Your Ultimate Guide to Sourcing Convenience Store Vending

Guide to Convenience Store Vending Machine

- Introduction: Navigating the Global Market for convenience store vending machine

- Understanding convenience store vending machine Types and Variations

- Key Industrial Applications of convenience store vending machine

- Strategic Material Selection Guide for convenience store vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for convenience store vending machine

- Comprehensive Cost and Pricing Analysis for convenience store vending machine Sourcing

- Spotlight on Potential convenience store vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for convenience store vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the convenience store vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of convenience store vending machine

- Strategic Sourcing Conclusion and Outlook for convenience store vending machine

Introduction: Navigating the Global Market for convenience store vending machine

In today’s fast-paced retail landscape, convenience store vending machines have emerged as a pivotal solution for maximizing sales and enhancing customer satisfaction. These machines not only provide quick access to a variety of products but also cater to the evolving consumer demand for convenience and efficiency. For international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe, understanding the intricacies of vending machine options is crucial.

This comprehensive guide delves into the multifaceted world of convenience store vending machines, covering essential topics including types of machines, materials used in manufacturing, quality control processes, reliable suppliers, cost considerations, and the current market landscape. Additionally, it addresses frequently asked questions, providing a holistic view that empowers buyers to make informed decisions.

By leveraging the insights presented in this guide, B2B buyers can strategically evaluate their options, ensuring they select vending machines that align with their operational needs and budget constraints. Whether you are looking to enhance your product offerings or streamline operations, understanding the global market for convenience store vending machines is essential for driving growth and remaining competitive. Equip yourself with the knowledge to navigate this dynamic sector and make sourcing decisions that will elevate your business.

Understanding convenience store vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Snack Vending | Dispenses packaged snacks and beverages | Convenience stores, offices | Pros: Low initial cost, easy to stock. Cons: Limited product variety, lower profit margins. |

| Fresh Food Vending | Refrigerated units for perishable items like sandwiches | Airports, universities | Pros: Attracts health-conscious consumers. Cons: Higher maintenance costs and spoilage risk. |

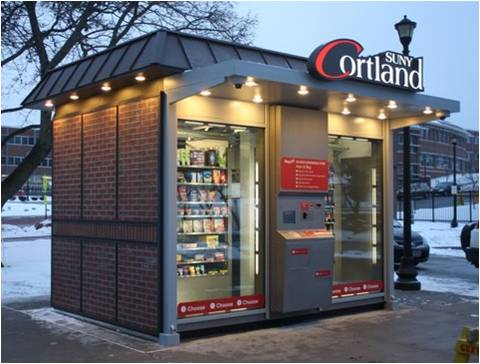

| Automated Retail Kiosks | Touchscreen interfaces, diverse product range | Shopping malls, train stations | Pros: Interactive experience, can sell non-food items. Cons: Higher upfront investment, tech dependency. |

| Coffee and Beverage Machines | Specializes in hot beverages, often with customization | Office break rooms, cafes | Pros: High demand, repeat customers. Cons: Requires regular maintenance and supply of fresh ingredients. |

| Specialty Vending Machines | Focused on niche markets (e.g., beauty products, electronics) | Airports, high-end retail | Pros: Unique offerings can drive sales. Cons: Potentially limited customer base, higher costs. |

Traditional Snack Vending

Traditional snack vending machines are the most common type found in convenience stores. They typically offer a range of packaged snacks and beverages, making them suitable for high-traffic areas such as schools and offices. When considering a purchase, B2B buyers should evaluate the machine’s capacity, ease of stocking, and reliability. These machines generally have a lower initial investment but may yield lower profit margins due to competition and limited product variety.

Fresh Food Vending

Fresh food vending machines are designed to store and dispense perishable items, such as sandwiches, salads, and fruits. Ideal for locations with health-conscious consumers, such as airports and universities, these machines require refrigeration and more frequent maintenance. Buyers should assess the spoilage risk and the cost of maintaining temperature control systems. While they attract a niche market, their higher operational costs can impact profitability.

Automated Retail Kiosks

Automated retail kiosks are advanced vending solutions equipped with touchscreen interfaces that allow for a wide range of product offerings, including electronics and personal care items. These machines are suitable for high-traffic areas like shopping malls and train stations, providing an interactive shopping experience. Buyers should consider the technology’s reliability and support services, as these units often require significant upfront investment and ongoing tech maintenance.

Coffee and Beverage Machines

Specialized in dispensing hot beverages, coffee machines are popular in office break rooms and cafes. They often allow customization of drinks, appealing to a broad customer base. B2B buyers should focus on the machine’s maintenance requirements and the supply chain for fresh ingredients. While these machines can create loyal customers and higher sales volumes, they also demand regular upkeep and ingredient management.

Specialty Vending Machines

Specialty vending machines cater to niche markets, offering products like beauty items or electronics. These machines can be strategically placed in high-end retail locations or airports. Buyers should evaluate the uniqueness of the offerings and potential customer interest, as these machines can drive sales in specific demographics. However, they come with a higher initial cost and may target a limited customer base, which can affect overall profitability.

Related Video: Machine Learning in 2024 – Beginner’s Course

Key Industrial Applications of convenience store vending machine

| Industry/Sector | Specific Application of Convenience Store Vending Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Automated Food and Beverage Sales | Increases sales volume, reduces labor costs | Stock management systems, payment integration options |

| Transportation | Travel Retail and Snack Dispensing | Enhances customer experience, convenience | Compact design, robust construction for high foot traffic |

| Healthcare | Pharmaceutical and Health Product Dispensing | Improves access to essential medications | Compliance with health regulations, temperature control |

| Education | Campus Snack and Beverage Services | Provides quick access to food, supports student life | Variety of offerings, user-friendly interface |

| Event Management | On-site Refreshments and Merchandise | Streamlines service delivery, reduces queue times | Custom branding options, flexible payment methods |

Retail: Automated Food and Beverage Sales

In the retail sector, convenience store vending machines are increasingly being utilized to automate food and beverage sales. This application addresses the challenge of managing labor costs while meeting consumer demand for quick, accessible food options. For international buyers, especially in regions like Africa and South America, it’s vital to consider stock management systems that can help maintain inventory levels and ensure product freshness. Additionally, integrating various payment options can cater to diverse customer preferences.

Transportation: Travel Retail and Snack Dispensing

In transportation hubs, such as airports and train stations, convenience store vending machines serve as efficient snack dispensing solutions. They enhance the customer experience by providing quick access to refreshments, which is crucial during travel. For buyers from the Middle East and Europe, selecting machines with a compact design and robust construction is essential to withstand high foot traffic. Moreover, ensuring that the machines are equipped with contactless payment options can significantly improve user convenience.

Healthcare: Pharmaceutical and Health Product Dispensing

In the healthcare industry, convenience store vending machines can be deployed to dispense pharmaceuticals and health products, providing patients with easy access to essential medications outside of pharmacy hours. This application is particularly beneficial in regions with limited healthcare access. International buyers, particularly from Africa, should prioritize machines that comply with health regulations and feature temperature control systems to ensure the integrity of sensitive products.

Education: Campus Snack and Beverage Services

Convenience store vending machines are an excellent fit for educational institutions, offering snacks and beverages that cater to student needs. They provide a quick and efficient way for students to access food between classes, fostering a better campus experience. Buyers in Europe and South America should focus on machines that offer a variety of healthy options and user-friendly interfaces, as these features can significantly enhance student satisfaction and encourage usage.

Event Management: On-site Refreshments and Merchandise

During events, convenience store vending machines can streamline the service delivery of refreshments and merchandise, reducing wait times and enhancing the overall attendee experience. This application is particularly valuable for event organizers looking to maximize efficiency. For international buyers, it’s crucial to consider custom branding options for machines to align with event themes, as well as flexible payment methods that accommodate a diverse audience.

Related Video: DIY Vending Machine – Arduino based Mechatronics Project

Strategic Material Selection Guide for convenience store vending machine

When selecting materials for convenience store vending machines, it is essential to consider factors such as durability, cost, and compatibility with various media. The following analysis examines four common materials used in the construction of vending machines, highlighting their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. It typically has a temperature rating of up to 800°C (1472°F) and can handle pressures up to 2000 psi, depending on the grade.

Pros & Cons:

The primary advantage of stainless steel is its durability and resistance to rust and stains, making it ideal for high-traffic environments. However, it is relatively expensive compared to other materials, and its manufacturing can be complex due to the need for specialized welding techniques.

Impact on Application:

Stainless steel is compatible with a variety of media, including food and beverages, making it a preferred choice for vending machines. Its resistance to corrosion ensures that it maintains hygiene standards.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure compliance with local health and safety regulations. In Europe, adherence to standards such as EN 10088 for stainless steel is crucial, while buyers in the Middle East may need to consider additional certifications related to food safety.

2. Aluminum

Key Properties:

Aluminum is lightweight, has good corrosion resistance, and can handle moderate temperature fluctuations. It typically has a temperature rating of about 600°C (1112°F) and is suitable for pressures up to 1500 psi.

Pros & Cons:

Aluminum’s lightweight nature makes it easy to transport and install, which can reduce overall costs. However, it is less durable than stainless steel and may not withstand heavy impacts or extreme conditions as well.

Impact on Application:

Aluminum is suitable for non-corrosive media but may not be ideal for high-temperature applications. Its use in vending machines often focuses on structural components rather than areas in direct contact with food or beverages.

Considerations for International Buyers:

B2B buyers should verify that aluminum grades comply with international standards such as ASTM B221. In regions like the UK, ensuring that the aluminum is sourced from sustainable practices may also be a consideration.

3. Polycarbonate

Key Properties:

Polycarbonate is a robust thermoplastic known for its impact resistance and transparency. It can withstand temperatures up to 135°C (275°F) and has good UV resistance.

Pros & Cons:

The key advantage of polycarbonate is its lightweight nature and high impact resistance, making it ideal for transparent panels in vending machines. However, it can be more susceptible to scratching and may not be suitable for high-temperature environments.

Impact on Application:

Polycarbonate is often used for display windows and protective covers, allowing visibility of products while providing safety. It is compatible with various media, but caution should be taken with hot items.

Considerations for International Buyers:

Buyers should ensure that polycarbonate products meet standards such as ISO 11607 for packaging materials. In regions like Africa and South America, sourcing from manufacturers with certifications for quality and safety can be beneficial.

4. Mild Steel

Key Properties:

Mild steel is a versatile material with good strength and weldability. It typically has a temperature rating of around 300°C (572°F) and can handle pressures up to 1000 psi.

Pros & Cons:

Mild steel is cost-effective and easy to work with, making it suitable for various structural components in vending machines. However, it is prone to corrosion and requires protective coatings or treatments to enhance durability.

Impact on Application:

Mild steel is best suited for non-corrosive environments or where protective coatings are applied. It is often used for frames and supports in vending machines.

Considerations for International Buyers:

Compliance with standards such as ASTM A36 is essential for quality assurance. Buyers in the Middle East should be aware of the need for additional protective coatings due to the humid climate.

Summary Table

| Material | Typical Use Case for convenience store vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, food contact surfaces | Excellent corrosion resistance | High cost, complex manufacturing | High |

| Aluminum | Structural components, non-food contact areas | Lightweight, easy to install | Less durable than stainless steel | Medium |

| Polycarbonate | Display panels, protective covers | High impact resistance, visibility | Susceptible to scratching | Medium |

| Mild Steel | Frames, supports | Cost-effective, easy to work with | Prone to corrosion | Low |

This guide provides a comprehensive overview of material selection for convenience store vending machines, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for convenience store vending machine

The manufacturing process for convenience store vending machines involves several critical stages that ensure the final product meets quality and functionality standards. Understanding these processes is essential for B2B buyers looking to invest in vending machines for their operations. This section will outline the main stages of manufacturing, key techniques employed, and the quality assurance measures that are vital for maintaining international standards.

Manufacturing Processes

Material Preparation

The first stage in manufacturing vending machines is material preparation. This involves sourcing high-quality materials that can withstand the rigors of outdoor usage and frequent interaction with customers. Common materials include:

Illustrative Image (Source: Google Search)

- Metal Alloys: Often used for the structural framework due to their durability and resistance to wear and tear.

- Plastics: Used for components such as panels and coin mechanisms, offering lightweight and corrosion-resistant options.

- Electronic Components: Sourced from certified suppliers to ensure reliability in payment processing and machine operation.

Buyers should ensure that suppliers have robust sourcing strategies and can provide certifications for the materials used, as this impacts the longevity and performance of the machines.

Forming

Once materials are prepared, they undergo various forming processes. Key techniques include:

- CNC Machining: Precision cutting and shaping of metal parts to ensure they fit together seamlessly.

- Injection Molding: Used for plastic components, allowing for complex shapes and designs that can enhance user interaction.

- Sheet Metal Fabrication: Essential for creating the outer casing of the vending machine, ensuring it is sturdy and aesthetically appealing.

B2B buyers should inquire about the specific technologies and machinery used in forming processes, as advanced techniques can lead to higher precision and better overall quality.

Assembly

The assembly stage is where all components come together. This stage typically follows these steps:

- Subassembly Creation: Smaller components are assembled into modules (e.g., refrigeration units, payment systems).

- Main Assembly Line: The subassemblies are integrated into the main structure of the vending machine.

- Quality Checks: As each module is added, quality checks are performed to ensure functionality and fit.

For buyers, understanding the assembly process can provide insights into the efficiency of production and the potential for customization based on specific needs.

Finishing

The final stage is finishing, which includes:

- Surface Treatment: Processes such as powder coating or painting to enhance durability and aesthetics.

- Functional Testing: Machines undergo rigorous testing to ensure all components work correctly, including payment processing, refrigeration, and user interface.

Finishing is crucial for the machine’s resilience against environmental factors, particularly for operations in regions with extreme weather conditions.

Quality Assurance

Quality assurance is an integral part of the manufacturing process, ensuring that vending machines meet both international standards and specific industry requirements.

International Standards

B2B buyers should be familiar with the following standards:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers maintain consistent quality and continual improvement.

- CE Marking: A certification indicating that the machine meets European health, safety, and environmental protection standards.

Understanding these certifications helps buyers assess the credibility and reliability of suppliers.

Industry-Specific Standards

In addition to general standards, there are industry-specific certifications that may be relevant:

- API (American Petroleum Institute): Important for vending machines dispensing fuel or related products.

- UL (Underwriters Laboratories): Certifies safety standards for electrical components.

Buyers should verify that the machines they are considering have the necessary certifications relevant to their market.

Quality Control Checkpoints

Quality control (QC) checkpoints play a crucial role in maintaining product quality. Key checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to identify defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product before it leaves the factory.

These checkpoints help mitigate risks associated with faulty machines and enhance customer satisfaction.

Common Testing Methods

To verify quality, manufacturers may employ various testing methods, including:

- Functional Testing: Ensures that all features, such as payment processing and product dispensing, work correctly.

- Durability Testing: Simulates real-world usage to assess how well the machine performs under stress.

- Safety Testing: Verifies that the machine adheres to safety regulations, particularly regarding electrical components.

Verifying Supplier QC

B2B buyers can take several steps to ensure that their suppliers maintain rigorous quality control:

- Audits: Conduct regular audits of suppliers’ facilities to assess their quality management systems.

- Quality Reports: Request detailed quality reports and certifications from suppliers to verify compliance with standards.

- Third-Party Inspections: Engage third-party inspection services to conduct unbiased assessments of product quality before shipment.

Quality Control Considerations for International Buyers

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, it is vital to consider the following nuances:

- Regulatory Compliance: Each region may have specific regulations governing the operation of vending machines. Ensure that suppliers are knowledgeable about these requirements.

- Cultural Preferences: Understand local consumer behavior and preferences, which may influence machine design and product offerings.

- Logistical Challenges: Consider the logistics of shipping and installation in different regions, which may affect the choice of vending machine features.

By understanding the manufacturing processes and quality assurance measures associated with convenience store vending machines, international B2B buyers can make informed decisions that enhance their operational efficiency and customer satisfaction.

Related Video: Amazing scenes。Top 6 Most Popular Factory Manufacturing Videos in China

Comprehensive Cost and Pricing Analysis for convenience store vending machine Sourcing

When sourcing convenience store vending machines, a thorough understanding of the cost structure and pricing dynamics is essential for international B2B buyers. This analysis will cover key cost components, price influencers, and provide actionable tips for effective negotiation and sourcing strategies.

Cost Components

-

Materials: The primary materials include metal, plastic, and electronic components. The choice of materials significantly impacts the cost; for example, high-quality stainless steel may increase durability but also the price. Buyers should consider the long-term benefits of investing in better materials.

-

Labor: Labor costs can vary widely based on the manufacturing location. For instance, labor in countries with higher wage standards (like parts of Europe) will contribute more to the overall cost compared to regions with lower wages (like parts of Africa and South America).

-

Manufacturing Overhead: This includes utilities, rent, and general operational costs. A factory’s efficiency and technology adoption can affect overhead costs. Companies employing automation may offer lower prices due to reduced labor costs.

-

Tooling: Specific tooling is required for manufacturing vending machines, which can be a significant upfront cost. Customization of machines may necessitate unique tooling, further increasing initial expenses.

-

Quality Control (QC): Implementing rigorous QC processes ensures the reliability of machines, but it also adds to costs. Buyers should inquire about the supplier’s QC measures to balance cost and quality.

-

Logistics: Shipping costs can vary based on distance, weight, and shipping method. Buyers should consider Incoterms that clarify responsibilities for shipping costs and risks, which can influence the total cost.

-

Margin: Suppliers typically include a profit margin that can range from 10% to 30%, depending on competition and demand. Understanding market dynamics can provide leverage during negotiations.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to significant discounts. Buyers should assess their needs to maximize cost-efficiency.

-

Specifications/Customization: Custom features increase production costs. Buyers should weigh the necessity of specific features against budget constraints.

-

Materials and Quality Certifications: Machines with certifications (like ISO) may come at a premium, but they often ensure better quality and compliance with international standards.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more but offer better service and assurance.

-

Incoterms: Understanding the implications of different Incoterms is crucial. For example, FOB (Free on Board) may shift some costs to the buyer, affecting overall pricing.

Buyer Tips

-

Negotiation: Always negotiate prices. Suppliers may have room for discounts, especially for larger orders or long-term contracts.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. Cheaper machines may incur higher long-term costs due to reliability issues.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, machines sourced from Europe may be pricier due to higher labor and material costs compared to those from Asia or Africa.

-

Research and Comparison: Conduct thorough research on multiple suppliers and compare their offerings. This can provide insights into fair market pricing and help in negotiations.

-

Quality Assurance: Prioritize suppliers who offer warranties and after-sales support. This can save costs in maintenance and replacements in the long run.

Disclaimer

Prices for convenience store vending machines can vary significantly based on the factors mentioned above. The figures provided in discussions are indicative and should be verified with suppliers for accurate quotes based on specific requirements and conditions.

Spotlight on Potential convenience store vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘convenience store vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for convenience store vending machine

Key Technical Properties of Convenience Store Vending Machines

When purchasing vending machines for convenience stores, international B2B buyers should be aware of several critical technical properties that affect performance, durability, and customer satisfaction. Here are essential specifications to consider:

-

Material Grade

The materials used in vending machines significantly impact their durability and resistance to wear. Common materials include high-grade stainless steel for the exterior and high-density polyethylene (HDPE) for internal components. Buyers should ensure that the machines are built to withstand varying environmental conditions, especially in regions like Africa and the Middle East, where heat and humidity can be extreme. -

Capacity and Configuration

This refers to the number of products the vending machine can hold and the arrangement of those products. Machines come in various configurations, such as snack-only, beverage-only, or combined. Understanding the capacity helps buyers select machines that fit their location’s demand and space constraints, maximizing sales opportunities. -

Power Consumption

Efficiency ratings, often expressed in kilowatt-hours (kWh), are vital for assessing operational costs. Machines with lower power consumption are more cost-effective in the long run, especially for businesses in regions where electricity costs are high. This is particularly relevant for buyers in South America and Africa, where energy efficiency can lead to substantial savings. -

User Interface Technology

The sophistication of the user interface, such as touchscreen technology or mobile payment compatibility, can enhance customer experience. A modern interface attracts more customers and increases sales, making it essential for buyers to consider the technology available in the machines they are evaluating. -

Temperature Control Systems

For vending machines that offer perishable items, effective temperature control is crucial. Machines should have reliable refrigeration systems to maintain product freshness and safety. Buyers should verify the temperature ranges and the machine’s ability to recover quickly from door openings, which is vital in hot climates. -

Safety and Compliance Standards

Machines must meet local and international safety standards to ensure safe operation. Buyers should check for certifications such as CE (European Conformity) or ISO standards, particularly in Europe and the Middle East, to ensure compliance with regulations.

Common Trade Terms in Vending Machine Procurement

Understanding industry jargon is crucial for effective communication and negotiation in vending machine procurement. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce products that are sold by another company under its brand name. Buyers should consider OEM options for better pricing and reliability, as these manufacturers often provide higher quality and support. -

MOQ (Minimum Order Quantity)

This is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for buyers to manage inventory and cash flow, especially when entering new markets or testing new products. -

RFQ (Request for Quotation)

An RFQ is a document that buyers use to solicit price quotes from suppliers. It is essential for ensuring competitive pricing and evaluating multiple suppliers before making a purchasing decision. -

Incoterms (International Commercial Terms)

These are a set of predefined international rules that clarify the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms helps buyers understand shipping costs and risks associated with international transactions. -

Lead Time

This term refers to the time it takes from placing an order to receiving the goods. Understanding lead times is essential for planning inventory and ensuring that vending machines are available when needed, particularly in fast-paced retail environments. -

Warranty Period

This is the time frame during which the manufacturer guarantees the machine’s performance and will repair or replace defective parts. Buyers should carefully review warranty terms to protect their investment and minimize potential downtime.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing convenience store vending machines, ultimately enhancing their business operations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the convenience store vending machine Sector

Market Overview & Key Trends

The convenience store vending machine sector is experiencing a significant transformation driven by technological advancements and changing consumer behaviors. Globally, the rise of contactless payments, cashless transactions, and smart vending solutions are reshaping the landscape. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

Key trends include the integration of IoT technology, enabling real-time inventory management and predictive analytics. This shift allows operators to optimize stock levels, reduce waste, and enhance customer satisfaction. Additionally, the growing demand for healthy and locally sourced products is prompting manufacturers to innovate their offerings, catering to health-conscious consumers. Buyers should consider suppliers who can provide diverse product ranges that align with these preferences.

Furthermore, emerging markets in Africa and South America present unique opportunities for growth. As urbanization increases, the need for convenient retail solutions rises, making vending machines an attractive option for both new entrants and established brands. Understanding regional preferences and adapting to local market conditions can provide a competitive edge in these expanding markets.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming increasingly important in the convenience store vending machine sector. International B2B buyers must consider the environmental impact of their sourcing decisions. The use of eco-friendly materials, such as biodegradable plastics and energy-efficient technologies, is essential for reducing the carbon footprint of vending operations.

Ethical sourcing practices are also gaining traction, with a focus on transparent supply chains and fair labor practices. Buyers should prioritize suppliers who demonstrate commitment to sustainability through certifications such as Fair Trade, Rainforest Alliance, or other ‘green’ credentials. These certifications not only assure the integrity of the supply chain but also enhance brand reputation among environmentally conscious consumers.

Moreover, implementing recycling programs within vending operations can significantly reduce waste. Encouraging customers to recycle packaging can foster a sense of community responsibility and promote a positive brand image. B2B buyers should seek partners that align with these sustainability goals to ensure long-term success and compliance with increasing regulatory requirements.

Brief Evolution/History

The convenience store vending machine sector has evolved significantly since its inception in the early 20th century. Initially focused on simple snack and beverage dispensing, the industry has embraced technological advancements, particularly in the last two decades. The introduction of cashless payment systems, touchless interfaces, and smart technology has not only improved user experience but also expanded the range of products offered.

Today, vending machines can serve fresh food, healthy snacks, and even personal care items, adapting to consumer trends and preferences. This evolution is particularly relevant for B2B buyers, as the shift towards automation and customization in vending solutions creates new opportunities for businesses to engage with customers in innovative ways. Understanding this historical context helps buyers appreciate the trajectory of the market and the potential for future developments.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of convenience store vending machine

-

What should I consider when vetting suppliers for convenience store vending machines?

When vetting suppliers, focus on their industry experience, reputation, and client testimonials. Check for certifications relevant to your market, such as ISO or CE, which indicate quality and compliance with international standards. Additionally, assess their production capabilities, including technology and materials used, to ensure they can meet your specific needs. Engaging in a trial order or requesting samples can also help gauge product quality and service reliability. -

Can I customize the vending machines to fit my brand?

Yes, many suppliers offer customization options for convenience store vending machines. This can include branding through colors, logos, and graphics, as well as modifications in size, design, and features. Discuss your requirements upfront to determine the extent of customization available and any additional costs associated with it. Be sure to consider how these customizations align with your target market and operational needs. -

What are the typical minimum order quantities (MOQ) and lead times for vending machines?

MOQs vary by supplier, but they can range from a few units to several dozen, depending on the manufacturer’s production capacity and your customization requests. Lead times can also differ significantly, typically ranging from 4 to 12 weeks. It’s advisable to confirm these details during your initial discussions with suppliers to plan your inventory and marketing strategies effectively. -

What payment terms should I expect when sourcing vending machines internationally?

Payment terms can vary widely depending on the supplier’s policies and your negotiation. Common terms include a deposit (usually 30-50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer credit terms for established buyers. Always clarify payment methods accepted, such as wire transfers or letters of credit, and ensure they align with your financial processes to mitigate risks. -

What quality assurance (QA) measures should I look for in vending machines?

Quality assurance measures can include rigorous testing for durability, functionality, and safety standards. Look for suppliers who provide detailed QA documentation, including test results and certifications. Additionally, inquire about their warranty policies and after-sales support, as these can be indicators of a supplier’s commitment to quality and customer satisfaction. -

How should I approach logistics when importing vending machines?

Logistics planning is crucial when importing vending machines. Collaborate with your supplier to understand their shipping options and timelines. Consider working with a freight forwarder experienced in handling such equipment to navigate customs regulations and tariffs effectively. Be proactive in discussing insurance options for your shipment to protect against potential damage during transit. -

What steps can I take to resolve disputes with my supplier?

To resolve disputes, maintain clear and professional communication with your supplier, documenting all interactions. Identify the root cause of the dispute and propose a solution that is fair for both parties. If direct negotiation fails, consider mediation or arbitration as alternatives to legal action. Establishing a clear contract that outlines dispute resolution processes at the outset can also help in mitigating issues later. -

Are there specific certifications I need to check for when sourcing vending machines?

Yes, certifications can vary by region and product type, but common ones include CE marking for compliance with European health and safety standards, and UL certification for safety in North America. For African and South American markets, local certifications may apply. Always check with local regulatory bodies to ensure compliance and ask suppliers for relevant certification documentation to avoid legal issues.

Strategic Sourcing Conclusion and Outlook for convenience store vending machine

In conclusion, the strategic sourcing of convenience store vending machines presents a significant opportunity for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. By understanding regional market demands, leveraging technological advancements, and prioritizing supplier relationships, businesses can enhance their competitive edge. Key takeaways include the importance of local market adaptability, sustainability initiatives, and customer engagement strategies to cater to diverse consumer needs.

Investing in innovative vending solutions not only increases operational efficiency but also elevates the customer experience, driving sales and brand loyalty. As the vending machine landscape evolves, staying abreast of emerging trends and technologies will be crucial.

International B2B buyers are encouraged to act now—evaluate your current vending strategies, explore potential suppliers, and assess the latest machine features. By making informed sourcing decisions today, you can position your business for success in the dynamic convenience store market of tomorrow. Embrace the future of vending; the opportunity for growth is at your fingertips.