling points. Buyers should consider the potential variability in quality and the legal implications associated with selling used intimate apparel.

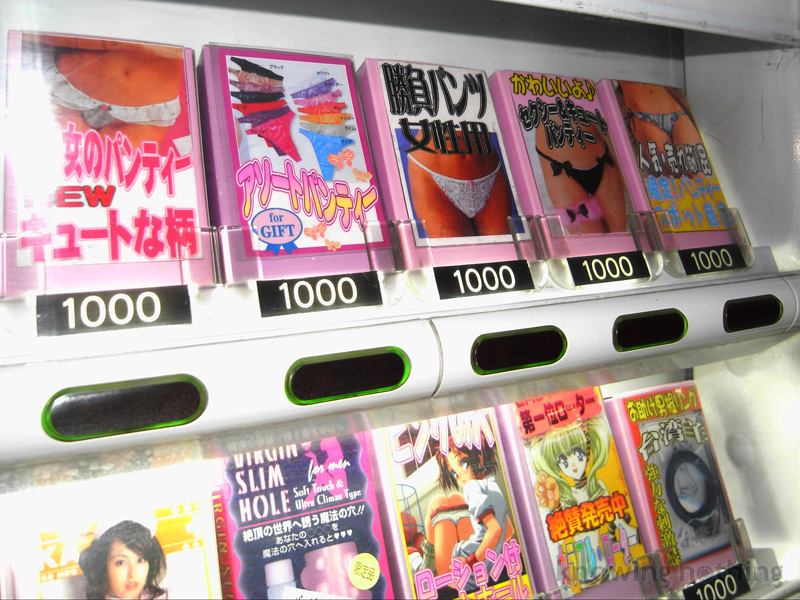

Illustrative Image (Source: Google Search)

Premium Used Knickers Vending Machine

These machines offer a curated selection of high-end, designer used knickers, appealing to customers looking for quality and brand recognition. Typically located in upscale boutiques or specialty shops, they provide a luxurious shopping experience. However, the higher price point may limit the customer base, and buyers should ensure they can maintain quality standards to uphold brand reputation.

Customizable Used Knickers Vending Machine

This innovative option allows buyers to customize their selections based on customer preferences, enhancing customer engagement. Ideal for custom retail setups and event-based sales, these machines can adapt to specific market demands. However, they require careful inventory management and may incur higher operational costs due to customization features.

Themed Used Knickers Vending Machine

Focusing on specific themes, such as anime or pop culture, these machines target niche markets and attract customers with unique interests. They are often utilized at pop culture events or in niche retail environments. While they can create a strong market appeal, the limited audience may pose challenges in maintaining stock and ensuring consistent sales.

Automated Used Knickers Vending Machine

Leveraging advanced technology, these machines offer features like contactless payments and inventory tracking, appealing to tech-savvy consumers in urban centers. They enhance the user experience and streamline operations for retailers. However, the initial investment and ongoing maintenance costs can be significant, so buyers should evaluate their budget and operational capabilities before purchasing.

Related Video: THE TRUTH BEHIND JAPANS USED PANTY VENDING MACHINES

Key Industrial Applications of japan used knickers vending machine

| Industry/Sector | Specific Application of japan used knickers vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Fashion | Unique merchandise in niche markets | Attracts curious customers, boosts foot traffic | Regulatory compliance, product authenticity, and sourcing ethics |

| Adult Entertainment | Discreet purchase options for adult products | Enhances customer privacy, increases sales volume | Local laws on adult products, machine placement, and maintenance |

| Tourism & Hospitality | Novelty souvenirs for tourists | Differentiates offerings, creates memorable experiences | Cultural sensitivity, market demand, and operational logistics |

| Event Management | Interactive installations at festivals and events | Engages attendees, drives social media attention | Event duration, setup requirements, and insurance considerations |

| E-commerce | Online integration with vending machine sales | Expands sales channels, enhances customer reach | Technology compatibility, payment processing, and logistics |

Key Industrial Applications Explained

Retail & Fashion

In the retail sector, Japan used knickers vending machines serve as unique merchandise options in niche markets. These machines can attract curious customers, leading to increased foot traffic and sales. International buyers should consider the regulatory compliance of vending machines in their countries, ensuring that the products meet local standards. Additionally, buyers must verify the authenticity of the items to maintain brand integrity and customer trust.

Adult Entertainment

Within the adult entertainment industry, these vending machines provide discreet purchase options for adult products. This feature enhances customer privacy and can significantly increase sales volume in locations where such products are legally permitted. Buyers must be aware of local laws regarding adult merchandise and consider the strategic placement of these machines to maximize visibility while respecting community standards.

Tourism & Hospitality

In the tourism and hospitality sector, Japan used knickers vending machines can be utilized as novelty souvenirs for tourists. By offering culturally unique items, businesses can differentiate their offerings and create memorable experiences for visitors. When sourcing these machines, it is crucial to assess cultural sensitivity and market demand to ensure that the products align with tourist interests. Operational logistics, such as machine maintenance and product replenishment, are also key considerations.

Event Management

Event management companies can leverage these vending machines as interactive installations at festivals and events. They engage attendees and can drive social media attention, enhancing the overall experience. Buyers in this sector should consider the duration of the event, setup requirements, and potential insurance implications to mitigate risks associated with operating these machines in public spaces.

E-commerce

Incorporating Japan used knickers vending machines into e-commerce strategies offers a unique sales channel. By integrating online sales with vending machine offerings, businesses can enhance their customer reach and drive sales. Buyers should focus on technology compatibility, ensuring that payment processing systems are efficient and reliable. Logistics for restocking and maintaining these machines are essential for sustaining customer satisfaction and operational efficiency.

Related Video: Japan’s Biggest Retro Vending Machine Wonderland – Over 100 Machines 🍔 🍭 🍜 🥤

Strategic Material Selection Guide for japan used knickers vending machine

When selecting materials for Japan’s used knickers vending machines, several factors must be considered to ensure optimal performance, durability, and compliance with international standards. Below is an analysis of common materials used in these vending machines, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. It typically has a temperature rating of up to 870°C (1600°F) and can handle pressures of 1000 psi or more, depending on the grade.

Pros & Cons: The primary advantages of stainless steel include its durability and resistance to rust and staining, making it ideal for environments where hygiene is critical. However, it can be more expensive than other metals and may require specialized manufacturing processes, which can increase costs.

Impact on Application: Stainless steel is compatible with various media, including moisture and potentially corrosive substances, ensuring the longevity of the vending machine components.

Specific Considerations: International buyers should ensure compliance with standards such as ASTM A240 for stainless steel sheets and plates. In regions like Europe, adherence to EN 10088 standards is also essential.

2. Mild Steel

Key Properties: Mild steel is characterized by its good tensile strength and ductility. It has a lower corrosion resistance than stainless steel and typically operates effectively at temperatures below 400°C (752°F).

Pros & Cons: Mild steel is cost-effective and easy to manufacture, making it a popular choice for many applications. However, its susceptibility to rust and corrosion can be a significant drawback, especially in humid environments.

Impact on Application: This material is suitable for structural components of vending machines but may require protective coatings or treatments to enhance its corrosion resistance.

Specific Considerations: Buyers in regions like Africa and South America should consider local climate conditions when choosing mild steel. Compliance with international standards such as ASTM A36 is also recommended.

3. Polycarbonate

Key Properties: Polycarbonate is a high-performance plastic known for its impact resistance, transparency, and lightweight nature. It can withstand temperatures ranging from -40°C to 120°C (-40°F to 248°F).

Pros & Cons: The advantages of polycarbonate include its lightweight nature and excellent impact resistance, making it suitable for transparent panels or protective covers. However, it may not be as durable as metals in high-stress applications and can be more expensive than other plastics.

Impact on Application: Polycarbonate is ideal for components that require visibility, such as display windows, but may not be suitable for structural elements subjected to heavy loads.

Specific Considerations: Buyers should ensure that the polycarbonate used meets relevant standards such as ISO 7391 for safety and performance. In Europe, compliance with REACH regulations is also crucial.

4. Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It typically operates effectively at temperatures up to 600°C (1112°F) and can handle moderate pressures.

Pros & Cons: The key advantages of aluminum include its low weight and resistance to corrosion, making it suitable for portable vending machines. However, it has lower strength compared to steel and may require thicker sections to achieve the same strength.

Impact on Application: Aluminum is suitable for various components, including frames and panels, but may not be ideal for load-bearing applications without proper design considerations.

Specific Considerations: Buyers should verify that the aluminum used complies with ASTM B221 for extruded aluminum products. In regions like the Middle East, attention to local environmental conditions is essential to prevent corrosion.

Summary Table

| Material | Typical Use Case for japan used knickers vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, exterior panels | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Mild Steel | Structural frames, non-exposed components | Cost-effective, easy to work with | Susceptible to rust, requires coating | Low |

| Polycarbonate | Transparent panels, protective covers | Lightweight, impact resistant | Less durable under heavy loads | Medium |

| Aluminum | Frames, panels, portable components | Lightweight, corrosion-resistant | Lower strength compared to steel | Medium |

This guide provides international B2B buyers with essential insights into material selection for Japan’s used knickers vending machines, emphasizing the importance of compliance with relevant standards and the specific characteristics of each material.

In-depth Look: Manufacturing Processes and Quality Assurance for japan used knickers vending machine

Manufacturing Processes of Japan Used Knickers Vending Machines

The manufacturing of Japan used knickers vending machines involves a series of intricate processes, ensuring that each machine is produced to meet the high standards expected by international buyers. Understanding these processes can help B2B buyers from Africa, South America, the Middle East, and Europe make informed decisions when sourcing these unique vending machines.

Main Stages of Manufacturing

-

Material Preparation

– Material Selection: The primary materials used include high-quality steel for the frame, tempered glass for display panels, and specialized plastic for internal components. Suppliers must ensure that materials meet durability and aesthetic standards.

– Pre-treatment: Metals undergo processes such as galvanization or powder coating to enhance corrosion resistance and longevity. This step is crucial for machines intended for outdoor or humid environments. -

Forming

– Sheet Metal Fabrication: Cutting, bending, and shaping of metal sheets are done using CNC machines. Precision in this step is vital to ensure all components fit correctly during assembly.

– Plastic Molding: Components like buttons and internal trays are produced through injection molding, allowing for intricate designs and strong structural integrity. -

Assembly

– Sub-assembly: Various components, such as electronic circuits, coin mechanisms, and vending trays, are pre-assembled to streamline the final assembly process.

– Final Assembly: All parts are assembled in a controlled environment. This includes integrating the vending machine’s electronic systems, ensuring the correct operation of sensors and payment mechanisms. -

Finishing

– Quality Coating: Final coats of paint or finishes are applied to enhance aesthetics and protect against wear and tear. This step often includes branding elements tailored to specific market requirements.

– Testing and Calibration: Each machine undergoes rigorous testing to ensure that it operates correctly, including checks on coin acceptance, product dispensing, and electronic functionalities.

Quality Assurance Protocols

Quality assurance (QA) is a critical component in the manufacturing process of used knickers vending machines. For international B2B buyers, understanding the QA measures can provide assurance of product reliability and compliance with global standards.

Relevant International Standards

- ISO 9001: This standard is pivotal for organizations aiming to ensure quality management systems are in place. It focuses on customer satisfaction and consistent quality of products and services.

- CE Marking: Particularly important for machines sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For machines incorporating advanced technology, compliance with American Petroleum Institute (API) standards may be relevant, particularly for electronic components.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– Materials and components are inspected upon arrival at the manufacturing facility. This includes verifying that suppliers meet the required specifications. -

In-Process Quality Control (IPQC)

– Regular inspections occur at various stages of the manufacturing process. This helps identify defects early, minimizing waste and ensuring that corrective actions are taken promptly. -

Final Quality Control (FQC)

– Comprehensive testing is conducted on completed machines. This includes functional tests, safety checks, and aesthetic inspections to ensure compliance with international standards.

Common Testing Methods

- Functional Testing: Verifies that all operational components, such as coin mechanisms and product dispensers, work seamlessly.

- Durability Testing: Machines are subjected to stress tests to evaluate their performance under various conditions, including weight loads and environmental factors.

- Safety Testing: Ensures that all electrical components meet safety regulations to prevent hazards.

Verifying Supplier Quality Control

For international B2B buyers, verifying the quality control practices of suppliers is essential. Here are several methods to ensure compliance and reliability:

- Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes, quality control measures, and working conditions.

- Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s quality management practices and their adherence to standards like ISO 9001.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing process and product quality.

Quality Control and Certification Nuances for International Buyers

Understanding the nuances of quality control and certification is crucial for B2B buyers from diverse regions. For instance, buyers in Africa may face different logistical challenges compared to those in Europe or South America.

- Regional Compliance: Ensure that the product meets local regulations and standards, which may differ significantly from the manufacturer’s country.

- Documentation: Request all relevant certifications and compliance documents, including ISO certificates and CE markings, to ensure that products meet required standards before importation.

- Cultural Considerations: Be aware of cultural differences in business practices and negotiation styles, which can influence supplier relationships and contract terms.

By understanding the manufacturing processes and quality assurance practices associated with Japan used knickers vending machines, B2B buyers can make more informed decisions, ensuring they select reliable suppliers that meet their specific needs.

Related Video: Incredible! Top5 Most viewed: Manufacturing And Recycling Factory Process Videos

Comprehensive Cost and Pricing Analysis for japan used knickers vending machine Sourcing

When sourcing Japan used knickers vending machines, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis delves into the various cost components involved, price influencers, and practical tips to enhance negotiation strategies.

Cost Components

-

Materials: The primary cost driver for vending machines includes the materials used in their construction. This encompasses metals, plastics, and electronic components. Sourcing high-quality, durable materials can lead to increased upfront costs but may reduce maintenance and replacement expenses in the long run.

-

Labor: Labor costs vary significantly based on the production location and local wage standards. In Japan, labor costs may be higher compared to other regions, reflecting the skill level and efficiency of the workforce. Buyers should account for these differences when evaluating overall costs.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and administrative expenses. Understanding the overhead can help buyers assess the total cost of production and negotiate better pricing.

-

Tooling: Tooling costs are incurred in the creation of molds and fixtures necessary for manufacturing the machines. Customizations may require additional tooling, which can significantly impact the overall price.

-

Quality Control (QC): Ensuring the quality of the machines involves rigorous testing and inspections, contributing to additional costs. Buyers should verify the QC processes in place to ensure product reliability.

-

Logistics: Shipping costs, including freight and insurance, can add substantial amounts to the final price. Logistics can be particularly complex for international shipments, so it’s essential to factor in these costs early in the sourcing process.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding the market rates and average margins can aid in negotiations.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for discounts, reducing the per-unit cost. Buyers should evaluate their needs against the supplier’s MOQs to optimize pricing.

-

Specifications/Customization: Custom features can significantly alter the price. Buyers should clarify their requirements upfront to avoid unexpected costs later in the process.

-

Materials and Quality: Higher-quality materials and certifications (e.g., ISO standards) can lead to increased costs but may enhance durability and performance.

-

Supplier Factors: Supplier reputation, experience, and reliability can influence pricing. Established suppliers may charge a premium for their proven track record.

-

Incoterms: The chosen Incoterms can affect shipping costs and responsibilities. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is vital for accurate cost estimation.

Buyer Tips

-

Negotiation: Leverage the insights gathered about cost components and market conditions to negotiate effectively. Presenting data can strengthen your position.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. A lower initial price might not always be the best value.

-

Pricing Nuances: Be aware of regional pricing differences and additional costs associated with international transactions. Currency fluctuations, tariffs, and taxes can all impact the final price.

-

Research Suppliers: Conduct thorough research on potential suppliers. Requesting quotes from multiple sources can provide a clearer picture of the market and help identify the best deal.

Disclaimer

Prices can vary widely based on market conditions, supplier negotiations, and specific project requirements. It’s advisable for buyers to conduct their own thorough market research and consult with industry experts to obtain accurate and relevant pricing information tailored to their needs.

Spotlight on Potential japan used knickers vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘japan used knickers vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for japan used knickers vending machine

When considering the purchase of used knickers vending machines from Japan, international B2B buyers should be well-acquainted with critical technical properties and trade terminology that can impact their purchasing decisions. Understanding these specifications and terms will help ensure that the machines meet operational requirements and align with business strategies.

Key Technical Properties

-

Material Grade

– Definition: The quality of materials used in the construction of the vending machine, typically categorized by durability and resistance to wear and tear.

– B2B Importance: High-grade materials ensure longevity and reliability, reducing maintenance costs and downtime. Buyers should seek machines made from rust-resistant metals and high-quality plastics. -

Operational Tolerance

– Definition: The permissible limits of variation in the machine’s operational parameters, such as temperature range, humidity tolerance, and power supply specifications.

– B2B Importance: Understanding operational tolerances helps buyers ensure that the vending machines can function effectively in their specific environments, whether in humid tropical climates or cooler regions. -

Capacity

– Definition: The number of items the machine can hold and dispense, usually measured in units (e.g., number of knickers).

– B2B Importance: Knowing the capacity is crucial for inventory management. A larger capacity may reduce the frequency of restocking, making it more efficient for high-traffic areas. -

Dimensions and Weight

– Definition: The physical size and weight of the vending machine, which affect installation and placement.

– B2B Importance: Buyers must ensure that the machine fits within their intended space and meets local regulations regarding equipment size. Additionally, weight can impact transportation costs. -

Payment System Compatibility

– Definition: The types of payment methods the vending machine accepts, such as cash, credit cards, or mobile payments.

– B2B Importance: Compatibility with various payment systems can increase sales and customer satisfaction. Businesses in regions with advanced payment technologies should prioritize machines that support these options. -

Energy Efficiency Rating

– Definition: A classification indicating the machine’s energy consumption relative to its performance.

– B2B Importance: Energy-efficient machines reduce operational costs and are often favored by environmentally conscious consumers. Buyers may also consider potential tax incentives for energy-efficient equipment.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Relevance: In the context of used knickers vending machines, OEM parts can ensure compatibility and quality, enhancing machine reliability. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units a supplier is willing to sell.

– Relevance: Buyers should be aware of MOQ requirements, as they can affect inventory levels and cash flow. Understanding MOQ helps in planning purchases strategically. -

RFQ (Request for Quotation)

– Definition: A document issued to suppliers requesting pricing and delivery information for specific products.

– Relevance: Issuing an RFQ is essential for comparing costs and terms from multiple suppliers, ensuring competitive pricing for vending machines. -

Incoterms (International Commercial Terms)

– Definition: A series of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers.

– Relevance: Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery obligations, which are critical for international transactions. -

Lead Time

– Definition: The time taken from placing an order to delivery.

– Relevance: Knowing the lead time is vital for inventory management and planning. Buyers should inquire about lead times to avoid disruptions in service. -

Warranty Period

– Definition: The duration during which the manufacturer guarantees the machine’s performance and covers repairs or replacements.

– Relevance: A longer warranty period can indicate confidence in the machine’s quality and provide peace of mind for buyers, making it an essential factor in decision-making.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and market strategies when sourcing used knickers vending machines from Japan.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the japan used knickers vending machine Sector

Market Overview & Key Trends

The Japan used knickers vending machine sector is experiencing significant growth, driven by a combination of cultural fascination and niche market demand. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly recognizing the potential of this unique product line. The global interest in Japanese culture, combined with the novelty of vending machines selling used intimate apparel, has created a unique market dynamic that offers both opportunities and challenges.

Key trends include the rise of e-commerce platforms facilitating international trade, as well as advancements in vending machine technology. These machines are now equipped with features such as cashless payment options, enhanced security measures, and improved user interfaces, catering to a tech-savvy consumer base. Furthermore, the emerging trend of personalization—where machines can offer tailored selections based on user preferences—presents a significant opportunity for B2B buyers to differentiate themselves in the marketplace.

Market dynamics are influenced by regulatory considerations, particularly concerning hygiene and ethical sourcing, which are paramount for international buyers. Understanding local market regulations and consumer attitudes towards used apparel is crucial for successful entry and sustainability in this sector. Buyers should also keep an eye on shifting consumer preferences toward unique and culturally significant products, which could further drive demand.

Sustainability & Ethical Sourcing in B2B

As global awareness of environmental issues grows, sustainability in the Japan used knickers vending machine sector is becoming increasingly important. B2B buyers must consider the environmental impact of sourcing used apparel and ensure that their supply chains are ethical and transparent. This includes evaluating the sourcing practices of suppliers, ensuring that they adhere to strict hygiene and safety standards, and that the products are responsibly procured.

The importance of ethical supply chains cannot be overstated. Buyers should seek suppliers that prioritize sustainable practices, such as using eco-friendly materials and minimizing waste during the production process. Certifications such as Fair Trade and organic labeling can enhance credibility and appeal to environmentally-conscious consumers.

Moreover, the use of green certifications and materials is becoming a vital differentiator in the market. Buyers should look for products that incorporate sustainable practices, from production to packaging. This not only mitigates environmental impact but also aligns with the growing consumer demand for responsible and ethical products, making it a key factor in purchasing decisions.

Brief Evolution/History

The concept of vending machines selling used intimate apparel in Japan emerged in the late 1990s, reflecting unique cultural attitudes towards intimacy and novelty. Initially viewed as a curiosity, these machines have evolved into a legitimate niche market, appealing to both locals and international tourists. As cultural exchange increases, the appeal of these products is expanding globally, paving the way for B2B opportunities.

This evolution is characterized by a growing acceptance of unconventional products and the rise of e-commerce, allowing international buyers to access this unique market. Understanding this historical context is essential for B2B buyers to navigate current market dynamics effectively and seize emerging opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of japan used knickers vending machine

-

What should I consider when vetting suppliers of used knickers vending machines?

When vetting suppliers, prioritize their reputation, experience, and compliance with local regulations. Request references and case studies from previous international clients. Verify their certifications, particularly regarding health and safety standards. Additionally, assess their production capabilities and after-sales support, which are crucial for ongoing operations. -

Can I customize the vending machines to suit my market needs?

Yes, many suppliers offer customization options. You can request specific features, such as branding, machine size, or payment systems. Ensure that you discuss your requirements upfront to avoid complications later. Customizations may affect lead times and costs, so factor these into your planning. -

What are the typical minimum order quantities (MOQs) and lead times for these machines?

MOQs can vary significantly depending on the supplier and your customization requirements. Generally, expect MOQs to range from 10 to 50 units. Lead times also depend on these factors, typically ranging from 4 to 12 weeks. Always confirm these details before placing an order to align your inventory needs with supplier capabilities.

Illustrative Image (Source: Google Search)

-

What payment terms are commonly offered by suppliers?

Payment terms can vary widely, with options including upfront payments, installments, or letters of credit. Ensure you understand the total cost, including shipping and customs duties. Negotiate terms that provide you with sufficient cash flow while ensuring the supplier is secure in their transaction. -

How can I ensure quality assurance and certification for used knickers vending machines?

Request detailed information on the supplier’s quality assurance processes and any certifications they possess. Look for ISO certifications or other relevant industry standards that indicate adherence to quality and safety protocols. A well-defined QA process will help mitigate risks associated with product defects. -

What logistics options are available for shipping the vending machines internationally?

Suppliers often offer various logistics solutions, including sea freight, air freight, and door-to-door delivery services. Evaluate these options based on cost, speed, and reliability. Ensure that the supplier has experience with international shipping and can handle customs clearance to avoid delays. -

How should I handle disputes with suppliers over product quality or delivery issues?

Establish clear communication channels and procedures for addressing disputes before they arise. Document all transactions, agreements, and communications. If issues occur, initially address them directly with the supplier. If unresolved, consider mediation or arbitration as outlined in your contract. -

What are the legal considerations for importing used knickers vending machines?

Research the import regulations in your country regarding used goods, as restrictions may apply. Ensure compliance with health and safety standards and any necessary certifications. Consult with a legal expert in international trade to navigate complex regulations and avoid potential fines or shipment delays.

Strategic Sourcing Conclusion and Outlook for japan used knickers vending machine

In conclusion, the strategic sourcing of Japan’s used knickers vending machines presents a unique opportunity for international B2B buyers looking to diversify their product offerings and tap into niche markets. Key takeaways include the importance of understanding regional regulations, consumer preferences, and the cultural context surrounding this unconventional product. By leveraging strategic sourcing techniques, businesses can effectively navigate these complexities, ensuring compliance and maximizing market potential.

As buyers from Africa, South America, the Middle East, and Europe (including Germany and Argentina) explore these vending machines, it’s crucial to prioritize partnerships with reliable suppliers who maintain high standards of quality and hygiene. This not only mitigates risks but also enhances brand reputation in local markets.

Looking ahead, the demand for innovative and unique products is expected to grow. Companies that embrace this trend and invest in strategic sourcing will position themselves as leaders in their respective markets. Now is the time to act—evaluate your sourcing strategy and consider integrating Japan’s used knickers vending machines into your portfolio to capitalize on this emerging opportunity.