Your Ultimate Guide to Sourcing Ice Cream Vending Machine

Guide to Ice Cream Vending Machine For Sale

- Introduction: Navigating the Global Market for ice cream vending machine for sale

- Understanding ice cream vending machine for sale Types and Variations

- Key Industrial Applications of ice cream vending machine for sale

- Strategic Material Selection Guide for ice cream vending machine for sale

- In-depth Look: Manufacturing Processes and Quality Assurance for ice cream vending machine for sale

- Comprehensive Cost and Pricing Analysis for ice cream vending machine for sale Sourcing

- Spotlight on Potential ice cream vending machine for sale Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for ice cream vending machine for sale

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ice cream vending machine for sale Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of ice cream vending machine for sale

- Strategic Sourcing Conclusion and Outlook for ice cream vending machine for sale

Introduction: Navigating the Global Market for ice cream vending machine for sale

In an increasingly competitive global market, the ice cream vending machine has emerged as a lucrative investment opportunity for businesses targeting consumers’ sweet cravings. These machines not only offer convenience but also cater to the growing demand for on-the-go dessert options, making them an attractive addition to various commercial settings, from shopping malls to amusement parks. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe—such as Poland and Nigeria—understanding the dynamics of this market is crucial for making informed sourcing decisions.

This comprehensive guide delves into the essential aspects of ice cream vending machines, including types available, materials used in manufacturing, quality control processes, and reputable suppliers. Additionally, it covers cost considerations and market trends that can influence purchasing decisions. By providing answers to frequently asked questions, this guide empowers B2B buyers to navigate the complexities of sourcing, ensuring they can select the best machines that align with their business needs and customer expectations.

Equipped with actionable insights and expert analysis, international buyers will be better positioned to capitalize on the growing demand for ice cream vending solutions, ultimately enhancing their competitive edge in the marketplace. With this guide, you will be able to make strategic choices that drive profitability and customer satisfaction in your operations.

Understanding ice cream vending machine for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Ice Cream Vending Machine | Classic design, typically offers a variety of pre-packaged ice creams and cones | Schools, parks, shopping malls | Pros: Familiarity, ease of use; Cons: Limited product variety, potential maintenance issues. |

| Soft Serve Ice Cream Machine | Dispenses soft-serve ice cream, often with customizable flavors | Restaurants, ice cream shops, events | Pros: High profit margins, customizable; Cons: Requires regular cleaning, higher initial cost. |

| Gelato Vending Machine | Focused on gelato, often includes premium ingredients and flavors | Upscale venues, gourmet shops | Pros: Appeals to high-end customers, unique offerings; Cons: Higher operating costs, niche market. |

| Mobile Ice Cream Cart | Portable unit, can be moved to various locations, often manually operated | Festivals, markets, outdoor events | Pros: Flexibility in location, lower initial investment; Cons: Limited capacity, labor-intensive. |

| Smart Ice Cream Vending Machine | Technology-enabled, allows for cashless payments and inventory tracking | Corporate offices, tech-savvy locations | Pros: Modern appeal, data-driven insights; Cons: Higher upfront cost, requires reliable internet connection. |

Traditional Ice Cream Vending Machine

Traditional ice cream vending machines are characterized by their classic design, offering a variety of pre-packaged ice creams and cones. These machines are commonly found in schools, parks, and shopping malls, where they cater to a wide audience. For B2B buyers, the advantages include familiarity and ease of use, while the limitations involve a restricted product variety and potential maintenance issues. Buyers should consider the machine’s location and expected foot traffic to maximize revenue.

Soft Serve Ice Cream Machine

Soft serve ice cream machines are designed to dispense creamy soft-serve ice cream, often featuring customizable flavors. They are primarily utilized in restaurants, ice cream shops, and events. The key benefits include high profit margins due to the ability to create unique flavors and combinations. However, they require regular cleaning and maintenance, and the initial investment may be higher compared to traditional machines. Buyers should evaluate their target market’s preferences and the potential for upselling.

Gelato Vending Machine

Gelato vending machines focus on offering high-quality gelato, often made with premium ingredients and unique flavors. These machines are typically found in upscale venues and gourmet shops, appealing to discerning customers. While they can command higher prices and attract a niche market, the operating costs are also elevated. B2B buyers should assess the local demand for gelato and consider partnerships with local producers to enhance product offerings.

Mobile Ice Cream Cart

Mobile ice cream carts provide flexibility and can be moved to various locations, making them ideal for festivals, markets, and outdoor events. These manually operated units have lower initial investments but limited capacity. They are labor-intensive, requiring staff to operate. For B2B buyers, the advantages include the ability to reach diverse audiences and the potential for lower overhead costs. Buyers should consider the logistics of transportation and staffing to ensure operational efficiency.

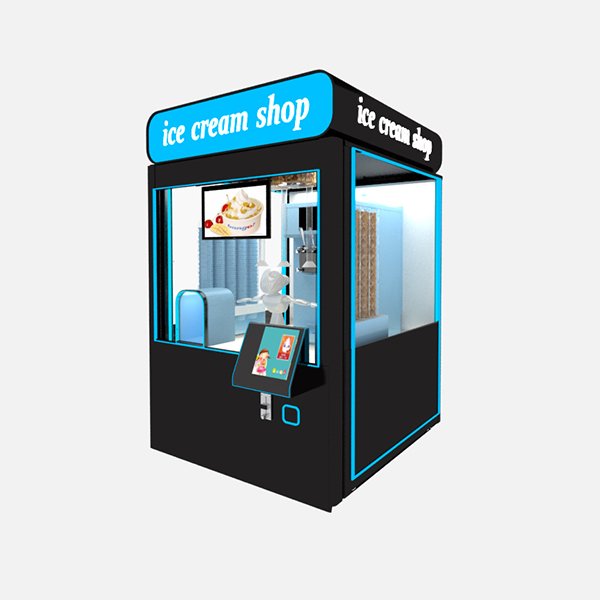

Smart Ice Cream Vending Machine

Smart ice cream vending machines integrate technology to offer cashless payment options and inventory tracking capabilities. They are ideal for corporate offices and tech-savvy locations, appealing to modern consumers. While they provide valuable data-driven insights and a contemporary appeal, the upfront costs are generally higher, and they require a reliable internet connection. B2B buyers should weigh the benefits of advanced features against the initial investment and ongoing operational requirements.

Related Video: Smart Ice Cream Vending Machine: Perfect Cones Every Time!

Key Industrial Applications of ice cream vending machine for sale

| Industry/Sector | Specific Application of ice cream vending machine for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Hotel lobbies and resorts | Enhances guest experience, increases revenue from impulse buys | Compact design, energy efficiency, payment system integration |

| Retail | Shopping malls and supermarkets | Attracts foot traffic, provides an additional revenue stream | Size, product variety, ease of replenishment |

| Education | Schools and universities | Offers convenient snack options, promotes healthy eating | Compliance with health regulations, ease of use for students |

| Events and Entertainment | Concerts, festivals, and sporting events | Provides quick service to large crowds, boosts event satisfaction | Durability, mobility, and capacity to handle high demand |

| Healthcare | Hospitals and clinics | Provides quick access to snacks for patients and visitors | Hygiene standards, ease of cleaning, product variety |

Hospitality

In the hospitality sector, ice cream vending machines serve as a delightful addition to hotel lobbies and resorts. They enhance the guest experience by providing quick access to a variety of ice cream flavors, promoting impulse purchases. For international buyers, particularly in regions like Africa and the Middle East, it is essential to consider the machine’s compact design and energy efficiency, which can be critical in areas with limited space and variable power supply.

Retail

In retail environments such as shopping malls and supermarkets, ice cream vending machines can significantly attract foot traffic and create an additional revenue stream. These machines can be strategically placed near entrances or high-traffic areas, offering customers a quick treat while they shop. B2B buyers should focus on the size and product variety of the vending machines, ensuring they can accommodate popular flavors and cater to diverse customer preferences, particularly in multicultural regions like South America and Europe.

Education

Schools and universities can leverage ice cream vending machines to provide students with convenient snack options that promote healthy eating habits. These machines can be stocked with low-sugar or dairy-free options to cater to health-conscious consumers. For buyers in this sector, compliance with health regulations is paramount, and machines must be easy to use and maintain to encourage student engagement while adhering to hygiene standards.

Events and Entertainment

At concerts, festivals, and sporting events, ice cream vending machines offer quick service to large crowds, enhancing overall event satisfaction. Their ability to serve a high volume of customers in a short time can significantly improve the attendee experience. Buyers in this sector should consider the durability and mobility of these machines, as they will need to withstand heavy usage and be easily relocated to different event sites, especially in dynamic environments across Europe and South America.

Healthcare

In healthcare settings like hospitals and clinics, ice cream vending machines provide a quick and enjoyable snack option for patients and visitors. They can help improve patient morale and offer nutritional options for those who may have dietary restrictions. Buyers in this sector must prioritize hygiene standards and ease of cleaning, ensuring that the machines can be maintained in a sterile environment while offering a variety of products that cater to different dietary needs.

Related Video: Ice Cream Vending Machine

Strategic Material Selection Guide for ice cream vending machine for sale

When selecting materials for ice cream vending machines, international B2B buyers must consider various factors, including the properties of the materials, their suitability for specific applications, and compliance with regional standards. Below is an analysis of four common materials used in the construction of ice cream vending machines, focusing on their key properties, advantages, disadvantages, and considerations for international markets.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. It typically has a temperature rating of up to 1000°F (538°C) and can handle pressures of up to 1500 psi, depending on the grade.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust and staining, making it ideal for food-grade applications. However, it can be more expensive than other materials, and its manufacturing process can be complex, requiring specialized equipment.

Impact on Application: Stainless steel is compatible with food products, ensuring hygiene and safety. Its resistance to corrosion makes it suitable for environments with high humidity or exposure to cleaning chemicals.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local food safety standards, such as those set by the FDA or EU regulations. Additionally, they should consider the availability of specific grades, such as 304 or 316, which are commonly used in food applications.

Polycarbonate

Key Properties: Polycarbonate is a strong, lightweight plastic known for its impact resistance and clarity. It can withstand temperatures ranging from -40°F to 240°F (-40°C to 115°C) and has good UV resistance.

Pros & Cons: The main advantage of polycarbonate is its lightweight nature, which reduces shipping costs and ease of installation. However, it can be less durable than metals and may scratch easily, requiring protective coatings.

Impact on Application: Polycarbonate is often used for transparent panels in vending machines, allowing visibility of the product while providing insulation. It is suitable for environments where weight is a concern.

Considerations for International Buyers: Buyers should check for compliance with safety standards such as ASTM D256 for impact resistance. In regions like South America, the availability of high-quality polycarbonate can vary, affecting overall product quality.

Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has a temperature tolerance of up to 600°F (316°C). It is also a good conductor of heat, which can be beneficial for cooling applications.

Pros & Cons: Aluminum’s lightweight nature makes it easy to handle and install, and it is generally less expensive than stainless steel. However, it may not be as strong as stainless steel, and its surface can be prone to scratching and denting.

Impact on Application: Aluminum is often used in the structural components of vending machines, where weight savings are crucial. It is suitable for indoor environments but may require additional protective coatings for outdoor use.

Considerations for International Buyers: Buyers should be aware of local recycling regulations, as aluminum is highly recyclable. Compliance with standards such as ISO 9001 for quality management can also be important, especially in European markets.

Mild Steel

Key Properties: Mild steel is known for its good tensile strength and ductility. It typically has a temperature rating of up to 400°F (204°C) and can handle moderate pressure.

Pros & Cons: The main advantage of mild steel is its low cost and ease of manufacturing. However, it is susceptible to corrosion and rust if not properly coated or painted.

Impact on Application: Mild steel is often used in the framework of vending machines. Its strength makes it suitable for structural applications, but it may require additional coatings to ensure longevity in humid environments.

Considerations for International Buyers: Buyers should consider the availability of protective coatings to enhance corrosion resistance. Compliance with local standards, such as DIN for European buyers, is also essential.

Summary Table

| Material | Typical Use Case for ice cream vending machine for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, food contact surfaces | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Polycarbonate | Transparent panels for visibility | Lightweight, impact-resistant | Scratches easily, less durable | Medium |

| Aluminum | Structural components, framework | Lightweight, cost-effective | Less strong, prone to scratching | Medium |

| Mild Steel | Framework and structural support | Low cost, easy to manufacture | Susceptible to corrosion without coating | Low |

This guide provides valuable insights for international B2B buyers, allowing them to make informed decisions based on material properties, application suitability, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for ice cream vending machine for sale

The manufacturing of ice cream vending machines involves several critical stages, each contributing to the overall quality and functionality of the final product. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these processes is essential for making informed purchasing decisions.

Manufacturing Processes

1. Material Preparation

The first step in manufacturing ice cream vending machines involves sourcing and preparing materials. Key components typically include stainless steel for durability and hygiene, high-quality plastics for various machine parts, and electronic components for controls and payment systems. Suppliers should ensure that materials meet specific standards, such as food safety regulations, to prevent contamination.

Key Techniques:

– Material Selection: Focus on food-grade and corrosion-resistant materials.

– Pre-Processing: Cutting, shaping, and treating materials to enhance durability and performance.

2. Forming

This stage involves shaping the materials into the required parts of the vending machine. Techniques like stamping, molding, and laser cutting are commonly used.

Key Techniques:

– CNC Machining: Precision machining for parts that require tight tolerances.

– Injection Molding: Used for producing complex plastic components with high volume and consistency.

3. Assembly

Once the individual components are formed, they are assembled into the final machine. This process can be labor-intensive and requires skilled technicians to ensure proper installation of mechanical and electronic systems.

Illustrative Image (Source: Google Search)

Key Techniques:

– Modular Assembly: Using pre-assembled modules can streamline the assembly process and reduce assembly time.

– Automated Assembly Lines: Incorporating robotics can improve efficiency and reduce human error.

4. Finishing

The finishing process enhances the aesthetics and functionality of the vending machine. This stage may include painting, coating, and quality checks.

Key Techniques:

– Powder Coating: Provides a durable finish that is resistant to scratches and corrosion.

– Final Assembly Checks: Ensuring all components are securely fastened and functioning before moving to quality control.

Quality Assurance

Quality assurance (QA) is paramount in the manufacturing of ice cream vending machines, ensuring they meet international and industry-specific standards.

Relevant International Standards

- ISO 9001: A key quality management standard that emphasizes consistency and customer satisfaction.

- CE Marking: Indicates compliance with European safety, health, and environmental protection standards.

- API Standards: Relevant for mechanical components to ensure they meet industry specifications.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Inspecting raw materials upon receipt to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product to ensure it meets all operational and safety standards.

Common Testing Methods

- Functional Testing: Ensuring that the vending machine operates correctly, including ice cream dispensing and payment systems.

- Durability Testing: Subjecting machines to stress tests to evaluate their performance over time.

- Hygiene Testing: Verifying that all surfaces meet food safety regulations.

Verifying Supplier Quality Control

For B2B buyers, particularly those in diverse regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are several strategies:

- Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes and quality assurance practices.

- Request Quality Reports: Ask suppliers for documentation of their quality control practices, including testing results and compliance certifications.

- Third-Party Inspections: Engage independent inspectors to evaluate the manufacturing facilities and processes to ensure compliance with international standards.

Quality Control and Certification Nuances

International B2B buyers must be aware of the specific quality control and certification nuances that may vary by region:

- Regional Regulations: Different countries may have unique regulations regarding food safety and equipment standards. Buyers should familiarize themselves with local laws in their target markets.

- Certification Validity: Ensure that certifications are up-to-date and relevant to the specific type of vending machine being purchased. For example, European buyers should prioritize CE marking, while buyers in other regions may look for different certifications.

- Cultural Considerations: In some markets, personal relationships and trust play a significant role in business transactions. Building rapport with suppliers can lead to better transparency regarding quality practices.

Conclusion

Understanding the manufacturing processes and quality assurance measures for ice cream vending machines is essential for international B2B buyers. By focusing on the key stages of production and quality control, buyers can make informed decisions, ensuring they procure machines that meet their operational requirements and comply with international standards. Investing time in supplier verification and understanding regional nuances will further enhance the procurement process, leading to successful business outcomes.

Related Video: INSIDE THE FACTORY HÄAGEN DAZS ICE CREAM MAKING MACHINES

Comprehensive Cost and Pricing Analysis for ice cream vending machine for sale Sourcing

The cost structure and pricing for ice cream vending machines involve several critical components that international B2B buyers should understand to make informed purchasing decisions. Below is a detailed analysis of the cost components, price influencers, and practical tips for buyers.

Cost Components

-

Materials

The primary materials include stainless steel, refrigeration units, electrical components, and vending mechanism parts. The choice of materials impacts both durability and cost. High-quality materials may result in a higher upfront cost but can lead to lower maintenance expenses over time. -

Labor

Labor costs encompass the wages for workers involved in the manufacturing process. This can vary significantly based on the region of production, labor laws, and skill levels. For instance, labor costs in Europe may be higher compared to Africa or South America, affecting the final pricing. -

Manufacturing Overhead

This includes utilities, facility costs, and administrative expenses. Efficient production processes can help reduce these costs, allowing manufacturers to offer competitive pricing. -

Tooling

Tooling costs are associated with the production equipment required to manufacture the machines. Custom designs may incur higher tooling costs, impacting the overall price. -

Quality Control (QC)

Implementing rigorous QC measures ensures that the machines meet safety and operational standards. While this adds to the cost, it is essential for maintaining product reliability and customer satisfaction. -

Logistics

Shipping and handling costs can vary based on distance, shipping methods, and Incoterms. International buyers should consider these costs when evaluating offers from suppliers. -

Margin

Manufacturers typically add a profit margin to cover costs and ensure sustainability. This margin can vary based on market conditions and competition.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity)

Higher order volumes often lead to reduced unit prices due to economies of scale. Buyers should negotiate MOQs to optimize their purchasing cost. -

Specifications/Customization

Customized machines tailored to specific needs will generally have higher costs than standard models. Clear communication of requirements can help manage costs. -

Materials and Quality Certifications

The choice of materials and the presence of quality certifications (e.g., ISO, CE) can significantly influence pricing. Buyers should assess whether the certifications align with their market requirements. -

Supplier Factors

Reputation, reliability, and location of suppliers can impact pricing. Established suppliers may charge a premium but often provide better quality and service. -

Incoterms

Understanding Incoterms is crucial, as they define responsibilities for shipping, insurance, and tariffs. Buyers should clarify these terms to avoid unexpected costs.

Buyer Tips

-

Negotiation: Leverage your purchasing power by negotiating prices and terms, especially for larger orders. Discuss potential discounts based on volume or long-term agreements.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes initial purchase price, operational costs, maintenance, and potential resale value. A higher initial investment may lead to lower operational costs.

-

Pricing Nuances: Be aware of regional pricing trends. For example, machines may be priced higher in Europe due to stricter regulations and higher labor costs compared to Africa or South America.

-

Research Suppliers: Conduct thorough research on potential suppliers, including their financial stability, production capabilities, and customer feedback. This can help mitigate risks associated with international sourcing.

-

Disclaimer on Indicative Prices: Keep in mind that pricing may fluctuate based on market conditions, currency exchange rates, and raw material costs. Always request updated quotes before finalizing any purchase.

In conclusion, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers looking to source ice cream vending machines. By focusing on the outlined components and influencers, buyers can make informed decisions that align with their business goals.

Spotlight on Potential ice cream vending machine for sale Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘ice cream vending machine for sale’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ice cream vending machine for sale

Key Technical Properties of Ice Cream Vending Machines

Understanding the technical specifications of ice cream vending machines is crucial for international B2B buyers looking to make informed purchasing decisions. Here are some essential properties to consider:

-

Material Grade

The material used in manufacturing the vending machine, typically stainless steel or high-grade plastic, determines its durability and resistance to corrosion. Stainless steel, for example, not only offers a sleek appearance but also ensures longevity, especially in humid environments common in regions like Africa and South America. Selecting the right material can significantly impact maintenance costs and machine lifespan. -

Cooling Capacity

Measured in BTUs (British Thermal Units), cooling capacity indicates the machine’s ability to maintain optimal temperatures for ice cream storage. For effective operation, especially in hot climates, a machine with higher BTU ratings is preferred. This specification is crucial for ensuring product quality and customer satisfaction, which can directly influence sales. -

Power Consumption

Power consumption, typically measured in watts, affects operational costs. Machines with energy-efficient designs may have a higher initial cost but can result in significant savings over time, making them a wise investment for businesses aiming for sustainability and cost-effectiveness.

Illustrative Image (Source: Google Search)

-

Storage Capacity

This specification refers to the volume of ice cream the machine can hold, often expressed in liters or gallons. A larger storage capacity is advantageous for high-traffic areas or during peak seasons, allowing businesses to serve more customers without frequent refills. Understanding the expected customer volume can guide buyers in selecting the appropriate size. -

Temperature Range

The temperature range indicates the machine’s ability to maintain varying temperatures for different ice cream types. This is particularly important for operators offering multiple products, such as soft serve and hard ice cream. A wider temperature range allows for greater flexibility in product offerings and can cater to diverse customer preferences. -

User Interface

The ease of use of the vending machine’s interface can significantly affect customer experience. Machines equipped with touch screens, clear instructions, and multiple language options can enhance user satisfaction and streamline the purchasing process.

Common Trade Terms in Ice Cream Vending Machine Sales

Navigating the B2B landscape involves familiarizing oneself with industry-specific jargon. Here are some common terms that buyers should understand:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can be vital for ensuring product quality and availability of replacement parts. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity a supplier is willing to sell. This is important for budget-conscious buyers, as it can influence the total cost of procurement. Understanding MOQ can also help in planning inventory levels and managing cash flow. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For buyers, issuing an RFQ can facilitate competitive pricing and ensure they receive the best deal based on their requirements. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Understanding Incoterms is crucial for B2B buyers to clarify shipping responsibilities, risk transfer, and cost allocation, which can affect overall pricing and logistics.

- Lead Time

This refers to the time taken from placing an order to receiving the product. For ice cream vending machines, shorter lead times can enhance responsiveness to market demand and seasonal fluctuations, making it essential for buyers to inquire about lead times when negotiating with suppliers.

- Warranty

A warranty offers assurance regarding the machine’s performance and quality over a specified period. Understanding warranty terms can protect buyers from unforeseen repair costs and ensure they invest in reliable equipment.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions, ultimately leading to successful procurement and operational efficiency in their ice cream vending business.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ice cream vending machine for sale Sector

Market Overview & Key Trends

The global ice cream vending machine market is witnessing robust growth, driven by rising consumer demand for convenient, on-the-go dessert options. Key trends influencing this market include the integration of advanced technology, such as cashless payment systems and IoT connectivity, allowing operators to monitor inventory and machine performance remotely. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these technological advancements is crucial to remaining competitive.

Emerging markets are experiencing a surge in demand for ice cream vending solutions, with notable growth in urban areas where busy lifestyles drive the need for quick service. In Europe, for instance, countries like Poland are increasingly adopting modern vending solutions that cater to health-conscious consumers, featuring lower-calorie and organic ice cream options. Additionally, the COVID-19 pandemic has accelerated the shift towards touchless transactions, making machines equipped with mobile payment options more appealing to buyers.

B2B buyers should also consider the importance of local sourcing and partnerships with suppliers who can provide high-quality ingredients and support. This approach not only enhances product quality but also fosters community engagement and loyalty among consumers. As the market evolves, leveraging these trends will be essential for maximizing profitability and meeting consumer expectations.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly becoming a key consideration for B2B buyers in the ice cream vending machine sector. The environmental impact of manufacturing and operating these machines, including energy consumption and waste generation, necessitates a shift towards eco-friendly practices. Buyers should prioritize vendors that utilize sustainable materials and energy-efficient technologies in their machines.

Ethical sourcing is equally vital. Establishing supply chains that prioritize fair labor practices and environmentally responsible ingredient sourcing can enhance brand reputation and consumer trust. Certifications such as Fair Trade and organic labels can serve as significant differentiators in a competitive market. Additionally, using biodegradable or recyclable packaging can appeal to eco-conscious consumers, further aligning with global sustainability goals.

Investing in “green” vending machines, which minimize energy usage and utilize renewable energy sources, can also contribute to long-term cost savings and operational efficiency. As the demand for sustainable solutions grows, B2B buyers who adopt these practices will not only fulfill regulatory requirements but also position themselves favorably in the market.

Brief Evolution/History

The evolution of ice cream vending machines dates back to the mid-20th century when the first machines offered limited selections and required manual operation. Over the years, technological advancements have transformed these machines into sophisticated units capable of offering a wide range of products, including soft serve and frozen yogurt. The introduction of cashless payment systems and touch screens has made these machines more user-friendly and appealing to a broader audience.

Today, the focus is on enhancing customer experience through personalized options and real-time inventory management. As the market continues to evolve, B2B buyers must stay informed about these developments to capitalize on new opportunities and address shifting consumer preferences effectively.

Related Video: Can India-US Secure Trade Deal Soon? | Trump Tariffs War | Global Trade War | US News | News18

Frequently Asked Questions (FAQs) for B2B Buyers of ice cream vending machine for sale

-

What factors should I consider when vetting suppliers of ice cream vending machines?

When vetting suppliers, focus on their reputation, experience, and reliability. Check for certifications that ensure compliance with international quality standards, such as ISO or CE. Request references or case studies from previous clients, especially those in your region. It’s also beneficial to assess their customer service responsiveness and willingness to provide ongoing support and maintenance. Additionally, consider their financial stability to ensure they can fulfill large orders over time. -

Can ice cream vending machines be customized to fit my business needs?

Yes, many manufacturers offer customization options for ice cream vending machines. You can request specific features such as branding, size, flavor variety, and payment options. Be clear about your requirements and ask for a prototype or design mock-up before finalizing the order. Customization may impact lead times and costs, so ensure you discuss these factors upfront with your supplier. -

What is the typical minimum order quantity (MOQ) and lead time for ice cream vending machines?

The MOQ can vary widely depending on the supplier, ranging from one machine for small businesses to larger quantities for bulk buyers. Lead times typically range from 4 to 12 weeks, influenced by customization requirements and the supplier’s production schedule. Always confirm these details in advance to align your purchasing strategy with your operational needs. -

What payment methods are commonly accepted when purchasing ice cream vending machines internationally?

Common payment methods include bank transfers, letters of credit, and online payment platforms. Many suppliers may require a deposit upfront, with the balance due upon shipment or delivery. Ensure you understand the payment terms, including any potential for currency fluctuations. Discuss payment security measures to protect your transaction, especially for large orders. -

How can I ensure quality assurance and certifications for the ice cream vending machines I purchase?

Request documentation for quality assurance processes, including certifications that demonstrate compliance with safety and operational standards. Look for products that have passed rigorous testing by recognized bodies. Additionally, inquire about the manufacturer’s quality control procedures during production. Consider performing a factory audit if feasible, or use third-party inspection services to verify product quality before shipment. -

What logistics considerations should I keep in mind when importing ice cream vending machines?

When importing, factor in shipping methods (air vs. sea), customs duties, and potential delays at ports. Ensure that your supplier provides proper packaging to prevent damage during transit. Collaborate with a logistics partner experienced in international shipping to navigate customs regulations effectively. Be prepared to manage any unexpected fees or documentation requirements that may arise. -

What steps should I take if a dispute arises with my supplier?

Maintain clear and open communication with your supplier to address issues promptly. Document all communications and agreements to have a record in case of disputes. If a resolution cannot be reached, refer to the contract terms regarding dispute resolution mechanisms, such as mediation or arbitration. Consider involving legal counsel familiar with international trade laws to advise on the best course of action. -

How can I effectively market my ice cream vending machines in my region?

To market your ice cream vending machines, focus on understanding your target market’s preferences and behaviors. Utilize social media and online advertising to reach potential customers. Engage in partnerships with local events, festivals, or businesses to increase visibility. Offer promotions or introductory pricing to attract initial customers and gather feedback to improve your offerings.

Strategic Sourcing Conclusion and Outlook for ice cream vending machine for sale

In conclusion, the strategic sourcing of ice cream vending machines presents a valuable opportunity for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. By leveraging diverse sourcing strategies, businesses can optimize their procurement processes, enhance product quality, and ultimately deliver superior customer experiences.

Key takeaways include the importance of understanding local market preferences, evaluating supplier capabilities, and integrating technology for efficient operations. Engaging with reputable suppliers can mitigate risks and ensure compliance with regional regulations, while also fostering long-term partnerships that drive innovation.

As the demand for automated food service solutions continues to rise, now is the ideal time for businesses to invest in high-quality ice cream vending machines. By taking proactive steps in sourcing and procurement, international buyers can not only meet current market demands but also position themselves for future growth.

Take action today to explore potential suppliers and capitalize on this thriving market. Embrace the future of vending solutions and transform your business offerings.