Your Ultimate Guide to Sourcing 2 Inch Capsule Vending

Guide to 2 Inch Capsule Vending Machine

- Introduction: Navigating the Global Market for 2 inch capsule vending machine

- Understanding 2 inch capsule vending machine Types and Variations

- Key Industrial Applications of 2 inch capsule vending machine

- Strategic Material Selection Guide for 2 inch capsule vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for 2 inch capsule vending machine

- Comprehensive Cost and Pricing Analysis for 2 inch capsule vending machine Sourcing

- Spotlight on Potential 2 inch capsule vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for 2 inch capsule vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 2 inch capsule vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 2 inch capsule vending machine

- Strategic Sourcing Conclusion and Outlook for 2 inch capsule vending machine

Introduction: Navigating the Global Market for 2 inch capsule vending machine

In an era where convenience and innovation drive consumer engagement, the 2 inch capsule vending machine stands out as a game-changing solution for businesses seeking to enhance their product offerings. These compact machines not only cater to the growing demand for novelty items and collectibles but also present a unique opportunity for B2B buyers to tap into new revenue streams. Whether you’re operating in bustling urban centers or expanding into emerging markets in Africa, South America, the Middle East, and Europe, these vending machines can be a valuable addition to your retail strategy.

This comprehensive guide delves into the multifaceted world of 2 inch capsule vending machines. It covers essential aspects such as types and materials, ensuring you understand the various options available and their suitability for your specific market. Additionally, we explore manufacturing and quality control processes, providing insights into sourcing reliable suppliers who meet international standards.

Understanding cost factors is crucial for making informed purchasing decisions, especially in diverse economic landscapes. This guide also examines current market trends and addresses frequently asked questions, empowering you to navigate this niche market with confidence. By leveraging the insights presented here, international B2B buyers can enhance their sourcing strategies, optimize their investments, and ultimately drive profitability in an increasingly competitive environment.

Understanding 2 inch capsule vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Capsule Vending Machine | Basic design, accepts 2-inch capsules, manual operation | Retail, amusement parks, events | Pros: Affordable, simple design. Cons: Limited capacity, less automation. |

| Electronic Capsule Vending Machine | Digital interface, accepts cash and cards, automated dispensing | Shopping malls, airports, public places | Pros: Higher sales potential, user-friendly. Cons: Higher initial investment, requires power source. |

| Customizable Capsule Vending Machine | Modular design, can be tailored for specific products | Specialty shops, promotional events | Pros: Versatile, can enhance branding. Cons: Potentially higher maintenance costs. |

| High-Capacity Capsule Vending Machine | Larger size, multiple dispensing slots, bulk capacity | Theme parks, large venues | Pros: Increased revenue per transaction, reduced restocking frequency. Cons: Requires more space, higher upfront cost. |

| Eco-Friendly Capsule Vending Machine | Made from sustainable materials, promotes eco-friendly products | Green events, health-focused venues | Pros: Attracts eco-conscious consumers, enhances brand image. Cons: May have limited product range, higher manufacturing costs. |

Standard Capsule Vending Machine

The standard capsule vending machine is the most basic model available, designed to accept 2-inch capsules and operate manually. It is commonly used in retail environments, amusement parks, and events due to its affordability and straightforward design. Buyers should consider the machine’s limited capacity and the necessity for frequent manual restocking, which may impact operational efficiency in high-traffic areas.

Electronic Capsule Vending Machine

This type features a digital interface that allows for cash and card transactions, along with automated dispensing. It is ideal for shopping malls, airports, and other public places where convenience is paramount. While it offers a user-friendly experience and the potential for increased sales, buyers must weigh the higher initial investment and the need for a reliable power source against the benefits of automation.

Customizable Capsule Vending Machine

Customizable machines offer modular designs that can be tailored to dispense specific products, making them suitable for specialty shops and promotional events. Their versatility allows businesses to enhance branding and target niche markets effectively. However, buyers should be aware of potentially higher maintenance costs associated with specialized components and the need for ongoing customization.

High-Capacity Capsule Vending Machine

These machines are designed for larger venues like theme parks, featuring multiple dispensing slots and bulk capacity. They provide an opportunity for increased revenue per transaction and reduce the frequency of restocking. However, businesses must consider the need for more space and the higher upfront costs associated with these machines, which may not be feasible for smaller operations.

Eco-Friendly Capsule Vending Machine

Eco-friendly models are constructed from sustainable materials and often promote eco-conscious products. They are well-suited for green events and health-focused venues, appealing to environmentally aware consumers. While they enhance brand image and attract a specific customer base, buyers should note that these machines may have a limited product range and potentially higher manufacturing costs, which could affect profitability.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of 2 inch capsule vending machine

| Industry/Sector | Specific Application of 2 inch capsule vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Dispensing capsule toys and collectibles | Increases foot traffic, enhances customer engagement | Location suitability, payment integration options |

| Food & Beverage | Selling small snacks or beverages | Quick service, impulse buying opportunities | Compliance with health regulations, product variety |

| Education | Providing educational materials or stationery | Supports learning initiatives, convenient access | Product selection, user-friendly interface |

| Entertainment | Offering novelty items at events or amusement parks | Enhances visitor experience, generates additional revenue | Customization options, durability under outdoor conditions |

| Corporate Gifts | Distributing promotional items or branded merchandise | Boosts brand visibility, engages clients and partners | Branding capabilities, inventory management solutions |

Retail

In the retail sector, 2 inch capsule vending machines are commonly used to dispense capsule toys and collectibles. These machines attract customers, particularly children, increasing foot traffic and enhancing engagement. Retailers in regions like Africa and South America can capitalize on local trends by offering region-specific collectibles. Buyers should consider location suitability, ensuring the machine is placed in high-traffic areas, and explore payment integration options to accommodate diverse customer preferences.

Food & Beverage

The food and beverage industry utilizes 2 inch capsule vending machines to sell small snacks or beverages. This application provides a quick service option that encourages impulse buying, particularly in busy environments such as airports, train stations, and shopping malls. For international buyers, compliance with local health regulations is crucial, alongside ensuring a diverse product variety that caters to regional tastes and dietary restrictions.

Education

In educational settings, these vending machines can dispense educational materials or stationery items, supporting various learning initiatives. By providing convenient access to supplies, schools and universities can enhance the learning experience for students. Buyers in this sector should focus on product selection that aligns with educational goals and ensure the machines feature a user-friendly interface to cater to students of all ages.

Entertainment

The entertainment industry benefits from 2 inch capsule vending machines by offering novelty items at events, amusement parks, or cinemas. These machines enhance the visitor experience and serve as an additional revenue stream. Buyers should consider customization options to align with specific events or themes, and ensure the machines are durable enough to withstand outdoor conditions, especially in regions like the Middle East where climate can be a factor.

Corporate Gifts

For corporate gifting, 2 inch capsule vending machines can be employed to distribute promotional items or branded merchandise. This application boosts brand visibility and engages clients and partners in a unique way. International B2B buyers should look for machines that allow for easy branding and customization, as well as effective inventory management solutions to ensure a seamless gifting experience.

Related Video: How To Make Toy Capsule Vending Machine from Cardboard | Coin-Operated Invention | Easy DIY Craft

Strategic Material Selection Guide for 2 inch capsule vending machine

When selecting materials for a 2-inch capsule vending machine, various factors such as durability, cost, and compatibility with the intended media must be considered. Below, we analyze four common materials used in the construction of these machines, providing insights tailored for international B2B buyers from regions like Africa, South America, the Middle East, and Europe.

1. Stainless Steel (e.g., AISI 304)

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It typically has a temperature rating of up to 870°C (1600°F) and is resistant to various chemicals.

Pros & Cons:

The primary advantage of stainless steel is its durability and aesthetic appeal, making it suitable for high-traffic environments. However, it can be relatively expensive compared to other materials, and its manufacturing process can be complex, often requiring specialized equipment.

Impact on Application:

Stainless steel is particularly well-suited for environments where hygiene is critical, such as in food and beverage vending. It is compatible with a wide range of media, including water, soft drinks, and snacks.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A240 for stainless steel sheets. In regions like Europe, adherence to EN standards is also crucial. The cost may vary significantly based on local availability and tariffs.

2. Plastic (e.g., Polycarbonate)

Key Properties:

Polycarbonate is lightweight, impact-resistant, and has a temperature rating of approximately -40°C to 120°C (-40°F to 248°F). It is also transparent, allowing for visibility of the capsules inside.

Pros & Cons:

The main advantage of polycarbonate is its lower cost and ease of manufacturing, making it suitable for mass production. However, it is less durable than metals and may become brittle over time, especially under UV exposure.

Impact on Application:

This material is ideal for transparent sections of vending machines, allowing customers to see the product. However, it is not suitable for harsh chemical environments.

Considerations for International Buyers:

Buyers should check for compliance with safety standards such as FDA regulations for food contact materials. In regions with high UV exposure, selecting UV-stabilized polycarbonate is advisable.

3. Aluminum (e.g., 6061-T6)

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It typically has a temperature rating up to 150°C (302°F) and is easily machinable.

Pros & Cons:

Aluminum offers a good balance between strength and weight, making it a popular choice for vending machines. However, it can be more expensive than steel and may require protective coatings to enhance corrosion resistance.

Impact on Application:

Aluminum is suitable for both structural and aesthetic components of vending machines. It can withstand various environmental conditions but may not be ideal for highly acidic or alkaline products.

Considerations for International Buyers:

Buyers should ensure compliance with standards like ASTM B221 for aluminum extrusions. In Europe, adherence to EN 573 is essential. The cost can vary based on local market conditions and availability.

4. Mild Steel (e.g., A36)

Key Properties:

Mild steel is known for its good tensile strength and weldability. It typically has a temperature rating of up to 400°C (752°F) but is prone to corrosion without protective coatings.

Pros & Cons:

Mild steel is cost-effective and widely available, making it a popular choice for many applications. However, its susceptibility to rust and corrosion can limit its use in outdoor or humid environments.

Impact on Application:

Mild steel is often used for structural components of vending machines but may require additional treatments, such as painting or galvanizing, to prevent corrosion.

Considerations for International Buyers:

Buyers should be aware of the need for protective coatings in humid climates, especially in regions like Africa and South America. Compliance with standards such as ASTM A36 is also important.

Summary Table

| Material | Typical Use Case for 2 inch capsule vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel (e.g., AISI 304) | Structural and aesthetic components | Excellent durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic (e.g., Polycarbonate) | Transparent sections for visibility | Lightweight and cost-effective | Less durable, can become brittle | Low |

| Aluminum (e.g., 6061-T6) | Structural components and frames | Good strength-to-weight ratio | Higher cost, requires protective coatings | Medium |

| Mild Steel (e.g., A36) | Structural components | Cost-effective and widely available | Prone to corrosion without treatment | Low |

This guide provides a comprehensive overview for international B2B buyers to make informed decisions regarding material selection for 2-inch capsule vending machines, considering both performance and compliance factors relevant to their specific markets.

In-depth Look: Manufacturing Processes and Quality Assurance for 2 inch capsule vending machine

The manufacturing of a 2-inch capsule vending machine is a complex process that involves several stages, from material preparation to quality control, ensuring that the final product meets international standards. This section provides a comprehensive overview of the manufacturing processes, quality assurance protocols, and actionable insights for B2B buyers from Africa, South America, the Middle East, and Europe.

Manufacturing Processes

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Common materials for vending machines include:

- Metal Components: Typically steel or aluminum for structural integrity.

- Plastic Parts: High-density polyethylene (HDPE) or polycarbonate for the vending mechanism and housing.

- Electronic Components: Circuit boards, sensors, and motors.

Key Techniques:

– Material Testing: Before use, materials undergo tests for durability, corrosion resistance, and electrical conductivity.

– Supplier Verification: Establishing relationships with reliable suppliers is critical. Buyers should ensure suppliers have certifications and a history of providing quality materials.

2. Forming

Once materials are prepared, the next stage is forming, which involves shaping the materials into the required components.

Key Techniques:

– CNC Machining: Used for precision cutting of metal parts, ensuring tight tolerances.

– Injection Molding: Commonly used for producing plastic components, allowing for complex shapes and designs.

– Laser Cutting: Employed for creating intricate designs in metal sheets, enhancing the aesthetic appeal of the machine.

3. Assembly

The assembly stage integrates all components into a functional vending machine. This phase is critical as it requires meticulous attention to detail to ensure all parts fit and operate correctly.

Key Techniques:

– Automated Assembly Lines: Utilizing robotics for repetitive tasks increases efficiency and consistency.

– Manual Assembly: Skilled workers perform tasks that require dexterity, such as wiring and fitting electronic components.

– Quality Checks During Assembly: Regular checks are conducted at various points to catch any defects early in the process.

4. Finishing

The final stage involves finishing processes that enhance the machine’s appearance and functionality.

Key Techniques:

– Surface Treatment: Processes such as powder coating or painting protect the machine from environmental factors and provide an appealing finish.

– Final Assembly Inspection: A thorough inspection ensures that the machine meets design specifications and is ready for operation.

Quality Assurance

Quality assurance is critical in the manufacturing of vending machines to ensure reliability and safety. The following standards and practices are essential:

International Standards

- ISO 9001: This standard ensures that organizations have a quality management system in place, focusing on customer satisfaction and continuous improvement.

- CE Marking: Required for products sold in the European Economic Area, it indicates conformity with health, safety, and environmental protection standards.

- API Standards: Relevant for machines that may interact with food products, ensuring that materials are safe and hygienic.

Quality Control Checkpoints

Quality control is integrated throughout the manufacturing process, with specific checkpoints including:

- Incoming Quality Control (IQC): Inspecting materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing checks during the assembly process to identify defects early.

- Final Quality Control (FQC): A comprehensive inspection of the completed machine before shipment.

Common Testing Methods

- Functional Testing: Verifying that all components operate as intended.

- Durability Testing: Simulating long-term use to assess the machine’s reliability.

- Safety Testing: Ensuring compliance with electrical safety standards.

Verifying Supplier Quality Control

For B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial. Here are actionable steps:

- Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes and quality control systems. This can include checking certifications, production capabilities, and previous client feedback.

- Request Quality Reports: Ask suppliers to provide documentation of their quality control processes and outcomes, including any relevant certifications.

- Third-Party Inspections: Engage third-party inspection services to conduct independent assessments of the manufacturing facilities and processes.

QC/Certifications Nuances for International Buyers

International buyers must navigate various regulations and standards that can differ significantly across regions. Here are some considerations:

- Regional Standards: Familiarize yourself with the local regulations in your target market. For example, while CE marking is essential in Europe, different standards may apply in Africa or South America.

- Cultural Considerations: Understand the local business practices and expectations regarding quality and certification. Building relationships with local partners can facilitate smoother transactions and compliance.

- Documentation: Ensure all necessary documentation, including quality certificates and compliance reports, is readily available and understandable in your preferred language.

Conclusion

Understanding the manufacturing processes and quality assurance practices for 2-inch capsule vending machines is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, and implementing rigorous quality control measures, buyers can ensure they procure reliable and compliant machines. Leveraging audits, reports, and third-party inspections will further enhance confidence in supplier capabilities, ultimately leading to successful international partnerships.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for 2 inch capsule vending machine Sourcing

Cost Structure of 2 Inch Capsule Vending Machines

When sourcing 2-inch capsule vending machines, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: This encompasses the cost of raw materials such as metal, plastic, electronic components, and any custom parts required for the machine. Prices can vary based on quality and sourcing regions.

-

Labor: Labor costs involve wages for assembly workers, engineers, and quality control personnel. In regions with higher labor costs, such as parts of Europe, this can significantly impact overall pricing.

-

Manufacturing Overhead: This includes expenses related to utilities, equipment maintenance, and factory space. Efficient manufacturing processes can help reduce these costs.

-

Tooling: The costs associated with molds and dies used for production are a critical factor, especially for customized machines. High tooling costs can affect the price significantly, particularly for low-volume orders.

-

Quality Control (QC): Implementing quality assurance measures ensures that machines meet required standards. This can include testing and certifications, which add to the overall cost.

-

Logistics: Shipping and handling costs are influenced by the size and weight of the machines, as well as the shipping distance. Import tariffs and local taxes in the destination country can also affect the final price.

-

Margin: Supplier profit margins vary significantly based on market competition and perceived value. Buyers should be aware that margins may be higher for customized or specialty machines.

Price Influencers

Several factors influence the pricing of 2-inch capsule vending machines:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often lead to lower unit prices. Suppliers may offer discounts for larger quantities, making it beneficial for buyers to negotiate terms based on anticipated demand.

-

Specifications/Customization: Custom features, such as branding or specific functionality, can lead to increased costs. Buyers should clearly outline their requirements to avoid unexpected expenses.

-

Materials and Quality: Higher quality materials and components will increase the initial cost but may result in lower maintenance and operational costs over time. Certifications (e.g., ISO) can also impact pricing.

-

Supplier Factors: The reputation and experience of the supplier can affect pricing. Established suppliers may charge more due to their reliability and service history.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) dictate who bears responsibility for shipping costs and risks. Understanding these terms is essential for calculating the total landed cost.

Buyer Tips for Cost Efficiency

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation and cost management strategies are vital:

-

Negotiate Terms: Always negotiate payment terms and delivery schedules. Flexibility in these areas can lead to better pricing arrangements.

-

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with maintenance, repairs, and energy consumption, not just the initial purchase price. A more expensive machine may offer better durability and lower operational costs.

-

Understand Pricing Nuances: Be aware of regional pricing differences. For example, sourcing from a local supplier in Spain may reduce shipping costs compared to sourcing from Asia.

-

Utilize Technology: Employ procurement platforms that offer comparative pricing and supplier evaluations to make informed decisions.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and service. Long-term partnerships often yield better terms and flexibility.

Disclaimer

The prices and cost structures outlined in this analysis are indicative and can vary significantly based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable for buyers to conduct thorough research and seek multiple quotes to ensure they are making informed decisions.

Spotlight on Potential 2 inch capsule vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘2 inch capsule vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for 2 inch capsule vending machine

When considering the procurement of a 2-inch capsule vending machine, understanding its essential technical properties and trade terminology is crucial for making informed purchasing decisions. This section outlines key specifications and industry jargon that will aid international B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

Critical Technical Properties

-

Material Grade

– Definition: The quality of materials used in the vending machine, typically stainless steel or high-grade plastics.

– Importance: High-grade materials ensure durability and resistance to corrosion, which is vital for machines placed in various environmental conditions. For instance, machines in humid regions require materials that withstand moisture. -

Tolerance

– Definition: The allowable variation in manufacturing dimensions, often expressed in millimeters.

– Importance: Tighter tolerances enhance the precision of machine components, ensuring smooth operation and reducing maintenance costs. This is particularly important for the dispensing mechanism that must accurately release capsules. -

Power Consumption

– Definition: The amount of electrical energy the vending machine requires to operate, usually measured in watts.

– Importance: Low power consumption is essential for cost-effectiveness and sustainability, especially in regions with limited access to reliable electricity. Buyers should consider energy-efficient models to reduce operational costs. -

Capacity

– Definition: The number of capsules the machine can hold, typically measured in units.

– Importance: A higher capacity machine reduces the frequency of restocking, which can be crucial for businesses in high-traffic areas. Understanding capacity helps in evaluating return on investment (ROI). -

Dispensing Speed

– Definition: The time it takes for the machine to dispense a capsule, usually measured in seconds.

– Importance: Faster dispensing speeds improve customer satisfaction and increase sales volume, particularly in busy locations. This is a key metric for machines positioned in high-demand environments.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Context: Understanding OEM relationships can help buyers identify the source of machine components and their quality standards, essential for maintenance and replacement parts. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units a supplier is willing to sell.

– Context: Knowing the MOQ is vital for budgeting and planning inventory, especially for small businesses or startups that may not need large quantities initially. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers asking for a price quote on specific goods or services.

– Context: An RFQ helps buyers compare prices and terms from different suppliers, ensuring they receive competitive offers tailored to their needs. -

Incoterms

– Definition: International commercial terms that define the responsibilities of buyers and sellers in international transactions.

– Context: Familiarity with Incoterms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is crucial for understanding shipping costs and responsibilities, which can significantly impact total purchase costs. -

Lead Time

– Definition: The time between the initiation of an order and its completion.

– Context: Buyers need to consider lead times when planning inventory and sales strategies, particularly in regions where delivery times may vary significantly.

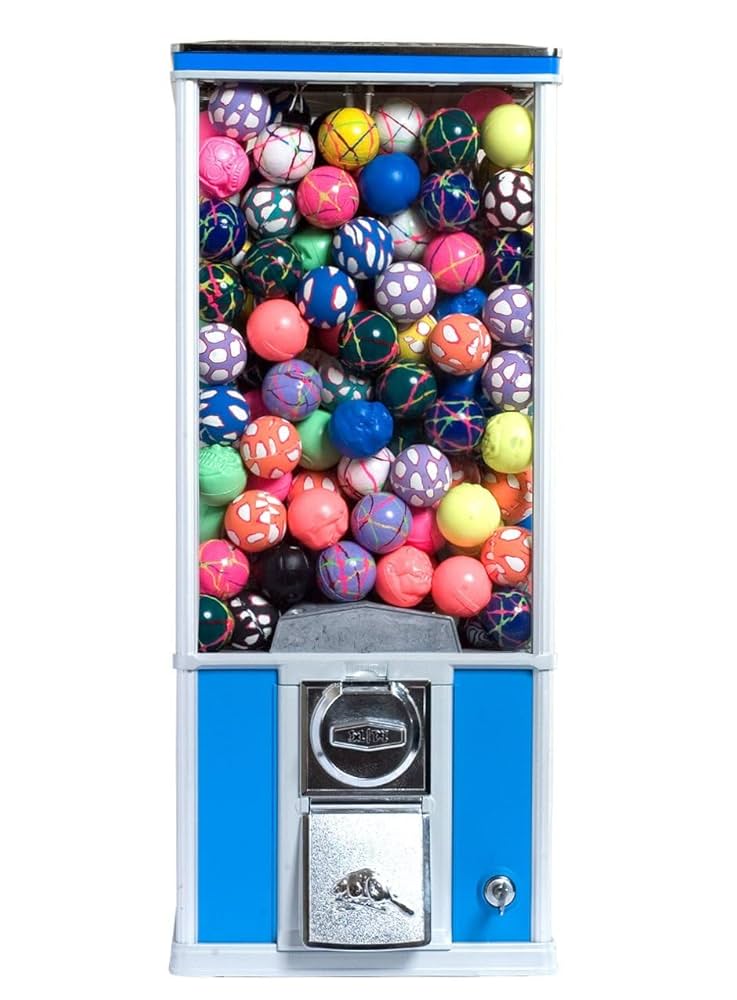

Illustrative Image (Source: Google Search)

By comprehensively understanding these technical properties and trade terms, international B2B buyers can make informed decisions that align with their operational goals and market demands.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 2 inch capsule vending machine Sector

Market Overview & Key Trends

The 2-inch capsule vending machine sector has witnessed significant growth, driven by the global demand for automated retail solutions. Key factors influencing this market include the rising trend of contactless transactions, increased consumer preference for convenience, and the expansion of vending machine services in various sectors such as hospitality, education, and retail. In emerging markets like Africa and South America, the potential for vending machines to serve remote areas with limited access to retail is particularly compelling, offering a unique opportunity for international B2B buyers.

Current technological trends in the sector include the integration of IoT (Internet of Things) capabilities, allowing machines to provide real-time data on inventory and customer preferences. This data can be leveraged by B2B buyers to optimize product offerings and improve operational efficiency. Additionally, the adoption of mobile payment systems and cashless transactions is gaining traction, catering to tech-savvy consumers and enhancing the overall user experience.

Moreover, sustainability is becoming a focal point in sourcing decisions. Buyers are increasingly prioritizing machines that utilize energy-efficient technologies and recyclable materials, aligning with global efforts to reduce environmental footprints. This trend is especially relevant in Europe, where regulatory frameworks around sustainability are robust, but it is also gaining momentum in regions like the Middle East and Africa, where eco-friendly practices are becoming a competitive differentiator.

Sustainability & Ethical Sourcing in B2B

The environmental impact of vending machines, particularly in terms of energy consumption and waste generation, necessitates a shift towards more sustainable practices. For B2B buyers, this means prioritizing suppliers who demonstrate a commitment to sustainability through the use of energy-efficient components and eco-friendly materials.

Ethical sourcing is also critical in this sector. Buyers should seek vendors who adhere to fair labor practices and ensure that their supply chains are transparent and accountable. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Furthermore, the use of biodegradable or recyclable capsules is becoming increasingly important. As consumers become more environmentally conscious, offering products that minimize environmental impact can enhance brand reputation and customer loyalty. B2B buyers should actively inquire about the materials used in the capsules and the vending machines themselves, ensuring they are aligned with sustainability goals.

Brief Evolution/History

The evolution of vending machines dates back to ancient times, with early iterations offering simple goods like coins and holy water. However, the modern 2-inch capsule vending machine emerged in the late 20th century, primarily in the amusement and entertainment sectors. Initially designed to dispense toys and collectibles, these machines have expanded their offerings significantly.

Today, they serve a diverse range of products, including snacks, beverages, and even personal care items, reflecting changing consumer preferences. The shift towards automation and technology integration has further transformed the landscape, making these machines not only a source of convenience but also a vital component of retail strategy for many businesses worldwide. Understanding this historical context can provide B2B buyers with valuable insights into market dynamics and consumer behavior, aiding in more informed sourcing decisions.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of 2 inch capsule vending machine

-

What should I consider when vetting suppliers for 2 inch capsule vending machines?

When vetting suppliers, focus on their experience in manufacturing vending machines, reputation, and customer reviews. Request references from previous clients and assess their response times and communication skills. Also, evaluate their production capacity and quality assurance processes. Certifications such as ISO 9001 can indicate adherence to international quality standards. For international buyers, understanding the supplier’s compliance with local regulations and import/export laws is crucial. -

Can I customize the 2 inch capsule vending machine to fit my branding?

Yes, many manufacturers offer customization options for vending machines. This may include branding with your logo, color schemes, and specific product configurations. Discuss your requirements early in the negotiation process, as customization can affect pricing and lead times. Ensure that the supplier provides clear options and examples of previous custom projects to gauge their capability.

-

What are the typical minimum order quantities (MOQ) and lead times for these machines?

MOQs can vary significantly among suppliers, typically ranging from 10 to 50 units, depending on the manufacturer’s policies and production capacity. Lead times generally range from 4 to 12 weeks, influenced by factors like customization, order size, and supplier location. Always confirm these details before placing an order to avoid unexpected delays in your supply chain. -

What payment terms should I expect when ordering from an international supplier?

Payment terms can vary, but common practices include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers might offer letters of credit or escrow services for added security. It’s vital to clarify payment methods accepted, such as bank transfers or credit cards, and ensure that currency exchange rates are considered if dealing with international transactions. -

How can I ensure quality assurance and certification compliance for my vending machines?

Request documentation for quality certifications such as CE, UL, or ISO standards that the manufacturer complies with. Conducting an initial quality audit of the supplier’s facility can provide insight into their production processes. Additionally, consider implementing a third-party inspection service to verify that the machines meet your specifications before shipment, which can mitigate risks of receiving substandard products. -

What logistics considerations should I keep in mind when importing these machines?

Logistics can be complex, so it’s essential to understand shipping options, costs, and timelines. Determine whether the supplier offers shipping services or if you’ll need to arrange your own logistics. Familiarize yourself with customs regulations in your country and ensure that all necessary documentation, such as invoices and certificates of origin, is prepared. Partnering with a logistics provider experienced in international shipping can simplify this process. -

How can disputes with suppliers be effectively managed?

Clearly outline terms of agreement in a contract, specifying payment terms, delivery schedules, and quality expectations. In case of disputes, maintain open communication to resolve issues amicably. If necessary, refer to the contract’s dispute resolution clause, which may involve mediation or arbitration. Having a legal advisor familiar with international trade law can also be beneficial in navigating complex disputes. -

What are the common challenges faced by international buyers of vending machines?

Common challenges include navigating customs regulations, managing currency fluctuations, and ensuring product quality. Cultural differences can also impact negotiations and communication. To mitigate these issues, conduct thorough market research, establish clear communication channels, and consider working with local agents or consultants who understand the nuances of doing business in the target region. Building strong relationships with suppliers can also help in overcoming these challenges effectively.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for 2 inch capsule vending machine

As the market for 2-inch capsule vending machines continues to evolve, the importance of strategic sourcing cannot be overstated. By leveraging a well-structured sourcing strategy, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe can significantly enhance their procurement processes. Key takeaways include the necessity of evaluating suppliers based on reliability, quality, and compliance with local regulations. Additionally, buyers should prioritize partnerships that offer competitive pricing without compromising product integrity.

Investing in high-quality vending machines not only boosts customer satisfaction but also drives repeat business, making it a pivotal area for growth. Buyers are encouraged to explore innovative features that cater to local preferences and enhance operational efficiency.

Looking ahead, the demand for customizable and technologically advanced vending solutions is expected to rise. Now is the time for B2B buyers to engage with suppliers who can provide tailored solutions that meet their unique market needs. Embrace strategic sourcing to position your business at the forefront of the vending machine industry and capitalize on emerging opportunities.