Your Ultimate Guide to Sourcing Japan Pantie Vending Machine

Guide to Japan Pantie Vending Machine

- Introduction: Navigating the Global Market for japan pantie vending machine

- Understanding japan pantie vending machine Types and Variations

- Key Industrial Applications of japan pantie vending machine

- Strategic Material Selection Guide for japan pantie vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for japan pantie vending machine

- Comprehensive Cost and Pricing Analysis for japan pantie vending machine Sourcing

- Spotlight on Potential japan pantie vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for japan pantie vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the japan pantie vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of japan pantie vending machine

- Strategic Sourcing Conclusion and Outlook for japan pantie vending machine

Introduction: Navigating the Global Market for japan pantie vending machine

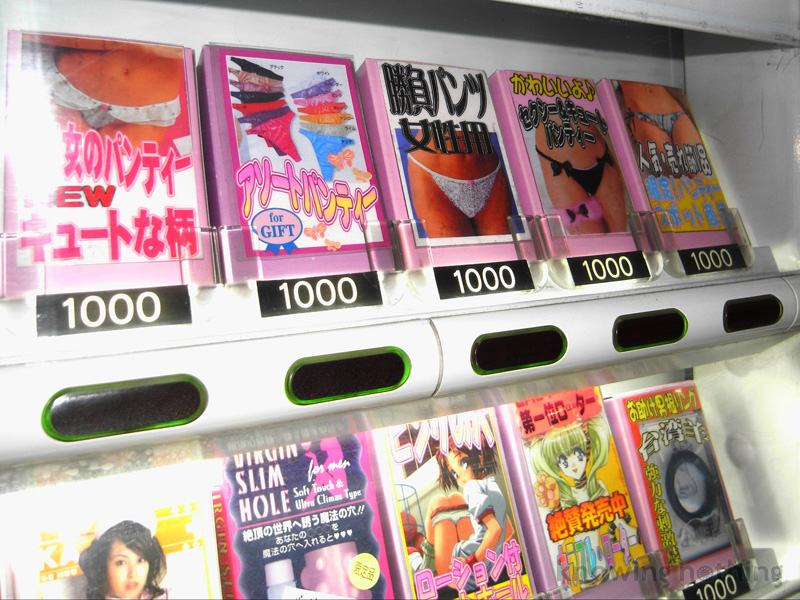

In recent years, Japan’s unique pantie vending machines have captured the imagination of international markets, blending cultural curiosity with entrepreneurial opportunity. For B2B buyers from Africa, South America, the Middle East, and Europe, understanding this niche market can unlock new avenues for revenue and customer engagement. These vending machines not only reflect a distinct aspect of Japanese culture but also present a viable business model that has fascinated consumers worldwide.

This comprehensive guide delves into the intricate world of Japan’s pantie vending machines, providing essential insights into various types, materials, and manufacturing quality control practices. It offers a detailed analysis of suppliers, cost structures, and the current market landscape, ensuring that buyers are well-equipped to make informed sourcing decisions.

Whether you are located in Colombia or Poland, this guide empowers you to navigate the complexities of sourcing these machines effectively. By addressing frequently asked questions and common concerns, we aim to bridge cultural gaps and enhance your understanding of a product that, while unconventional, holds significant potential in the global marketplace. Prepare to engage with a unique segment of the vending machine industry that combines novelty with business acumen, ultimately leading to successful procurement strategies tailored to your market needs.

Understanding japan pantie vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Used Panty Machine | Dispenses used panties, typically from local sellers | Adult novelty shops, specialty stores | High demand in niche markets; legal concerns in sourcing |

| Automated Panty Vending System | Fully automated, often with RFID technology | Retail environments, vending franchises | Reduces labor costs; requires maintenance and tech support |

| Luxury Panty Vending Machine | Offers high-end brands or designer underwear | Upscale boutiques, luxury malls | Attracts affluent customers; higher initial investment |

| Themed Panty Vending Machine | Features unique themes (e.g., anime, cosplay) | Event merchandising, pop culture stores | Appeals to specific fan bases; seasonal demand fluctuations |

| Customizable Panty Vending Unit | Allows buyers to select styles and sizes | Online retail, personalized services | Enhances customer engagement; complex inventory management |

Traditional Used Panty Machine

Traditional used panty machines are designed to dispense second-hand underwear, often sourced from local sellers. These machines cater to niche markets, primarily adult novelty shops and specialty stores that target specific consumer interests. Buyers should consider the legal implications of sourcing used garments and the need for compliance with local regulations. While these machines can generate significant revenue, they may also attract scrutiny regarding the origin of the products.

Automated Panty Vending System

The automated panty vending system incorporates advanced technology, such as RFID, to manage inventory and enhance user experience. These units are suitable for retail environments and vending franchises, providing a hands-free operation that reduces labor costs. However, they require ongoing maintenance and technical support, which can increase operational costs. Buyers should evaluate the initial investment against potential long-term savings and customer engagement benefits.

Luxury Panty Vending Machine

Luxury panty vending machines focus on high-end or designer brands, appealing to a more affluent customer base. These machines are commonly found in upscale boutiques and luxury malls, making them suitable for businesses aiming to enhance their brand image. While they can attract high-spending customers, the initial investment is typically higher due to the quality of products offered. Buyers should assess market demand in their target area to justify the investment.

Themed Panty Vending Machine

Themed panty vending machines offer unique designs and styles, often inspired by popular culture, such as anime or cosplay. These machines are ideal for event merchandising or pop culture stores, catering to specific fan bases. While they can generate excitement and attract foot traffic, demand may fluctuate seasonally based on trends. Buyers should consider the potential for limited-time offers to capitalize on current interests.

Customizable Panty Vending Unit

Customizable panty vending units allow consumers to select styles and sizes, enhancing the shopping experience. These units are particularly appealing for online retail and personalized services, enabling businesses to engage customers effectively. However, they require complex inventory management to ensure a diverse offering. Buyers should weigh the benefits of customization against the logistical challenges of maintaining adequate stock levels.

Related Video: 30 Vending Machines in Tokyo

Key Industrial Applications of japan pantie vending machine

| Industry/Sector | Specific Application of japan pantie vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Adult Entertainment | Novelty product sales | Unique offering that attracts niche market | Compliance with local regulations, cultural sensitivity |

| Retail | Specialty vending machines | Diversifies product range, increases foot traffic | Machine durability, payment system integration |

| Tourism | Cultural experience attraction | Enhances tourist experiences, boosts local economy | Location selection, marketing strategies |

| Fashion & Apparel | Limited edition merchandise | Appeals to collectors and fashion enthusiasts | Authenticity verification, sourcing of trendy designs |

| Event Management | Thematic event installations | Creates unique experiences for attendees | Customization options, logistics for machine placement |

Industry Applications Explained

Adult Entertainment

In the adult entertainment sector, the japan pantie vending machine serves as a novelty product that caters to a niche market. Businesses can capitalize on the unique aspect of these machines to attract customers looking for unconventional experiences. For international buyers, understanding local regulations and cultural sensitivities is crucial to ensure compliance and acceptance within the target market.

Illustrative Image (Source: Google Search)

Retail

Retail environments can benefit from incorporating specialty vending machines that offer used panties as a unique product. This diversification can increase foot traffic and encourage impulse purchases. For B2B buyers, sourcing considerations include ensuring the machines are durable and equipped with modern payment systems to handle various transaction types, especially in markets where cashless payments are preferred.

Tourism

Tourism industries can utilize japan pantie vending machines as part of cultural experience attractions. By providing tourists with a quirky, memorable experience, businesses can enhance their offerings and promote local culture, potentially boosting the local economy. Buyers must focus on strategic location selection for the machines and develop effective marketing strategies to attract attention from tourists.

Fashion & Apparel

In the fashion and apparel sector, japan pantie vending machines can be used to sell limited edition merchandise, appealing to collectors and fashion enthusiasts. This application can create a buzz around exclusive items that are not readily available in traditional retail settings. Buyers should prioritize authenticity verification and seek partnerships with designers to ensure trendy and appealing product offerings.

Event Management

Event management companies can incorporate japan pantie vending machines into thematic installations at parties, festivals, or conventions. This unique offering can create unforgettable experiences for attendees, setting the event apart from others. Key sourcing considerations include customization options for the machines to align with the event theme and logistics planning for the placement and servicing of the machines during the event.

Related Video: Japan’s Biggest Retro Vending Machine Wonderland – Over 100 Machines 🍔 🍭 🍜 🥤

Strategic Material Selection Guide for japan pantie vending machine

When selecting materials for Japan’s pantie vending machines, it’s essential to consider the unique operational environment and consumer expectations. The materials used must not only withstand the rigors of vending operations but also comply with cultural and regulatory standards. Below is an analysis of several common materials suitable for this application, highlighting their properties, advantages, disadvantages, and considerations for international buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance and high strength. It can withstand a wide range of temperatures and pressures, making it suitable for various environments.

Pros & Cons:

– Pros: Highly durable, resistant to rust and staining, easy to clean, and maintains aesthetic appeal over time.

– Cons: Higher initial cost compared to other materials, and can be more challenging to machine.

Impact on Application:

Stainless steel is ideal for the external casing of vending machines, as it protects against moisture and environmental factors. Its smooth surface also deters dirt accumulation, which is crucial for hygiene standards.

Considerations for International Buyers:

Buyers should ensure compliance with local health and safety regulations. Standards like ASTM A240 for stainless steel may be relevant, particularly in regions like Europe and North America.

2. High-Density Polyethylene (HDPE)

Key Properties:

HDPE is a lightweight, impact-resistant plastic with good chemical resistance. It performs well in various temperatures, though it may not be suitable for extreme heat.

Pros & Cons:

– Pros: Cost-effective, easy to manufacture, and offers good insulation properties.

– Cons: Less durable than metals, can become brittle over time, and may not provide the same level of security against tampering.

Impact on Application:

HDPE can be used for internal components such as product dispensers or trays. Its resistance to moisture makes it suitable for environments where humidity is a concern.

Considerations for International Buyers:

Buyers should check for compliance with local plastics regulations and standards, such as those set by the European Union for food safety.

3. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It is also easy to machine and form into various shapes.

Pros & Cons:

– Pros: Lower weight reduces shipping costs, good strength-to-weight ratio, and aesthetically pleasing finish.

– Cons: More expensive than some plastics, and may require surface treatments to enhance corrosion resistance.

Impact on Application:

Aluminum is often used in the structural components of vending machines, providing a balance between weight and durability.

Considerations for International Buyers:

Aluminum should meet standards such as ASTM B221 for extruded aluminum products. Buyers in Europe may also need to consider REACH compliance for materials used in consumer products.

4. Powder Coating

Key Properties:

Powder coating is a finishing process that provides a protective layer over metal surfaces. It enhances corrosion resistance and can be applied in various colors.

Pros & Cons:

– Pros: Provides a durable finish that resists scratches and fading, offers aesthetic versatility.

– Cons: Requires a specific application process and may be more costly than traditional paint.

Impact on Application:

Powder coating is suitable for the exterior of vending machines, enhancing both durability and appearance. It can also help in branding by allowing custom colors and designs.

Considerations for International Buyers:

Buyers should ensure that the powder coating meets local environmental regulations regarding VOC emissions, especially in regions like Europe and North America.

Summary Table

| Material | Typical Use Case for japan pantie vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | External casing and structural components | Highly durable and corrosion-resistant | Higher initial cost, machining complexity | High |

| High-Density Polyethylene (HDPE) | Internal dispensers and trays | Cost-effective and lightweight | Less durable, potential brittleness | Low |

| Aluminum | Structural components and aesthetic features | Lightweight with good strength-to-weight ratio | More expensive than plastics, requires treatments | Medium |

| Powder Coating | Exterior finish for aesthetic appeal | Durable finish with color versatility | Requires specific application process | Medium |

This strategic material selection guide provides international B2B buyers with insights into the materials best suited for Japan’s pantie vending machines, ensuring that they can make informed purchasing decisions tailored to their regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for japan pantie vending machine

Japan’s pantie vending machines represent a unique intersection of manufacturing innovation and cultural specificity. For international B2B buyers looking to enter this niche market, understanding the manufacturing processes and quality assurance measures is crucial. Here, we delve into the typical stages of manufacturing and the quality control (QC) protocols that ensure the machines meet international standards.

Manufacturing Process

The manufacturing of pantie vending machines involves several critical stages, each requiring meticulous attention to detail to ensure functionality and compliance with safety standards.

1. Material Preparation

The initial stage focuses on sourcing high-quality materials, which typically include:

- Metal Framework: Often steel or aluminum for durability.

- Plastic Components: Used for panels and vending mechanisms, these must be robust yet lightweight.

- Electronic Parts: Including payment systems, sensors, and vending mechanisms.

Suppliers should be vetted for material quality, ensuring they use materials that comply with international standards.

2. Forming

Once the materials are ready, the forming stage begins. This involves several key techniques:

- Metal Stamping: Used to create the machine’s outer casing and internal components. Precision is crucial to ensure parts fit together seamlessly.

- Injection Molding: Employed for plastic parts, allowing for complex shapes that are lightweight and strong.

Both techniques should adhere to ISO 9001 standards, which ensure consistent quality in production processes.

3. Assembly

The assembly stage is where all components come together. Key aspects include:

- Integration of Electronic Systems: Ensuring that the payment systems and vending mechanisms function correctly.

- Quality Checks: Conducting initial quality control checks during assembly to catch any defects early. This can include visual inspections and basic functional tests.

Assembly lines should be designed for efficiency, allowing for quick yet thorough assembly while maintaining high standards.

4. Finishing

The finishing stage includes painting, labeling, and packaging the machines. This is also where final quality checks occur:

- Surface Treatment: Ensures the machine is resistant to wear and corrosion, particularly important for outdoor units.

- Labeling: Must meet local regulations, ensuring that all necessary safety and operational information is clear.

Quality Assurance

Quality assurance is paramount in manufacturing vending machines, especially those that deal with sensitive products like used panties.

International Standards

For B2B buyers, understanding the relevant international standards is critical. The following are particularly important:

- ISO 9001: Focuses on quality management systems and ensuring consistent service and product quality.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: Relevant for certain mechanical and electronic components to ensure safety and reliability.

QC Checkpoints

The QC process typically includes several checkpoints:

- Incoming Quality Control (IQC): Inspecting materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product, ensuring it meets all operational and safety standards.

Common Testing Methods

Testing methods employed to verify machine functionality and safety include:

- Functional Testing: Verifying that all electronic systems work as intended.

- Stress Testing: Ensuring that the machine can handle various environmental conditions and usage levels.

- Safety Compliance Testing: Confirming that the machine meets all necessary safety standards and regulations.

Verifying Supplier QC

For international B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is essential. Here are some strategies:

- Supplier Audits: Conduct regular audits to assess the manufacturing facility’s adherence to quality standards. This can include reviewing their processes, materials used, and compliance with international standards.

- Quality Reports: Request detailed QC reports that outline the findings from IQC, IPQC, and FQC. This documentation should provide insights into any issues found and how they were addressed.

- Third-Party Inspections: Engage third-party inspection services to conduct independent checks on the manufacturing process and final products. This adds an extra layer of assurance regarding product quality.

QC and Certification Nuances for International Buyers

When sourcing pantie vending machines, international buyers must navigate various QC and certification nuances. Here are key considerations:

- Cultural Sensitivity: Understand the cultural context of the product. In regions where such machines may not be widely accepted, ensure that the design and marketing strategies are culturally appropriate.

- Regulatory Compliance: Different countries have varying regulations regarding the sale of used clothing. Buyers must ensure that the vending machines comply with local laws to avoid legal complications.

- Certification Verification: Ensure that any certifications claimed by suppliers are verifiable. Request copies of certificates and check their validity through appropriate regulatory bodies.

In conclusion, for B2B buyers interested in Japan’s pantie vending machines, a thorough understanding of manufacturing processes and quality assurance practices is critical. By focusing on the outlined steps and ensuring compliance with international standards, buyers can navigate the complexities of this unique market effectively.

Related Video: Honda factory tour – Production in Japan plant

Comprehensive Cost and Pricing Analysis for japan pantie vending machine Sourcing

When sourcing Japanese pantie vending machines, understanding the comprehensive cost and pricing structure is essential for international B2B buyers. Several cost components contribute to the overall pricing, and various factors can influence these costs. This analysis aims to provide actionable insights for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary materials involved in the manufacturing of pantie vending machines include steel, plastic, and electronic components. The quality of these materials significantly influences the final price. High-grade materials may incur higher upfront costs but can lead to better durability and lower maintenance expenses over time.

-

Labor: Labor costs vary considerably by region. In Japan, skilled labor can be more expensive than in other manufacturing countries. However, the expertise ensures high-quality production. For buyers from regions with lower labor costs, this aspect may offer negotiation leverage when discussing overall pricing.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and other indirect expenses. Manufacturers in Japan often have higher overhead costs due to stringent regulations and quality assurance processes. Understanding these costs can help buyers gauge the pricing structure.

-

Tooling: The tooling costs involve the equipment and molds needed to produce the vending machines. Custom tooling can significantly increase initial costs but is necessary for unique designs or specifications.

-

Quality Control (QC): A robust QC process is critical in the production of vending machines. While this may add to the cost, it ensures that the machines meet safety and performance standards, which is particularly important for international buyers concerned about compliance.

-

Logistics: Shipping costs can vary widely based on the shipping method, distance, and Incoterms. For buyers in Africa or South America, air freight may be significantly more expensive than sea freight, affecting the total landed cost.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on competition, demand, and the supplier’s positioning in the market.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact pricing. Larger orders often qualify for bulk discounts, making it essential for buyers to assess their needs carefully.

-

Specifications/Customization: Customized machines tailored to specific needs may incur higher costs. Buyers should weigh the benefits of custom features against the additional expenses involved.

-

Materials and Quality/Certifications: The choice of materials and the level of certification (e.g., ISO) can influence costs. Higher-quality certifications often come with a price premium but can enhance trust and marketability.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Different Incoterms can shift responsibilities and costs between buyers and suppliers, impacting the overall pricing strategy. Understanding these terms is crucial for budgeting and negotiation.

Buyer Tips

-

Negotiation: Engage suppliers in discussions about pricing, particularly if placing large orders or exploring long-term partnerships. Use your understanding of cost components to negotiate effectively.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. A cheaper upfront cost may lead to higher long-term expenses if quality is compromised.

-

Pricing Nuances: Be aware of regional pricing differences, especially when sourcing from a country like Japan. Currency fluctuations and trade tariffs may also influence final costs, so consider these factors when budgeting.

Disclaimer

The prices associated with Japanese pantie vending machines can vary widely based on the factors outlined above. This analysis provides indicative insights; however, actual costs may differ based on specific supplier negotiations and market conditions. Buyers are encouraged to conduct thorough research and obtain quotes from multiple suppliers to ensure competitive pricing.

Spotlight on Potential japan pantie vending machine Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for japan pantie vending machine.)*

Essential Technical Properties and Trade Terminology for japan pantie vending machine

Key Technical Properties of Japan Pantie Vending Machines

Understanding the essential technical properties of Japan’s pantie vending machines is crucial for international B2B buyers. Here are some of the critical specifications that influence operational efficiency, product quality, and market acceptance:

-

Material Grade

The machines are typically constructed from high-grade stainless steel or durable plastic. Stainless steel offers corrosion resistance and strength, essential for longevity in various environments. The material choice is vital for maintaining hygiene standards, especially given the nature of the product being sold. -

Capacity

The capacity of a vending machine—measured in the number of items it can store—is a significant aspect. Machines can typically hold between 20 to 50 pairs of panties, depending on their design. Higher capacity can lead to increased sales potential, making it a key consideration for businesses looking to maximize revenue. -

Payment Systems

Modern vending machines incorporate various payment options, including cash, credit/debit cards, and mobile payments. Flexibility in payment methods is essential for attracting a broader customer base and enhancing user experience, especially in regions where cash transactions may be declining. -

Temperature Control

Some machines may include temperature control features to ensure the maintenance of hygienic standards. This is particularly important for products that require specific storage conditions. Buyers should assess whether temperature control is a feature, as it can impact both product quality and customer satisfaction. -

User Interface

A user-friendly interface, often with touch screens or simple button layouts, is critical for ensuring that customers can navigate the machine with ease. This includes clear product descriptions and images, which can enhance consumer confidence and transaction speed. -

Security Features

Given the unique nature of the products being sold, security features such as locking mechanisms and surveillance cameras are vital. These not only protect the inventory but also provide reassurance to buyers regarding the legitimacy and safety of the purchase experience.

Common Trade Terminology in the Vending Machine Industry

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some common terms relevant to the vending machine sector, particularly concerning pantie vending machines:

-

OEM (Original Equipment Manufacturer)

This refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of pantie vending machines, an OEM might supply the machine components, ensuring quality and compatibility with the final product. -

MOQ (Minimum Order Quantity)

This term indicates the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it affects inventory management and cost efficiency. Buyers should negotiate MOQs based on their market demand and financial capabilities. -

RFQ (Request for Quotation)

An RFQ is a procurement document used to invite suppliers to bid on specific products or services. For buyers looking to procure vending machines, issuing an RFQ can help gather competitive pricing and terms from multiple suppliers. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial for understanding shipping costs and risk management.

-

Lead Time

This is the time taken from placing an order until it is delivered. For pantie vending machines, lead time can vary significantly based on manufacturing processes and shipping logistics. Buyers should account for lead time to ensure timely market entry. -

Warranty Period

This term pertains to the duration during which the manufacturer is responsible for repairing or replacing faulty products. Understanding warranty conditions is essential for buyers to mitigate risk and ensure long-term operational reliability.

By grasping these technical properties and trade terminologies, international B2B buyers can make well-informed decisions when engaging with suppliers of Japan’s unique pantie vending machines.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the japan pantie vending machine Sector

Market Overview & Key Trends

The Japanese pantie vending machine sector operates within a unique cultural and economic landscape, driven by factors such as consumer anonymity, niche markets, and technological innovation. Global drivers for this market include the rise of adult entertainment and fetish communities, particularly in urban areas where privacy is paramount. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe explore this sector, they must consider the evolving demographics and purchasing behaviors of consumers, which increasingly favor unique and personalized experiences.

Current and emerging trends in technology are shaping the landscape of vending machines. Innovations such as cashless payment systems, smart vending solutions, and enhanced user interfaces are becoming standard. These advancements not only streamline the purchasing process but also improve inventory management for operators. Sourcing trends are also shifting towards more sophisticated, automated machines that can cater to diverse consumer needs. International buyers should focus on suppliers who offer integrated technology solutions that enhance user experience while maintaining operational efficiency.

Market dynamics indicate a growing interest in the novelty and exclusivity of products offered through these machines. As cultural perceptions evolve, especially among younger consumers, there is an opportunity for B2B buyers to tap into this niche market by sourcing machines that can accommodate a range of products beyond traditional offerings. Understanding local regulations and cultural sensitivities is essential, especially for buyers from regions like Colombia and Poland, where the acceptance of such products may vary.

Sustainability & Ethical Sourcing in B2B

As sustainability becomes a critical concern globally, the pantie vending machine sector must adapt to ethical sourcing practices. The environmental impact of production and disposal of textiles is significant; therefore, sourcing suppliers that prioritize sustainable practices is crucial. This includes using organic or recycled materials for the products sold in vending machines and ensuring that manufacturing processes minimize waste and energy consumption.

Importance of ethical supply chains cannot be overstated. B2B buyers should ensure that their suppliers adhere to fair labor practices and environmental regulations. This includes conducting audits and requiring transparency in sourcing materials. Certifications such as GOTS (Global Organic Textile Standard) and OEKO-TEX can help verify the sustainability of materials used in production. By prioritizing ethical sourcing, buyers not only contribute to environmental conservation but also enhance their brand image, appealing to a growing segment of environmentally-conscious consumers.

Investing in ‘green’ materials for products offered through vending machines, such as biodegradable packaging and ethically produced textiles, can differentiate offerings in the market. This approach aligns with global trends towards sustainability and can create a competitive edge for international B2B buyers looking to enter or expand in the Japanese market.

Brief Evolution/History

The concept of pantie vending machines in Japan emerged in the early 1990s, rooted in cultural phenomena like buru-sera, which fetishizes schoolgirl uniforms and underwear. Initially, enterprising individuals began selling their used underwear, leading to the installation of vending machines that offered anonymous purchasing options. Despite facing legal challenges and societal backlash, the machines became emblematic of Japan’s complex relationship with sexuality and consumerism.

Over the years, regulatory frameworks evolved to address the sale of used clothing, particularly concerning the age of sellers. The machines have since become less common in public spaces, but they still hold a niche appeal, reflecting broader trends in adult entertainment and consumer behavior. For B2B buyers, understanding this historical context can provide valuable insights into market dynamics and consumer preferences.

Related Video: EU Ready for U.S. Trade Deal, Warns of Fallout If Ukraine Aid Falters | N18G

Frequently Asked Questions (FAQs) for B2B Buyers of japan pantie vending machine

-

What should I consider when vetting suppliers for Japanese pantie vending machines?

When vetting suppliers, focus on their experience and reputation in the industry. Look for companies that have a history of exporting vending machines, particularly specialized ones like pantie vending machines. Request references from previous international clients to gauge reliability. Additionally, verify their compliance with local regulations concerning the sale of used items, as standards may vary significantly across regions, particularly in Africa, South America, the Middle East, and Europe. -

Can I customize the vending machines to fit my market needs?

Yes, customization is often an option with reputable suppliers. Discuss your specific market requirements, such as machine size, design, and branding. Some suppliers may offer add-ons like payment system integration or advertising space. Ensure to clarify any additional costs associated with customization and request samples or mock-ups before finalizing your order to ensure the design meets your expectations. -

What are the typical minimum order quantities (MOQ) and lead times for these machines?

MOQs can vary significantly between suppliers, but they often range from 10 to 50 units for specialized machines. Lead times typically depend on the level of customization and can range from 4 to 12 weeks. Always confirm these details upfront and consider negotiating for lower MOQs if you are a first-time buyer to assess the market response without a large upfront investment. -

What payment terms should I expect when purchasing these machines?

Payment terms can vary by supplier but typically include a deposit (often 30-50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer financing options or letter of credit arrangements for larger orders. It’s crucial to establish clear payment terms and methods (e.g., bank transfer, PayPal) to ensure security and transparency in the transaction. -

How can I ensure quality assurance and certification of the machines?

Request certifications that verify compliance with international safety and quality standards, such as ISO 9001 or other relevant local regulations. A good supplier will provide documentation to prove the quality of their products. Additionally, consider conducting a factory audit or hiring a third-party quality assurance service to inspect the machines before shipment to ensure they meet your specifications. -

What logistics options should I consider for shipping these machines?

Logistics for international shipping can include sea freight, air freight, or courier services, depending on your budget and urgency. Discuss with your supplier about their preferred logistics partners and whether they offer assistance with customs clearance. Factor in additional costs such as duties, taxes, and insurance, and ensure that the machines are adequately packaged for transport to prevent damage. -

What should I do in case of disputes with the supplier?

In the event of a dispute, communication is key. Start by discussing the issue directly with the supplier to reach an amicable solution. If necessary, refer to your contract for terms regarding dispute resolution, which may include mediation or arbitration. Additionally, consider leveraging platforms like Alibaba or Trade Assurance if applicable, as they often provide buyer protection policies for transactions.

Illustrative Image (Source: Google Search)

- Are there any cultural considerations I should be aware of when doing business with Japanese suppliers?

Understanding Japanese business culture is essential for successful negotiations. Emphasize respect and formality in your communications, and be prepared for a slower decision-making process as building trust is crucial. It’s advisable to engage in face-to-face meetings (when possible) or video calls to strengthen relationships. Additionally, being punctual and polite during interactions will be well-received and can facilitate smoother business dealings.

Strategic Sourcing Conclusion and Outlook for japan pantie vending machine

As the market for unique and niche products evolves, the strategic sourcing of Japan’s pantie vending machines presents an intriguing opportunity for international B2B buyers. Understanding the cultural context and the historical background of these machines is essential for effectively navigating this niche market. Key takeaways for buyers include the importance of establishing reliable supplier relationships and ensuring compliance with local regulations, particularly regarding the sale of used items.

Strategic sourcing not only allows buyers to tap into a distinctive product line but also facilitates access to a broader market segment that values novelty and cultural authenticity. Buyers from Africa, South America, the Middle East, and Europe can leverage the growing interest in Japanese pop culture and unique retail experiences to establish a competitive edge in their local markets.

Looking ahead, the potential for expanding into this sector is promising. By fostering partnerships with Japanese suppliers and understanding regional consumer preferences, international buyers can capitalize on the allure of these vending machines. Now is the time to explore this unique opportunity—consider investing in market research, attending trade shows, and initiating discussions with Japanese manufacturers to better position your business for success in this unconventional market.