Your Ultimate Guide to Sourcing Japan Underwear Vending

Guide to Japan Underwear Vending Machine

- Introduction: Navigating the Global Market for japan underwear vending machine

- Understanding japan underwear vending machine Types and Variations

- Key Industrial Applications of japan underwear vending machine

- Strategic Material Selection Guide for japan underwear vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for japan underwear vending machine

- Comprehensive Cost and Pricing Analysis for japan underwear vending machine Sourcing

- Spotlight on Potential japan underwear vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for japan underwear vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the japan underwear vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of japan underwear vending machine

- Strategic Sourcing Conclusion and Outlook for japan underwear vending machine

Introduction: Navigating the Global Market for japan underwear vending machine

In the rapidly evolving landscape of retail, the Japan underwear vending machine emerges as a unique and innovative solution, capturing the interest of international B2B buyers. With the rise of urbanization and the demand for convenience, these vending machines offer a discreet, efficient, and readily accessible way to purchase intimate apparel. As markets in Africa, South America, the Middle East, and Europe continue to diversify, understanding the potential of this niche product is critical for businesses looking to stay ahead.

This comprehensive guide delves into the multifaceted world of Japan’s underwear vending machines. It covers essential topics such as the various types of machines available, the materials used in production, and the manufacturing and quality control processes. Buyers will also gain insights into identifying reputable suppliers, analyzing cost factors, and exploring the broader market trends that influence purchasing decisions. Moreover, we address common FAQs to clarify any uncertainties and empower buyers with the knowledge needed to make informed choices.

By equipping international B2B buyers with actionable insights and practical information, this guide serves as a valuable resource for navigating the global market. Whether you’re in Egypt, the UAE, or beyond, understanding the dynamics of Japan’s underwear vending machines can enhance your sourcing strategies and open new revenue streams in a competitive retail landscape. Embrace this opportunity to differentiate your offerings and meet the evolving needs of consumers worldwide.

Understanding japan underwear vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Underwear Vending | Basic model offering a variety of underwear styles | Convenience stores, shopping malls | Easy to operate; limited product variety may not cater to all customers. |

| Luxury Underwear Vending | High-end brands and premium materials | High-end boutiques, hotels | Attracts affluent customers; higher initial investment required. |

| Novelty Underwear Vending | Unique or themed designs, often with humor | Tourist areas, entertainment venues | Differentiates from competitors; may have niche appeal leading to limited sales. |

| Subscription-Based Vending | Monthly or quarterly underwear delivery options | Online retail, subscription services | Steady revenue stream; requires robust logistics and inventory management. |

| Smart Vending Machines | Integrated technology for inventory tracking and payment | Tech-savvy markets, urban areas | Enhanced user experience; higher maintenance costs due to technology. |

Standard Underwear Vending

Standard underwear vending machines are the most common type found in various locations, including convenience stores and shopping malls. These machines typically offer a selection of basic underwear styles at competitive prices. For B2B buyers, these machines provide a reliable option with minimal operational complexity. However, the limited variety may not appeal to all customer segments, which could affect sales volume. Buyers should consider location and target demographics when investing in standard models.

Luxury Underwear Vending

Luxury underwear vending machines cater to consumers seeking high-end brands and premium materials. These machines are often placed in upscale boutiques and hotels, targeting affluent customers who value quality and exclusivity. For B2B buyers, investing in luxury machines can enhance brand image and attract a niche market. However, the higher initial investment and ongoing maintenance costs may require careful financial planning to ensure profitability.

Novelty Underwear Vending

Novelty underwear vending machines offer unique and themed designs, often incorporating humor or pop culture references. These machines are typically found in tourist areas and entertainment venues, appealing to customers looking for fun and memorable purchases. For B2B buyers, novelty machines can help differentiate their offerings from competitors. However, the niche appeal may lead to limited sales, necessitating an understanding of local market trends and customer preferences.

Subscription-Based Vending

Subscription-based vending machines provide customers with the option to receive underwear on a monthly or quarterly basis. This model is increasingly popular in online retail and subscription services, offering a steady revenue stream for B2B buyers. However, it requires robust logistics and inventory management to ensure timely deliveries. Buyers should assess their ability to manage these aspects effectively before investing in subscription-based models.

Smart Vending Machines

Smart vending machines integrate advanced technology for inventory tracking and payment processing, enhancing the user experience. These machines are ideal for tech-savvy markets and urban areas, appealing to customers who appreciate convenience and innovation. For B2B buyers, investing in smart vending machines can provide a competitive edge. However, they come with higher maintenance costs due to the technology involved, necessitating a thorough cost-benefit analysis before purchase.

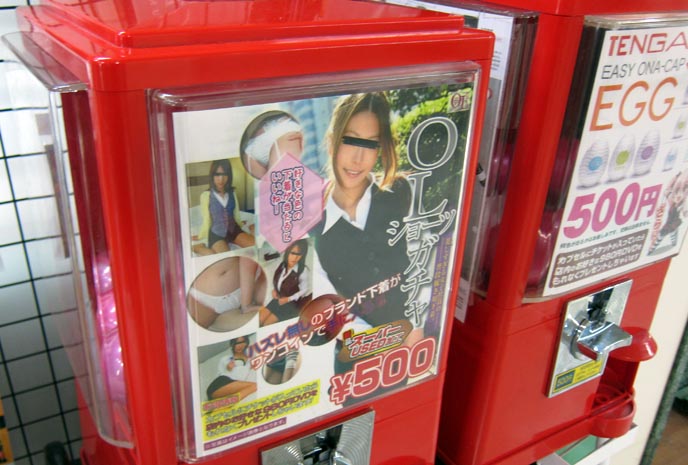

Related Video: Underwear Vending Machine in Japan

Key Industrial Applications of japan underwear vending machine

| Industry/Sector | Specific Application of Japan Underwear Vending Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | In-room guest amenities for hotels | Enhances guest experience, increases convenience | Machine size, payment options, product variety |

| Retail | Standalone vending units in shopping centers | Attracts foot traffic, captures impulse purchases | Location analytics, inventory management, aesthetics |

| Transportation | On-site vending in airports and train stations | Provides essential items for travelers, reduces downtime | Machine reliability, product selection, branding |

| Events and Festivals | Temporary vending solutions for large gatherings | Meets high demand during peak times, boosts sales | Quick setup, product customization, payment systems |

| Health and Wellness | Vending solutions in gyms and wellness centers | Offers convenience for patrons, promotes hygiene | Product quality, machine durability, user interface |

Hospitality

In the hospitality industry, Japan underwear vending machines serve as a unique in-room amenity for hotels, providing guests with a discreet and convenient option for purchasing personal items. This application enhances the overall guest experience, ensuring that travelers have access to necessities without the need to leave the premises. For international B2B buyers, especially from regions like Africa and the Middle East, sourcing machines that are compact and compatible with various payment methods is crucial to meet diverse customer needs.

Retail

In retail environments, especially in shopping centers, Japan underwear vending machines can be strategically placed to attract foot traffic and facilitate impulse purchases. The presence of such vending units can differentiate a retail space by offering unique products that cater to specific demographics, including tourists and local shoppers. B2B buyers should consider location analytics to determine optimal placement, as well as inventory management solutions to ensure product availability and minimize stockouts.

Transportation

Airports and train stations are prime locations for Japan underwear vending machines, where they provide essential items for travelers in a hurry. By addressing the immediate needs of passengers, these machines can significantly reduce downtime and enhance customer satisfaction. International buyers in the transportation sector should prioritize machine reliability and product selection to cater to diverse traveler preferences and ensure a seamless shopping experience.

Events and Festivals

During large gatherings such as events and festivals, temporary vending solutions featuring Japan underwear vending machines can effectively meet the high demand for personal items. These machines can be deployed quickly and are designed to handle significant foot traffic, boosting sales during peak times. For B2B buyers, considerations around quick setup, product customization, and efficient payment systems are essential to capitalize on the unique opportunities presented by such events.

Health and Wellness

In gyms and wellness centers, Japan underwear vending machines provide a convenient solution for patrons seeking hygiene products post-workout. This application not only promotes personal care but also enhances the overall experience of gym-goers. B2B buyers in this sector should focus on sourcing machines that emphasize product quality, durability, and an intuitive user interface to ensure a positive customer interaction.

Strategic Material Selection Guide for japan underwear vending machine

When selecting materials for Japan’s underwear vending machines, it is crucial to consider various factors that influence performance, durability, and compliance with international standards. Here, we analyze four common materials used in the construction of these machines, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers, particularly from Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It typically has a temperature rating of up to 800°C and is resistant to a variety of chemicals.

Pros & Cons: The primary advantage of stainless steel is its durability and low maintenance requirements, making it ideal for high-traffic environments. However, it can be more expensive than other materials and may require specialized manufacturing processes, which can increase lead times.

Impact on Application: Stainless steel is compatible with various media, including moisture and cleaning agents, making it suitable for vending machines that dispense personal items.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A240 for stainless steel grades. In regions like the UAE and Egypt, local regulations may dictate specific grades suitable for vending machines.

Plastic (Polycarbonate/ABS)

Key Properties: Plastic materials such as polycarbonate and ABS offer good impact resistance and can withstand temperatures up to 100°C. They are lightweight and can be molded into complex shapes.

Pros & Cons: The main advantage of using plastic is its cost-effectiveness and ease of manufacturing, allowing for rapid production and design flexibility. However, plastics may not offer the same level of durability as metals and can be susceptible to UV degradation over time.

Impact on Application: These plastics are suitable for internal components or outer casings, where weight and design flexibility are essential. However, they may not be suitable for areas exposed to high heat or direct sunlight.

Considerations for International Buyers: Buyers should check for compliance with safety standards such as ASTM D638 for tensile properties. In regions like South America, preferences may lean towards more eco-friendly materials, which could influence the choice of plastics.

Aluminum

Key Properties: Aluminum is lightweight, has good corrosion resistance, and can withstand temperatures up to 600°C. It is also an excellent conductor of heat, which can be beneficial in certain applications.

Pros & Cons: The advantages of aluminum include its lightweight nature and good strength-to-weight ratio, making it ideal for portable vending machines. However, it can be more expensive than other materials and may require additional coatings for enhanced corrosion resistance.

Impact on Application: Aluminum is suitable for both structural and aesthetic components, providing a modern look while maintaining functionality.

Considerations for International Buyers: Compliance with standards such as ASTM B221 for aluminum extrusions is essential. In Europe, buyers should also consider REACH regulations regarding materials used in consumer products.

Galvanized Steel

Key Properties: Galvanized steel is carbon steel that has been coated with zinc to improve corrosion resistance. It can withstand temperatures similar to stainless steel but is primarily used in less demanding environments.

Pros & Cons: The key advantage of galvanized steel is its cost-effectiveness and good strength, making it suitable for structural applications. However, it is less resistant to corrosion compared to stainless steel and may require regular maintenance.

Impact on Application: This material is often used for the structural framework of vending machines, where exposure to moisture is limited.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A123 for zinc coatings. In the Middle East, considerations regarding humidity and salt exposure are critical for long-term performance.

Summary Table

| Material | Typical Use Case for japan underwear vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | External and internal components requiring durability | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic (Polycarbonate/ABS) | Casings and internal components requiring design flexibility | Cost-effective and lightweight | Susceptible to UV degradation | Low |

| Aluminum | Structural and aesthetic components for modern design | Lightweight with good strength | More expensive, may need coatings | Medium |

| Galvanized Steel | Structural framework in less demanding environments | Cost-effective and strong | Less corrosion resistance than stainless | Low |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decisions that align with regional standards and operational requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for japan underwear vending machine

Understanding the Manufacturing Processes for Japan Underwear Vending Machines

The manufacturing of Japan’s underwear vending machines is a sophisticated process that combines advanced technology with meticulous craftsmanship. For international B2B buyers, understanding these processes is crucial for making informed purchasing decisions. Below, we outline the main stages involved in production, key techniques utilized, and insights into quality assurance protocols.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Materials: The first step involves selecting high-quality materials, primarily using durable metals and plastics that can withstand varying environmental conditions. Stainless steel is often favored for its corrosion resistance.

– Supplier Verification: It is essential for buyers to verify the credibility of material suppliers. International standards such as ISO 9001 can be used to assess the quality management systems of suppliers. -

Forming

– Metal Fabrication: This stage typically involves processes like laser cutting, bending, and welding. Precision is critical, as the components must align perfectly for the machine to function efficiently.

– Plastic Injection Molding: For non-metal parts, injection molding is commonly used. This technique allows for complex shapes and designs, optimizing the internal mechanisms of the vending machine. -

Assembly

– Modular Assembly Line: Assembly often takes place in a modular format, where different teams handle specific components such as coin mechanisms, control panels, and product dispensers. This approach enhances efficiency and quality.

– Integration of Electronics: The incorporation of electronic components, including payment systems and inventory management sensors, is another crucial aspect. Ensuring compatibility and proper installation is vital for operational success. -

Finishing

– Surface Treatment: Finishing processes such as powder coating or anodizing enhance the aesthetic appeal and durability of the machines. These treatments also contribute to the machine’s resistance to wear and tear.

– Final Inspection: Before shipping, a thorough inspection is conducted to ensure all components meet specified standards. This includes aesthetic checks as well as functional tests.

Key Techniques in Manufacturing

- Automation: Many manufacturers employ automated machinery for precision tasks, reducing human error and increasing production speed. Automation also allows for scalability in response to demand fluctuations.

- Lean Manufacturing: Adopting lean manufacturing principles helps in minimizing waste and optimizing production processes. This approach can lead to cost savings which can be passed on to B2B buyers.

- Prototype Development: Before full-scale production, prototypes are often created to test design and functionality. This stage is critical for identifying potential issues early in the process.

Quality Assurance Protocols

International and Industry-Specific Standards

For B2B buyers, understanding the quality assurance landscape is essential. Key standards include:

- ISO 9001: This standard focuses on quality management systems and is pivotal for ensuring that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: Essential for products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: If the vending machines incorporate specific technology or materials, compliance with API (American Petroleum Institute) standards may be relevant, particularly for machines that may be used in specific industrial contexts.

Quality Control Checkpoints

- Incoming Quality Control (IQC): At this stage, raw materials and components are inspected before they enter the production process. Ensuring the quality of inputs is crucial for the overall quality of the final product.

- In-Process Quality Control (IPQC): During manufacturing, continuous checks are performed to monitor processes and identify defects early. This proactive approach minimizes the risk of defective products reaching the final inspection stage.

- Final Quality Control (FQC): The final inspection involves a comprehensive evaluation of the completed machines against established quality benchmarks. This step often includes functional tests to ensure all components work as intended.

Common Testing Methods

- Functional Testing: This verifies that all operational aspects of the vending machine work correctly, including payment processing, product dispensing, and user interface.

- Durability Testing: Machines are subjected to stress tests to assess their longevity and resistance to wear under normal operational conditions.

- Safety Testing: Ensuring that machines meet safety regulations to protect users and operators is non-negotiable. This may include electrical safety tests and structural integrity assessments.

Verifying Supplier Quality Control

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is crucial. Here are actionable insights:

- Supplier Audits: Conducting regular audits of potential suppliers helps assess their quality management systems and manufacturing processes. This can be done through on-site visits or through third-party auditing firms.

- Requesting Quality Reports: Buyers should request documented evidence of quality control practices, including inspection reports and certifications. This transparency is essential for trust and reliability.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of product quality before shipping. This is especially important for buyers who may not be able to visit factories in person.

Quality Control and Certification Nuances for International Buyers

When sourcing from Japan, international buyers should be aware of specific nuances in quality control and certification:

- Regulatory Compliance: Different regions may have unique regulatory requirements. Understanding these can prevent legal challenges upon importing goods.

- Cultural Considerations: The Japanese manufacturing culture places a significant emphasis on quality and precision. Understanding this ethos can help in negotiations and relationship-building with suppliers.

- Language Barriers: Communication can be a challenge; thus, employing intermediaries or translators with industry knowledge can facilitate better understanding and compliance.

Conclusion

For international B2B buyers, particularly in emerging markets, comprehending the manufacturing processes and quality assurance measures of Japan’s underwear vending machines is critical. By leveraging this knowledge, buyers can make informed decisions, ensuring they source high-quality, reliable products that meet their market needs. Understanding the intricacies of manufacturing and quality control not only aids in risk mitigation but also enhances the overall purchasing experience.

**Related Video: Cone crusher factory production, assembly and testing process demonstration! **

Comprehensive Cost and Pricing Analysis for japan underwear vending machine Sourcing

Understanding the cost structure and pricing dynamics of sourcing Japanese underwear vending machines is essential for international B2B buyers aiming to make informed purchasing decisions. This analysis will provide insights into the various cost components, price influencers, and actionable buyer tips that cater specifically to markets in Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary materials for vending machines include high-quality metals for the structure, electronics for the vending mechanism, and aesthetic components such as screens and branding elements. The choice of materials directly affects durability, functionality, and cost.

-

Labor: Labor costs can vary significantly based on the manufacturing location. In Japan, labor is typically higher due to skilled workforce requirements. However, outsourcing production to countries with lower labor costs is a common practice, which can help mitigate expenses.

-

Manufacturing Overhead: This includes costs associated with factory operations such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead, impacting the overall pricing.

-

Tooling: Initial tooling costs for the production of custom vending machines can be substantial. Buyers should consider whether they need special designs or features, as these will add to the initial investment.

-

Quality Control (QC): Implementing rigorous QC processes is crucial for ensuring product reliability. While this adds to the cost, it helps prevent future issues that could lead to greater expenses through returns or repairs.

-

Logistics: Shipping costs, which can be particularly high for bulky items like vending machines, need careful consideration. Factors include shipping distance, mode of transport, and any tariffs or duties that may apply.

-

Margin: Suppliers will typically add a profit margin to the total cost of production. Understanding the typical margin in the industry can help buyers negotiate better terms.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Larger orders often qualify for bulk discounts, making it essential to evaluate demand forecasts carefully.

-

Specifications/Customization: Custom features can lead to higher costs. Buyers should weigh the benefits of customization against the potential increase in price.

-

Materials and Quality/Certifications: Higher quality materials and certifications (e.g., ISO standards) can increase costs but also enhance the product’s marketability and durability.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may command higher prices but can offer better quality assurance and after-sales support.

-

Incoterms: Understanding the terms of delivery is crucial. Different Incoterms (e.g., FOB, CIF) can affect the total landed cost and financial responsibilities.

Buyer Tips

-

Negotiation: Approach negotiations with a clear understanding of market prices and your anticipated order volume. Building a rapport with suppliers can also lead to better terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the upfront price. Consider maintenance, operational costs, and potential downtime when assessing value.

-

Pricing Nuances for International Buyers: Different regions may have varying expectations regarding pricing and quality. It is essential to communicate clearly about specifications and quality standards to avoid misunderstandings.

-

Market Research: Conduct thorough research on local market conditions, as this can influence pricing strategies. Understanding local purchasing power and preferences can help tailor offerings effectively.

Disclaimer

Prices and costs mentioned in this analysis are indicative and can vary based on specific requirements, market conditions, and supplier negotiations. Buyers are encouraged to conduct due diligence and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential japan underwear vending machine Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for japan underwear vending machine.)*

Essential Technical Properties and Trade Terminology for japan underwear vending machine

Key Technical Properties for Japan Underwear Vending Machines

When considering the procurement of underwear vending machines from Japan, B2B buyers must evaluate several critical technical specifications that directly impact functionality, durability, and user satisfaction. Here are the essential properties to consider:

-

Material Grade

– Definition: This refers to the quality and type of materials used in the machine’s construction, often categorized by factors such as corrosion resistance, strength, and weight.

– Importance: Higher-grade materials ensure longevity and reliability in high-traffic environments. For instance, stainless steel components are preferred for their durability and ease of cleaning, which is essential in hygiene-sensitive markets. -

Power Consumption

– Definition: This metric indicates how much electricity the vending machine requires to operate effectively.

– Importance: Understanding power consumption is vital for cost management and sustainability. Machines with lower energy requirements can significantly reduce operational costs, making them more appealing in regions with high electricity prices. -

Capacity and Size

– Definition: Refers to the number of items the machine can hold and its physical dimensions.

– Importance: A machine’s capacity affects inventory turnover and customer satisfaction. Buyers should assess their target market’s demand to choose a size that maximizes product availability without compromising space efficiency. -

User Interface Technology

– Definition: This encompasses the software and hardware components that facilitate user interaction, including touch screens, payment systems, and product selection methods.

– Importance: An intuitive user interface enhances customer experience and can increase sales. Machines equipped with advanced payment options, such as mobile payments, are particularly appealing in tech-savvy markets. -

Security Features

– Definition: These include locks, alarms, and tamper-proof designs that protect the machine from theft and vandalism.

– Importance: Security is paramount, especially in urban areas. Investing in robust security features can prevent losses and ensure consistent product availability, thereby fostering customer trust. -

Maintenance Requirements

– Definition: This refers to the frequency and complexity of upkeep needed to keep the machine operational.

– Importance: Machines that are easier to maintain can lead to lower operational downtime and reduced service costs. B2B buyers should inquire about warranty terms and availability of spare parts for easier maintenance management.

Common Trade Terminology

Understanding industry jargon is essential for effective communication and negotiation in the B2B space. Here are some key terms relevant to the procurement of underwear vending machines:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Usage: When sourcing machines, identifying OEMs can help buyers ensure they are getting high-quality products that meet industry standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Usage: Knowing the MOQ is crucial for budgeting and inventory planning, particularly for smaller businesses or those entering new markets. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and availability for specific products.

– Usage: Issuing an RFQ helps buyers compare prices and terms from different suppliers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions.

– Usage: Familiarity with Incoterms is essential for understanding shipping costs, risk management, and delivery responsibilities. -

Lead Time

– Definition: The total time it takes from placing an order to receiving the goods.

– Usage: Knowing the lead time helps buyers plan their inventory and ensure they meet market demand without overstocking. -

Warranty Period

– Definition: The duration for which a manufacturer guarantees the functionality of their product against defects.

– Usage: A longer warranty period can signify confidence in product quality and reduce potential repair costs for buyers.

By understanding these technical properties and industry terms, B2B buyers can make more informed decisions when sourcing Japanese underwear vending machines, ultimately enhancing operational efficiency and customer satisfaction in their markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the japan underwear vending machine Sector

Market Overview & Key Trends

The Japanese underwear vending machine sector is experiencing a notable transformation driven by technological advancements, changing consumer preferences, and the need for convenience. As urbanization accelerates in regions like Africa, South America, the Middle East, and Europe, the demand for accessible and discreet purchasing options is on the rise. B2B buyers should note that vending machines are evolving to incorporate smart technology, including cashless payment systems and inventory tracking, which enhance user experience and operational efficiency.

Emerging trends also include the customization of products offered within these machines, as manufacturers are increasingly recognizing the diverse needs of consumers. For instance, offering a variety of sizes, styles, and even sustainable materials can appeal to a broader audience. Additionally, the integration of e-commerce capabilities into vending machines allows for a seamless shopping experience, making it easier for buyers to restock and manage inventory remotely.

International B2B buyers should stay attuned to local market dynamics, such as cultural attitudes towards vending machines and underwear purchases. In regions like Egypt and the UAE, where traditional retail may dominate, understanding consumer behavior and preferences can provide a competitive edge. Furthermore, partnerships with local distributors can facilitate entry into these markets, allowing for better alignment with regional consumer demands.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical focus in the global underwear vending machine market. The environmental impact of textile production is significant, making sustainable practices essential for both manufacturers and distributors. B2B buyers must look for suppliers that prioritize ethical sourcing and use eco-friendly materials, such as organic cotton or recycled fibers. These choices not only contribute to environmental conservation but also resonate with increasingly eco-conscious consumers.

Moreover, obtaining green certifications can enhance a brand’s reputation and appeal to a broader audience. Certifications such as OEKO-TEX or GOTS (Global Organic Textile Standard) signify commitment to sustainability, making products more attractive to ethically-minded consumers. For international buyers, this means sourcing from manufacturers who not only comply with sustainability standards but also transparently communicate their supply chain practices.

In addition to product materials, the operational aspect of vending machines can also be optimized for sustainability. Energy-efficient machines and eco-friendly packaging are emerging best practices that can reduce waste and energy consumption. By prioritizing these elements, B2B buyers can not only fulfill their corporate social responsibility (CSR) goals but also tap into a growing market segment that values sustainability.

Brief Evolution/History

The concept of vending machines in Japan dates back to the early 20th century, but the introduction of underwear vending machines specifically began to gain traction in the late 1990s. Initially designed to cater to the convenience of busy urban dwellers, these machines have evolved significantly to meet changing consumer needs. The rise of digital technology has facilitated the transition from traditional vending machines to smart, connected units that offer enhanced features and user experiences.

As the market continues to innovate, the Japanese underwear vending machine sector serves as a case study for how technology and consumer trends can shape a niche industry. For international B2B buyers, understanding this evolution is crucial, as it highlights the potential for growth and adaptation in their own markets.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of japan underwear vending machine

-

What criteria should I use to vet suppliers of Japanese underwear vending machines?

When vetting suppliers, focus on their experience in the industry, customer reviews, and the quality of their products. Request references and conduct background checks to assess their reliability. It’s also beneficial to review their manufacturing processes and certifications, such as ISO standards, to ensure they meet international quality benchmarks. Consider engaging with suppliers through trade shows or industry events to evaluate their credibility and establish relationships. -

Can I customize the vending machines to fit my market’s preferences?

Yes, many suppliers offer customization options to suit regional tastes and preferences. You can customize elements such as machine size, branding, product selection, and payment methods. Ensure you communicate your specific requirements clearly to the supplier and discuss any additional costs associated with customization. This adaptability can enhance market acceptance and customer satisfaction in your region. -

What are the typical minimum order quantities (MOQs) and lead times for these machines?

MOQs can vary significantly based on the supplier and the complexity of the order. Generally, expect MOQs to range from 10 to 50 units. Lead times typically range from 4 to 12 weeks, depending on the supplier’s production capacity and the level of customization required. It’s advisable to inquire about bulk discounts and negotiate terms that align with your business goals and inventory strategy. -

What payment terms should I expect when purchasing these machines?

Payment terms can vary but commonly include options like a deposit upfront (20-30%) with the balance due upon delivery or before shipment. Some suppliers may offer extended payment plans or letters of credit for larger orders. Always clarify the payment structure, currency, and any additional fees involved in international transactions to avoid unexpected costs and ensure a smooth purchasing process. -

How can I ensure product quality and compliance with international standards?

To ensure quality, request samples before placing a bulk order. Verify that the supplier adheres to international standards such as CE or RoHS certifications. Additionally, consider conducting third-party inspections during production and before shipment. Establishing clear quality assurance agreements with suppliers can help mitigate risks and ensure that the products meet your specifications and market regulations. -

What logistics considerations should I keep in mind when importing these machines?

Logistics is critical in managing the supply chain effectively. Consider factors such as shipping methods, customs duties, insurance, and delivery timelines. Collaborate with a freight forwarder experienced in international trade to navigate customs regulations specific to your region. Ensure that the supplier provides all necessary documentation, such as bills of lading and customs declarations, to facilitate smooth clearance.

Illustrative Image (Source: Google Search)

-

How should I handle disputes or issues with suppliers?

Establish clear communication channels with your suppliers from the outset to address any potential disputes quickly. It’s advisable to draft a comprehensive contract that outlines terms, responsibilities, and dispute resolution processes. If issues arise, attempt to resolve them amicably through direct negotiation. If necessary, consider mediation or arbitration as a cost-effective means of dispute resolution while maintaining the business relationship. -

What support can I expect from suppliers after the purchase?

Post-purchase support varies by supplier but should generally include installation guidance, maintenance tips, and access to spare parts. Discuss warranty terms and the availability of technical support during negotiations. Having a reliable support structure in place is essential, especially for international buyers, as it ensures smooth operation and minimizes downtime, ultimately protecting your investment in the vending machines.

Strategic Sourcing Conclusion and Outlook for japan underwear vending machine

As the demand for innovative retail solutions continues to grow globally, the Japanese underwear vending machine sector presents a unique opportunity for international B2B buyers. Key takeaways highlight the importance of strategic sourcing in capitalizing on this niche market. Buyers should prioritize partnerships with reliable suppliers who can provide high-quality products that cater to local preferences, ensuring a competitive edge in their respective regions.

Illustrative Image (Source: Google Search)

Furthermore, understanding consumer behavior in targeted markets—such as Africa, South America, the Middle East, and Europe—will be crucial. Tailoring offerings to meet cultural norms and preferences can significantly enhance market penetration and brand loyalty.

In conclusion, the future of the Japanese underwear vending machine market is promising, with potential for expansion in diverse international landscapes. B2B buyers are encouraged to explore this avenue, leveraging strategic sourcing to secure advantageous partnerships and innovative solutions. Embrace this opportunity to diversify your portfolio and meet the evolving needs of consumers in your region. The time to act is now—position your business at the forefront of this unique market trend.