Your Ultimate Guide to Sourcing Ice Vending Machine Nearby

Guide to Ice Vending Machine Nearby

- Introduction: Navigating the Global Market for ice vending machine nearby

- Understanding ice vending machine nearby Types and Variations

- Key Industrial Applications of ice vending machine nearby

- Strategic Material Selection Guide for ice vending machine nearby

- In-depth Look: Manufacturing Processes and Quality Assurance for ice vending machine nearby

- Comprehensive Cost and Pricing Analysis for ice vending machine nearby Sourcing

- Spotlight on Potential ice vending machine nearby Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for ice vending machine nearby

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ice vending machine nearby Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of ice vending machine nearby

- Strategic Sourcing Conclusion and Outlook for ice vending machine nearby

Introduction: Navigating the Global Market for ice vending machine nearby

In today’s fast-paced global economy, the demand for efficient and accessible ice vending machines is on the rise, particularly in regions like Africa, South America, the Middle East, and Europe. These machines not only serve the essential purpose of providing ice but also represent a lucrative business opportunity for international B2B buyers seeking to enhance their service offerings. The convenience of having an ice vending machine nearby can attract a diverse clientele, from restaurants and catering services to retail outlets and event organizers.

This comprehensive guide delves into the multifaceted world of ice vending machines, covering critical aspects such as various types of machines, materials used in their construction, manufacturing processes, and quality control measures. Additionally, it highlights key suppliers and provides insights into cost considerations and market trends. By equipping B2B buyers with the knowledge to make informed sourcing decisions, this guide aims to simplify the procurement process and reduce the risks associated with purchasing.

Understanding the nuances of ice vending machines empowers buyers to select the right equipment that aligns with their operational needs and market demands. Whether you’re based in Argentina or France, this guide serves as your go-to resource for navigating the global market of ice vending machines, ensuring you can capitalize on this essential service with confidence and expertise.

Understanding ice vending machine nearby Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Self-Service Ice Machines | User-operated machines dispensing ice directly to customers | Convenience stores, gas stations, events | Pros: Low maintenance, high customer engagement; Cons: Initial investment can be high. |

| Ice Vending Kiosks | Compact, automated units with payment systems | Urban areas, festivals, outdoor markets | Pros: Space-efficient, cashless transactions; Cons: Limited ice variety, potential technical issues. |

| Bulk Ice Delivery Machines | Large capacity machines for wholesale ice distribution | Restaurants, catering services | Pros: Cost-effective for bulk purchases; Cons: Requires more space and infrastructure. |

| Mobile Ice Vending Units | Portable units for temporary locations | Events, fairs, and outdoor gatherings | Pros: Flexible location options, quick setup; Cons: Limited operational hours, potential regulatory hurdles. |

| Ice Production and Vending | Machines that produce and dispense ice on-site | Supermarkets, hotels, and resorts | Pros: Fresh ice production, reduced supply chain costs; Cons: Higher operational complexity. |

Self-Service Ice Machines

Self-service ice machines are designed for user operation, allowing customers to dispense ice directly. These machines are commonly found in convenience stores and gas stations, providing a quick and easy solution for customers looking for ice. B2B buyers should consider the machine’s maintenance requirements and the potential for customer engagement, as these units can enhance the shopping experience. However, the initial investment might be significant, which could be a barrier for smaller businesses.

Ice Vending Kiosks

Ice vending kiosks are compact, automated units equipped with payment systems, making them ideal for urban settings and events. They offer a cashless transaction process, appealing to tech-savvy consumers. B2B buyers should evaluate the kiosk’s space requirements and the types of ice available, as some may offer limited options. While they require less physical space than traditional ice machines, technical issues may arise that necessitate prompt attention.

Bulk Ice Delivery Machines

These machines are designed for bulk ice distribution, catering primarily to businesses like restaurants and catering services. They typically have a larger capacity, allowing for cost-effective purchases. Buyers should assess the necessary space and infrastructure to accommodate these machines, as they may require more extensive installation than smaller units. While they offer significant savings on bulk purchases, their larger footprint can be a downside for locations with limited space.

Mobile Ice Vending Units

Mobile ice vending units provide flexibility for temporary locations, such as events and fairs. They can be quickly set up and relocated as needed, making them perfect for seasonal or special occasions. B2B buyers should consider the operational hours and local regulations governing mobile vending, as these can affect profitability. While they offer great adaptability, their limited hours of operation may impact sales.

Ice Production and Vending Machines

These machines not only dispense ice but also produce it on-site, making them suitable for supermarkets, hotels, and resorts. They offer the advantage of providing fresh ice and reducing supply chain costs associated with buying pre-packaged ice. However, the complexity of operations can be higher, requiring careful consideration of maintenance and operational expertise. B2B buyers should weigh the benefits of fresh production against the potential challenges of running such machines efficiently.

Related Video: DIY SQUISHY ICE VENDING MACHINE

Key Industrial Applications of ice vending machine nearby

| Industry/Sector | Specific Application of ice vending machine nearby | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Ice supply for restaurants and bars | Ensures consistent beverage quality and customer satisfaction | Energy efficiency, capacity, and maintenance requirements |

| Events & Catering | On-site ice supply for large gatherings | Provides immediate ice availability, enhancing service speed | Mobility, ease of use, and ice production rate |

| Healthcare | Ice supply for medical facilities | Supports patient care with reliable ice availability for treatments | Compliance with health regulations, hygiene standards |

| Retail | Ice vending for convenience stores | Increases foot traffic and sales through added service | Location analysis, machine durability, and payment options |

| Agriculture | Ice for perishable goods transport | Preserves product quality during transport | Temperature control capabilities, ice production speed, energy consumption |

Food & Beverage

In the food and beverage industry, ice vending machines are crucial for restaurants and bars. They provide a consistent supply of ice, ensuring that beverages are served at optimal temperatures, which enhances customer satisfaction. For international buyers, especially in regions like Africa and South America, considerations include energy efficiency and ease of maintenance to ensure the machine operates effectively in varying climates.

Events & Catering

For the events and catering sector, ice vending machines serve as a vital resource during large gatherings, festivals, and weddings. They offer immediate access to ice, enabling caterers to serve cold beverages efficiently. Buyers from the Middle East and Europe should prioritize machines that are mobile and easy to operate, as well as those that can produce ice quickly to meet high demand during events.

Healthcare

In healthcare settings, ice vending machines are used to supply ice for various medical treatments, such as physical therapy and post-operative care. Reliable ice availability is essential for patient care, particularly in hospitals and clinics. Buyers in this sector must ensure that the machines comply with health regulations and hygiene standards, which are critical for maintaining patient safety.

Retail

Convenience stores benefit from ice vending machines by offering ice to customers, which can increase foot traffic and boost sales. The presence of an ice vending machine can attract customers seeking quick and easy access to ice for their needs. Retail buyers, especially in Europe, should consider the machine’s durability and its ability to accept various payment methods to cater to a diverse customer base.

Agriculture

In agriculture, ice vending machines play a significant role in transporting perishable goods. They help maintain the quality of products during transit by providing a reliable source of ice. Buyers from regions with extensive agricultural activities should focus on machines that offer effective temperature control, quick ice production, and low energy consumption to ensure cost-effectiveness during operations.

Related Video: Everest Ice & Water Vending Machine | BEST Vending Machine for 2022?

Strategic Material Selection Guide for ice vending machine nearby

Material Analysis for Ice Vending Machines

When selecting materials for ice vending machines, it’s crucial to consider various factors that impact performance, durability, and compliance with international standards. Below, we analyze four common materials used in the construction of ice vending machines, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Stainless Steel (e.g., 304, 316)

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. Grades like 304 are suitable for general use, while 316 offers superior resistance to chlorides, making it ideal for coastal areas.

Pros & Cons:

Stainless steel is highly durable and easy to clean, making it suitable for food applications. However, it can be more expensive than other materials and may require specialized manufacturing processes, which can increase costs.

Impact on Application:

Due to its corrosion resistance, stainless steel is ideal for environments where moisture is prevalent, such as ice production and storage. It is compatible with various cleaning agents, ensuring hygiene.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with food safety standards such as EN 10088 for stainless steel. Additionally, understanding the specific grade requirements based on local environmental conditions is essential.

2. Carbon Steel

Key Properties:

Carbon steel is known for its strength and toughness. It can withstand high pressures and is generally cost-effective.

Pros & Cons:

While carbon steel is durable and less expensive than stainless steel, it is prone to corrosion if not properly coated or maintained. This can lead to increased maintenance costs over time.

Impact on Application:

Carbon steel can be used in non-corrosive environments or where protective coatings are applied. However, its use in direct contact with ice or water is limited due to corrosion concerns.

Considerations for International Buyers:

Buyers must consider local regulations regarding the use of carbon steel in food applications. Standards such as ASTM A36 may apply, and buyers should be aware of the need for protective coatings in humid climates, especially in Africa and South America.

3. Polyethylene (PE)

Key Properties:

Polyethylene is a lightweight, flexible plastic with good chemical resistance and low moisture absorption. It can operate at temperatures ranging from -40°C to 60°C.

Pros & Cons:

PE is cost-effective and easy to mold into various shapes, making it suitable for parts like ice bins. However, it may not be as durable as metals and can degrade under UV exposure.

Impact on Application:

Polyethylene is suitable for components that require flexibility and resistance to moisture. It is often used in ice storage areas where corrosion is a concern.

Considerations for International Buyers:

International buyers should ensure that the polyethylene used meets food-grade standards, such as FDA regulations in the U.S. or EU regulations in Europe. Additionally, understanding local recycling regulations for plastics is vital.

4. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can be anodized for enhanced durability.

Pros & Cons:

Aluminum is easy to work with and offers a good strength-to-weight ratio. However, it can be more expensive than carbon steel and may not be as strong as stainless steel in high-stress applications.

Impact on Application:

Aluminum is suitable for components exposed to moisture and can be used in various parts of ice vending machines, including structural frames and panels.

Considerations for International Buyers:

Buyers should consider compliance with standards such as ASTM B221 for aluminum extrusions. Understanding the local market for aluminum products is crucial, especially in regions with high import tariffs.

Summary Table

| Material | Typical Use Case for ice vending machine nearby | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel (e.g., 304, 316) | Structural components, ice storage bins | Excellent corrosion resistance, hygienic | Higher cost, requires specialized manufacturing | High |

| Carbon Steel | Non-corrosive parts, structural frames | Cost-effective, strong | Prone to corrosion, requires maintenance | Low |

| Polyethylene (PE) | Ice storage bins, liners | Lightweight, flexible, cost-effective | Less durable, UV degradation | Low |

| Aluminum | Structural frames, panels | Lightweight, corrosion-resistant | More expensive than carbon steel, lower strength than stainless | Medium |

This strategic material selection guide provides international B2B buyers with essential insights into the materials used in ice vending machines, helping them make informed purchasing decisions based on performance, cost, and compliance with local regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for ice vending machine nearby

Manufacturing Processes for Ice Vending Machines

Manufacturing ice vending machines involves several critical stages, each requiring specific techniques and quality control measures to ensure a reliable final product. Below is an in-depth overview of the manufacturing processes and the quality assurance protocols that international B2B buyers should consider.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Materials: The primary materials used in ice vending machines typically include stainless steel for durability, high-density polyethylene (HDPE) for the body, and copper for the refrigeration components. Selecting corrosion-resistant materials is crucial, especially for machines operating in humid environments.

– Pre-Processing: Materials undergo cutting, bending, and surface treatment to prepare them for assembly. Stainless steel sheets, for example, are cut to size and polished to prevent rust. -

Forming

– Fabrication Techniques: The forming process may involve stamping, welding, and machining to create the machine’s structural components. Advanced techniques like laser cutting and CNC machining ensure precision and reduce waste.

– Insulation and Refrigeration Setup: Insulation materials are added during this stage to enhance energy efficiency. The refrigeration system, often a hermetic compressor, is installed to ensure optimal ice production. -

Assembly

– Component Integration: All fabricated parts, including the ice production unit, dispensing mechanism, control panel, and payment system, are assembled. This stage is critical for ensuring that all components function seamlessly together.

– Testing During Assembly: Initial functionality tests are conducted to verify that components are correctly installed and operational before proceeding to the finishing stage. -

Finishing

– Surface Treatment: After assembly, machines undergo finishing processes such as painting, powder coating, or applying a protective coating to enhance aesthetics and durability.

– Final Assembly Checks: A thorough inspection is conducted to ensure that all features (e.g., coin acceptors, ice dispensers) are functioning properly before the machine is packaged for shipping.

Quality Assurance Protocols

Quality assurance is essential in the manufacturing of ice vending machines to ensure reliability and compliance with international standards. Below are key aspects of quality assurance that B2B buyers should be aware of:

Relevant International Standards

- ISO 9001: This standard outlines the requirements for a quality management system (QMS). Manufacturers should be certified to ISO 9001 to ensure consistent quality and customer satisfaction.

- CE Marking: In Europe, CE marking signifies that products meet safety and environmental standards. Ice vending machines sold in European markets must have this certification.

- API Standards: For refrigeration components, adherence to American Petroleum Institute (API) standards ensures safety and efficiency in the machinery.

Quality Control Checkpoints

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted at various stages to identify defects early. This includes monitoring critical processes like welding and assembly.

- Final Quality Control (FQC): After assembly and finishing, machines undergo a comprehensive testing process to confirm they meet performance specifications, including ice production rates and dispensing accuracy.

Common Testing Methods

- Functional Testing: Each machine is tested for operational efficiency, including ice production and dispensing mechanisms.

- Safety Testing: Electrical safety tests are performed to ensure compliance with relevant electrical standards.

- Durability Testing: Machines are subjected to stress tests to simulate long-term usage and identify potential weaknesses.

Verifying Supplier Quality Control

For international B2B buyers, ensuring the quality of suppliers is crucial. Here are actionable insights on how to verify supplier QC:

-

Supplier Audits:

– Conduct on-site audits to assess manufacturing capabilities and quality control processes. This includes reviewing documentation related to certifications and previous audits.

– Evaluate the production environment and ensure compliance with health and safety regulations. -

Quality Reports:

– Request detailed quality reports from suppliers that outline their QC processes, testing results, and any corrective actions taken for defects.

– Review historical data on product quality, including defect rates and customer complaints. -

Third-Party Inspections:

– Engage independent third-party inspection services to evaluate manufacturing processes and conduct product tests. This adds an extra layer of verification and assurance.

– Utilize these services to conduct random inspections throughout the production cycle to ensure ongoing compliance with quality standards.

QC and Certification Nuances for International Buyers

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification:

- Regional Standards: Understand the specific regulatory requirements in your region. For example, in the Middle East, local certifications may be required alongside international standards.

- Cultural Considerations: Be aware of cultural differences that may affect supplier communications and negotiations. Building relationships based on trust can enhance cooperation on quality issues.

- Supply Chain Transparency: Ensure that suppliers are transparent about their sourcing and manufacturing processes. This is particularly important for buyers concerned about sustainability and ethical sourcing.

By understanding the manufacturing processes and quality assurance protocols for ice vending machines, B2B buyers can make informed decisions and foster successful partnerships with manufacturers that prioritize quality and compliance.

Related Video: INSIDE THE FACTORY HÄAGEN DAZS ICE CREAM MAKING MACHINES

Comprehensive Cost and Pricing Analysis for ice vending machine nearby Sourcing

In the international market for ice vending machines, understanding the comprehensive cost structure and pricing dynamics is crucial for buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe. This analysis covers the cost components, pricing influencers, and practical tips for buyers to make informed purchasing decisions.

Cost Components

-

Materials: The primary materials include stainless steel for durability, refrigeration components, and electronic controls. Prices can vary significantly based on quality and sourcing location. Consider bulk purchasing to reduce costs.

-

Labor: Labor costs depend on the region of production. For instance, manufacturing in regions with lower labor costs can lead to savings. However, ensure that the quality of workmanship is not compromised.

-

Manufacturing Overhead: This includes factory rent, utilities, and administrative costs. Efficient manufacturing processes can help minimize overhead, affecting overall pricing.

-

Tooling: Specialized tools for production can add to initial costs but are necessary for high-quality output. Investing in advanced tooling may enhance production efficiency and reduce long-term costs.

-

Quality Control (QC): Implementing rigorous QC processes ensures that machines meet safety and performance standards. While this adds to costs, it significantly reduces the risk of defects and warranty claims.

-

Logistics: Shipping costs can vary greatly depending on the distance from the supplier, shipping method, and freight rates. Buyers should consider the total landed cost, including customs duties and taxes.

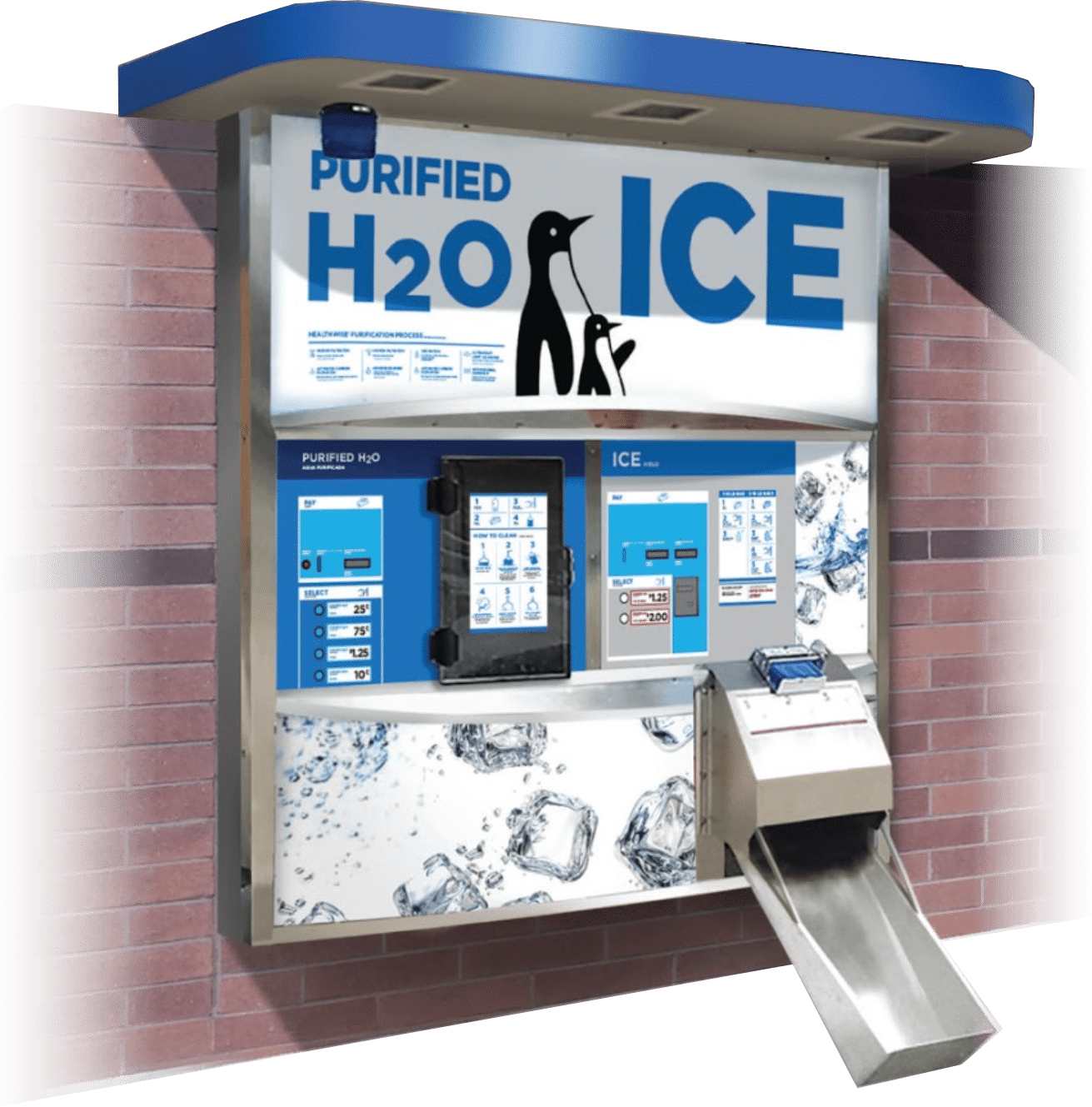

Illustrative Image (Source: Google Search)

- Margin: Suppliers typically add a profit margin ranging from 10% to 30% based on market conditions and competition. Understanding the margin expectations can aid in negotiations.

Price Influencers

-

Volume/MOQ: Bulk orders often attract discounts. Establishing a minimum order quantity (MOQ) can lead to better pricing, particularly for international buyers.

-

Specifications/Customization: Custom features can increase costs. Clearly define specifications to avoid unnecessary alterations that could inflate the price.

-

Materials: The choice of materials directly impacts the cost. High-grade materials may increase initial expenses but can lead to lower maintenance and replacement costs.

-

Quality/Certifications: Machines that meet international quality standards or certifications may command higher prices. Assess the long-term value of investing in certified equipment.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but often provide better service and warranty support.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for cost management. They dictate who is responsible for shipping, insurance, and tariffs, impacting the total cost.

Buyer Tips

-

Negotiation: Leverage multiple supplier quotes to negotiate better terms. Consider discussing payment terms, delivery schedules, and after-sales support to secure a favorable deal.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO), which includes purchase price, installation, operation, and maintenance costs. A lower upfront cost may lead to higher operational expenses.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and international tariffs that can affect pricing. Establishing contracts in stable currencies can mitigate risks.

-

Regional Insights: Buyers from Africa, South America, the Middle East, and Europe should consider regional market dynamics, such as local demand, supply chain challenges, and regulatory requirements, which can impact pricing and availability.

Disclaimer

Prices for ice vending machines are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough due diligence and market research before finalizing purchases.

Spotlight on Potential ice vending machine nearby Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘ice vending machine nearby’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ice vending machine nearby

Key Technical Properties of Ice Vending Machines

When sourcing ice vending machines, international B2B buyers should focus on several critical technical properties that ensure performance, durability, and efficiency. Here are some essential specifications to consider:

-

Cooling Capacity

This refers to the machine’s ability to produce and store ice within a specific timeframe. Measured in kilograms per hour (kg/h), a higher cooling capacity is vital for businesses with high demand, ensuring a steady supply of ice. Understanding the cooling capacity helps buyers match the machine’s output with their operational needs. -

Material Grade

The materials used in the construction of ice vending machines, typically stainless steel, are crucial for durability and hygiene. Stainless steel grades such as 304 and 316 offer resistance to corrosion and are easy to clean, making them ideal for food-related applications. Selecting the right material ensures longevity and compliance with health regulations. -

Energy Efficiency Rating

This specification indicates how much energy the machine consumes relative to its output, typically expressed in kilowatt-hours (kWh). An energy-efficient model reduces operational costs and minimizes environmental impact, aligning with corporate sustainability goals. Buyers should look for machines with high energy efficiency ratings to optimize their long-term investments. -

Water Supply Requirements

Understanding the water supply needs, including the type (potable or non-potable) and pressure requirements, is critical. Many machines specify a minimum water pressure (measured in psi) for optimal operation. Ensuring compatibility with existing water infrastructure can prevent operational disruptions. -

Ice Production Type

Ice vending machines can produce different types of ice, such as flake, nugget, or cube ice. Each type serves various applications, from drinks to food preservation. Buyers should consider the specific requirements of their business to select a machine that produces the desired ice type. -

Temperature Control Range

This property indicates the operational temperature range for the ice storage compartment, usually measured in degrees Celsius. Proper temperature control is essential to maintain ice quality and prevent melting. Ensuring the machine can operate effectively within local climate conditions is critical for optimal performance.

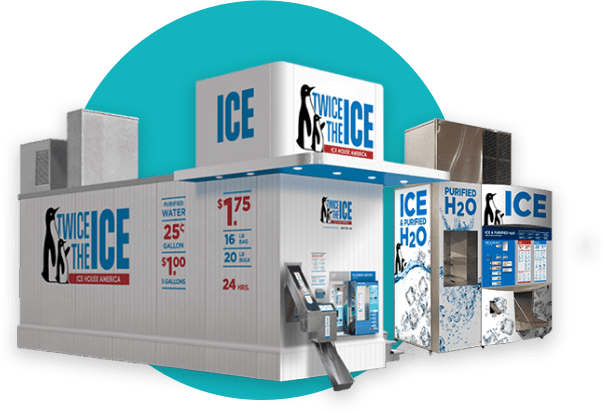

Illustrative Image (Source: Google Search)

Common Trade Terminology

Familiarity with industry jargon can streamline communication and negotiation processes. Here are several essential terms relevant to ice vending machines:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that may be marketed by another company. In the context of ice vending machines, buyers may source machines directly from OEMs to ensure quality and authenticity. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for budgeting and inventory management, especially for smaller businesses or startups that may not require large quantities. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request price quotes from suppliers for specific products or services. This process helps buyers compare prices and terms, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms is essential for understanding shipping costs, risks, and logistics. -

Lead Time

This refers to the time taken from placing an order to receiving it. In the context of ice vending machines, lead time can affect business operations and inventory levels, making it a critical factor in procurement planning. -

Warranty Period

The warranty period is the duration during which the manufacturer guarantees the performance of the machine and covers repairs or replacements. A longer warranty period indicates the manufacturer’s confidence in their product, providing peace of mind for buyers.

By understanding these technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing ice vending machines, ensuring they meet both operational needs and budgetary constraints.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ice vending machine nearby Sector

Market Overview & Key Trends

The ice vending machine sector is undergoing significant transformation driven by technological advancements and changing consumer behaviors. Global drivers include increasing demand for convenience and on-the-go consumption, particularly in urban areas across Africa, South America, the Middle East, and Europe. This trend is further accelerated by the rise of outdoor events and festivals, where portable ice solutions are essential. Additionally, as health consciousness rises, businesses are seeking efficient ways to serve cold beverages and food items, making ice vending machines an attractive option.

Current and emerging B2B tech trends include the integration of IoT (Internet of Things) technology, allowing machines to monitor inventory levels, optimize energy consumption, and enhance user experience through mobile payments. This tech-savvy approach appeals to international buyers looking for efficient and reliable solutions. Furthermore, market dynamics reflect a growing emphasis on local sourcing and suppliers, especially in regions like Africa and South America, where logistical challenges can impact supply chains. B2B buyers are increasingly prioritizing partnerships with manufacturers that can provide quick service and local support.

With the increasing popularity of eco-friendly products, businesses are also focusing on energy-efficient models that reduce electricity consumption and lower operational costs. Overall, the ice vending machine market is poised for growth, with an emphasis on technological integration, local sourcing, and sustainability as key differentiators for international B2B buyers.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical consideration in the ice vending machine sector, as environmental concerns prompt both manufacturers and buyers to rethink their sourcing strategies. The environmental impact of traditional ice production methods—often reliant on energy-intensive processes—has led to a push for more sustainable alternatives. B2B buyers are increasingly seeking machines that utilize energy-efficient technologies and eco-friendly refrigerants to minimize their carbon footprint.

Ethical supply chains are also gaining prominence, with an emphasis on transparency and fair labor practices throughout the production process. Buyers are encouraged to look for manufacturers who can provide certifications and evidence of responsible sourcing practices. Furthermore, obtaining green certifications—such as Energy Star or similar local certifications—can enhance a company’s marketability while aligning with global sustainability goals.

Incorporating green materials in the manufacturing of ice vending machines not only appeals to environmentally conscious consumers but also positions businesses as leaders in sustainability. By prioritizing eco-friendly innovations, international B2B buyers can contribute to a more sustainable future while reaping the benefits of reduced operational costs and improved brand reputation.

Brief Evolution/History

The evolution of ice vending machines can be traced back to the late 20th century, when the concept of automated retail began to gain traction. Initially designed for convenience, these machines have undergone substantial technological advancements, integrating features such as cashless payment systems and remote monitoring capabilities.

In recent years, the shift towards sustainability has prompted manufacturers to innovate further, focusing on energy efficiency and eco-friendly materials. This evolution reflects broader trends in consumer behavior and business practices, pushing the ice vending machine sector to adapt to an increasingly competitive and environmentally conscious marketplace. Today, these machines are not just a novelty but a practical solution for businesses looking to meet the demands of modern consumers while minimizing their environmental impact.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of ice vending machine nearby

-

What should I consider when vetting suppliers for ice vending machines?

When vetting suppliers, it’s essential to assess their industry experience, reputation, and customer feedback. Request references and case studies to evaluate their previous work. Additionally, verify their certifications and compliance with international quality standards, such as ISO 9001. Consider their production capacity and whether they can meet your specific requirements. Engaging in direct communication can also help gauge their responsiveness and willingness to collaborate. -

Can I customize the ice vending machines to fit my specific needs?

Most reputable suppliers offer customization options for ice vending machines, allowing you to tailor features such as size, ice type, branding, and payment systems. Discuss your specific requirements during the initial stages of negotiation. Ensure the supplier provides clear documentation on available customizations and any additional costs involved. This will help you align the machine’s capabilities with your operational needs. -

What are the typical minimum order quantities (MOQs) and lead times for ice vending machines?

Minimum order quantities vary by supplier, typically ranging from one unit for small-scale operations to larger quantities for bulk purchases. Lead times can also differ based on the complexity of customization and supplier location, usually spanning from 4 to 12 weeks. It’s crucial to discuss these details upfront to plan your procurement strategy effectively and avoid potential delays in your operations. -

What payment options are available when purchasing ice vending machines?

Payment options can include bank transfers, letters of credit, or installment plans, depending on the supplier’s policies. Ensure you clarify the terms, including any deposits required and final payment conditions. Additionally, consider using secure payment methods that protect your transaction, especially in international trade. Always obtain a formal invoice detailing the payment terms to maintain transparency. -

How can I ensure quality assurance and certifications for the machines?

To ensure quality assurance, request documentation of certifications relevant to ice vending machines, such as CE, UL, or NSF. Ask the supplier about their quality control processes, including testing protocols and standards compliance. It may be beneficial to conduct an on-site inspection or third-party audit if possible. Establishing these practices helps mitigate risks associated with product quality and safety. -

What logistics considerations should I keep in mind when importing ice vending machines?

Logistics considerations include shipping methods, customs regulations, and import duties. Determine whether the supplier offers shipping assistance or if you need to engage a freight forwarder. Ensure you are aware of the destination country’s import laws to avoid delays. Additionally, factor in transportation costs and timeframes to optimize your supply chain management effectively. -

How can I handle disputes with suppliers during the purchasing process?

To handle disputes effectively, maintain clear and open communication with the supplier. Document all agreements and correspondences to provide a reference in case of misunderstandings. If a dispute arises, attempt to resolve it amicably through negotiation. If necessary, consider mediation or arbitration as outlined in your contract. Understanding the local laws governing international trade can also provide guidance on resolving disputes. -

What are the maintenance requirements for ice vending machines?

Maintenance requirements for ice vending machines include regular cleaning, checking for ice blockages, and ensuring the refrigeration system is functioning properly. Suppliers often provide a maintenance guide or service agreement to assist in upkeep. It’s wise to establish a routine maintenance schedule to prolong the machine’s lifespan and ensure optimal performance. Additionally, inquire whether the supplier offers maintenance support or spare parts.

Strategic Sourcing Conclusion and Outlook for ice vending machine nearby

In conclusion, strategic sourcing for ice vending machines presents a significant opportunity for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. By understanding market dynamics and leveraging regional advantages, businesses can enhance their operational efficiency and customer satisfaction. Key takeaways include the importance of evaluating supplier capabilities, considering local regulations, and ensuring the sustainability of sourcing practices.

Value of Strategic Sourcing:

– Cost Efficiency: Streamlined procurement processes can lead to reduced expenses.

– Quality Assurance: Partnering with reliable suppliers ensures high-quality machines and services.

– Market Responsiveness: Local sourcing allows businesses to adapt quickly to changing consumer demands.

Looking ahead, the ice vending machine market is poised for growth as consumer preferences shift towards convenience and accessibility. Now is the time for B2B buyers to capitalize on this momentum by forging strategic partnerships and investing in innovative solutions. Engage with suppliers who understand your specific market needs and can offer tailored solutions to enhance your business operations. Let this guide serve as a stepping stone towards informed decisions that drive success in your sourcing strategy.