Your Ultimate Guide to Sourcing Five Below Vending Machine

Guide to Five Below Vending Machine

- Introduction: Navigating the Global Market for five below vending machine

- Understanding five below vending machine Types and Variations

- Key Industrial Applications of five below vending machine

- Strategic Material Selection Guide for five below vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for five below vending machine

- Comprehensive Cost and Pricing Analysis for five below vending machine Sourcing

- Spotlight on Potential five below vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for five below vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the five below vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of five below vending machine

- Strategic Sourcing Conclusion and Outlook for five below vending machine

Introduction: Navigating the Global Market for five below vending machine

In today’s competitive landscape, the five below vending machine represents an innovative solution that caters to the growing demand for accessible and affordable products. These machines, often stocked with a variety of items priced at five dollars or below, are not only a testament to consumer preferences but also a lucrative opportunity for international B2B buyers seeking to expand their offerings. With rising urbanization in regions like Africa, South America, the Middle East, and Europe, the potential for these vending machines to thrive is immense, providing a unique retail experience that aligns with budget-conscious shopping habits.

This guide serves as a comprehensive resource, delving into the various types of five below vending machines, their construction materials, manufacturing processes, and quality control standards. Buyers will also gain insights into identifying reliable suppliers, understanding cost structures, and navigating the market dynamics specific to their regions. Additionally, frequently asked questions will be addressed to empower buyers with the knowledge necessary for informed sourcing decisions.

By equipping B2B buyers with actionable insights and strategic recommendations, this guide not only enhances their procurement strategies but also positions them to capitalize on the burgeoning demand for five below vending machines. With the right information, businesses can effectively tap into this profitable segment, ensuring they meet consumer needs while maximizing their return on investment.

Understanding five below vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Snack Machine | Offers a variety of snack options in bulk | Retail stores, schools, offices | Pros: Wide selection, easy to stock; Cons: Limited to snacks only. |

| Beverage Vending Machine | Dispenses chilled drinks, often with a mix | Gyms, lounges, airports | Pros: High demand for beverages; Cons: Requires regular maintenance for cooling systems. |

| Electronics Vending Machine | Sells gadgets, accessories, and chargers | Airports, tech hubs, universities | Pros: Capitalizes on impulse buys; Cons: Higher initial investment. |

| Health & Wellness Machine | Focuses on nutritious snacks and drinks | Gyms, health clubs, corporate offices | Pros: Attracts health-conscious consumers; Cons: Niche market may limit sales. |

| Seasonal & Holiday Machine | Rotates products based on seasonal themes | Malls, tourist areas, festivals | Pros: Engages customers with timely offerings; Cons: Requires careful inventory management. |

Standard Snack Machine

The standard snack machine is a staple in various environments, providing an assortment of snacks such as chips, candies, and chocolate bars. These machines are ideal for retail stores, schools, and office settings where quick snack options are in high demand. B2B buyers should consider the machine’s capacity and ease of restocking, as well as the variety of snacks offered to cater to diverse consumer preferences.

Beverage Vending Machine

Beverage vending machines specialize in dispensing a range of chilled drinks, including sodas, juices, and bottled water. Commonly found in gyms, lounges, and airports, these machines are essential for locations with high foot traffic. Buyers should evaluate the machine’s cooling efficiency and maintenance requirements, as consistent operation is critical to meet consumer expectations for freshness.

Electronics Vending Machine

Electronics vending machines offer convenience by providing gadgets, accessories, and chargers on-the-go. These machines are strategically placed in airports, tech hubs, and universities, appealing to tech-savvy consumers. When purchasing, B2B buyers should assess the machine’s capacity for high-value items and the security features to prevent theft, as well as the initial investment required to stock it effectively.

Health & Wellness Machine

Focusing on nutritious snacks and beverages, health and wellness machines cater to the growing demand for healthier options. They are commonly placed in gyms, health clubs, and corporate offices, attracting health-conscious consumers. B2B buyers should consider the machine’s product range and branding opportunities, as well as the potential for higher profit margins in a niche market.

Seasonal & Holiday Machine

Seasonal and holiday vending machines rotate their product offerings based on current themes, such as Halloween candy or summer snacks. These machines are often placed in malls, tourist areas, and festivals, creating a sense of urgency and excitement among consumers. Buyers must manage inventory carefully to align with seasonal trends while ensuring the machine’s adaptability for various product types throughout the year.

Related Video: All Machine Learning Models Clearly Explained!

Key Industrial Applications of five below vending machine

| Industry/Sector | Specific Application of five below vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | In-store product distribution | Increased impulse purchases, efficient space usage | Product variety, stock management systems, payment options |

| Education | Campus convenience stores | Accessibility for students, low-cost essentials | Supply chain logistics, pricing agreements, local regulations |

| Hospitality | Hotel lobbies and break rooms | Enhanced guest experience, 24/7 access to snacks | Space optimization, inventory turnover rates, local preferences |

| Healthcare | Waiting rooms and clinics | Quick access to essentials for patients and visitors | Compliance with health regulations, product safety standards, inventory management |

| Events and Festivals | Event merchandise and snack sales | Streamlined sales process, reduced labor costs | Event duration, product selection, payment processing capabilities |

Retail

In retail environments, five below vending machines serve as efficient in-store product distribution points. They enable retailers to offer a variety of low-cost items like snacks, toys, and stationery, effectively increasing impulse purchases. For international B2B buyers, especially from regions like Africa and South America, it is crucial to consider the local consumer preferences and product assortment that resonate with the target demographic. Additionally, retailers should evaluate stock management systems to ensure optimal inventory levels and payment options to facilitate seamless transactions.

Education

In educational institutions, five below vending machines can be strategically placed in high-traffic areas such as hallways and student lounges, providing students with quick access to affordable snacks and supplies. This accessibility supports student well-being and promotes a positive campus experience. For buyers in this sector, understanding local regulations regarding food sales in schools and establishing reliable supply chains are critical. Additionally, pricing agreements should be competitive to meet the budget constraints of educational institutions.

Hospitality

In the hospitality sector, five below vending machines can enhance guest experiences by providing 24/7 access to snacks and beverages in hotel lobbies and break rooms. This convenience can significantly improve guest satisfaction and retention. For international buyers, understanding the local hospitality market’s expectations and guest preferences is essential. Moreover, considerations around space optimization and inventory turnover rates will help ensure that the vending machines are stocked with the right products at the right time.

Healthcare

In healthcare settings, five below vending machines can be placed in waiting rooms and clinics, offering patients and visitors quick access to essential items such as bottled water, snacks, and personal care products. This convenience can improve the overall patient experience during potentially stressful visits. Buyers in the healthcare sector must prioritize compliance with health regulations and product safety standards. Furthermore, effective inventory management strategies are necessary to maintain stock levels that meet patient needs without excessive overstock.

Events and Festivals

Five below vending machines are ideal for events and festivals, where they can streamline merchandise and snack sales. They reduce labor costs by minimizing the need for staff at sales points and can handle high volumes of transactions efficiently. For B2B buyers in this space, factors such as event duration, product selection tailored to the audience, and robust payment processing capabilities are vital for success. Understanding local event regulations and consumer behavior will further enhance the effectiveness of vending machine placements in these settings.

Related Video: Kooler Ice Vending Machines – IM600XL vs. IM1000

Strategic Material Selection Guide for five below vending machine

Material Analysis for Five Below Vending Machines

When selecting materials for five below vending machines, international B2B buyers must consider various factors, including performance, cost, and compliance with regional standards. Below, we analyze four common materials used in the construction of vending machines, highlighting their properties, advantages, disadvantages, and specific considerations for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. It typically features a temperature rating of up to 800°C and is resistant to many chemicals, making it suitable for various environments.

Pros & Cons:

The durability of stainless steel is a significant advantage, as it can endure heavy usage without degrading. However, its higher cost compared to other metals may be a drawback for budget-conscious buyers. Manufacturing complexity is moderate, requiring specialized equipment for cutting and welding.

Impact on Application:

Stainless steel is compatible with various media, including food and beverages, making it ideal for vending machines. Its hygienic properties are crucial in maintaining product quality.

Considerations for International Buyers:

Buyers should ensure compliance with local health and safety standards, such as ASTM or EN standards for food contact materials. Additionally, stainless steel grades (like 304 or 316) may vary in availability and cost across different regions.

2. Carbon Steel

Key Properties:

Carbon steel is characterized by its high tensile strength and low cost. It is suitable for structural components but is susceptible to corrosion without proper treatment.

Pros & Cons:

The primary advantage of carbon steel is its affordability, making it a popular choice for budget-sensitive projects. However, its susceptibility to rust and corrosion limits its lifespan unless coated or treated, which can add to manufacturing complexity.

Impact on Application:

Carbon steel is suitable for non-corrosive environments. However, its use in vending machines that handle food products may require additional protective coatings to prevent contamination.

Considerations for International Buyers:

Buyers should be aware of the need for protective coatings and ensure compliance with local corrosion resistance standards. In regions with high humidity or salt exposure, such as coastal areas, carbon steel may not be the best choice.

3. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has a good strength-to-weight ratio. It can withstand temperatures up to 600°C and is often used in applications requiring lightweight materials.

Pros & Cons:

The lightweight nature of aluminum makes it easy to transport and install, reducing overall project costs. However, it is less durable than stainless or carbon steel, making it more prone to dents and scratches.

Impact on Application:

Aluminum’s corrosion resistance makes it suitable for various environments, but it may not be ideal for high-impact areas. Its compatibility with food and beverages is generally acceptable, provided it meets relevant standards.

Considerations for International Buyers:

Buyers should verify that the aluminum used complies with local regulations regarding food safety. The availability of specific grades may vary by region, impacting cost and performance.

4. Polycarbonate

Key Properties:

Polycarbonate is a high-performance plastic known for its impact resistance and clarity. It can withstand temperatures ranging from -40°C to 120°C and is often used for transparent components in vending machines.

Pros & Cons:

The main advantage of polycarbonate is its lightweight and shatter-resistant properties, making it ideal for safety applications. However, it is less durable against UV exposure and may yellow over time if not treated.

Impact on Application:

Polycarbonate is excellent for display panels and protective covers, allowing visibility of products while ensuring safety. Its chemical resistance is suitable for various environments.

Considerations for International Buyers:

International buyers should ensure that polycarbonate complies with local safety and environmental regulations. The availability of UV-resistant grades can vary, affecting long-term performance.

Summary Table

| Material | Typical Use Case for five below vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, exterior panels | Excellent corrosion resistance | Higher cost compared to other metals | High |

| Carbon Steel | Structural framework, non-food contact areas | Cost-effective | Susceptible to corrosion without coating | Low |

| Aluminum | Lightweight panels, display sections | Lightweight and easy to install | Less durable, prone to dents | Medium |

| Polycarbonate | Transparent covers, safety panels | Impact-resistant and clear | Less UV resistance, may yellow over time | Medium |

This material selection guide provides insights into the various options available for five below vending machines, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

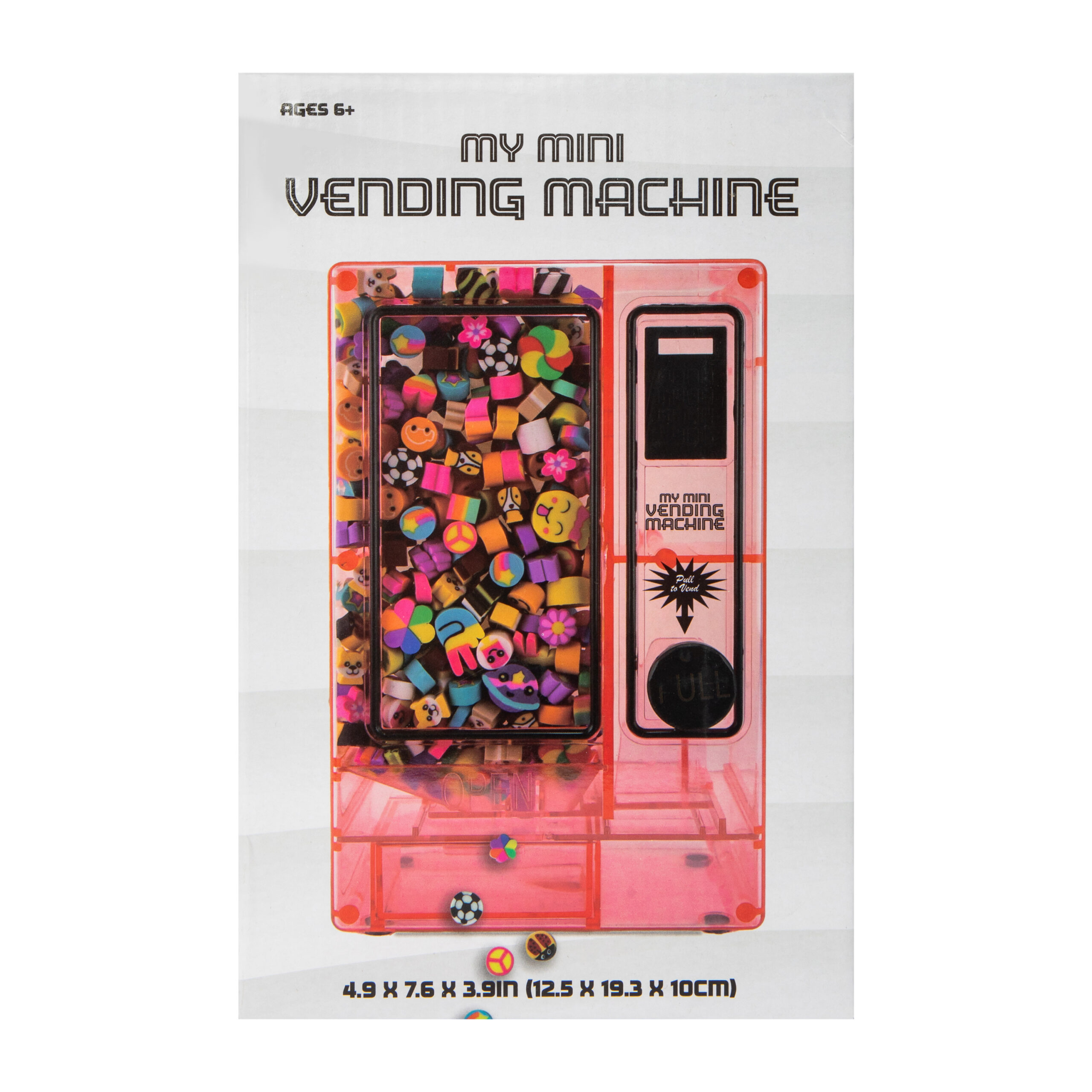

Illustrative Image (Source: Google Search)

In-depth Look: Manufacturing Processes and Quality Assurance for five below vending machine

Manufacturing Processes for Five Below Vending Machines

The manufacturing of Five Below vending machines involves several key stages, each essential for ensuring the final product meets the desired quality and functionality. Understanding these processes can help international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, make informed decisions when sourcing these machines.

Material Preparation

1. Material Selection:

The first step in the manufacturing process is selecting the appropriate materials. Typically, vending machines are made from durable materials such as steel or high-grade plastic to withstand frequent use. Buyers should inquire about the source of these materials and their compliance with international standards to ensure longevity and safety.

2. Pre-Processing:

After selection, materials undergo various pre-processing steps, including cutting, bending, and surface treatment. Techniques such as laser cutting and CNC machining are often employed for precision. Buyers should look for suppliers who utilize advanced technologies to enhance accuracy and reduce waste.

Forming

1. Shape and Structure Formation:

The forming stage involves shaping the prepared materials into the components of the vending machine, including the frame, panels, and internal mechanisms. This is achieved through processes like stamping and welding. High-quality welding techniques are essential for structural integrity, especially in high-traffic environments.

2. Component Manufacturing:

At this stage, other components such as coin mechanisms, electronic displays, and refrigeration units are also produced or sourced. Buyers should verify that the components meet relevant industry standards and are compatible with the overall vending machine design.

Assembly

1. Component Integration:

The assembly process combines all manufactured parts into the final vending machine structure. This includes the installation of electronic systems, mechanical components, and aesthetic finishes. Automated assembly lines may be utilized to enhance efficiency and precision.

2. Final Assembly Quality Checks:

During assembly, quality checkpoints are implemented to ensure each component is correctly installed and functions as intended. This includes testing electrical connections and mechanical movements.

Finishing

1. Surface Treatment and Coating:

Once assembled, the vending machines undergo finishing processes such as painting, powder coating, or applying protective films. These treatments not only enhance the appearance but also provide protection against corrosion and wear.

2. Branding and Customization:

Buyers often have the option to customize their vending machines with branding and specific color schemes. This process should be discussed with manufacturers to ensure that branding materials are durable and adhere properly.

Quality Assurance Processes

Quality assurance (QA) is critical in the manufacturing of vending machines. International buyers should be aware of both general and industry-specific standards to assess supplier credibility.

International Standards

1. ISO 9001 Certification:

This globally recognized standard for quality management systems (QMS) ensures that manufacturers have processes in place to consistently provide products that meet customer and regulatory requirements. Buyers should prioritize suppliers with ISO 9001 certification, as it indicates a commitment to quality.

2. CE Marking:

For machines intended for the European market, CE marking indicates compliance with European health, safety, and environmental protection standards. B2B buyers in Europe should ensure that their suppliers provide CE documentation for their vending machines.

Industry-Specific Certifications

1. API Standards:

For vending machines that dispense food or beverages, compliance with American Petroleum Institute (API) standards may also be necessary. This ensures that the materials and processes used are safe for food contact.

2. UL Certification:

In North America, Underwriters Laboratories (UL) certification is important for electrical safety. Buyers should confirm that the vending machines have undergone UL testing to mitigate risks associated with electrical components.

Quality Control Checkpoints

To maintain high-quality standards throughout the manufacturing process, several checkpoints are established:

1. Incoming Quality Control (IQC):

This step involves inspecting raw materials and components upon arrival at the manufacturing facility. Suppliers should have documented procedures for IQC to ensure only quality materials are used.

2. In-Process Quality Control (IPQC):

During the manufacturing process, ongoing inspections are conducted to monitor the quality of assembly and adherence to specifications. This includes checks at various stages of production to catch defects early.

3. Final Quality Control (FQC):

Before shipment, a final inspection is performed to ensure that the finished product meets all quality standards. This may include functional testing, visual inspections, and compliance checks.

Verification of Supplier Quality Control

B2B buyers can take several steps to verify a supplier’s quality control processes:

1. Supplier Audits:

Conducting regular audits of suppliers can provide insights into their manufacturing practices and adherence to quality standards. Buyers should develop an audit checklist based on relevant certifications and quality benchmarks.

2. Quality Reports:

Requesting detailed quality reports from suppliers can help buyers understand the quality management processes in place. These reports should include data on defect rates, inspection results, and corrective actions taken.

3. Third-Party Inspections:

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. This is particularly valuable for international buyers who may not have the resources to conduct onsite inspections.

Nuances for International Buyers

When sourcing vending machines from international suppliers, particularly in Africa, South America, the Middle East, and Europe, buyers should consider the following:

1. Language and Communication:

Ensure clear communication regarding quality standards, specifications, and certifications. Language barriers can lead to misunderstandings, so consider suppliers who can provide documentation in multiple languages.

2. Local Regulations:

Familiarize yourself with local regulations regarding vending machines, especially concerning food safety and electrical standards. This knowledge can help avoid compliance issues upon importation.

3. Cultural Sensitivity:

Understanding cultural differences in business practices can enhance negotiations and foster better supplier relationships. Building trust and rapport can lead to better collaboration and product quality.

By understanding the manufacturing processes and quality assurance measures in place for Five Below vending machines, international B2B buyers can make more informed decisions, ensuring they select reliable suppliers that meet their quality expectations.

Related Video: Exploring 5 Intriguing Factory Mass Production Processes in China.

Comprehensive Cost and Pricing Analysis for five below vending machine Sourcing

When evaluating the cost structure and pricing for sourcing five below vending machines, it’s crucial for international B2B buyers to understand the various components that contribute to the final price. This analysis will provide insights into the cost elements, price influencers, and effective strategies for negotiation and procurement.

Cost Components

-

Materials: The primary materials required for vending machines include steel for the chassis, plastic for the dispensers, and electronic components for payment systems. The quality and sourcing of these materials significantly affect the overall cost.

-

Labor: Labor costs are influenced by the region of manufacturing. In countries with lower labor costs, such as some in Africa or South America, buyers may benefit from reduced pricing. However, it is essential to consider the skill level and productivity of the workforce.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and administrative expenses. These costs can vary widely based on the efficiency of the manufacturing facility.

-

Tooling: The cost of tooling is often a significant upfront expense, especially for custom machines. Buyers should inquire about tooling costs and whether they can be amortized over larger orders.

-

Quality Control (QC): Implementing stringent quality control measures can add to the cost but is essential for ensuring that the machines function reliably. Certifications such as ISO can also influence both costs and pricing.

-

Logistics: Shipping costs can be substantial, particularly for international buyers. Factors such as distance, shipping method, and import duties must be considered to understand the total cost fully.

-

Margin: Suppliers typically add a profit margin to cover risks and business operations. This margin can vary based on the supplier’s reputation and the perceived value of the product.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Negotiating MOQ can help buyers achieve better pricing, especially when entering new markets.

-

Specifications/Customization: Custom features can significantly increase costs. Buyers should balance the need for unique specifications with budget constraints.

-

Materials: The choice of materials can affect not only the price but also the durability and lifespan of the vending machines. Opting for higher-quality materials may incur higher initial costs but can lead to lower Total Cost of Ownership (TCO) in the long run.

-

Quality/Certifications: Machines that meet international quality standards can command higher prices but often result in fewer maintenance issues and increased customer satisfaction.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may offer better warranties and support, justifying higher costs.

-

Incoterms: Understanding the terms of shipping and delivery (such as FOB, CIF, etc.) is crucial. These terms determine who bears the cost and risk at various stages of the shipment.

Buyer Tips

-

Negotiation: Leverage volume and long-term relationships to negotiate better pricing. Suppliers often value repeat business and may offer discounts for larger orders.

-

Cost-Efficiency: Analyze the Total Cost of Ownership rather than just the initial purchase price. Consider maintenance, energy consumption, and potential revenue from the machines.

-

Pricing Nuances: Be aware of regional pricing differences. For example, suppliers in Europe may have different pricing strategies compared to those in Africa or South America due to market dynamics.

-

Local Regulations: Familiarize yourself with import regulations and tariffs in your region. These can add unexpected costs to your procurement process.

Disclaimer

The prices and costs discussed in this analysis are indicative and can vary based on numerous factors, including market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough due diligence and seek multiple quotes to ensure competitive pricing.

Spotlight on Potential five below vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘five below vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for five below vending machine

When evaluating a five below vending machine, understanding its essential technical properties and associated trade terminology is crucial for making informed purchasing decisions. This section outlines the key specifications and terms that are commonly used in the industry, catering specifically to B2B buyers in regions such as Africa, South America, the Middle East, and Europe.

Key Technical Properties

-

Material Grade

– The material grade of a vending machine typically refers to the type of metal or plastic used in its construction. Common materials include stainless steel for durability and high-impact plastics for lighter units.

– Importance: A higher material grade ensures longevity and resistance to vandalism or environmental wear, which is vital in high-traffic areas. -

Dimensions and Capacity

– This includes the overall size of the vending machine, as well as the number of products it can hold. Dimensions are often measured in height, width, and depth, while capacity refers to the total number of items or weight it can support.

– Importance: Understanding dimensions helps buyers assess space requirements, while capacity influences inventory management and product turnover. -

Power Requirements

– Vending machines typically operate on specific voltage and wattage, which can vary by model. Common specifications include 110V or 220V configurations.

– Importance: Knowing power requirements is essential for ensuring compatibility with local electrical systems, which can prevent operational failures and additional installation costs. -

Temperature Control

– Some vending machines come with refrigeration systems to store perishable items. Specifications may include temperature range and energy efficiency ratings.

– Importance: For machines dispensing food and beverages, effective temperature control is critical for product safety and quality, directly impacting customer satisfaction.

- User Interface

– This includes the type of payment systems accepted (e.g., cash, credit card, mobile payments) and the usability of the display interface.

– Importance: A user-friendly interface can enhance the customer experience, leading to increased sales and repeat business.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the vending machine context, it often relates to components like payment systems or refrigeration units.

– Significance: Understanding OEM relationships can help buyers ensure they are sourcing high-quality components from reputable manufacturers. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest amount of product that a supplier is willing to sell. This can vary widely based on the vendor and the product type.

– Significance: Knowing the MOQ helps buyers plan their purchases effectively, ensuring they meet supplier requirements without overcommitting financially. -

RFQ (Request for Quotation)

– An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products or services.

– Significance: Utilizing RFQs allows buyers to compare offers from different suppliers, fostering competitive pricing and better negotiation outcomes. -

Incoterms (International Commercial Terms)

– These are predefined commercial terms published by the International Chamber of Commerce (ICC) that outline the responsibilities of buyers and sellers in international transactions.

– Significance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risks, and costs, which is critical for budgeting and logistics planning. -

Lead Time

– Lead time refers to the time taken from placing an order to the delivery of the product.

– Significance: Understanding lead times helps businesses plan their inventory and sales strategies, ensuring they maintain adequate stock levels to meet customer demand.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing five below vending machines, ultimately enhancing their operational efficiency and profitability.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the five below vending machine Sector

Market Overview & Key Trends

The global vending machine market, particularly the “five below” segment, is experiencing significant growth, driven by several key factors. Increased urbanization and a growing preference for convenience among consumers are enhancing the demand for vending solutions. For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, the rise of e-commerce and digital payment systems is transforming traditional vending operations. The integration of technology, such as cashless payment systems and IoT connectivity, is becoming a critical trend, allowing operators to streamline operations and enhance customer engagement.

Emerging trends indicate a shift towards healthier snack options and environmentally friendly packaging, catering to the growing consumer awareness of health and sustainability. Buyers should keep an eye on suppliers who adapt to these trends, as they may gain a competitive edge in local markets. Additionally, the COVID-19 pandemic has accelerated the demand for contactless vending solutions, making it essential for B2B buyers to consider the technological capabilities of vending machine suppliers.

Furthermore, regional differences in consumer behavior must be recognized. For instance, in Africa and South America, there is a rising demand for local flavors and products, while European markets may prioritize sustainability and innovation. Understanding these dynamics will enable international buyers to make informed decisions when sourcing vending machines that align with their target markets.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly crucial in the vending machine sector, where environmental impacts can be significant. International B2B buyers must prioritize suppliers that demonstrate a commitment to sustainable practices, including energy-efficient machines and recyclable materials. The importance of ethical supply chains cannot be overstated; ensuring that products are sourced from suppliers who uphold fair labor practices and environmental standards is vital for brand reputation and consumer trust.

Buyers should look for vending machines that incorporate “green” certifications, such as ENERGY STAR or those compliant with ISO 14001 standards. These certifications not only indicate lower energy consumption but also signal a commitment to reducing environmental footprints. The use of sustainable materials, such as biodegradable or recyclable components, is becoming a selling point for manufacturers. As consumers increasingly demand transparency regarding the sustainability of the products they purchase, B2B buyers must ensure that their vending machine suppliers align with these values.

Furthermore, engaging with suppliers who adopt circular economy principles can provide a competitive advantage. This approach not only reduces waste but also enhances brand loyalty among environmentally conscious consumers. By focusing on sustainability, international buyers can meet regulatory requirements while catering to a growing market segment that prioritizes environmental responsibility.

Brief Evolution/History

The vending machine industry has evolved significantly since its inception in the late 19th century. Originally designed to dispense simple items like postcards and chewing gum, vending machines have transformed into sophisticated retail solutions offering a wide array of products, from snacks to electronics. The introduction of digital technology in the early 2000s marked a turning point, enabling cashless transactions and remote inventory management.

In recent years, the focus has shifted towards enhancing consumer experience through personalization and automation. As the market continues to innovate, B2B buyers must adapt to these changes, ensuring they partner with suppliers who are at the forefront of technological advancements and sustainability practices. The evolution of the vending machine sector reflects broader shifts in consumer behavior, making it essential for international buyers to stay informed about industry trends and innovations.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of five below vending machine

-

What should I consider when vetting suppliers for five below vending machines?

When vetting suppliers, prioritize their experience in manufacturing vending machines, particularly those that cater to your target market. Check for certifications such as ISO or CE, which indicate quality and compliance with international standards. Evaluate their production capacity, lead times, and past client testimonials. Additionally, request samples to assess product quality firsthand. Establish communication channels to ensure responsive customer service and support. -

Can I customize my five below vending machines to reflect my brand?

Yes, many suppliers offer customization options for vending machines, including branding, color schemes, and product selections. Discuss your specific needs with potential suppliers, ensuring they have the capability to implement your design preferences. Ask for examples of previous custom projects to gauge their expertise. Be clear about your expectations regarding design timelines and additional costs associated with customization. -

What are the typical minimum order quantities (MOQs) and lead times for five below vending machines?

MOQs for vending machines can vary significantly between suppliers, typically ranging from 10 to 50 units. Discuss your volume requirements upfront to find a supplier that aligns with your purchasing needs. Lead times generally range from 4 to 12 weeks depending on the supplier’s production schedule, customization requests, and shipping logistics. Always confirm these details in writing to prevent misunderstandings. -

What payment terms are commonly offered by suppliers of five below vending machines?

Payment terms can differ widely among suppliers. Common arrangements include a deposit upon order confirmation (usually 30-50%) and the balance upon shipment. Some suppliers may offer payment via letters of credit, especially for larger orders. Ensure you clarify payment terms early in negotiations and consider using escrow services for additional security in transactions, particularly for international orders. -

How can I ensure quality assurance (QA) and certifications for the machines?

Request documentation from suppliers that demonstrates their quality assurance processes and relevant certifications. Look for ISO 9001 for quality management systems and any specific certifications related to electrical safety or international standards. Conduct regular quality checks throughout the production process and consider third-party inspections before shipment to verify compliance with your standards. -

What logistics considerations should I be aware of when importing five below vending machines?

Logistics are crucial when importing vending machines. Assess the shipping methods available (air vs. sea freight) based on your budget and urgency. Understand the customs regulations in your country to avoid delays. Work with a logistics partner who has experience in handling similar products to ensure smooth transportation. Also, consider insurance options to protect your investment during transit. -

How should I handle disputes with suppliers?

To handle disputes effectively, establish clear communication channels and maintain a record of all correspondences. If issues arise, start with direct negotiations to resolve the matter amicably. If unresolved, refer to the contract terms regarding dispute resolution, such as mediation or arbitration. Familiarize yourself with international trade laws that may apply, particularly if dealing with suppliers from different countries. -

What are the key features to look for in five below vending machines?

Key features to consider include size, capacity, payment options (cash, credit card, mobile payments), and user interface design. Ensure the machines are equipped with reliable technology for inventory management and reporting. Look for energy-efficient models to reduce operational costs and machines that can accommodate various product types. Additionally, consider the machine’s durability and ease of maintenance to ensure longevity and operational efficiency.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for five below vending machine

In conclusion, the strategic sourcing of Five Below vending machines presents a significant opportunity for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. The insights gathered underscore the importance of understanding local market dynamics, consumer preferences, and the operational efficiencies that these vending machines can provide.

Investing in Five Below vending machines allows businesses to capitalize on the growing trend of affordable retail solutions while enhancing product accessibility in various settings. By leveraging strategic sourcing, buyers can optimize costs, ensure supply chain reliability, and foster long-term partnerships with manufacturers and distributors.

As we look ahead, it is essential for international buyers to remain agile and responsive to market changes. Engaging with suppliers who prioritize innovation and sustainability will be crucial in meeting the evolving demands of consumers. Now is the time to take action—explore potential partnerships, assess local market needs, and position your business to thrive with Five Below vending machines in your portfolio. Your proactive approach could set the stage for future success in a competitive landscape.