Your Ultimate Guide to Sourcing Do Vending Machines Take 5

Guide to Do Vending Machines Take 5 Dollar Bills

- Introduction: Navigating the Global Market for do vending machines take 5 dollar bills

- Understanding do vending machines take 5 dollar bills Types and Variations

- Key Industrial Applications of do vending machines take 5 dollar bills

- Strategic Material Selection Guide for do vending machines take 5 dollar bills

- In-depth Look: Manufacturing Processes and Quality Assurance for do vending machines take 5 dollar bills

- Comprehensive Cost and Pricing Analysis for do vending machines take 5 dollar bills Sourcing

- Spotlight on Potential do vending machines take 5 dollar bills Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for do vending machines take 5 dollar bills

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the do vending machines take 5 dollar bills Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of do vending machines take 5 dollar bills

- Strategic Sourcing Conclusion and Outlook for do vending machines take 5 dollar bills

Introduction: Navigating the Global Market for do vending machines take 5 dollar bills

In the rapidly evolving landscape of international commerce, vending machines have emerged as a pivotal point of contact between consumers and businesses. As B2B buyers explore innovative avenues for revenue generation, understanding whether vending machines accept five-dollar bills becomes crucial. This seemingly simple question holds significant implications for profitability, inventory turnover, and customer satisfaction.

This guide offers a comprehensive exploration of the vending machine market, focusing on their capability to handle five-dollar bills. It addresses various types of vending machines available, from traditional snack dispensers to advanced models equipped with cashless payment options. Buyers will gain insights into the materials and manufacturing processes that ensure quality and durability, alongside supplier recommendations to facilitate informed purchasing decisions.

Furthermore, the guide delves into cost considerations, market trends, and frequently asked questions, providing a holistic view of the vending machine ecosystem. By equipping B2B buyers—especially those from Africa, South America, the Middle East, and Europe (including Italy and Vietnam)—with critical knowledge, this resource empowers them to make strategic sourcing decisions. Whether enhancing existing product lines or venturing into new markets, understanding vending machine capabilities is essential for driving business success in today’s global economy.

Understanding do vending machines take 5 dollar bills Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Snack Vending | Accepts multiple bill denominations including $5 | Office buildings, schools | Pros: Wide variety of snacks; Cons: May require frequent restocking. |

| Beverage Vending Machines | Specialized for drinks, often with refrigeration | Gyms, public transport stations | Pros: High turnover; Cons: Limited product variety. |

| Combo Vending Machines | Offers both snacks and beverages in one unit | Airports, shopping malls | Pros: Space-saving; Cons: Complex maintenance. |

| Cashless Payment Vending | Primarily accepts digital payments, but can take $5 bills | Tech-savvy environments | Pros: Reduces cash handling; Cons: May alienate cash-only customers. |

| High-End Food Vending | Provides gourmet or specialty food options | Corporate offices, events | Pros: Attracts premium clientele; Cons: Higher upfront cost. |

Traditional Snack Vending

Traditional snack vending machines are ubiquitous in various settings, such as office buildings and schools. These machines accept multiple bill denominations, including $5 bills, making them accessible to a wide range of customers. B2B buyers should consider the frequency of restocking, as these machines may require regular replenishment to meet high demand. Additionally, the variety of snacks can attract more users, but buyers must also weigh the operational costs associated with maintenance.

Beverage Vending Machines

Beverage vending machines are specifically designed to dispense drinks, often featuring refrigeration systems to keep beverages cold. They are commonly found in gyms and public transport stations, where quick refreshment is desired. For B2B buyers, these machines typically have a high turnover rate, making them a potentially profitable investment. However, the limited product variety may not cater to all consumer preferences, which should be considered when selecting the right vending solution.

Combo Vending Machines

Combo vending machines offer both snacks and beverages in a single unit, making them ideal for locations like airports and shopping malls, where space is at a premium. This type of machine accepts $5 bills and can cater to a diverse audience. The primary advantage is space-saving; however, the complexity of maintenance and the potential for mechanical failures may pose challenges for operators. B2B buyers should evaluate the trade-offs between convenience and maintenance needs.

Cashless Payment Vending

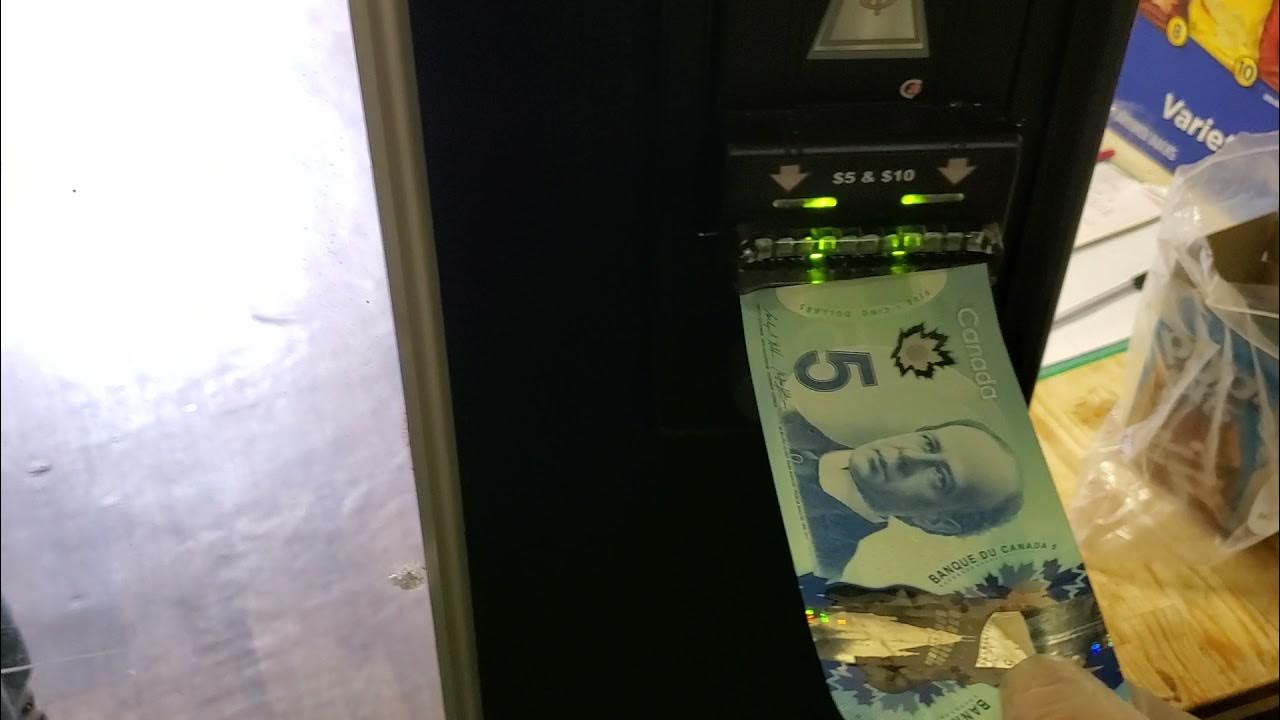

Cashless payment vending machines are increasingly popular in tech-savvy environments, accepting digital payments while still being able to take $5 bills. These machines are ideal for locations where cash handling is minimized, such as co-working spaces and modern offices. While they reduce the complexities associated with cash transactions, they may alienate customers who prefer cash. B2B buyers should assess their target market’s payment preferences before investing in this technology.

High-End Food Vending

High-end food vending machines offer gourmet or specialty food options, catering to corporate offices and events where quality is paramount. They can accept $5 bills, but the primary focus is on providing premium products. For B2B buyers, these machines can attract a higher-end clientele and create a unique offering in competitive environments. However, the higher upfront costs and maintenance requirements may be a consideration, making it essential to analyze potential ROI against these factors.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of do vending machines take 5 dollar bills

| Industry/Sector | Specific Application of do vending machines take 5 dollar bills | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Self-service kiosks in hotels and restaurants | Increased convenience for guests, reduces wait times | Machine reliability, payment processing integration |

| Education | Snack and beverage vending in schools and universities | Provides quick access to food and drink for students | Compliance with health regulations, machine durability |

| Transportation | Vending machines at airports and train stations | Enhances passenger experience, generates additional revenue | Compact size, ability to accept multiple currencies |

| Healthcare | Vending machines in hospitals for staff and visitors | Offers easy access to snacks and drinks during long shifts | Hygiene standards, product variety and health options |

| Corporate Offices | Breakroom vending solutions for employees | Boosts employee satisfaction and productivity | Variety of products, machine maintenance and support |

Hospitality

In the hospitality sector, vending machines that accept five-dollar bills can significantly enhance guest experiences in hotels and restaurants. By providing self-service kiosks that allow for quick transactions, establishments can reduce wait times during busy hours. This is particularly beneficial in high-traffic areas where guests may prefer quick access to snacks or beverages. For international buyers, it is essential to consider machine reliability and integration with existing payment processing systems to ensure seamless operations.

Education

In educational institutions, vending machines equipped to accept five-dollar bills serve a vital role in providing students with quick access to snacks and beverages. This convenience can improve student satisfaction and reduce the need for extensive cafeteria services. Buyers in this sector should prioritize compliance with health regulations and the durability of machines, especially in environments with high student traffic. Additionally, offering healthy options can cater to growing health-conscious student populations.

Transportation

Vending machines located in airports and train stations that accept five-dollar bills enhance the travel experience by providing passengers with quick access to refreshments. This service can generate additional revenue for transportation hubs while improving customer satisfaction. International buyers should focus on sourcing compact machines that can fit in limited spaces and are capable of accepting multiple currencies to accommodate diverse travelers.

Healthcare

In healthcare settings, vending machines that accept five-dollar bills are crucial for providing staff and visitors with easy access to snacks and drinks during long shifts. This convenience can significantly improve morale and ensure that healthcare workers remain energized throughout their demanding schedules. Buyers in this sector must ensure that machines meet hygiene standards and offer a variety of healthy options to cater to the dietary needs of patients and staff alike.

Corporate Offices

Corporate offices benefit from vending machines that accept five-dollar bills by enhancing employee satisfaction and productivity. By providing a variety of snacks and beverages in break rooms, companies can create a more enjoyable workplace environment. For B2B buyers, it is important to consider the variety of products offered, as well as the maintenance and support services available for the machines to ensure they remain operational and stocked.

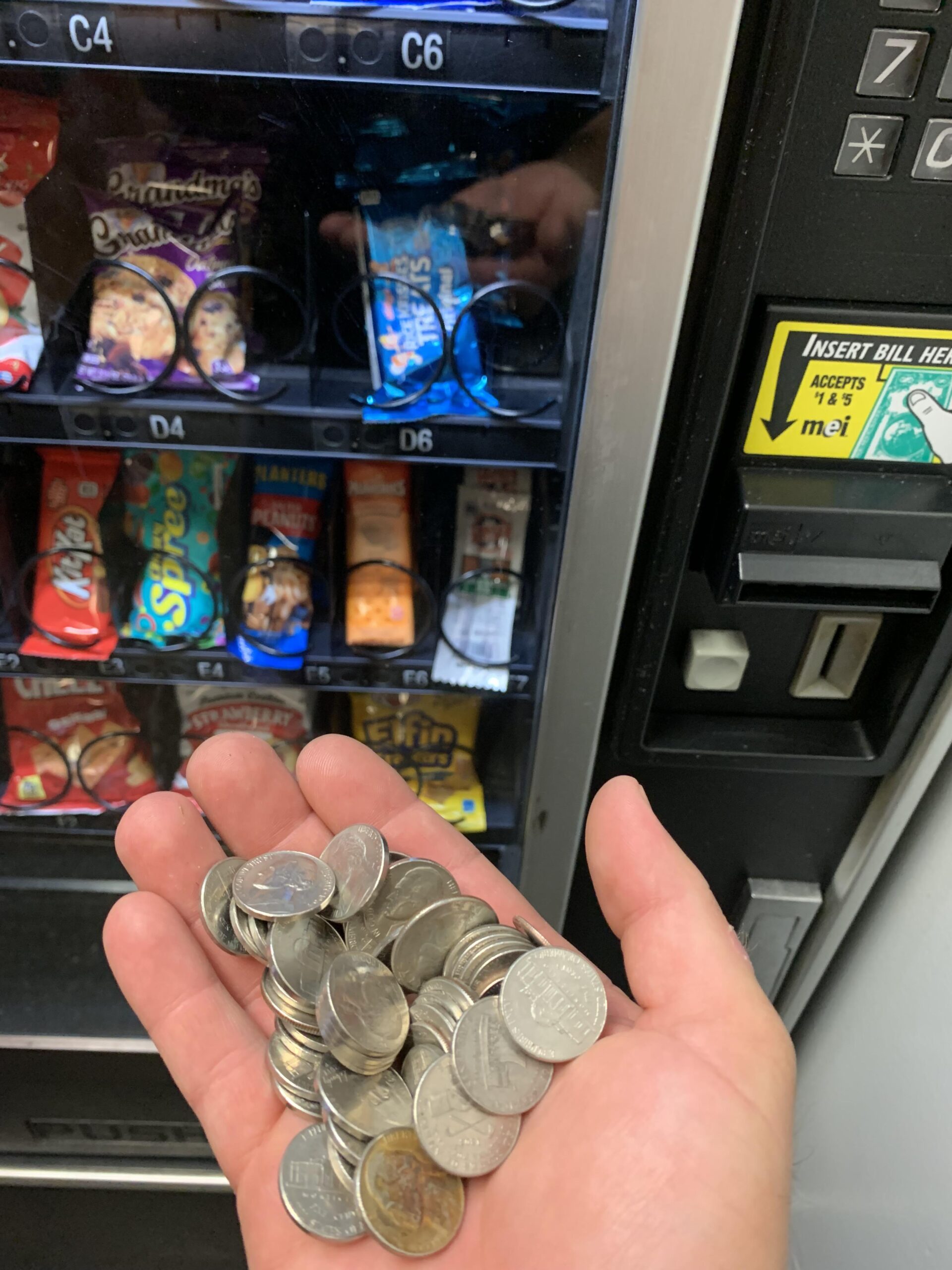

Related Video: How Do Vending Machines Detect Fake Coins?

Strategic Material Selection Guide for do vending machines take 5 dollar bills

When selecting materials for vending machines that accept five-dollar bills, it is essential to consider various factors that can influence performance, durability, and compliance with international standards. Below is an analysis of several common materials used in the construction of vending machines, specifically focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand various environmental conditions. Its temperature rating can vary depending on the specific grade, but it generally performs well in both high and low temperatures.

Pros & Cons:

Stainless steel is highly durable and resistant to rust, making it suitable for outdoor installations. However, it can be more expensive than other materials, and manufacturing processes may require specialized techniques, increasing costs.

Impact on Application:

Due to its corrosion resistance, stainless steel is ideal for vending machines in humid or coastal areas where exposure to moisture is a concern. It is compatible with various media, including food and beverages.

Considerations for International Buyers:

Buyers from Africa, South America, the Middle East, and Europe should ensure compliance with local health and safety standards. Common standards such as ASTM and DIN may apply, and preferences for specific grades (e.g., 304 or 316) may vary by region.

2. Aluminum

Key Properties:

Aluminum is lightweight, has good corrosion resistance, and offers decent strength-to-weight ratios. It is also relatively easy to machine and form into complex shapes.

Pros & Cons:

The primary advantage of aluminum is its low weight, which can reduce shipping costs and ease installation. However, it is less durable than stainless steel and may dent or scratch more easily, leading to potential aesthetic issues over time.

Impact on Application:

Aluminum is suitable for indoor vending machines or those in protected environments. Its compatibility with various media is generally good, but it may not be ideal for high-temperature applications.

Considerations for International Buyers:

When sourcing aluminum components, buyers should verify compliance with local regulations regarding recyclability and environmental impact. Standards such as JIS may be relevant in Asian markets.

3. Polycarbonate

Key Properties:

Polycarbonate is a high-performance plastic known for its impact resistance and transparency. It can withstand a range of temperatures, making it suitable for various environments.

Pros & Cons:

The major advantage of polycarbonate is its lightweight nature and high impact resistance, which can reduce the risk of breakage. However, it may not be as durable as metals and can be susceptible to scratching and UV degradation over time.

Impact on Application:

Polycarbonate is often used for transparent panels in vending machines, allowing customers to see products. Its compatibility with food products is generally good, but UV exposure can lead to discoloration.

Considerations for International Buyers:

Buyers should ensure that polycarbonate materials meet food safety standards in their respective regions. Compliance with regulations such as REACH in Europe may also be necessary.

4. Carbon Steel

Key Properties:

Carbon steel is a strong material with good tensile strength, but it is susceptible to corrosion unless properly coated or treated.

Pros & Cons:

Carbon steel is cost-effective and widely available, making it a popular choice for many applications. However, its susceptibility to rust can limit its use in environments with high humidity or exposure to moisture.

Impact on Application:

While carbon steel can be used in vending machines, it is typically limited to non-visible components or those that are adequately protected with coatings. Compatibility with various media is good, but corrosion can be a concern.

Considerations for International Buyers:

Buyers should be aware of the need for protective coatings and may need to consider local standards for corrosion resistance. Compliance with ASTM standards is common in many regions.

Summary Table

| Material | Typical Use Case for do vending machines take 5 dollar bills | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outer casing and internal components | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Indoor vending machines | Lightweight and easy to install | Less durable, prone to dents/scratches | Medium |

| Polycarbonate | Transparent panels for product visibility | High impact resistance | Susceptible to UV degradation | Medium |

| Carbon Steel | Non-visible components with protective coatings | Cost-effective and strong | Susceptible to corrosion | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions when sourcing materials for vending machines that accept five-dollar bills.

In-depth Look: Manufacturing Processes and Quality Assurance for do vending machines take 5 dollar bills

The manufacturing processes and quality assurance measures for vending machines, particularly those capable of accepting five-dollar bills, require a thorough understanding of the production stages and compliance with international standards. This section outlines the critical aspects of manufacturing, quality control, and actionable insights for B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe.

Manufacturing Processes

1. Material Preparation

The manufacturing process for vending machines begins with careful material selection. Typically, manufacturers use high-quality steel for the frame to ensure durability and resistance to wear and tear. Components such as electronic bill validators, coin mechanisms, and control panels are often made from specialized plastics and electronic materials that can withstand frequent usage.

Key Techniques:

– Material Sourcing: Establish relationships with reliable suppliers who provide certified materials to ensure compliance with international standards.

– Pre-Processing: Materials are cut, shaped, and pre-treated (e.g., powder coating) to prevent corrosion and enhance aesthetics.

2. Forming

In this stage, the prepared materials are shaped into the necessary components of the vending machine. This involves several sub-processes:

- Sheet Metal Fabrication: Using techniques like laser cutting and CNC machining, manufacturers create the various panels and frames.

- Injection Molding: For plastic components, injection molding is employed to produce precise parts such as buttons and housing for electronic components.

Best Practices:

– Invest in advanced machinery to ensure precision in forming parts, which can significantly reduce assembly time and improve the overall quality of the machine.

3. Assembly

The assembly phase involves fitting together all manufactured components, including mechanical and electronic systems. This includes:

- Mechanical Assembly: Attaching the frame, installing the bill acceptor, coin mechanism, and other hardware.

- Electrical Assembly: Integrating wiring, circuit boards, and the user interface.

Techniques:

– Lean Manufacturing: Implement lean principles to optimize the assembly process, reduce waste, and enhance efficiency.

4. Finishing

After assembly, the vending machines undergo finishing processes that enhance their appearance and functionality. This includes painting, applying decals, and conducting final checks to ensure all components are securely installed.

Illustrative Image (Source: Google Search)

Considerations:

– Ensure that the finishing materials used (like paints and coatings) comply with environmental regulations, which can vary by region.

Quality Assurance

Quality assurance is paramount in manufacturing vending machines, especially those designed to accept five-dollar bills. Adhering to international standards can help mitigate risks and improve product reliability.

Relevant International Standards

- ISO 9001: This standard provides a framework for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Standards: In specific markets, adherence to American Petroleum Institute (API) standards may also be necessary, especially for electronic components.

Quality Control Checkpoints

To ensure quality throughout the manufacturing process, several checkpoints are established:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to verify they meet specified standards.

- In-Process Quality Control (IPQC): Conducting checks during various manufacturing stages to catch defects early in the process.

- Final Quality Control (FQC): Performing comprehensive testing of the finished product to ensure it functions correctly and meets all specifications.

Common Testing Methods

- Functional Testing: Assessing the operation of the vending machine, including the ability to accept five-dollar bills.

- Durability Testing: Simulating extended use to ensure reliability under typical operational conditions.

- Safety Testing: Ensuring compliance with electrical safety standards to protect users.

Verifying Supplier Quality Control

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are actionable steps:

- Supplier Audits: Conduct regular audits of your suppliers to assess their compliance with quality standards and manufacturing practices. This can be done in-person or through third-party services.

- Quality Reports: Request detailed quality control reports from suppliers, documenting their processes and results from various checkpoints.

- Third-Party Inspections: Engage third-party inspection services to verify the quality of goods before shipment. This provides an unbiased assessment and helps mitigate risks associated with poor quality.

QC and Certification Nuances for International Buyers

International buyers must navigate varying certification requirements across regions. For example, while CE marking is essential in Europe, other markets may prioritize different certifications. Additionally, understanding local regulations regarding the acceptance of cash (like five-dollar bills) can impact machine design and functionality.

Actionable Insights:

– Stay informed about regional regulations and standards that may affect your purchasing decisions.

– Build strong relationships with suppliers who are well-versed in international compliance to facilitate smoother transactions.

By understanding the manufacturing processes and quality assurance measures involved in vending machines, particularly those that accept five-dollar bills, B2B buyers can make informed purchasing decisions that ensure quality, compliance, and reliability in their investments.

Related Video: Business English Vocabulary : VV 47 – Manufacturing & Production Process (1) | English Vocabulary

Comprehensive Cost and Pricing Analysis for do vending machines take 5 dollar bills Sourcing

When sourcing vending machines that accept $5 bills, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis highlights the various cost components, price influencers, and actionable tips tailored for buyers in Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary materials involved in manufacturing vending machines include metals, plastics, and electronic components. The quality and source of these materials can significantly affect the overall cost. For instance, using durable, high-quality materials may increase initial costs but can lead to lower maintenance and repair expenses over time.

-

Labor: Labor costs vary by region and are influenced by local wage standards. In regions with higher labor costs, manufacturers may pass these expenses onto buyers. Buyers should consider the labor market in the manufacturing country when evaluating total costs.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, which can be beneficial for price competitiveness.

-

Tooling: The cost of specialized tools and molds required for producing vending machines can be substantial. Custom tooling for unique specifications may lead to higher upfront costs, but these can be amortized over larger production runs.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability and longevity, which is particularly important for vending machines that will be used in public spaces. While this can increase costs, it reduces the risk of defects and subsequent warranty claims.

-

Logistics: Transportation costs depend on the shipping method, distance, and Incoterms. International shipping can introduce additional complexities, such as customs duties and tariffs, which should be factored into the total cost.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the expected margin for your region can help in negotiations and budgeting.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for discounts, significantly affecting unit pricing. Buyers should assess their demand to maximize cost efficiency.

-

Specifications/Customization: Customized features, such as specific payment systems or branding, can increase costs. It’s essential to clearly define requirements to avoid unexpected charges.

-

Materials and Quality Certifications: Higher quality certifications (e.g., ISO) can enhance product reliability but may also lead to increased costs. Buyers should balance quality with budget constraints.

-

Supplier Factors: Supplier reputation, experience, and reliability can influence pricing. Established suppliers may charge a premium but often provide better support and quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial as they define the responsibilities of buyers and sellers in shipping. They can impact overall costs related to logistics and insurance.

Buyer Tips

-

Negotiation: Engage in negotiations to secure favorable pricing, especially for bulk orders. Leverage competitor quotes to strengthen your position.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, operational costs, maintenance, and potential resale value. This approach can lead to better long-term financial decisions.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and local economic conditions that might affect pricing. Additionally, understanding local market trends can provide leverage in negotiations.

-

Due Diligence: Conduct thorough research on potential suppliers, including reviews and case studies, to ensure reliability and quality.

Disclaimer

The prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific project requirements. Always seek updated quotes and conduct a detailed cost analysis before making purchasing decisions.

Spotlight on Potential do vending machines take 5 dollar bills Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘do vending machines take 5 dollar bills’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for do vending machines take 5 dollar bills

When considering the purchase of vending machines that accept five-dollar bills, it is crucial to understand various technical properties and industry terminology that can significantly impact your buying decision. This knowledge will help you navigate the complexities of vending machine specifications and ensure that you make informed purchases that meet your operational needs.

Essential Technical Properties

-

Bill Acceptor Mechanism

– The bill acceptor is a critical component that determines whether a vending machine can accept five-dollar bills. Look for machines equipped with advanced acceptance technology that can handle various bill types and conditions (e.g., crumpled or worn). This feature reduces the likelihood of transaction errors and enhances customer satisfaction. -

Material Grade

– The materials used in the construction of vending machines influence durability and reliability. Stainless steel is commonly used for its resistance to corrosion and wear, making it suitable for high-traffic environments. Understanding material grades helps buyers assess the longevity of the equipment, which can lead to lower maintenance costs over time. -

Transaction Processing Speed

– This specification indicates how quickly a vending machine can process payments. A faster transaction speed enhances customer experience, particularly in busy locations. Machines that process transactions in less than 10 seconds are generally preferred, as they minimize wait times and improve overall sales. -

Power Requirements

– Vending machines have specific power needs that must be met for optimal operation. Understanding voltage and amperage requirements is essential, especially when considering machines for different regions, like Africa or South America, where power supply can vary. Ensuring compatibility with local electrical standards can prevent operational disruptions. -

Size and Capacity

– The physical dimensions and product capacity of vending machines are critical for space management and product offerings. Evaluate the size against your intended installation location and the volume of products you wish to offer. A machine with a larger capacity can lead to fewer restocking trips, ultimately improving efficiency. -

Security Features

– Security is paramount in vending operations. Look for features such as tamper-proof designs, secure locks, and surveillance capabilities. These features help protect your investment against theft and vandalism, which is particularly important in high-risk areas.

Industry and Trade Terminology

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable vendors and ensure that they are purchasing high-quality components compatible with their machines. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest number of units that a supplier is willing to sell. Knowing the MOQ helps businesses plan their inventory purchases and negotiate better terms with suppliers, especially when considering bulk orders for vending machines or spare parts.

-

RFQ (Request for Quotation)

– An RFQ is a document that buyers send to suppliers to request pricing and other details for specific products. This process is essential for comparing offers from multiple vendors, ensuring competitive pricing and favorable terms. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps buyers understand shipping costs, insurance responsibilities, and risk transfer, which is crucial when importing vending machines from other regions. -

Lead Time

– Lead time refers to the period between placing an order and receiving the product. Understanding lead times is vital for inventory planning and ensuring that vending machines are available when needed, particularly in competitive markets. -

Warranty and Support Terms

– Warranty terms outline the conditions under which the manufacturer will repair or replace faulty equipment. Familiarity with warranty details can save buyers from unexpected costs and ensure proper support throughout the machine’s lifespan.

By grasping these essential technical properties and industry terms, international B2B buyers can make better-informed decisions when sourcing vending machines that accept five-dollar bills, ultimately leading to more successful operations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the do vending machines take 5 dollar bills Sector

Market Overview & Key Trends

The vending machine industry has witnessed significant transformations driven by technological advancements and changing consumer behaviors. Global drivers include the increasing demand for convenience, a rise in cashless transactions, and the integration of smart technology into vending machines. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for strategic sourcing decisions.

Current and emerging B2B tech trends encompass the adoption of IoT (Internet of Things) for real-time inventory management and customer interaction. Machines equipped with touchscreens and mobile payment options are becoming standard, enhancing user experience and operational efficiency. Additionally, data analytics is enabling operators to optimize product offerings based on consumer preferences, leading to increased sales.

The market dynamics are also shaped by regional variances. In Europe, there is a push towards healthier snack options, while in Africa, the focus is on affordability and accessibility. The Middle East is seeing a surge in luxury vending machines offering gourmet food and beverages. For South American buyers, the integration of local flavors and products is key to capturing market interest.

B2B buyers should consider these trends when sourcing vending machines, focusing on suppliers who can offer innovative solutions that align with regional consumer demands and technological advancements.

Sustainability & Ethical Sourcing in B2B

In the context of vending machines, sustainability is becoming a critical factor for B2B buyers. The environmental impact of vending machines includes energy consumption and waste generated from packaging. As consumers increasingly prioritize eco-friendly options, businesses must adapt to this demand by sourcing machines that utilize energy-efficient technologies and sustainable materials.

The importance of ethical supply chains cannot be overstated. Buyers should prioritize vendors who demonstrate commitment to responsible sourcing practices, such as fair labor standards and environmentally friendly production methods. Green certifications, such as LEED (Leadership in Energy and Environmental Design) or Energy Star ratings, can help buyers identify machines that meet stringent environmental standards.

Illustrative Image (Source: Google Search)

Additionally, using biodegradable or recyclable materials for packaging and machine components can enhance a company’s sustainability profile. By investing in eco-friendly vending solutions, businesses not only meet regulatory requirements but also appeal to a growing demographic of environmentally conscious consumers.

Brief Evolution/History

The vending machine sector has evolved significantly since its inception in the late 19th century. Originally designed to dispense simple products like postcards and cigarettes, vending machines have transformed into sophisticated devices capable of offering a wide range of goods, from snacks to electronics.

The introduction of cashless payment systems in the early 2000s marked a pivotal shift, enabling greater convenience and accessibility. Today, the focus is on integrating advanced technologies such as AI and IoT, enhancing not only operational efficiency but also the overall customer experience. This evolution reflects broader trends in consumer behavior and technology, presenting new opportunities for B2B buyers to capitalize on innovative solutions in the vending machine market.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of do vending machines take 5 dollar bills

-

What types of vending machines accept $5 bills?

Most modern vending machines are equipped with bill acceptors that can process various denominations, including $5 bills. It is essential to confirm with the supplier that the specific model you are considering has this capability. Additionally, machines designed for higher transaction volumes, often found in locations like airports and shopping malls, typically include advanced bill acceptors. Always request a demonstration or detailed specifications to ensure compatibility with your local currency. -

How can I vet suppliers for vending machines that accept $5 bills?

When vetting suppliers, consider their experience in the vending machine market and their reputation for quality. Look for reviews from previous clients, request references, and check if they have certifications like ISO 9001 for quality management. Additionally, assess their responsiveness and willingness to provide documentation, such as product specifications and warranty details. Engaging with suppliers at trade shows or industry events can also provide insights into their credibility and product offerings. -

What customization options are available for vending machines?

Customization can vary widely among manufacturers. Most suppliers will offer branding options, such as customized colors and logos, as well as the ability to select product offerings tailored to your target market. Some machines allow for specific configurations, such as temperature settings for food items. It’s crucial to discuss your requirements early in the negotiation process to ensure the supplier can meet your needs and to understand any additional costs associated with customization. -

What are the typical minimum order quantities (MOQ) and lead times?

MOQs can differ significantly based on the supplier and the complexity of the vending machines. For standard models, MOQs might range from 5 to 20 units, while customized machines could require larger orders. Lead times also vary, typically ranging from 4 to 12 weeks, depending on the level of customization and the supplier’s production capacity. Always clarify these details upfront to align your purchasing strategy with your operational needs. -

What payment options should I expect when purchasing vending machines?

Payment terms can vary widely by supplier and region. Common options include upfront payments, partial deposits, or payment upon delivery. Some suppliers might offer financing options or extended payment terms for larger orders. It’s advisable to negotiate terms that align with your cash flow and budget constraints. Additionally, ensure that any payment methods accepted are secure and that you receive a clear invoice detailing all costs associated with your order. -

How can I ensure quality assurance and certification for vending machines?

Quality assurance should be a top priority when sourcing vending machines. Request documentation regarding the manufacturer’s quality control processes, including any certifications like CE, UL, or ISO standards. Conducting a factory audit can also provide insights into their manufacturing practices. Additionally, inquire about warranty terms and after-sales support, as these can indicate the supplier’s commitment to quality and customer satisfaction. -

What logistics considerations should I take into account when importing vending machines?

When importing vending machines, consider shipping methods, customs duties, and import regulations specific to your region. It is advisable to work with a logistics partner experienced in handling such equipment to navigate these complexities. Additionally, ensure that the supplier provides proper packaging to prevent damage during transit. Clarifying delivery timelines and responsibilities for customs clearance can help streamline the process and reduce unexpected delays. -

How should disputes with suppliers be handled?

Disputes can arise over various issues, such as product quality, delivery delays, or payment disputes. Establishing clear communication channels and a formal dispute resolution process in your contract is vital. Options might include mediation, arbitration, or legal action, depending on the severity of the issue. Document all communications and agreements to support your case if disputes escalate. It is also beneficial to have a local legal advisor familiar with international trade laws to guide you through the resolution process.

Strategic Sourcing Conclusion and Outlook for do vending machines take 5 dollar bills

In conclusion, understanding whether vending machines accept $5 bills is pivotal for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Key takeaways include the importance of selecting vending machines equipped with modern payment systems that accommodate various currencies and denominations, including $5 bills. This capability not only enhances customer convenience but also optimizes cash flow management for businesses.

Strategic sourcing plays a crucial role in this context. By partnering with manufacturers and suppliers that prioritize versatile payment solutions, businesses can ensure a seamless purchasing experience for their customers. Additionally, investing in machines that support digital payment methods can further streamline operations and appeal to a tech-savvy clientele.

Looking ahead, it is essential for B2B buyers to stay informed about evolving payment technologies and customer preferences. By doing so, businesses can adapt their offerings to meet market demands effectively. Take action now: evaluate your vending machine suppliers and consider how you can enhance your payment options to stay competitive in the global marketplace.