Your Ultimate Guide to Sourcing Ice And Water Vending

Guide to Ice And Water Vending Machines Near Me

- Introduction: Navigating the Global Market for ice and water vending machines near me

- Understanding ice and water vending machines near me Types and Variations

- Key Industrial Applications of ice and water vending machines near me

- Strategic Material Selection Guide for ice and water vending machines near me

- In-depth Look: Manufacturing Processes and Quality Assurance for ice and water vending machines near me

- Comprehensive Cost and Pricing Analysis for ice and water vending machines near me Sourcing

- Spotlight on Potential ice and water vending machines near me Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for ice and water vending machines near me

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ice and water vending machines near me Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of ice and water vending machines near me

- Strategic Sourcing Conclusion and Outlook for ice and water vending machines near me

Introduction: Navigating the Global Market for ice and water vending machines near me

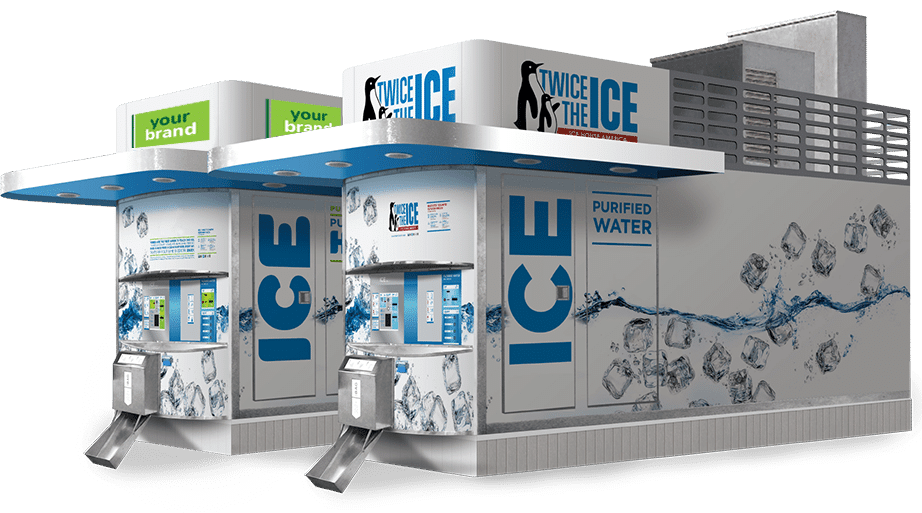

In today’s fast-paced global economy, the demand for ice and water vending machines is surging across diverse markets, from bustling urban centers in Africa to the vibrant cities of South America, the Middle East, and Europe. These machines serve not only as convenient solutions for hydration and cooling but also represent a lucrative business opportunity for B2B buyers seeking to meet consumer needs efficiently. With a growing emphasis on sustainability and innovation, the ice and water vending machine sector is evolving, offering advanced technologies that enhance user experience while ensuring environmental responsibility.

This comprehensive guide delves into the critical aspects of sourcing ice and water vending machines, covering various types and materials that cater to different market demands. It highlights manufacturing and quality control standards essential for maintaining product integrity and reliability. Furthermore, buyers will gain insights into evaluating suppliers, understanding cost structures, and navigating the market landscape to make informed purchasing decisions.

Whether you are a buyer from Indonesia exploring new vending solutions or an Italian entrepreneur seeking to expand your offerings, this guide empowers you with actionable insights. By addressing frequently asked questions and providing a thorough analysis of the market dynamics, it equips you with the knowledge necessary to confidently source ice and water vending machines that align with your business objectives.

Understanding ice and water vending machines near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Self-Service Water Vending Machines | Automated systems allowing customers to fill their own containers | Restaurants, offices, public spaces | Pros: Low operating costs, high convenience. Cons: Requires regular maintenance and water supply management. |

| Ice Vending Machines | Machines that produce and dispense ice on demand | Convenience stores, event venues | Pros: High demand in hot climates, minimal labor needed. Cons: Initial investment can be high, requires electricity. |

| Bulk Water Vending Stations | Designed for large quantities of water, often with filtration systems | Construction sites, agricultural use | Pros: Cost-effective for bulk purchases. Cons: Space-consuming and requires plumbing infrastructure. |

| Compact Ice & Water Combo Units | Dual-function machines offering both ice and water | Hotels, festivals, catering services | Pros: Space-efficient, versatile for different needs. Cons: Higher upfront cost, complexity in service. |

| Mobile Water Vending Units | Portable units that can be relocated as needed | Outdoor events, emergency services | Pros: Flexibility in location, ideal for temporary setups. Cons: Limited capacity, may require frequent refills. |

Self-Service Water Vending Machines

These automated systems allow customers to fill their own containers with purified water. They are commonly found in restaurants, offices, and public spaces, appealing to environmentally conscious consumers seeking refillable options. For B2B buyers, the key consideration is the machine’s reliability and water source management. Maintenance schedules and water quality assurance are critical for ensuring customer satisfaction and compliance with health regulations.

Ice Vending Machines

Ice vending machines produce and dispense ice on demand, making them essential for convenience stores and event venues, especially in warmer climates. The primary purchasing consideration for B2B buyers is the machine’s ice production capacity and energy efficiency. While these machines require a higher initial investment, their minimal labor requirements and ability to meet high demand can lead to significant returns.

Bulk Water Vending Stations

These stations are designed for users needing large quantities of water, often incorporating advanced filtration systems. They are ideal for construction sites and agricultural applications where bulk purchases are necessary. B2B buyers should evaluate the station’s filtration technology and the logistics of water supply. While they can be cost-effective, the need for plumbing infrastructure and space can be limiting factors.

Compact Ice & Water Combo Units

These dual-function machines provide both ice and water, making them popular in hotels, festivals, and catering services. Their space-efficient design is a significant advantage for businesses with limited space. However, the higher upfront cost and the complexity of maintenance can be drawbacks. Buyers should assess the versatility of the unit to ensure it meets diverse customer needs.

Mobile Water Vending Units

Mobile water vending units are portable and can be relocated as needed, making them suitable for outdoor events and emergency services. Their flexibility allows businesses to adapt to changing demands quickly. However, they typically have a limited capacity and may require frequent refills, which can affect operational efficiency. B2B buyers must consider the trade-offs between mobility and water storage capacity.

Related Video: How to Use an Everest Ice and Water Vending Machine – It’s EASY!

Key Industrial Applications of ice and water vending machines near me

| Industry/Sector | Specific Application of ice and water vending machines near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Guest services in hotels and resorts | Enhances guest experience, reduces staff workload | Energy efficiency, water quality standards |

| Food & Beverage | Supply for restaurants and cafes | Ensures consistent ice and water supply, cost-effective | Capacity, maintenance support, reliability |

| Construction | On-site ice and water supply for workers | Improves worker hydration and safety, portable | Durability, mobility, ease of setup |

| Healthcare | Patient hydration and ice supply in medical facilities | Supports patient care and comfort, reduces waste | Hygiene compliance, filtration systems |

| Events & Catering | Ice and water supply at events and festivals | Efficient service delivery, enhances guest satisfaction | Volume capacity, ease of use, serviceability |

Hospitality

In the hospitality sector, ice and water vending machines are critical for enhancing guest services in hotels and resorts. These machines provide guests with convenient access to ice and chilled water, significantly improving their overall experience. By automating ice and water distribution, hotels can reduce the workload on staff, allowing them to focus on more personalized service. International buyers should consider energy efficiency and compliance with local water quality standards when sourcing these machines to ensure they meet regulatory requirements in different regions.

Food & Beverage

Restaurants and cafes benefit from ice and water vending machines by ensuring a consistent supply of both, which is essential for food preparation and customer service. These machines help to streamline operations and reduce costs associated with traditional ice delivery services. For international B2B buyers, critical factors include the machine’s capacity, maintenance support, and reliability, especially in high-demand environments. Understanding local regulations regarding food safety and equipment sanitation is also essential for compliance.

Construction

In the construction industry, ice and water vending machines serve as vital resources for on-site hydration, promoting worker safety and productivity. Providing easy access to chilled water and ice helps ensure that workers remain hydrated, particularly in hot environments. Buyers in this sector should prioritize durability and mobility when sourcing these machines, as they need to withstand harsh conditions and be easily relocated. Moreover, ease of setup is crucial for quick deployment on job sites.

Healthcare

Healthcare facilities utilize ice and water vending machines to support patient hydration and comfort. These machines are especially beneficial in settings like hospitals, where patients may require frequent access to ice and water. By reducing reliance on staff for these needs, healthcare providers can improve patient care and reduce waste associated with single-use plastic bottles. Buyers must ensure that the machines comply with hygiene standards and include effective filtration systems to guarantee the quality of water dispensed.

Events & Catering

During events and festivals, ice and water vending machines provide an efficient solution for beverage service, enabling organizers to meet the high demand for refreshments. These machines enhance the guest experience by offering easy access to cold drinks while minimizing service bottlenecks. For B2B buyers in this sector, important considerations include the machine’s volume capacity to handle large crowds and its ease of use for staff and attendees alike. Serviceability is also a key factor, as prompt maintenance is essential during busy events.

Related Video: Kooler Ice Vending Machines – IM600XL vs. IM1000

Strategic Material Selection Guide for ice and water vending machines near me

Material Analysis for Ice and Water Vending Machines

When selecting materials for ice and water vending machines, it is crucial to consider factors such as durability, cost, and compliance with international standards. Below, we analyze four common materials used in the construction of these machines, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

1. Stainless Steel (e.g., 304, 316)

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. The 316 grade, in particular, offers superior resistance to chlorides, making it suitable for coastal areas.

Pros & Cons:

Stainless steel is highly durable and easy to clean, which is essential for food safety. However, it is more expensive than other materials, and its manufacturing can be complex due to the need for specialized welding techniques.

Impact on Application:

This material is compatible with both ice and water, ensuring that the quality of the product remains high. It is also resistant to bacterial growth, which is critical for hygiene.

Considerations for International Buyers:

Buyers in regions such as Africa and South America should ensure compliance with local food safety regulations and standards like ASTM or ISO. In Europe, adherence to EN standards is essential.

2. Polyethylene (PE)

Key Properties:

Polyethylene is a lightweight, flexible plastic that offers good chemical resistance and is relatively inexpensive. It can handle a temperature range from -40°C to 60°C.

Pros & Cons:

The primary advantage of polyethylene is its low cost and ease of fabrication. However, it has lower durability compared to metals and can degrade under UV exposure unless treated.

Impact on Application:

Polyethylene is suitable for water storage tanks and components that do not require high structural integrity. It is not recommended for high-pressure applications.

Considerations for International Buyers:

Buyers should check for compliance with food-grade standards, particularly in Europe and North America. The material’s recyclability may also be a selling point in regions focusing on sustainability.

3. Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance. It can withstand moderate temperatures and pressures, making it suitable for various applications.

Pros & Cons:

Aluminum is relatively cost-effective and easy to machine, allowing for complex designs. However, it is less durable than stainless steel and can corrode in certain environments without proper treatment.

Impact on Application:

This material is often used in structural components of vending machines where weight reduction is essential. However, it may not be suitable for direct contact with ice due to potential contamination.

Considerations for International Buyers:

International buyers should be aware of local recycling regulations and standards. In Europe, compliance with REACH regulations regarding chemical safety is crucial.

4. Carbon Steel (e.g., A36)

Key Properties:

Carbon steel is known for its high strength and affordability. It is suitable for structural applications but is susceptible to corrosion.

Pros & Cons:

While carbon steel is cost-effective and strong, it requires protective coatings to prevent rust, which can add to long-term maintenance costs.

Impact on Application:

This material is often used in the framework of vending machines but should not be in contact with water or ice without proper protection.

Considerations for International Buyers:

Buyers should ensure that carbon steel components meet local standards for corrosion resistance, especially in humid climates found in regions like the Middle East.

Summary Table

| Material | Typical Use Case for ice and water vending machines near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel (304, 316) | Structural components, contact surfaces | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Polyethylene (PE) | Water storage tanks, non-structural components | Low cost, easy fabrication | Lower durability, UV degradation | Low |

| Aluminum | Structural components, lightweight designs | Cost-effective, easy to machine | Less durable, potential corrosion | Medium |

| Carbon Steel (A36) | Framework, non-contact surfaces | High strength, low cost | Requires protective coatings | Low |

This guide provides a comprehensive overview of material selection for ice and water vending machines, emphasizing the importance of durability, compliance, and cost-effectiveness for international B2B buyers.

In-depth Look: Manufacturing Processes and Quality Assurance for ice and water vending machines near me

Manufacturing Processes for Ice and Water Vending Machines

The manufacturing of ice and water vending machines involves several critical stages, each designed to ensure the final product meets industry standards for functionality, safety, and durability. Understanding these processes can help B2B buyers make informed purchasing decisions.

1. Material Preparation

The first step in the manufacturing process is the preparation of raw materials. Common materials used in ice and water vending machines include stainless steel for the exterior, plastics for internal components, and specialized insulation materials.

- Material Selection: Buyers should look for suppliers who use high-grade stainless steel to resist corrosion and wear, particularly important in environments with high humidity.

- Supplier Verification: Before committing to a supplier, it’s prudent to verify the source of materials to ensure they meet international standards.

2. Forming

After materials are prepared, they undergo forming processes. This includes cutting, bending, and shaping the materials into the required components.

- Techniques: Common techniques include laser cutting for precision and CNC machining for consistent shapes. These methods enhance the quality and reduce waste.

- Importance of Precision: Precision in forming is critical for ensuring that components fit together correctly, which directly affects the machine’s efficiency and durability.

3. Assembly

Once the components are formed, the next stage is assembly. This involves putting together all parts, including the refrigeration system, water filtration, and control systems.

- Modular Design: Many manufacturers adopt a modular design approach, allowing for easier maintenance and upgrades. This can be a selling point for buyers who prioritize longevity and serviceability.

- Skilled Labor: The assembly process typically requires skilled technicians to ensure that all components are installed correctly and function cohesively.

4. Finishing

Finishing processes add the final touches to the machine, including painting, polishing, and applying protective coatings.

- Quality of Finish: The finish not only impacts aesthetics but also protects against environmental factors. For instance, a good coating can prevent rust and prolong the machine’s lifespan.

- Custom Branding: Many manufacturers offer customization options for branding, which can be beneficial for businesses looking to enhance brand visibility.

Quality Assurance in Manufacturing

Quality assurance (QA) is a critical aspect of the manufacturing process that ensures products meet specified standards before reaching the market. For ice and water vending machines, adhering to international and industry-specific standards is essential.

International Standards

- ISO 9001: This is a globally recognized quality management standard that outlines criteria for a quality management system. Suppliers should be certified to ISO 9001, indicating a commitment to quality and continuous improvement.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards. This is particularly important for buyers in the European market.

Industry-Specific Standards

- API Standards: For machines that utilize complex filtration or refrigeration systems, adherence to API (American Petroleum Institute) standards may be relevant, particularly in ensuring the safety and efficacy of water filtration systems.

- Local Regulations: Buyers must also be aware of and comply with local regulations in their respective countries, which may vary significantly.

Quality Control Checkpoints

Quality control (QC) processes should include several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): During assembly, inspections ensure that components are being assembled correctly and that any deviations are addressed promptly.

- Final Quality Control (FQC): Once assembly is complete, the final product undergoes rigorous testing to ensure it functions correctly and meets all quality standards.

Common Testing Methods

Testing methods can include:

- Functional Testing: Verifying that all machine functions operate correctly.

- Safety Testing: Ensuring that machines comply with safety regulations, including electrical safety and water quality standards.

- Durability Testing: Assessing the machine’s performance under various environmental conditions.

Verifying Supplier Quality Control

For international B2B buyers, it’s crucial to have a reliable method to verify the quality control processes of suppliers:

- Audits: Conducting regular audits can help ensure that suppliers adhere to their stated quality processes. Buyers can either perform these audits themselves or hire third-party firms.

- Quality Reports: Requesting comprehensive quality reports from suppliers can provide insight into their QC practices, including failure rates and corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the manufacturing process and product quality.

Navigating QC and Certification Nuances

B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe should be aware of the nuances in quality control and certification:

- Local Certifications: In addition to international standards, some countries may have specific certifications that are required for vending machines. Understanding these local requirements can prevent compliance issues.

- Cultural Differences: Different regions may have varying expectations regarding quality. Buyers should communicate their quality standards clearly to suppliers to avoid misunderstandings.

- Supply Chain Risks: Buyers should assess the entire supply chain, including potential risks related to sourcing materials and logistics, which can impact quality.

By understanding the manufacturing processes and quality assurance measures in place, B2B buyers can make more informed decisions when sourcing ice and water vending machines. This knowledge not only enhances their purchasing power but also ensures they receive products that meet their operational needs and quality expectations.

Related Video: Most Satisfying Factory Production Processes And Heavy-Duty Factory Machines!

Comprehensive Cost and Pricing Analysis for ice and water vending machines near me Sourcing

When sourcing ice and water vending machines, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This section will delve into the key cost components, price influencers, and provide actionable tips for buyers particularly from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary materials used in vending machines include stainless steel, plastic, and electronic components. The quality of these materials significantly influences the overall cost. High-grade stainless steel may increase initial costs but offers durability and longevity, reducing maintenance expenses over time.

-

Labor: Labor costs vary by region and can be a significant portion of manufacturing expenses. In countries with higher wage standards, such as those in Europe, labor costs can contribute more to the overall price than in regions with lower wage expectations, like parts of Africa and South America.

-

Manufacturing Overhead: This includes factory rent, utilities, and administrative costs. Efficient manufacturing processes can help reduce overhead, impacting the final pricing structure positively.

-

Tooling: The cost of specialized tools for manufacturing can be substantial, especially for custom designs. Buyers should consider whether off-the-shelf models can meet their needs to avoid excessive tooling costs.

Illustrative Image (Source: Google Search)

-

Quality Control (QC): Ensuring that machines meet safety and performance standards incurs additional costs. However, investing in robust QC processes can prevent costly recalls and repairs later.

-

Logistics: Shipping costs, including freight, customs duties, and insurance, can vary widely depending on the destination. For international buyers, understanding local import regulations is crucial to avoid unexpected expenses.

-

Margin: Suppliers typically add a margin to cover risks and ensure profitability. Understanding market standards for margins in different regions can aid buyers in negotiations.

Price Influencers

-

Volume/MOQ: Bulk orders can significantly reduce per-unit costs. Suppliers often provide discounts for larger orders, making it essential for buyers to assess their needs accurately.

-

Specifications/Customization: Custom features can drive up costs. Buyers should balance their requirements with budget constraints and consider whether standard models suffice.

-

Materials and Quality/Certifications: Machines with higher certifications (e.g., NSF, CE) may command higher prices due to the assurance of quality and safety. Buyers should evaluate the necessity of these certifications based on their target market.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their experience and service levels.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) agreed upon in contracts is essential, as they define the responsibilities of buyers and sellers regarding shipping costs, risks, and insurance.

Buyer Tips

-

Negotiation: Leverage your purchasing power by negotiating terms based on volume and long-term relationships. Suppliers may be willing to offer better pricing for commitments to future orders.

-

Cost-Efficiency: Look beyond the initial purchase price. Consider the Total Cost of Ownership (TCO), which includes maintenance, operational costs, and expected lifespan. A higher upfront cost for a durable machine may yield savings over time.

-

Pricing Nuances: Be aware of regional pricing strategies. For instance, suppliers in Europe may have different cost structures than those in Africa or South America, influenced by local economic conditions and currency fluctuations.

-

Research and Due Diligence: Conduct thorough research on suppliers, including customer reviews and case studies. This can help identify reliable partners and avoid costly mistakes.

Disclaimer

Prices for ice and water vending machines can vary widely based on the factors outlined above. The information provided is indicative and should be validated with suppliers to obtain accurate quotes tailored to specific requirements. Buyers are encouraged to conduct market comparisons to ensure competitive pricing.

Spotlight on Potential ice and water vending machines near me Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘ice and water vending machines near me’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ice and water vending machines near me

Critical Technical Properties of Ice and Water Vending Machines

When considering the procurement of ice and water vending machines, international B2B buyers should focus on several key technical properties that can significantly impact operational efficiency, maintenance, and long-term profitability. Here are some essential specifications to evaluate:

-

Material Grade

The quality of materials used in the construction of vending machines affects durability and resistance to environmental factors. Stainless steel is often preferred for its corrosion resistance and ease of cleaning. Understanding the material grade ensures that machines can withstand local climate conditions, particularly in regions with high humidity or extreme temperatures. -

Cooling Efficiency

This specification indicates how effectively the machine can produce and dispense ice or chilled water. It is typically measured in BTUs (British Thermal Units) per hour. Higher efficiency ratings lead to lower energy costs, which is critical for businesses operating in areas where energy prices are volatile. -

Production Capacity

This refers to the maximum amount of ice or water the machine can produce or dispense within a specific time frame, often expressed in pounds per hour or gallons per minute. Assessing production capacity is crucial for ensuring that the machine meets the demand of your target market, particularly in high-traffic areas. -

Filtration System

The quality of water dispensed from the vending machine is heavily influenced by the filtration system. Advanced filtration systems can reduce contaminants and improve taste, which is vital for customer satisfaction. Buyers should consider the type of filtration used (e.g., reverse osmosis, carbon filters) and maintenance requirements. -

Size and Footprint

The physical dimensions of the vending machine are important for space planning. Buyers should evaluate the machine’s footprint in relation to the installation site to ensure it fits without obstructing other operations. Additionally, consider the height and accessibility for users, particularly in high-traffic locations. -

Energy Consumption

Understanding the energy efficiency rating of the vending machine is essential for managing operational costs. Machines with Energy Star ratings or similar certifications often consume less power, providing savings over time while also aligning with sustainability goals.

Key Trade Terminology for Ice and Water Vending Machines

Familiarity with industry jargon is vital for effective communication and negotiation in the B2B marketplace. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of vending machines, OEM components can ensure compatibility and quality, making it crucial for buyers to understand who the OEM is for parts or machines they are purchasing. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is critical for budgeting and inventory management, especially for businesses just starting or looking to test market demand without significant upfront investment. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specified products or services. For buyers, issuing an RFQ can facilitate competitive pricing and help identify the best supplier for their needs. -

Incoterms (International Commercial Terms)

These are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Knowing Incoterms can help buyers minimize risks and manage costs effectively during the importation of vending machines. -

Lead Time

This term refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for planning inventory levels and ensuring that machines are available when needed, especially in seasonal markets. -

Warranty Period

The warranty period is the time frame during which the manufacturer guarantees repair or replacement of defective parts. A longer warranty can provide peace of mind and reduce long-term costs, making it an important consideration for buyers.

By focusing on these technical specifications and trade terms, B2B buyers can make informed decisions regarding ice and water vending machines, ensuring they select products that meet their operational needs while maximizing profitability.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ice and water vending machines near me Sector

Market Overview & Key Trends

The ice and water vending machine sector is experiencing transformative changes driven by several global factors. Increasing urbanization, particularly in regions like Africa and South America, is fueling demand for convenient, on-the-go hydration solutions. Moreover, the rise of health consciousness among consumers is prompting businesses to seek vending solutions that offer purified water and ice, leading to a burgeoning market for high-tech machines equipped with filtration and purification systems.

Emerging trends in B2B sourcing include the integration of IoT technology, which enables remote monitoring of vending machines for inventory management and maintenance. This tech-savvy approach enhances operational efficiency and reduces downtime, appealing to international buyers looking for reliability. Furthermore, the push for cashless transactions is reshaping the payment landscape, as consumers increasingly prefer mobile payments and contactless solutions. This trend is particularly relevant in Europe and the Middle East, where digital payment methods are becoming the norm.

For B2B buyers, understanding local market dynamics is crucial. Each region presents unique challenges and opportunities; for instance, regulatory requirements in Europe can differ significantly from those in Africa or South America. Buyers should conduct comprehensive market research to tailor their sourcing strategies effectively, ensuring alignment with regional consumer preferences and compliance standards.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer just a buzzword; it is a critical factor influencing purchasing decisions in the ice and water vending machine sector. The environmental impact of plastic waste from single-use bottles is prompting both consumers and businesses to seek eco-friendly alternatives. B2B buyers should prioritize suppliers that offer machines designed to reduce plastic usage, such as those that encourage reusable containers or provide filtered water directly.

Ethical sourcing is also gaining traction. Buyers should ensure that their supply chains are transparent and that materials used in manufacturing vending machines adhere to sustainable practices. This includes sourcing components from manufacturers that comply with environmental regulations and have certifications such as ISO 14001. Furthermore, investing in machines that utilize energy-efficient technologies can significantly reduce operational costs and appeal to environmentally conscious consumers.

Incorporating sustainability metrics into the procurement process is essential. Buyers can leverage certifications like Energy Star or Green Seal to validate the environmental claims of their suppliers, ensuring that their investments align with their corporate social responsibility goals.

Brief Evolution/History

The evolution of ice and water vending machines can be traced back to the late 20th century, when the first automated systems began to emerge. Initially, these machines primarily offered ice, but as consumer needs evolved, they began incorporating water dispensing capabilities. The introduction of advanced filtration technologies in the early 2000s marked a significant turning point, enabling these machines to provide high-quality, purified water.

Over the years, technological advancements have further transformed the sector. Features such as touchless interfaces, real-time monitoring, and mobile payment options have become standard, enhancing user experience and operational efficiency. As sustainability concerns rise, the focus has shifted towards eco-friendly designs and materials, shaping the future of ice and water vending solutions in the global market.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of ice and water vending machines near me

-

What factors should I consider when vetting suppliers of ice and water vending machines?

When vetting suppliers, prioritize their experience in the industry, customer reviews, and certifications. Look for suppliers with a proven track record of delivering quality products and excellent customer service. Ensure they have the necessary certifications for international trade, such as ISO standards, and inquire about their compliance with local regulations in your country. Additionally, assess their ability to provide after-sales support and spare parts, which is crucial for long-term operations. -

Can I customize the ice and water vending machines to suit my business needs?

Yes, many suppliers offer customization options for their vending machines. This can include branding with your logo, specific features like payment options (cashless payments), or machine size and capacity adjustments. Discuss your requirements with potential suppliers during the initial conversation to understand the extent of customization available and any associated costs or lead times. -

What is the typical minimum order quantity (MOQ) for ice and water vending machines?

The MOQ can vary significantly among suppliers, but it typically ranges from 1 to 10 units for initial orders. If you are a smaller buyer, some suppliers may be willing to negotiate lower MOQs, especially if you express potential for future orders. Always clarify MOQ details upfront to avoid misunderstandings and ensure that you can meet the supplier’s requirements.

Illustrative Image (Source: Google Search)

-

What are the usual lead times for ordering ice and water vending machines?

Lead times can vary based on the supplier’s location, the complexity of the order, and customization options. Typically, lead times range from 4 to 12 weeks. It’s essential to discuss these timelines upfront and factor in additional time for shipping, especially for international orders. Ensure you have a clear understanding of production schedules and delivery logistics to avoid disruptions in your business operations. -

What quality assurance measures should I look for in ice and water vending machines?

Quality assurance is critical when sourcing vending machines. Look for suppliers who adhere to industry standards and conduct rigorous testing on their products. Ask for documentation regarding quality checks, warranty terms, and any certifications they hold. Additionally, inquire about the materials used and the machine’s durability, as this can impact maintenance costs and longevity. -

What certifications should ice and water vending machines have for international trade?

Essential certifications include ISO standards for quality management, CE marking for compliance with European safety standards, and NSF certification for food safety in the United States. For buyers in Africa and South America, ensure the machines meet local health and safety regulations. Always verify that the supplier can provide copies of these certifications to avoid issues during importation. -

How should I handle logistics and shipping for my vending machine orders?

Logistics can be complex, especially for international shipments. Collaborate closely with your supplier to determine the best shipping method, whether by sea or air, and clarify who is responsible for shipping costs and customs duties. Utilize freight forwarders with experience in handling vending machine logistics to ensure timely delivery and compliance with customs regulations. Always track your shipments to address potential delays proactively. -

What steps can I take to resolve disputes with suppliers effectively?

To resolve disputes effectively, maintain clear and open communication with your supplier. Document all agreements, including specifications, prices, and delivery timelines, to have a reference point if issues arise. If a dispute occurs, attempt to resolve it amicably through negotiation. If necessary, consider mediation or arbitration as a formal resolution method, ensuring you understand the terms outlined in your contract regarding dispute resolution processes.

Strategic Sourcing Conclusion and Outlook for ice and water vending machines near me

In the evolving landscape of ice and water vending machines, strategic sourcing emerges as a critical factor for international B2B buyers. By prioritizing local suppliers, businesses can enhance their supply chain resilience, reduce transportation costs, and ensure timely access to essential products. Understanding regional market dynamics, particularly in Africa, South America, the Middle East, and Europe, allows buyers to align their procurement strategies with local demand and preferences.

Key Takeaways:

– Local Sourcing Benefits: Reduces logistics costs and shortens lead times.

– Market Knowledge: Tailoring offerings to meet specific regional needs enhances customer satisfaction.

– Sustainability Focus: Engaging with suppliers who prioritize eco-friendly practices can improve brand reputation and comply with emerging regulations.

As the demand for convenient access to clean water and ice continues to rise, now is the time for B2B buyers to act. Embrace strategic sourcing to not only secure competitive pricing but also to foster partnerships that align with your sustainability goals. The future is bright for those who adapt and innovate in this space. Take the next step—evaluate your sourcing strategy today and explore the opportunities that lie ahead in the vending machine market.