Your Ultimate Guide to Sourcing Ice Vending Machine

Guide to Ice Vending Machine Locations

- Introduction: Navigating the Global Market for ice vending machine locations

- Understanding ice vending machine locations Types and Variations

- Key Industrial Applications of ice vending machine locations

- Strategic Material Selection Guide for ice vending machine locations

- In-depth Look: Manufacturing Processes and Quality Assurance for ice vending machine locations

- Comprehensive Cost and Pricing Analysis for ice vending machine locations Sourcing

- Spotlight on Potential ice vending machine locations Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for ice vending machine locations

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ice vending machine locations Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of ice vending machine locations

- Strategic Sourcing Conclusion and Outlook for ice vending machine locations

Introduction: Navigating the Global Market for ice vending machine locations

In the evolving landscape of global commerce, the strategic placement of ice vending machines represents a significant opportunity for B2B buyers aiming to enhance their service offerings in various markets. Ice vending machines have become essential in sectors such as hospitality, catering, and retail, where the demand for convenience and quick access to ice is paramount. Understanding the nuances of selecting optimal locations for these machines can directly influence operational success and profitability.

This comprehensive guide delves into the critical aspects of ice vending machine locations, offering insights into types of machines, materials used, manufacturing quality control, and cost considerations. It also highlights potential suppliers and provides an overview of the market landscape, including regional trends and demand forecasts. By addressing frequently asked questions, this guide serves as an essential resource for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, including emerging markets like Brazil and Kenya.

Empowering buyers with actionable insights, this guide facilitates informed sourcing decisions, enabling businesses to capitalize on the growing demand for ice vending solutions. By understanding the market dynamics and leveraging strategic location placements, buyers can enhance their competitive edge and drive sustainable growth in their respective regions.

Understanding ice vending machine locations Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standalone Ice Vending | Independent units, often solar-powered | Retail, outdoor events | Pros: Low maintenance, flexible location. Cons: Limited capacity, weather dependency. |

| Gas Station Ice Vending | Integrated with fuel stations, high foot traffic | Convenience stores, gas stations | Pros: High visibility, consistent demand. Cons: Initial installation costs can be high. |

| Commercial Ice Vending | Larger capacity machines, often refrigerated | Restaurants, catering services | Pros: High output, efficient for bulk sales. Cons: Higher energy costs, requires more space. |

| Mobile Ice Vending | Portable units for events and festivals | Festivals, outdoor markets | Pros: Versatile, can reach diverse locations. Cons: Limited storage, requires transport logistics. |

| Automated Ice Kiosks | Touchscreen interfaces, cashless payments | Urban areas, tourist attractions | Pros: Modern appeal, user-friendly. Cons: Higher technology investment, maintenance of electronic components. |

Standalone Ice Vending

Standalone ice vending machines are typically self-contained units that can be placed in various locations, including parks or remote areas. They often operate independently, sometimes using solar power, making them ideal for off-grid locations. Buyers should consider maintenance needs and weather resilience, as these machines may be more susceptible to environmental factors.

Gas Station Ice Vending

Gas station ice vending machines are strategically located at fuel stations, benefiting from high foot traffic and visibility. These machines cater to customers looking for convenience, especially those purchasing ice for immediate use. Buyers should evaluate the initial investment and potential for consistent sales, as these locations typically generate steady demand.

Commercial Ice Vending

Commercial ice vending machines are designed for high-capacity output, making them suitable for businesses like restaurants and catering services. These machines often have refrigeration capabilities to maintain ice quality. When purchasing, businesses should consider energy consumption and space requirements, as these machines can be larger and more expensive to operate.

Mobile Ice Vending

Mobile ice vending units provide flexibility, allowing sellers to operate at various events, festivals, and markets. Their portability makes them appealing for businesses looking to reach a broader audience. However, buyers must account for transportation logistics and limited storage capacity, which can affect overall sales potential.

Automated Ice Kiosks

Automated ice kiosks feature modern technology, including touchscreen interfaces and cashless payment options. These kiosks are ideal for urban areas and tourist attractions, appealing to tech-savvy consumers. While they provide a contemporary buying experience, buyers should weigh the higher initial investment and ongoing maintenance of electronic components against potential sales growth.

Related Video: DIY SQUISHY ICE VENDING MACHINE

Key Industrial Applications of ice vending machine locations

| Industry/Sector | Specific Application of ice vending machine locations | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Retail ice sales for beverages and food preservation | Increased sales, convenience for customers | Local regulations, energy efficiency, maintenance support |

| Hospitality | Ice supply for hotels, restaurants, and bars | Enhanced guest experience, operational efficiency | Reliability, volume capacity, ease of use |

| Construction | Ice for concrete cooling and curing | Improved concrete quality, faster project timelines | Temperature control, delivery logistics, volume requirements |

| Agriculture | Ice for perishable goods transport and storage | Extended shelf life, reduced spoilage | Compliance with health standards, refrigeration capabilities |

| Healthcare | Ice for medical and laboratory applications | Safe transport of biological samples, patient care | Sterility, size and portability, regulatory compliance |

Food and Beverage

Ice vending machines are increasingly being utilized in the food and beverage industry to provide readily available ice for drinks and food preservation. This convenience can significantly enhance customer satisfaction and drive sales, especially in high-traffic areas. International B2B buyers should consider local regulations regarding food safety and energy efficiency standards, as well as the machine’s maintenance needs to ensure a reliable supply.

Hospitality

In the hospitality sector, ice vending machines serve hotels, restaurants, and bars by providing quick access to ice, which is essential for beverages and food service. The use of these machines can improve operational efficiency and enhance the overall guest experience. Buyers in this sector should prioritize reliability and volume capacity, ensuring that machines can meet peak demand without interruption.

Construction

The construction industry utilizes ice vending machines for cooling and curing concrete, which is crucial for maintaining the integrity and quality of concrete structures. By ensuring that concrete remains at optimal temperatures, these machines can help reduce project timelines and enhance the durability of the materials. Buyers should focus on temperature control capabilities and logistics for timely delivery, especially in regions with extreme weather conditions.

Agriculture

Ice vending machines play a vital role in the agricultural sector, particularly for transporting and storing perishable goods. By providing a reliable source of ice, businesses can extend the shelf life of products, reducing spoilage and ensuring quality. When sourcing ice vending machines, buyers should ensure compliance with health standards and consider the refrigeration capabilities to maintain product integrity during transport.

Healthcare

In healthcare, ice vending machines are essential for medical and laboratory applications, such as the transport of biological samples and patient care. The availability of sterile ice can be critical for maintaining sample integrity and ensuring patient safety. B2B buyers in this sector need to focus on sterility, machine size and portability, and compliance with regulatory standards to ensure that all operational requirements are met.

Related Video: Everest Ice & Water Vending Machine | BEST Vending Machine for 2022?

Strategic Material Selection Guide for ice vending machine locations

When selecting materials for ice vending machine locations, it’s crucial to consider properties that ensure durability, efficiency, and compliance with local regulations. Below is an analysis of four common materials used in the construction of ice vending machines, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Stainless Steel (e.g., 304, 316)

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. Grades like 304 are suitable for general use, while 316 offers enhanced corrosion resistance, making it ideal for environments with high salinity or exposure to chemicals.

Pros & Cons:

Stainless steel is highly durable and easy to clean, which is essential for maintaining hygiene in ice vending machines. However, it tends to be more expensive than other materials, and its manufacturing can be complex due to the need for specialized welding techniques.

Impact on Application:

Stainless steel is compatible with water and ice, ensuring that there is no leaching of harmful substances. Its durability allows it to withstand mechanical stresses and impacts.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure compliance with local food safety standards. In Europe, adherence to ASTM and DIN standards is critical. The choice of grade may vary based on climate and exposure conditions.

2. High-Density Polyethylene (HDPE)

Key Properties:

HDPE is a thermoplastic known for its high strength-to-density ratio, excellent impact resistance, and good chemical resistance. It can operate effectively in a wide temperature range, making it suitable for ice vending machines.

Pros & Cons:

HDPE is lightweight and cost-effective, making it an attractive option for manufacturers. However, it may not be as durable as metals in high-stress applications, and its UV resistance can be limited unless treated.

Impact on Application:

This material is compatible with water and ice, and its non-toxic nature makes it safe for food applications. However, it may not perform well in extreme temperatures over prolonged periods without degradation.

Considerations for International Buyers:

Buyers should verify compliance with local regulations regarding food safety and material standards. In regions with high UV exposure, additional treatments may be necessary to enhance durability.

3. Aluminum (e.g., 6061-T6)

Key Properties:

Aluminum is lightweight, has excellent corrosion resistance, and good thermal conductivity. The 6061-T6 alloy is particularly strong and is often used in structural applications.

Pros & Cons:

Aluminum is relatively inexpensive and easy to fabricate, which can reduce manufacturing costs. However, it is less durable than stainless steel and can be prone to denting and scratching.

Impact on Application:

Aluminum is suitable for ice vending machines, provided it is properly coated or treated to prevent corrosion. Its lightweight nature can facilitate easier installation and maintenance.

Considerations for International Buyers:

In regions like the Middle East, where humidity can be high, buyers should ensure that aluminum components are treated to resist corrosion. Compliance with local standards is essential, especially in food-related applications.

4. Carbon Steel (e.g., A36)

Key Properties:

Carbon steel is known for its high strength and toughness. It is less resistant to corrosion compared to stainless steel but can be treated with coatings to improve its durability.

Pros & Cons:

This material is cost-effective and widely available, making it a popular choice for many applications. However, its susceptibility to rusting requires regular maintenance and protective coatings.

Impact on Application:

Carbon steel can be used in structural applications within ice vending machines, but it may not be suitable for direct contact with ice unless adequately protected.

Considerations for International Buyers:

Buyers should consider the local climate when selecting carbon steel, as humid or coastal environments can accelerate corrosion. Compliance with ASTM standards is recommended for structural integrity.

Summary Table

| Material | Typical Use Case for ice vending machine locations | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel (e.g., 304, 316) | Structural components, contact surfaces | Excellent corrosion resistance, easy to clean | Higher cost, complex manufacturing | High |

| High-Density Polyethylene (HDPE) | Outer casing, internal components | Lightweight, cost-effective | Less durable under stress, limited UV resistance | Medium |

| Aluminum (e.g., 6061-T6) | Structural and aesthetic components | Lightweight, good corrosion resistance | Prone to dents, less durable than stainless steel | Medium |

| Carbon Steel (e.g., A36) | Structural applications | Cost-effective, strong | Susceptible to corrosion, requires maintenance | Low |

This guide serves as a strategic resource for international B2B buyers looking to make informed decisions regarding material selection for ice vending machine locations, ensuring compliance and suitability for their specific markets.

In-depth Look: Manufacturing Processes and Quality Assurance for ice vending machine locations

When considering the manufacturing processes and quality assurance for ice vending machines, international B2B buyers should be well-informed about the typical stages of production, key quality control measures, and the standards that apply to ensure product reliability and safety.

Manufacturing Processes

The manufacturing of ice vending machines generally involves several crucial stages:

-

Material Preparation

– Selection of Materials: High-grade stainless steel is commonly used due to its corrosion resistance and durability. Components such as compressors, condensers, and other mechanical parts are sourced from reputable suppliers.

– Cutting and Shaping: Materials are cut to size using laser cutting or water jet cutting techniques. These methods ensure precision, reducing material wastage and allowing for intricate designs. -

Forming

– Metal Forming: Techniques such as bending, stamping, and welding are employed to create the frame and body of the ice vending machine. CNC (Computer Numerical Control) machines are often used for enhanced accuracy.

– Insulation Installation: Insulation materials are integrated into the machine’s structure to maintain temperature efficiency and reduce energy consumption. -

Assembly

– Component Assembly: Key components, including the ice-making unit, water supply systems, and electronic controls, are assembled in a clean environment to minimize contamination.

– Integration of Systems: Various systems (e.g., refrigeration, electrical, and plumbing) are interconnected. This stage requires skilled technicians to ensure all parts function cohesively. -

Finishing

– Surface Treatment: The exterior surfaces are often treated with powder coating or polishing to enhance aesthetics and provide additional protection against environmental factors.

– Quality Finishing: Final checks are performed to ensure that all components are securely attached and that the machine meets design specifications.

Quality Assurance

Quality assurance is paramount in the manufacturing of ice vending machines. Adherence to international standards and rigorous testing protocols is essential for ensuring product safety and reliability.

Relevant International Standards

- ISO 9001: This standard outlines requirements for a quality management system (QMS). Manufacturers must demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Certification: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: For specific components, adherence to American Petroleum Institute standards may be necessary, especially for machines that interact with water supply systems.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to ensure they meet specified standards before manufacturing begins.

- In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are conducted to identify any deviations from quality standards. This includes monitoring dimensions, weld integrity, and component functionality.

- Final Quality Control (FQC): After assembly, the entire unit undergoes rigorous testing, including functionality tests, safety checks, and performance evaluations to ensure it operates correctly before delivery.

Common Testing Methods

- Performance Testing: Machines are tested for ice production capacity, energy consumption, and cooling efficiency under various conditions.

- Safety Testing: Electrical safety tests are conducted to ensure compliance with relevant electrical standards, minimizing the risk of hazards.

- Environmental Testing: Units may be subjected to temperature and humidity variations to ensure they perform reliably in different climates.

Verifying Supplier Quality Control

B2B buyers can take several steps to verify the quality control processes of potential suppliers:

- Supplier Audits: Conducting on-site audits provides insights into the manufacturing processes, quality control measures, and compliance with international standards.

- Requesting Quality Reports: Suppliers should be able to provide documentation that details their quality control processes, including test results and certifications.

- Third-Party Inspections: Engaging independent inspection agencies can provide unbiased assessments of the manufacturing facilities and product quality.

QC and Certification Nuances for International Buyers

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is crucial:

- Regional Standards: Be aware of local regulations and standards that may differ from international ones, particularly in areas such as energy efficiency and safety.

- Certification Validity: Ensure that the certifications held by suppliers are valid and recognized in your region. This can affect the machine’s acceptance in local markets.

- Language and Documentation: Documentation may be in different languages; therefore, ensuring that you can comprehend the specifications and quality standards is essential.

In conclusion, B2B buyers must thoroughly evaluate both the manufacturing processes and the quality assurance measures of ice vending machine suppliers. By understanding the stages of production, relevant standards, and quality control practices, buyers can make informed decisions that align with their operational needs and market expectations.

Related Video: The Production Planning Process

Comprehensive Cost and Pricing Analysis for ice vending machine locations Sourcing

When sourcing ice vending machines, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary cost driver includes the raw materials used in manufacturing ice vending machines, such as stainless steel, refrigeration components, and electronic systems. Prices for these materials can fluctuate based on global market conditions, so buyers should keep abreast of trends.

-

Labor: Labor costs will vary significantly depending on the manufacturing location. Countries with lower labor costs may present opportunities for savings, but quality assurance and skilled labor availability must be considered.

-

Manufacturing Overhead: This encompasses utilities, rent, and equipment maintenance related to the production facility. Overhead costs can vary by region, influenced by local economic conditions and regulations.

-

Tooling: Custom tooling for specific machine designs can add significant upfront costs. Buyers should evaluate whether standard models meet their needs to avoid unnecessary expenditures.

-

Quality Control (QC): Investing in robust quality control processes is essential to ensure reliability and longevity in ice vending machines. This might include testing materials and finished products, which can add to overall costs.

-

Logistics: Shipping costs, including freight charges and insurance, must be factored into the total cost. The choice of Incoterms will also affect how these costs are allocated between buyer and seller.

-

Margin: Suppliers will typically add a profit margin to cover all costs and risks associated with manufacturing and selling the machines. This margin can vary widely based on competition and market demand.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract discounts, making it essential for buyers to assess their capacity and demand to optimize purchasing.

-

Specifications/Customization: Custom features can increase costs. Buyers should weigh the benefits of specific functionalities against potential price hikes.

-

Materials Quality/Certifications: Higher quality materials or certifications (like energy efficiency ratings) can significantly influence pricing. Buyers should ensure that these certifications align with regulatory requirements in their target markets.

-

Supplier Factors: Supplier reputation, reliability, and previous performance can affect pricing. Engaging with well-established suppliers might come at a premium but can reduce risks associated with quality and delivery.

-

Incoterms: Understanding the implications of different Incoterms (e.g., FOB, CIF) is vital for cost management, as they dictate who is responsible for shipping, insurance, and tariffs.

Buyer Tips

-

Negotiation: Effective negotiation can lead to better pricing and terms. Buyers should be prepared to discuss order quantities, payment terms, and delivery schedules to secure favorable conditions.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes initial purchase price, operational costs, maintenance, and potential resale value. This holistic view can lead to more informed purchasing decisions.

-

Pricing Nuances: International buyers should be aware of regional pricing disparities and market conditions. Currency fluctuations and local economic factors can impact the final cost.

-

Due Diligence: Conduct thorough supplier assessments to ensure that they meet quality standards and can deliver on time. This reduces the risk of additional costs arising from delays or defects.

Disclaimer

Prices for ice vending machines can vary significantly based on the above factors. The information provided serves as a guideline and may not reflect the actual costs incurred. Always engage directly with suppliers for the most accurate and current pricing.

Spotlight on Potential ice vending machine locations Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘ice vending machine locations’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ice vending machine locations

Key Technical Properties for Ice Vending Machines

When considering the procurement of ice vending machines, understanding their essential technical properties is critical for ensuring operational efficiency, durability, and compliance with local regulations. Below are several key specifications that international buyers should evaluate:

-

Material Grade

The material grade of an ice vending machine typically refers to the quality and type of materials used in its construction, often stainless steel or food-grade plastics. Importance: High-quality materials ensure longevity, resistance to corrosion, and compliance with health standards, which is especially crucial in regions with high humidity or variable climates. -

Energy Efficiency Rating

This rating indicates how much energy the machine consumes during operation. Machines with higher energy efficiency ratings (like ENERGY STAR certification) consume less power, leading to lower operational costs. Importance: For businesses in Africa or South America where energy costs can be significant, selecting energy-efficient models can provide substantial savings over time.

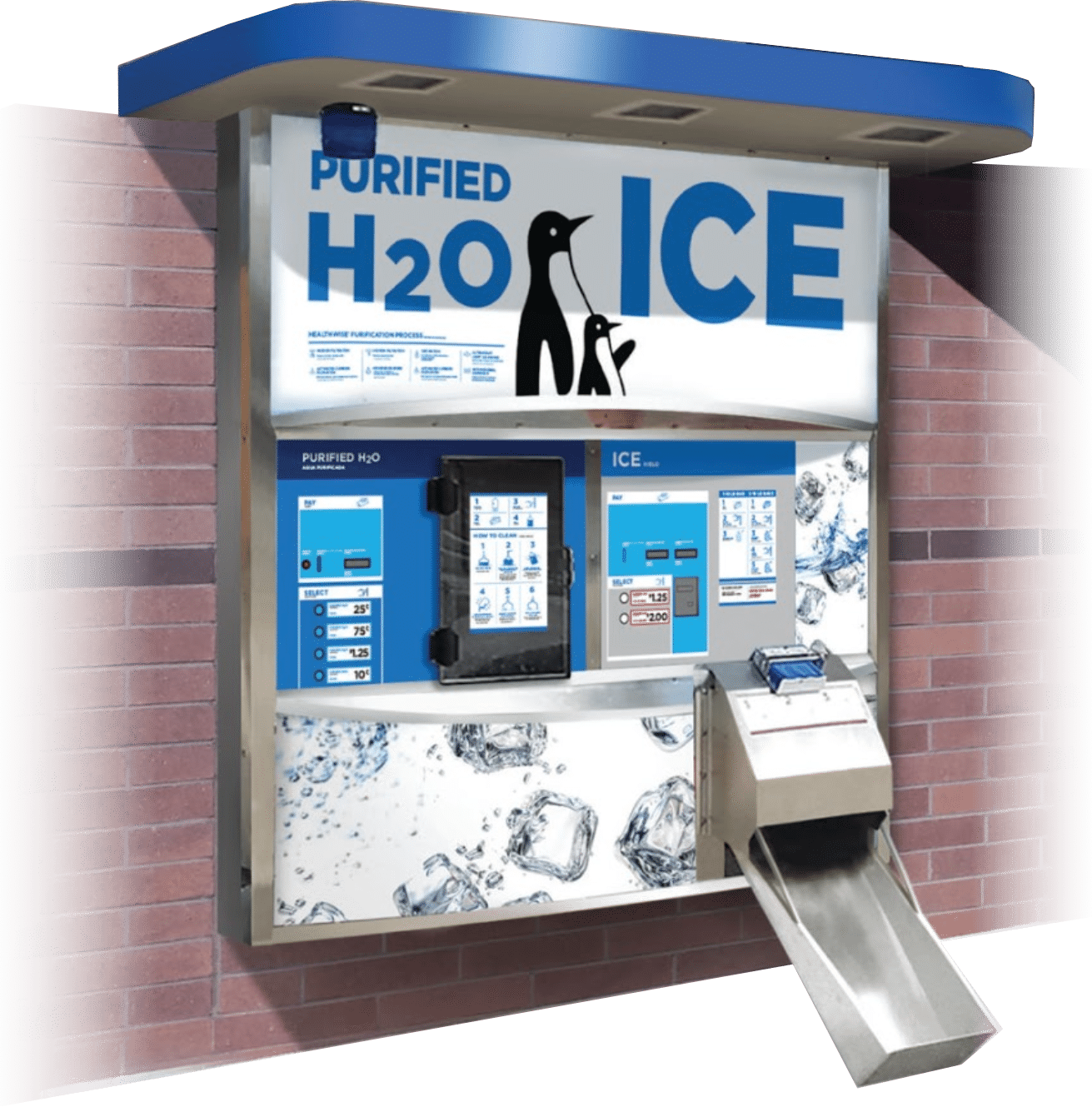

Illustrative Image (Source: Google Search)

-

Cooling Capacity

Measured in BTUs (British Thermal Units), the cooling capacity determines how quickly and effectively the machine can produce and store ice. Importance: Understanding the cooling capacity is vital for ensuring that the machine meets demand during peak usage times, particularly in hot climates or during large events. -

Ice Production Rate

This specification indicates how much ice the machine can produce in a given time frame, usually measured in pounds per day. Importance: Knowing the production rate helps buyers select machines that can satisfy customer demand, preventing potential losses from unmet needs. -

Water Supply Requirements

This includes the type of water supply needed (e.g., direct connection, gravity-fed) and the quality of water required (e.g., filtered). Importance: Understanding these requirements is essential to ensure that the installation site can accommodate the machine without incurring additional costs for plumbing or filtration systems. -

Temperature Range

The operational temperature range indicates the environmental conditions in which the machine can effectively function. Importance: In regions with extreme temperatures, ensuring that the machine operates efficiently in both high and low temperatures can prevent equipment failures and maintain consistent ice production.

Common Trade Terminology

In addition to technical specifications, familiarity with industry jargon is crucial for effective negotiations and procurement processes. Here are several terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce parts and equipment that may be marketed by another manufacturer. Importance: Buyers should consider OEM products for reliability and compatibility with existing equipment. -

MOQ (Minimum Order Quantity)

This term indicates the smallest number of units that a supplier is willing to sell. Importance: Understanding the MOQ helps buyers plan their purchases and manage inventory effectively, especially in regions where storage space might be limited.

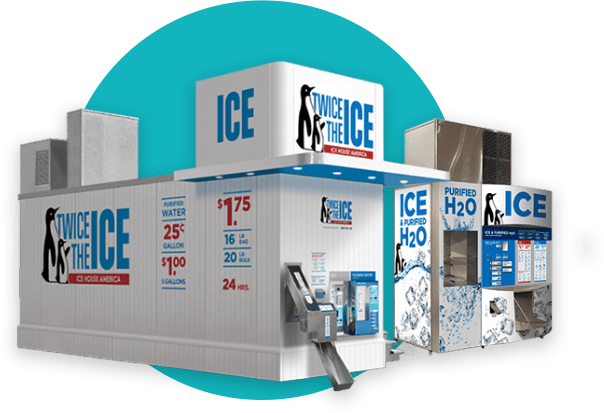

Illustrative Image (Source: Google Search)

-

RFQ (Request for Quotation)

A document that a buyer sends to suppliers to request pricing and availability for specific products. Importance: An RFQ allows buyers to compare costs and terms from multiple suppliers, ensuring competitive pricing and better negotiation outcomes. -

Incoterms

International commercial terms that define the responsibilities of buyers and sellers in international transactions. Importance: Knowledge of Incoterms is essential for understanding shipping logistics, risk transfer, and cost responsibilities, particularly when dealing with suppliers from different continents. -

Lead Time

The time it takes from placing an order to receiving the goods. Importance: Understanding lead times is critical for planning inventory and ensuring that machines are available when needed, especially during peak seasons. -

Warranty Period

The duration during which the manufacturer is responsible for repairing or replacing faulty equipment. Importance: A longer warranty period often reflects confidence in the product’s quality and can save buyers from unexpected repair costs.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions regarding ice vending machines that align with their business needs and market conditions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ice vending machine locations Sector

Market Overview & Key Trends

The ice vending machine locations sector is experiencing a significant transformation driven by globalization, technological advancements, and changing consumer behaviors. In regions like Africa, South America, the Middle East, and Europe, the demand for convenient and accessible ice solutions is surging, particularly in urban centers and tourist hotspots. Key market drivers include the rising popularity of outdoor events, food delivery services, and an increasing number of businesses seeking reliable ice supply options to enhance customer experiences.

Emerging technologies, such as IoT-enabled vending machines, are reshaping the landscape by allowing real-time monitoring of inventory levels and machine performance. This connectivity enables operators to optimize supply chains, reduce downtime, and improve maintenance schedules, ultimately leading to cost savings. Furthermore, the integration of mobile payment systems caters to the tech-savvy consumer base, enhancing convenience and driving sales.

For international B2B buyers, understanding local market dynamics is crucial. In Africa, for instance, the growth of urbanization presents opportunities for new installations, while in South America, environmental regulations are influencing the types of machines deployed. Buyers should also consider regional preferences and climate conditions, which can significantly impact the operational efficiency of ice vending machines.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a vital consideration in the ice vending machine sector, with increasing pressure on businesses to minimize environmental impacts. The production and operation of these machines can contribute to energy consumption and waste generation. Therefore, B2B buyers are encouraged to seek suppliers who prioritize sustainable practices, such as using energy-efficient machines and eco-friendly refrigerants.

Ethical sourcing is equally important, as it reflects a company’s commitment to social responsibility and environmental stewardship. Buyers should look for suppliers who demonstrate transparency in their supply chains, ensuring that materials are sourced responsibly and that labor practices meet ethical standards. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainability.

In addition, adopting ‘green’ materials in the manufacturing of vending machines, such as recyclable metals and biodegradable components, can significantly reduce the ecological footprint. B2B buyers should prioritize partnerships with manufacturers who are actively pursuing innovation in sustainable materials and processes, thus contributing to a more sustainable future for the industry.

Brief Evolution/History

The concept of ice vending machines originated in the United States in the late 20th century, primarily as a response to the growing demand for convenient, self-service options. Initially, these machines were simple in design, offering bulk ice to consumers. Over the years, advancements in technology have led to the development of more sophisticated models equipped with features like real-time inventory tracking and mobile payment integration.

As the market expanded globally, variations adapted to local climates and consumer preferences emerged. In regions with high tourism, such as the Caribbean and parts of Europe, ice vending machines became essential to cater to the needs of beachgoers and event organizers. Today, the sector is poised for further growth as sustainability and technological innovation continue to drive change, making it an appealing investment for international B2B buyers.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of ice vending machine locations

-

What should I consider when vetting suppliers for ice vending machine locations?

When vetting suppliers, prioritize their experience in the industry and reputation. Research online reviews and request references from previous clients. Verify their production capabilities, certifications, and compliance with local regulations. Consider visiting their facilities if possible. Additionally, assess their customer service responsiveness and willingness to provide support post-purchase. -

Can I customize the ice vending machines to fit my business needs?

Yes, many suppliers offer customization options. You can request features such as branding, machine size, ice production capacity, and payment options (e.g., cash, card, mobile payments). Discuss your specific requirements with potential suppliers to ensure they can meet your needs. Customization may impact lead times, so factor this into your planning. -

What are typical minimum order quantities (MOQs) and lead times for ice vending machines?

MOQs vary by supplier and can range from one machine to multiple units, depending on their production capacity. Generally, lead times can range from 4 to 12 weeks, influenced by customization and order size. Always confirm these details upfront to avoid delays in your project timeline. -

What payment terms are commonly accepted by suppliers?

Most suppliers accept various payment methods, including wire transfers, letters of credit, and PayPal. It’s common to require a deposit (often 30-50%) upon order confirmation, with the balance due before shipment or upon delivery. Negotiate favorable terms that suit your cash flow needs while ensuring supplier confidence in your commitment.

-

How can I ensure quality assurance and necessary certifications for the machines?

Request documentation of quality assurance processes and certifications from your suppliers, such as ISO certifications or compliance with local health and safety standards. Ensure they conduct regular quality checks during manufacturing and offer warranties on their machines. It may also be beneficial to have third-party inspections conducted before shipment. -

What logistics considerations should I keep in mind when sourcing ice vending machines?

Logistics are crucial in international trade. Discuss shipping options, costs, and timelines with suppliers to ensure timely delivery. Be aware of customs regulations in your country and any import duties that may apply. Consider the availability of local service providers for installation and maintenance once the machines arrive. -

What should I do if a dispute arises with a supplier?

If a dispute occurs, first attempt to resolve the issue amicably through direct communication. If that fails, refer to any signed contracts for dispute resolution clauses, which may include mediation or arbitration. Document all communications and gather evidence related to the dispute to support your case. In severe cases, consider legal counsel familiar with international trade laws. -

How can I assess the market demand for ice vending machines in my region?

Conduct market research to understand local demand. Analyze competitors, consumer preferences, and seasonal trends in your target regions, such as hot weather or tourist seasons. Surveys or focus groups can provide insights into potential customer behavior. Engaging local distributors can also offer valuable information on market dynamics and customer needs.

Strategic Sourcing Conclusion and Outlook for ice vending machine locations

In summary, strategic sourcing for ice vending machine locations presents a wealth of opportunities for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. By focusing on key factors such as market demand, location analysis, and technological integration, buyers can maximize their investment and enhance operational efficiency.

Key takeaways include:

- Market Research: Understand local consumer behavior and preferences to identify high-traffic areas that can sustain ice vending operations.

- Partnerships: Collaborating with local suppliers and distributors can streamline logistics and improve service delivery.

- Technology Utilization: Leverage advanced vending technologies that enhance user experience and operational reliability.

As the demand for convenient and accessible ice continues to rise, the potential for growth in this sector is significant. By adopting a strategic approach to sourcing, buyers can not only capitalize on existing market trends but also contribute to the development of sustainable practices in their regions.

Looking ahead, now is the time for international buyers to engage with suppliers and explore innovative solutions that can redefine the ice vending landscape. Embrace this opportunity to be at the forefront of a growing market and drive your business towards success.