Your Ultimate Guide to Sourcing Champagne Vending Machine

Guide to Champagne Vending Machine

- Introduction: Navigating the Global Market for champagne vending machine

- Understanding champagne vending machine Types and Variations

- Key Industrial Applications of champagne vending machine

- Strategic Material Selection Guide for champagne vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for champagne vending machine

- Comprehensive Cost and Pricing Analysis for champagne vending machine Sourcing

- Spotlight on Potential champagne vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for champagne vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the champagne vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of champagne vending machine

- Strategic Sourcing Conclusion and Outlook for champagne vending machine

Introduction: Navigating the Global Market for champagne vending machine

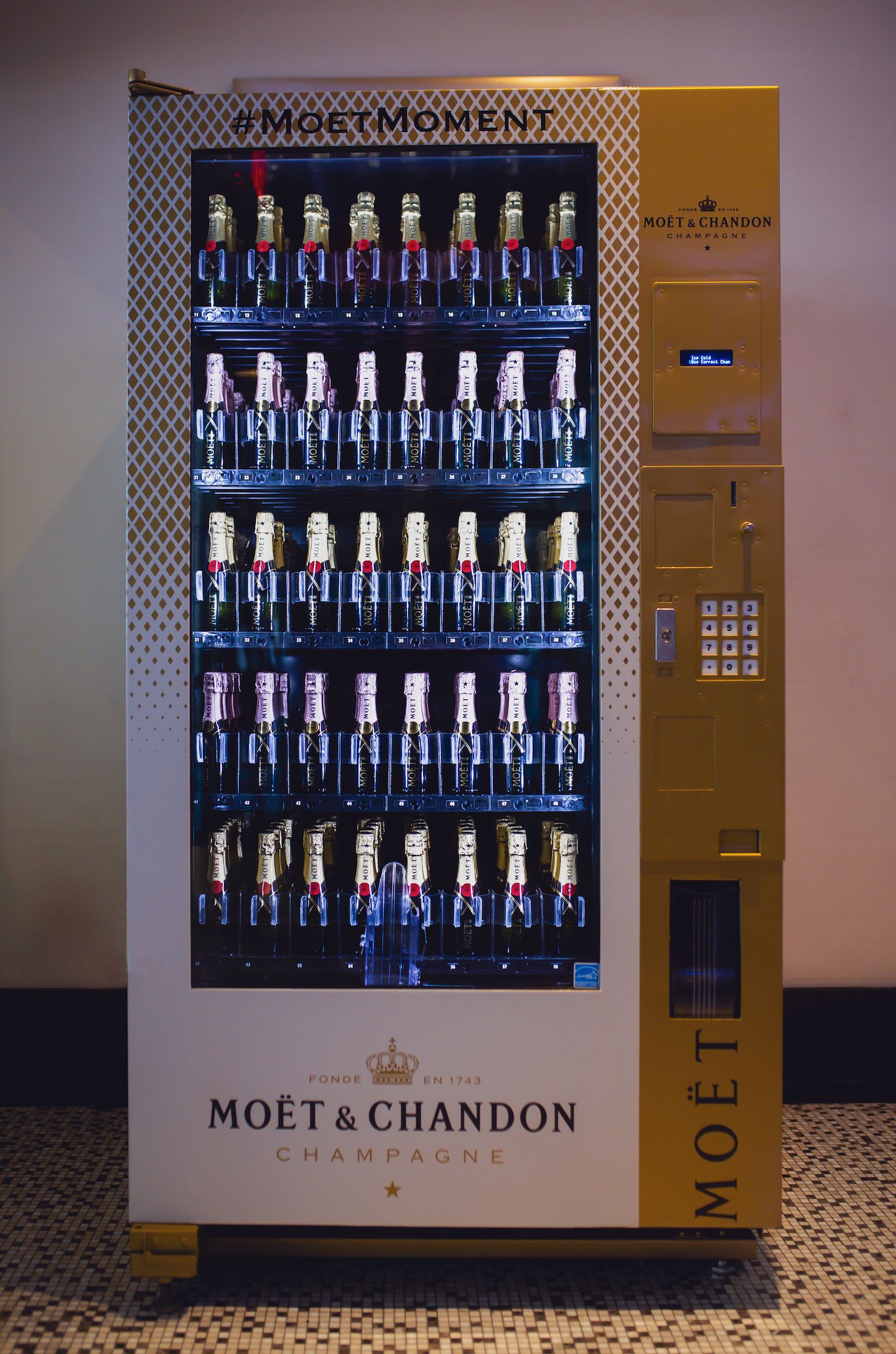

In an era where convenience meets luxury, champagne vending machines represent a unique fusion of technology and indulgence, capturing the attention of businesses across the globe. These innovative machines offer a streamlined way to serve premium sparkling wines, making them an attractive investment for venues ranging from upscale restaurants to event spaces. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the dynamics of this niche market is essential for making informed sourcing decisions.

This comprehensive guide delves into the various types of champagne vending machines available, exploring their construction materials, manufacturing processes, and quality control measures. Buyers will gain insights into reputable suppliers and pricing structures, ensuring they can navigate the complexities of the market with confidence. Furthermore, we address frequently asked questions that arise when considering such a purchase, enhancing your knowledge base and strategic approach.

As the demand for unique consumer experiences continues to rise, champagne vending machines not only elevate service offerings but also drive revenue growth. By utilizing this guide, B2B buyers can align their procurement strategies with current market trends, ensuring they remain competitive and responsive to consumer desires. Whether you’re looking to enhance a luxury venue in Paris or introduce a novel concept in Johannesburg, this guide serves as your roadmap to successfully navigating the global market for champagne vending machines.

Understanding champagne vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Vending Machine | Standard design with glass front and coin slot | Restaurants, hotels, event venues | Pros: Familiar design, easy maintenance. Cons: Limited to traditional payment methods. |

| Smart Vending Machine | Equipped with touch screens and digital payment options | Airports, shopping malls, luxury venues | Pros: Enhanced user experience, diverse payment options. Cons: Higher initial investment. |

| Mobile Champagne Cart | Portable unit with a selection of champagne brands | Outdoor events, festivals, private parties | Pros: Flexibility and mobility, attractive for events. Cons: Limited stock capacity. |

| Automated Wine Dispenser | Combines champagne with wine offerings, usually temperature controlled | Wine bars, upscale restaurants | Pros: Versatile beverage options, temperature control. Cons: More complex maintenance. |

| Custom Branded Vending Machine | Personalized design and branding opportunities | Corporate events, promotional activities | Pros: Strong brand visibility, tailored customer experience. Cons: Longer lead time for production. |

Traditional Vending Machine

Traditional champagne vending machines feature a standard design, typically with a glass front and coin slot for transactions. They are primarily used in restaurants, hotels, and event venues where ease of use and maintenance are crucial. B2B buyers should consider the familiarity of this design, which appeals to a broad audience. However, the limited payment methods may restrict sales in regions where cashless transactions are preferred.

Smart Vending Machine

Smart vending machines are characterized by touch screens and the ability to accept various digital payment options, making them ideal for high-traffic areas like airports and shopping malls. These machines enhance the customer experience through user-friendly interfaces and can offer real-time inventory updates. For B2B buyers, investing in smart vending machines can lead to increased sales and customer satisfaction, although the initial investment is higher compared to traditional models.

Mobile Champagne Cart

The mobile champagne cart is a versatile option that allows for the sale of champagne at outdoor events, festivals, and private parties. Its portability makes it attractive for businesses looking to cater to dynamic environments. While the flexibility and eye-catching design can drive sales, B2B buyers should be aware of the limited stock capacity, which may necessitate frequent restocking during larger events.

Automated Wine Dispenser

Automated wine dispensers often include champagne alongside a selection of wines, featuring temperature control for optimal serving conditions. These machines are suitable for wine bars and upscale restaurants, offering a diverse beverage selection. B2B buyers should consider the versatility of these dispensers, as they can appeal to a wider customer base. However, the complexity of maintenance and potential technical issues may be a drawback for some operators.

Custom Branded Vending Machine

Custom branded vending machines allow businesses to personalize the design and branding, making them ideal for corporate events and promotional activities. This type of machine enhances brand visibility and creates a tailored customer experience. For B2B buyers, the ability to align the vending machine with corporate branding can be a significant advantage, though it may involve longer lead times for production and setup.

Key Industrial Applications of champagne vending machine

| Industry/Sector | Specific Application of champagne vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality & Events | Automated champagne service at upscale events | Enhances guest experience, reduces service staff needs | Machine size, payment integration, service support |

| Retail | Luxury retail environments | Attracts high-end clientele, increases sales opportunities | Product selection, machine aesthetics, warranty terms |

| Corporate Offices | Employee perks in high-end offices | Boosts employee satisfaction, enhances company culture | Maintenance plans, ease of use, product availability |

| Entertainment Venues | Champagne service in nightclubs and lounges | Increases revenue per guest, creates a unique selling point | Durability, energy efficiency, compliance with local laws |

| Tourism | Tourist attractions and landmarks | Provides a unique experience, enhances brand image | Location suitability, local partnerships, machine branding |

Hospitality & Events

In the hospitality sector, champagne vending machines can be strategically placed at upscale events, such as weddings or corporate gatherings. This innovation allows for a seamless and automated champagne service, enhancing the guest experience while minimizing the need for dedicated service staff. For international B2B buyers, understanding local preferences for champagne brands and ensuring compliance with health regulations is crucial. Additionally, sourcing machines that are easy to maintain and offer a variety of payment options can significantly improve service efficiency.

Retail

In luxury retail environments, champagne vending machines serve as an attractive feature that draws in high-end clientele. This unique offering not only enhances the shopping experience but also provides an additional revenue stream through increased sales opportunities. Buyers in this sector should consider the aesthetics of the machine, ensuring it aligns with the brand image, as well as the selection of products offered. Establishing partnerships with local champagne producers can also enhance the machine’s appeal.

Corporate Offices

For corporate offices, particularly those in high-end sectors, champagne vending machines can act as a unique employee perk. This amenity boosts employee satisfaction and contributes to a positive company culture. When sourcing these machines, companies should focus on ease of use, maintenance plans, and the availability of popular champagne brands. Understanding the local market’s preferences can also help in selecting the right products to offer, ensuring that the machine meets employee expectations.

Entertainment Venues

In nightclubs and lounges, champagne vending machines can elevate the nightlife experience by offering quick and efficient service. This not only increases revenue per guest but also creates a unique selling point that differentiates the venue from competitors. Buyers in this sector should prioritize machines that are durable and energy-efficient, as they will endure high usage rates. Additionally, compliance with local laws regarding alcohol sales is essential to avoid legal complications.

Tourism

For tourist attractions and landmarks, champagne vending machines can provide visitors with a unique and memorable experience. This not only enhances the brand image of the attraction but also serves as an additional revenue source. When sourcing machines for this application, it’s important to assess location suitability and consider potential local partnerships for branding and marketing. Additionally, ensuring that the machine can handle diverse payment methods will cater to a broad range of international tourists.

Related Video: DIY Vending Machine – Arduino based Mechatronics Project

Strategic Material Selection Guide for champagne vending machine

When selecting materials for champagne vending machines, it is crucial to consider properties that influence performance, durability, and compliance with international standards. Below is an analysis of four common materials used in the construction of these machines, focusing on their characteristics and implications for B2B buyers in diverse markets.

Stainless Steel

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 800°C and is resistant to oxidation.

Pros & Cons: The durability of stainless steel makes it ideal for high-traffic environments, and it is relatively easy to clean, which is essential for hygiene in food and beverage applications. However, it can be more expensive than other materials and may require specialized manufacturing processes, which can increase lead times.

Impact on Application: Stainless steel is compatible with various media, including acidic beverages like champagne, ensuring that the taste and quality are preserved.

Considerations for International Buyers: Buyers from regions like Europe, where standards such as ASTM and DIN are prevalent, will find stainless steel compliant with most regulations. However, in regions like Africa and South America, local sourcing and cost considerations may influence material choice.

Aluminum

Key Properties: Aluminum is lightweight and has good thermal conductivity, making it suitable for applications requiring efficient heat transfer. It typically has a corrosion resistance rating that can be enhanced through anodizing.

Pros & Cons: The light weight of aluminum can reduce shipping costs and ease installation. However, it is less durable than stainless steel and may dent or scratch more easily. Additionally, its lower temperature resistance can be a limitation in certain environments.

Impact on Application: Aluminum is compatible with champagne and other carbonated beverages, but it may require protective coatings to prevent corrosion from acidic components.

Considerations for International Buyers: In markets like the Middle East and South America, where weight and transport costs are critical, aluminum can be an attractive option. Buyers should ensure compliance with local food safety standards, which may vary significantly.

Glass

Key Properties: Glass is non-reactive, providing excellent protection against contamination. It can withstand moderate pressure and temperature variations, depending on the type of glass used.

Pros & Cons: Glass offers an aesthetic appeal and allows customers to see the product, enhancing the buying experience. However, it is fragile and can break easily, posing risks in high-traffic environments. The cost of glass can also be higher than metals, especially for specialized types.

Impact on Application: Glass is ideal for displaying champagne, as it does not alter the taste or quality of the beverage. However, its fragility limits its use in certain high-impact areas.

Considerations for International Buyers: Buyers in Europe may prefer glass for its premium feel, while those in regions with high transportation risks, such as parts of Africa, may need to consider the potential for breakage and additional costs for protective packaging.

Plastic (Food-Grade)

Key Properties: Food-grade plastics, such as polyethylene and polypropylene, are lightweight, resistant to moisture, and can be molded into complex shapes. They typically have a temperature rating of up to 100°C.

Pros & Cons: Plastics are cost-effective and can be produced in various colors and designs, making them attractive for branding. However, they may not withstand high pressures and can degrade over time, especially with exposure to UV light.

Impact on Application: While suitable for holding non-carbonated beverages, plastics may not be ideal for champagne due to potential leaching and taste alteration.

Considerations for International Buyers: In regions like Africa and South America, where cost is a significant factor, food-grade plastics can be a viable option. However, compliance with food safety regulations is essential, as standards can vary widely.

Summary Table

| Material | Typical Use Case for champagne vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, storage tanks | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Aluminum | Frame, decorative elements | Lightweight, cost-effective shipping | Less durable, lower temperature resistance | Medium |

| Glass | Display cases, bottles | Aesthetic appeal, non-reactive | Fragile, higher costs | High |

| Plastic (Food-Grade) | Internal components, non-structural parts | Cost-effective, versatile | Not suitable for high pressure, can degrade | Low |

This strategic material selection guide provides a comprehensive overview of the key materials used in champagne vending machines, highlighting their advantages and limitations. Understanding these factors will empower international B2B buyers to make informed decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for champagne vending machine

The manufacturing process of champagne vending machines is crucial for ensuring that they meet the high standards expected in both functionality and aesthetics. Understanding the stages involved and the quality assurance measures in place can help B2B buyers make informed decisions.

Manufacturing Processes

1. Material Preparation

The initial stage of manufacturing involves selecting high-quality materials that can withstand the operational demands of a champagne vending machine. Common materials include:

- Stainless Steel: For the chassis and internal components due to its durability and resistance to corrosion.

- Glass: For the display and storage compartments to showcase the product aesthetically.

- Plastic Components: Used for the interface and buttons, often requiring specialized polymers that can endure frequent use.

Material sourcing should emphasize sustainability and compliance with international standards, especially for buyers focused on environmental impact.

2. Forming

Forming involves shaping the materials into the required components. Techniques commonly used include:

- CNC Machining: This technique allows for precise shaping of metal parts, ensuring that components fit together seamlessly.

- Injection Molding: Used for creating plastic parts, this method allows for mass production of complex shapes with high precision.

- Bending and Welding: Metal components are often bent and welded to create the frame and structural elements of the vending machine.

Buyers should ensure that their suppliers use advanced machinery and skilled labor, as these factors significantly affect the end product’s quality.

3. Assembly

The assembly phase is where all the components come together. Key aspects include:

- Modular Assembly: Many manufacturers use a modular approach, allowing for easier repairs and upgrades. This is especially important for B2B buyers looking for long-term investment.

- Quality Control Points: Throughout the assembly process, checkpoints are established to catch any defects early. This includes visual inspections and operational testing of key components.

Potential buyers should inquire about the assembly practices of their suppliers to ensure efficiency and quality.

4. Finishing

Finishing touches are crucial to enhance both functionality and aesthetics. This stage typically includes:

- Surface Treatments: Such as powder coating or anodizing to improve durability and resistance to wear.

- Final Assembly and Calibration: Ensuring that all electronic components are functioning correctly and that the machine is calibrated for optimal performance.

A well-finished product not only looks appealing but also assures buyers of its longevity and reliability.

Quality Assurance

Quality assurance is critical in the manufacturing process of champagne vending machines. Adhering to international standards ensures that the machines are safe and reliable for end-users.

Relevant International Standards

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is applicable to all manufacturing processes. Suppliers should be able to provide certification as proof of compliance.

- CE Marking: Required for products sold within the European Economic Area, CE marking indicates that the product meets EU safety, health, and environmental protection standards.

- API Standards: For machines dealing with food and beverages, compliance with API standards is essential to ensure the safety and quality of the products dispensed.

Buyers should prioritize suppliers that demonstrate compliance with these standards to mitigate risks associated with product quality.

Quality Control Checkpoints

To maintain high-quality standards, manufacturers implement various quality control checkpoints, including:

- Incoming Quality Control (IQC): Inspections of raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process to identify defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product, ensuring it meets all operational and safety standards before shipment.

B2B buyers should request details about these checkpoints from suppliers to gauge their commitment to quality.

Common Testing Methods

Testing methods used in the quality assurance process may include:

- Functional Testing: Verifying that all components work as intended.

- Stress Testing: Assessing the machine’s performance under extreme conditions to ensure durability.

- Safety Testing: Ensuring that the machine complies with safety regulations and does not pose risks to users.

Buyers should seek suppliers who provide detailed reports on testing outcomes to ensure transparency.

Verifying Supplier Quality Control

B2B buyers can take several steps to verify the quality control practices of potential suppliers:

- Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand.

- Quality Reports: Requesting detailed quality assurance reports can provide insights into the supplier’s practices and compliance with standards.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control measures.

QC and Certification Nuances for International Buyers

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification:

- Regional Regulations: Different regions may have varying standards and regulations. Understanding these can help buyers avoid compliance issues.

- Cultural Considerations: Engaging with suppliers in different cultural contexts may require adjustments in communication and negotiation styles.

- Logistics and Supply Chain: Buyers should consider the logistical aspects of sourcing, including shipping times and costs associated with international orders.

By understanding the manufacturing processes and quality assurance measures involved in champagne vending machines, B2B buyers can make informed purchasing decisions that align with their business needs and expectations.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for champagne vending machine Sourcing

The cost structure and pricing analysis of champagne vending machines is crucial for international B2B buyers aiming to optimize their sourcing strategies. Understanding the various components of cost and the factors influencing pricing can help buyers make informed decisions and secure favorable deals.

Cost Components

-

Materials: The primary materials used in champagne vending machines include stainless steel, glass, and electronic components. The quality of these materials directly impacts the durability and aesthetic appeal of the machines, which can influence the final price.

-

Labor: Labor costs can vary significantly by region. In countries with higher labor costs, such as those in Western Europe, the manufacturing expenses may be higher compared to regions in Africa or South America where labor costs are generally lower.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and indirect labor. These costs can be a substantial part of the total manufacturing price and should be assessed when evaluating suppliers.

-

Tooling: Initial tooling costs for customization can be significant, especially for bespoke designs. Buyers should consider the implications of tooling costs on the overall budget and seek suppliers who can offer competitive rates.

-

Quality Control (QC): Implementing stringent quality control measures ensures product reliability but adds to the overall cost. Buyers should look for suppliers who prioritize QC as part of their manufacturing process, as this can mitigate long-term risks.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, shipping mode, and local customs can significantly affect logistics costs.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding the typical margins in the industry can help buyers gauge whether they are receiving a fair price.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Larger orders often lead to better pricing due to economies of scale, so buyers should evaluate their purchasing power and negotiate accordingly.

-

Specifications/Customization: Custom features can increase costs. Buyers should clearly outline their specifications to avoid unexpected expenses and ensure they receive competitive quotes.

-

Materials: The choice of materials can drastically alter prices. For instance, opting for high-grade stainless steel or energy-efficient components may lead to higher upfront costs but lower maintenance and operational expenses.

-

Quality/Certifications: Machines that meet higher quality standards or possess specific certifications (e.g., CE, ISO) may command higher prices. However, these certifications can also be indicative of reliability and safety.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers with a proven track record may charge more but can offer better service and reliability.

-

Incoterms: Different Incoterms (International Commercial Terms) can impact the total cost of ownership. Buyers should understand the implications of terms such as FOB (Free On Board) versus CIF (Cost, Insurance, and Freight) in relation to their sourcing strategy.

Buyer Tips

-

Negotiation: Leverage your purchasing volume and long-term relationships to negotiate better terms. Don’t hesitate to ask for discounts or value-added services.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also maintenance, operation, and potential resale value. This holistic approach can lead to better long-term investments.

-

Pricing Nuances: Be aware of regional pricing differences. For example, European markets may have higher initial costs due to stricter regulations, while South American markets may offer lower prices but come with higher logistics costs.

-

Research: Conduct thorough market research to compare prices across suppliers and regions. This can provide valuable insights into fair pricing and help in making informed purchasing decisions.

Disclaimer

Prices and costs mentioned in this analysis are indicative and may vary based on specific supplier quotes, market conditions, and individual buyer circumstances. It is advisable to conduct detailed assessments and obtain multiple quotes to ensure competitive pricing.

Illustrative Image (Source: Google Search)

Spotlight on Potential champagne vending machine Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for champagne vending machine.)*

Essential Technical Properties and Trade Terminology for champagne vending machine

Key Technical Properties of Champagne Vending Machines

Understanding the essential technical properties of champagne vending machines is crucial for B2B buyers seeking to invest in this innovative solution. Here are some critical specifications to consider:

-

Material Grade

The construction material of a vending machine significantly impacts its durability and maintenance. Stainless steel is the most common choice due to its corrosion resistance and aesthetic appeal, especially in high-end environments. For buyers, selecting a machine made from high-grade materials can ensure longevity, reduce replacement costs, and maintain the machine’s appearance. -

Temperature Control Range

Champagne is best served at a specific temperature to preserve its flavor and effervescence. A vending machine equipped with advanced temperature control technology can maintain the champagne within an optimal range (typically 6-9°C). This feature is critical for B2B buyers focused on customer satisfaction and product quality, as serving champagne at the wrong temperature can affect taste and consumer experience. -

Capacity

The capacity of a vending machine determines how many bottles it can hold and dispense. Machines can range from small units that hold a few bottles to larger models capable of housing several dozen. Buyers must assess their target market and expected foot traffic to choose a machine with an appropriate capacity, ensuring efficient service during peak times. -

Payment System Compatibility

Modern vending machines should support multiple payment options, including credit/debit cards, mobile payments, and contactless transactions. This flexibility is essential for attracting a diverse customer base. For B2B buyers, investing in a machine with robust payment system compatibility can lead to increased sales and customer satisfaction. -

User Interface

An intuitive user interface enhances the customer experience by making it easy to select and purchase champagne. Features like touchscreen displays and multilingual support can cater to a broader audience. For businesses, a user-friendly interface can reduce transaction times and improve customer engagement, leading to higher sales. -

Security Features

Given the high value of champagne, security features such as reinforced locks and surveillance systems are crucial. These elements protect the machine from theft and vandalism, safeguarding the investment. B2B buyers should prioritize machines with advanced security features to ensure peace of mind and protect their assets.

Common Trade Terms in the Champagne Vending Machine Industry

Familiarizing yourself with industry jargon can enhance communication with suppliers and streamline the purchasing process. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can help identify quality suppliers and ensure that the vending machines meet specific standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it affects budgeting and inventory management. Knowing the MOQ helps buyers plan their purchases and avoid excess stock. -

RFQ (Request for Quotation)

An RFQ is a document that solicits quotes from suppliers for specific products or services. For buyers, issuing an RFQ can lead to competitive pricing and better deals, making it a strategic tool in procurement. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers as they clarify shipping costs, risk, and delivery responsibilities, ensuring smooth cross-border transactions. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. For B2B buyers, understanding lead times is crucial for inventory planning and ensuring timely availability of machines, especially during peak sales seasons. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the machine and its components. For buyers, assessing warranty terms can help mitigate risks associated with defects and ensure long-term satisfaction with their investment.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when investing in champagne vending machines, optimizing their operations and enhancing customer experiences.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the champagne vending machine Sector

Market Overview & Key Trends

The champagne vending machine sector is experiencing significant growth, driven by changing consumer behaviors and evolving market dynamics. As international B2B buyers look to innovate within their offerings, they should note the increasing demand for convenience and the unique experience these machines provide. Key drivers include a rise in social gatherings, events, and a burgeoning interest in luxury experiences among consumers in Africa, South America, the Middle East, and Europe.

Emerging technologies are also shaping this market. The integration of contactless payment systems, mobile app connectivity, and advanced inventory management software has streamlined operations and improved customer engagement. For buyers, this means sourcing machines that not only dispense high-quality champagne but also incorporate tech features that enhance user experience and operational efficiency.

Another notable trend is the customization of vending machines to cater to local tastes and preferences. For instance, in South America, buyers may consider machines that offer regional sparkling wines alongside traditional champagne, while European markets may prioritize artisanal or organic options. Understanding these regional nuances will be crucial for international buyers looking to establish or expand their presence in this dynamic sector.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a non-negotiable aspect of B2B sourcing in the champagne vending machine sector. The environmental impact of production and distribution processes cannot be overlooked, particularly as consumers increasingly prefer brands that demonstrate a commitment to eco-friendliness. For international buyers, sourcing machines made from sustainable materials and ensuring that the champagne offered is produced using environmentally responsible practices is paramount.

Buyers should also seek out suppliers who prioritize ethical sourcing. This includes ensuring fair labor practices in the production of champagne and utilizing green certifications that validate sustainable practices. For example, look for machines that feature recyclable components and those that utilize energy-efficient technologies. By aligning with suppliers who share these values, B2B buyers can enhance their brand reputation and appeal to a growing segment of environmentally conscious consumers.

Illustrative Image (Source: Google Search)

Furthermore, incorporating sustainability initiatives into the overall business model can lead to cost savings over time, such as reduced waste and energy consumption. As the market moves toward greater transparency, buyers should be proactive in requesting information about the sustainability practices of their suppliers.

Brief Evolution/History

The concept of vending machines has evolved significantly since their inception in the late 19th century. Initially designed for dispensing simple snacks and beverages, the introduction of champagne vending machines marks a notable shift towards luxury and experiential retail. The first champagne vending machines began appearing in high-traffic areas, such as airports and upscale venues, around the mid-2010s.

This evolution reflects broader trends in consumer behavior where convenience and premium experiences are increasingly intertwined. As the market continues to mature, B2B buyers must stay informed about technological advancements and changing consumer preferences to effectively navigate this vibrant sector. The ongoing innovation in machine design and functionality will likely dictate future trends, making it crucial for international buyers to adapt and evolve their sourcing strategies accordingly.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of champagne vending machine

-

What should I consider when vetting suppliers of champagne vending machines?

When vetting suppliers, focus on their industry experience, client references, and production capacity. Verify their certifications, such as ISO standards, which demonstrate quality management. Additionally, assess their financial stability and ability to provide after-sales support. Engaging in due diligence, including site visits or third-party audits, can mitigate risks associated with sourcing from international suppliers. -

Can champagne vending machines be customized to meet specific business needs?

Yes, many manufacturers offer customization options for champagne vending machines. This can include branding, sizes, and features such as payment systems and user interfaces. When discussing customization, clearly communicate your requirements and ask for examples of previous custom projects. Ensure that the supplier can accommodate your specific market preferences, such as bottle sizes popular in your region. -

What are the typical minimum order quantities (MOQs) and lead times for champagne vending machines?

MOQs can vary significantly based on the supplier and the complexity of the machine. Generally, expect MOQs to range from 5 to 50 units. Lead times typically span from 6 to 12 weeks, depending on customization and production schedules. Discuss these factors upfront to align your purchasing plans and avoid delays, especially if you’re launching a new service or entering a competitive market. -

What payment terms should I expect when purchasing champagne vending machines?

Payment terms can differ by supplier and region. Common arrangements include upfront deposits (20-50%) with the balance due upon delivery. Ensure you discuss payment methods, including bank transfers and letters of credit, to find what works best for your financial practices. Additionally, consider negotiating terms that provide flexibility in case of delays in shipment or installation. -

What quality assurance measures should I look for in champagne vending machines?

Quality assurance is critical when sourcing champagne vending machines. Inquire about the supplier’s quality control processes, including testing protocols and inspection standards. Look for products that have passed relevant safety certifications, such as CE marking in Europe or UL certification in the U.S. Request documentation of these certifications to ensure compliance with local regulations in your target market. -

How should I approach logistics for importing champagne vending machines?

Logistics planning is essential for ensuring timely delivery and minimizing costs. Consider partnering with logistics providers experienced in handling machinery imports. Discuss shipping options, including freight terms (FOB, CIF) and insurance coverage. Be aware of customs regulations in your country, as specific documentation may be required for importing food and beverage equipment, especially if they involve alcohol. -

What steps can I take to resolve disputes with suppliers?

To manage disputes effectively, establish clear contractual terms that outline responsibilities, timelines, and quality expectations. Include a dispute resolution clause that specifies mediation or arbitration procedures. Maintain open communication with your supplier to address issues as they arise. Document all interactions and agreements to support your position in case of further escalation. -

What after-sales support should I expect from champagne vending machine suppliers?

After-sales support is crucial for the longevity and performance of your vending machines. Confirm that the supplier offers comprehensive support, including installation, maintenance, and troubleshooting assistance. Inquire about warranty terms and the availability of spare parts. A reliable supplier should provide training for your staff on machine operation and maintenance to ensure smooth ongoing operations.

Strategic Sourcing Conclusion and Outlook for champagne vending machine

As the market for champagne vending machines continues to expand, strategic sourcing emerges as a vital component for international B2B buyers. Understanding regional preferences is crucial; for example, while European buyers may prioritize luxury and design, those in Africa and South America might focus on functionality and cost-effectiveness.

Key takeaways include:

– Supplier Diversity: Engaging with a range of suppliers can mitigate risks and enhance innovation. Establishing relationships with local manufacturers can also lead to better pricing and service.

– Quality Assurance: Ensure that the machines meet international quality standards, as this will enhance brand reputation and customer satisfaction.

– Market Research: Continuous analysis of market trends will help buyers anticipate changes in consumer preferences, enabling proactive sourcing decisions.

Looking ahead, the champagne vending machine market presents significant growth opportunities across diverse regions. International B2B buyers are encouraged to adopt a proactive approach, leveraging strategic sourcing to navigate the complexities of this evolving landscape. By embracing innovation and maintaining flexibility in their sourcing strategies, businesses can position themselves for success in this burgeoning market.