Unlock Profits with Vintage Snack Vending Machines: A B2B

Guide to Vintage Snack Vending Machine

- Introduction: Navigating the Global Market for vintage snack vending machine

- Understanding vintage snack vending machine Types and Variations

- Key Industrial Applications of vintage snack vending machine

- Strategic Material Selection Guide for vintage snack vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for vintage snack vending machine

- Comprehensive Cost and Pricing Analysis for vintage snack vending machine Sourcing

- Spotlight on Potential vintage snack vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for vintage snack vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vintage snack vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vintage snack vending machine

- Strategic Sourcing Conclusion and Outlook for vintage snack vending machine

Introduction: Navigating the Global Market for vintage snack vending machine

In today’s dynamic market, vintage snack vending machines are not merely relics of the past; they represent a unique fusion of nostalgia and modern convenience that appeals to consumers across diverse demographics. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the significance of these machines can unlock new avenues for revenue and customer engagement. The resurgence of interest in vintage aesthetics aligns perfectly with a growing demand for unique food experiences, making this an opportune time to explore this niche market.

This guide provides a comprehensive overview of the vintage snack vending machine landscape, covering essential aspects such as types, materials, manufacturing processes, quality control measures, and reliable suppliers. You will also find insights into pricing structures and market trends, empowering you to make informed purchasing decisions. Whether you’re a distributor looking to expand your offerings or a retailer aiming to enhance your customer experience, this guide is designed to equip you with the knowledge necessary to navigate the complexities of sourcing vintage snack vending machines.

By leveraging the insights offered in this guide, B2B buyers can confidently identify the best products that resonate with their target markets, ensuring a competitive edge in an increasingly crowded marketplace. Embrace the opportunity to innovate your vending solutions and cater to a discerning clientele that values both quality and character.

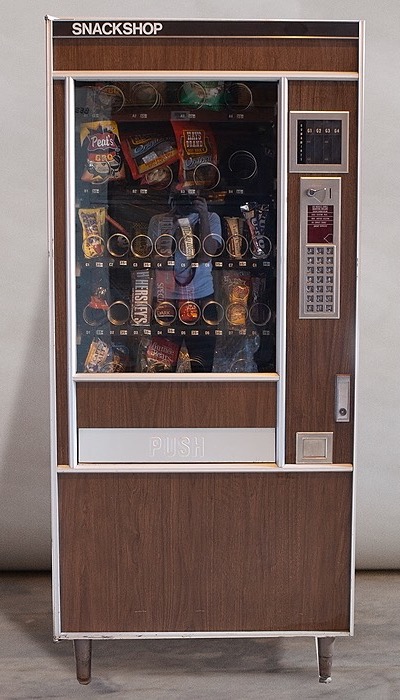

Illustrative Image (Source: Google Search)

Understanding vintage snack vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Mechanical Vending | Manual operation with mechanical mechanisms | Offices, schools, and public areas | Pros: Low maintenance; Cons: Limited product variety, slower service |

| Electronic Vending Machine | Digital interfaces and cashless payment options | Retail, airports, and hotels | Pros: High efficiency; Cons: Higher upfront costs, requires power supply |

| Retro Style Vending | Vintage aesthetics with modern functionality | Cafés, restaurants, and events | Pros: Unique appeal; Cons: May require more upkeep, potentially less durable |

| Snack and Beverage Combo | Dual compartments for snacks and drinks | Corporate lounges and event spaces | Pros: Versatile offerings; Cons: Larger footprint, higher complexity |

| Customizable Vending | Tailored designs to fit specific branding needs | Trade shows, promotional events | Pros: Strong brand presence; Cons: Longer lead times, potentially higher costs |

Classic Mechanical Vending

Classic mechanical vending machines are characterized by their manual operation, relying on mechanical mechanisms to dispense products. These machines are particularly suitable for low-traffic areas such as small offices or schools where the demand for snacks is consistent but not overwhelming. When considering a purchase, B2B buyers should evaluate maintenance costs, as these machines typically require less upkeep than their electronic counterparts. However, the limited product variety and slower service can deter buyers looking for high-volume solutions.

Electronic Vending Machine

Electronic vending machines incorporate digital interfaces and cashless payment options, making them ideal for high-traffic locations like retail stores, airports, and hotels. Their efficiency in transaction processing and product dispensing is a significant advantage for businesses aiming to enhance customer experience. Buyers should consider the higher upfront costs and the need for a reliable power source, but the potential for increased sales and customer satisfaction often justifies the investment.

Retro Style Vending

Retro style vending machines blend vintage aesthetics with modern functionality, appealing to businesses such as cafés, restaurants, and event organizers looking to create a unique atmosphere. These machines can attract customers with their nostalgic design while still offering contemporary features. B2B buyers should weigh the charm of these machines against potential durability issues and maintenance requirements, as they may not be as robust as more modern designs.

Snack and Beverage Combo

Snack and beverage combo machines provide the convenience of offering both snacks and drinks, making them suitable for corporate lounges and event spaces where variety is essential. Their versatility allows businesses to cater to diverse customer preferences, enhancing the overall service experience. However, buyers should be mindful of the larger footprint these machines require and the increased complexity in maintenance and stocking.

Customizable Vending

Customizable vending machines allow businesses to tailor the design and product offerings to align with their branding needs, making them an excellent choice for trade shows and promotional events. This customization can significantly enhance brand visibility and customer engagement. B2B buyers must consider the longer lead times associated with these machines and the potentially higher costs, but the unique marketing opportunities they provide can be invaluable for brand differentiation.

Related Video: Snack Vending Machine at Employee Break Room

Key Industrial Applications of vintage snack vending machine

| Industry/Sector | Specific Application of vintage snack vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | In-room snack services for hotels | Enhances guest experience, increases revenue | Size and capacity, product selection, maintenance support |

| Education | Snack stations in schools and universities | Provides convenient access to snacks, boosts morale | Compliance with health regulations, durability, ease of use |

| Corporate Offices | Breakroom snack solutions | Improves employee satisfaction, reduces downtime | Custom branding options, product variety, payment systems |

| Events and Trade Shows | Snack vending at exhibitions and conferences | Attracts attendees, generates additional revenue | Mobility, power supply options, inventory management |

| Transportation Hubs | Snack vending in airports and train stations | Meets high foot traffic demand, convenience for travelers | Security compliance, machine reliability, product shelf-life |

Hospitality

In the hospitality sector, vintage snack vending machines are increasingly used to provide in-room snack services in hotels. This application not only enhances the guest experience by offering a unique and nostalgic touch but also serves as an additional revenue stream for hotel operators. International buyers should consider the size and capacity of the machines to fit different room types, as well as the selection of products that align with local tastes and dietary restrictions. Maintenance support is also crucial to ensure uninterrupted service.

Education

In educational institutions, vintage snack vending machines serve as convenient snack stations in schools and universities. They provide students with easy access to snacks during breaks, which can help boost morale and academic performance. B2B buyers in this sector need to ensure compliance with health regulations regarding food items and consider the durability of machines to withstand high usage. Additionally, ease of use and product variety are important factors to cater to diverse student preferences.

Corporate Offices

Corporate offices are adopting vintage snack vending machines as breakroom snack solutions. These machines improve employee satisfaction by offering quick and convenient snack options, reducing downtime during work hours. When sourcing these machines, companies should look for options that allow for custom branding to enhance corporate identity, a diverse product selection to cater to different tastes, and reliable payment systems that accommodate various payment methods.

Events and Trade Shows

Vintage snack vending machines can be an attractive addition to exhibitions and conferences, providing snacks to attendees in a fun and engaging way. This application not only generates additional revenue but also helps draw in visitors to booths. For international B2B buyers, key sourcing considerations include the machine’s mobility for easy transport, power supply options to ensure functionality at various venues, and effective inventory management systems to track sales and stock levels.

Transportation Hubs

In transportation hubs like airports and train stations, vintage snack vending machines cater to high foot traffic, offering travelers convenient snack options. This application is particularly valuable in regions with busy transit systems, providing quick nourishment for passengers on the go. Buyers in this sector should prioritize security compliance to meet regulations, machine reliability to ensure consistent operation, and product shelf-life to minimize waste and maximize profitability.

Related Video: Vintage Snack Sets: A Look Back and How to Use Them Today

Strategic Material Selection Guide for vintage snack vending machine

Material Analysis for Vintage Snack Vending Machines

When selecting materials for vintage snack vending machines, it is essential to consider factors such as durability, cost, and performance under various conditions. Below are analyses of four common materials used in the construction of these machines, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high tensile strength, and ability to withstand a wide range of temperatures. It is often rated for high-pressure applications and can maintain structural integrity under thermal cycling.

Pros & Cons:

– Pros: Highly durable, easy to clean, and resistant to rust and stains. Its aesthetic appeal aligns well with the vintage theme.

– Cons: Higher initial cost compared to other metals and can be challenging to machine, which may increase manufacturing complexity.

Impact on Application:

Stainless steel is compatible with various snack products and can handle fluctuations in temperature, making it ideal for vending machines that dispense both chilled and room-temperature snacks.

Considerations for International Buyers:

Buyers in Africa, South America, the Middle East, and Europe should ensure compliance with local food safety regulations and standards such as ASTM and DIN. The preference for stainless steel may vary based on regional availability and cost considerations.

2. Powder-Coated Steel

Key Properties:

Powder-coated steel offers a protective layer that enhances corrosion resistance and provides a variety of color options. It can withstand moderate temperatures but is less effective under extreme conditions compared to stainless steel.

Pros & Cons:

– Pros: Cost-effective and customizable in terms of color and finish. The powder coating adds an extra layer of protection against scratches and wear.

– Cons: The coating can chip or scratch, exposing the underlying steel to corrosion. It may not be suitable for high-humidity environments.

Impact on Application:

This material is suitable for dry snacks but may not be ideal for products that require refrigeration due to potential moisture exposure.

Considerations for International Buyers:

Buyers should check for compliance with local environmental regulations regarding powder coating processes. Standards such as JIS may apply in certain regions, influencing the choice of this material.

3. Aluminum

Key Properties:

Aluminum is lightweight, resistant to corrosion, and has good thermal conductivity. It is often used in applications where weight savings are essential.

Pros & Cons:

– Pros: Lightweight and easy to manufacture, which can reduce shipping costs. Offers good resistance to corrosion and is generally more affordable than stainless steel.

– Cons: Less durable than stainless steel and can be prone to denting and scratching. It may also require additional coatings for enhanced durability.

Impact on Application:

Aluminum is suitable for non-refrigerated machines and can effectively handle a variety of snack types, although care should be taken with more delicate items.

Considerations for International Buyers:

Aluminum products must meet specific standards for food safety and quality. Buyers should verify compliance with local regulations and standards, particularly in Europe, where stringent guidelines may apply.

4. Glass

Key Properties:

Glass is often used in vending machines for its aesthetic appeal and visibility, allowing customers to see the products. It is non-reactive and can maintain product integrity.

Pros & Cons:

– Pros: Provides a premium look and feel, enhancing customer experience. Non-reactive and easy to clean.

– Cons: Fragile and can break easily, leading to potential safety hazards. Heavier than other materials, which can increase shipping costs.

Impact on Application:

Glass is suitable for displaying snacks but may not be ideal for machines that are frequently moved or in high-traffic areas due to the risk of breakage.

Considerations for International Buyers:

Buyers should consider local safety regulations regarding glass usage in vending machines. Compliance with standards such as ASTM for safety and durability is crucial, especially in regions with high foot traffic.

Summary Table

| Material | Typical Use Case for vintage snack vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | General construction for durability and hygiene | Excellent corrosion resistance | Higher initial cost | High |

| Powder-Coated Steel | Non-refrigerated machines with aesthetic appeal | Cost-effective and customizable | Coating can chip, exposing steel | Medium |

| Aluminum | Lightweight machines for easy transport | Lightweight and affordable | Less durable than stainless steel | Low |

| Glass | Display cases for snacks | Premium look and visibility | Fragile and heavier than alternatives | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for vintage snack vending machine

Understanding Manufacturing Processes for Vintage Snack Vending Machines

The manufacturing of vintage snack vending machines involves several intricate processes aimed at ensuring both aesthetics and functionality. For B2B buyers, particularly those from diverse markets like Africa, South America, the Middle East, and Europe, understanding these processes is crucial for making informed purchasing decisions.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Materials: The primary materials used in the construction of vending machines include metal (usually steel or aluminum), glass, and plastic. The choice of materials influences durability, cost, and aesthetic appeal.

– Cutting and Shaping: Sheet metal is typically cut using laser or water jet cutting techniques to ensure precision. Plastic components may be molded or extruded, depending on the design requirements. -

Forming

– Bending and Stamping: Forming processes such as bending and stamping are used to create the machine’s structure. This stage is crucial for the machine’s durability and functionality, as it must withstand frequent use.

– Welding: For metal components, welding techniques such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding are employed to assemble parts securely. -

Assembly

– Component Assembly: This stage involves the integration of various parts, including the vending mechanism, electronics, and aesthetic elements. Automated assembly lines may be used for efficiency, but manual assembly is common for vintage-style machines to maintain craftsmanship.

– Electrical Integration: Wiring and electronic components are installed at this stage. These include coin mechanisms, control boards, and lighting systems, which are essential for machine operation. -

Finishing

– Surface Treatment: To enhance durability and appearance, components undergo surface treatments such as powder coating or painting. This not only adds to the aesthetic appeal but also protects against corrosion.

– Quality Checks: After finishing, machines are subjected to various quality checks to ensure they meet industry standards and specifications.

Quality Assurance Practices

Quality assurance (QA) is vital in ensuring that vintage snack vending machines meet international standards and customer expectations. B2B buyers should be well-versed in the QA processes that manufacturers employ.

International Standards

- ISO 9001: This international standard outlines the criteria for a quality management system. Companies that are ISO 9001 certified demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: In Europe, CE marking is mandatory for vending machines, indicating compliance with health, safety, and environmental protection standards.

- API Certification: In some regions, particularly in the Middle East, API certification might be required, ensuring that products meet specific industry standards.

QC Checkpoints

-

Incoming Quality Control (IQC)

– Incoming materials are inspected for quality and compliance with specifications before they enter the production line. This is crucial for ensuring that the final product is built on a solid foundation. -

In-Process Quality Control (IPQC)

– During the manufacturing process, various checkpoints are established to monitor quality. This includes checking the accuracy of cuts, the integrity of welds, and the functionality of electronic components. -

Final Quality Control (FQC)

– Once the assembly is complete, a comprehensive final inspection is conducted. This includes testing machine functionality, ensuring proper operation of the vending mechanism, and verifying aesthetic details.

Common Testing Methods

- Functional Testing: Machines are tested for their operational performance, including coin acceptance, product dispensing, and electronic functionality.

- Durability Testing: Vending machines undergo stress tests to evaluate their resistance to wear and tear under typical usage conditions.

- Environmental Testing: Machines may be subjected to various environmental conditions to ensure they can operate effectively in different climates, which is particularly relevant for buyers in tropical or arid regions.

Verifying Supplier Quality Control

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential for mitigating risks associated with procurement.

- Supplier Audits: Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. Buyers should look for certifications and compliance with international standards.

- Quality Reports: Requesting detailed quality reports can help buyers assess the consistency and reliability of a supplier’s products. These reports should include data from IQC, IPQC, and FQC stages.

- Third-Party Inspections: Engaging third-party inspection services offers an unbiased assessment of the manufacturing process and product quality. This is particularly valuable for buyers unfamiliar with local suppliers.

Navigating QC/Cert Nuances

International buyers should be aware of the nuances in quality control and certification requirements across different regions:

- Regional Compliance: Different regions may have varying compliance standards. For example, while CE marking is essential in Europe, other regions may have alternative certifications or none at all.

- Cultural Considerations: Understanding local business practices and cultural nuances is vital when dealing with suppliers from different regions. Establishing good relationships can lead to better communication regarding quality expectations.

- Documentation: Ensure that all quality documentation is clear and accessible. This includes certificates of compliance, quality assurance plans, and test results, which are essential for importation and regulatory approvals.

By understanding these manufacturing and quality assurance processes, B2B buyers can make informed decisions when sourcing vintage snack vending machines. This knowledge not only enhances the purchasing process but also ensures that the machines acquired will meet the demands of their markets effectively.

Related Video: Parle-G Biscuits Manufacturing process – Food Factory Tour- Modern Food factory, Mega Factory II

Comprehensive Cost and Pricing Analysis for vintage snack vending machine Sourcing

Understanding the Cost Structure of Vintage Snack Vending Machines

When sourcing vintage snack vending machines, it is crucial to comprehend the underlying cost components that influence pricing. The total cost typically comprises several key elements:

-

Materials: The choice of materials significantly impacts the cost. Vintage machines often utilize durable metals and high-quality plastics, which can drive up expenses. Sourcing from local suppliers can mitigate some costs, but international sourcing may be necessary for specific vintage components.

-

Labor: Labor costs vary widely by region. In countries with higher labor costs, such as those in Western Europe, prices may be elevated. Conversely, sourcing from regions with lower labor costs can enhance overall cost-effectiveness.

-

Manufacturing Overhead: This includes utilities, rent, and equipment depreciation. Understanding the manufacturer’s operational efficiency is critical, as high overhead can lead to inflated prices.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. If you require unique features, it is important to factor in these costs early in negotiations.

-

Quality Control (QC): Investing in stringent QC processes ensures product reliability and compliance with safety standards. While this might increase upfront costs, it can reduce long-term expenses related to returns and repairs.

-

Logistics: Shipping costs can vary significantly depending on the origin and destination of the machines. Consideration of Incoterms is essential, as they define who is responsible for shipping, insurance, and tariffs.

-

Margin: Suppliers will include their profit margin in the final price. Understanding typical margins in the vintage vending machine market can help in negotiating more effectively.

Factors Influencing Pricing

Several external factors can influence the pricing of vintage snack vending machines:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to volume discounts. Understanding the MOQ of suppliers is essential for negotiating better terms.

-

Specifications and Customization: Custom features and specific design requests will invariably increase costs. Clearly defining your requirements upfront can help avoid unexpected charges.

-

Quality and Certifications: Machines that meet international safety and quality standards may command higher prices. Ensure that you assess the certifications that are essential for your target markets.

-

Supplier Factors: Evaluate suppliers based on their reputation, reliability, and past performance. Established suppliers may charge more but often deliver better quality and service.

-

Incoterms: Familiarity with Incoterms can help clarify responsibilities and costs associated with shipping. Choosing terms that align with your logistical capabilities can lead to more favorable pricing.

Buyer Tips for Cost Efficiency

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, consider the following tips:

-

Negotiate Wisely: Leverage your understanding of cost components and price influencers to negotiate better terms. Be prepared to discuss quantities, lead times, and payment terms to find a mutually beneficial arrangement.

-

Evaluate Total Cost of Ownership (TCO): Don’t just focus on the purchase price. Consider maintenance, operational costs, and potential repairs over the machine’s lifespan to get a clearer picture of overall expenses.

-

Pricing Nuances: Be aware of regional pricing variances and market conditions. For instance, machines may be cheaper in countries with a surplus of vintage products. Conduct market research to identify the best sources.

-

Consider Currency Fluctuations: When dealing with international suppliers, be mindful of currency exchange rates. Fluctuations can impact final costs, so consider locking in rates when favorable.

Disclaimer

The prices and cost components discussed are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential vintage snack vending machine Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for vintage snack vending machine.)*

Essential Technical Properties and Trade Terminology for vintage snack vending machine

Key Technical Properties of Vintage Snack Vending Machines

When considering the procurement of vintage snack vending machines, understanding the essential technical properties is crucial for ensuring operational efficiency and product longevity. Here are some critical specifications to consider:

-

Material Grade

– Definition: This refers to the quality of materials used in the construction of the vending machine, typically stainless steel or high-grade plastic.

– B2B Importance: High-quality materials enhance durability, resistance to corrosion, and the overall aesthetic of the machine, which can impact customer perception and sales. -

Capacity

– Definition: The total number of snack items the machine can hold, often measured in cubic feet or number of compartments.

– B2B Importance: Understanding capacity helps businesses assess the machine’s suitability for their target market. Higher capacity can support larger customer bases, particularly in high-traffic areas. -

Power Requirements

– Definition: The voltage and wattage specifications needed for the machine to operate effectively.

– B2B Importance: Knowledge of power requirements is essential for compatibility with local electrical systems, preventing operational failures and ensuring compliance with safety standards. -

Temperature Control

– Definition: The system that regulates the internal environment of the vending machine, particularly important for perishable snack items.

– B2B Importance: Effective temperature control is critical for maintaining product quality and safety, especially in regions with extreme climates. Buyers should ensure the machines are equipped with reliable refrigeration systems. -

Payment Systems

– Definition: The mechanisms through which customers can pay for items, including coin acceptors, bill validators, and cashless payment options.

– B2B Importance: Offering diverse payment options can enhance customer experience and increase sales. Understanding the compatibility of payment systems with local currencies and technologies is vital for international buyers. -

Dimensions and Weight

– Definition: The physical size and weight of the vending machine.

– B2B Importance: Knowing the dimensions is crucial for space planning and logistics. Heavy machines may require special handling during shipping, impacting overall costs.

Common Trade Terminology

Familiarity with industry jargon can significantly streamline communication and negotiations. Here are some essential terms:

- OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify reputable manufacturers and ensure product quality.

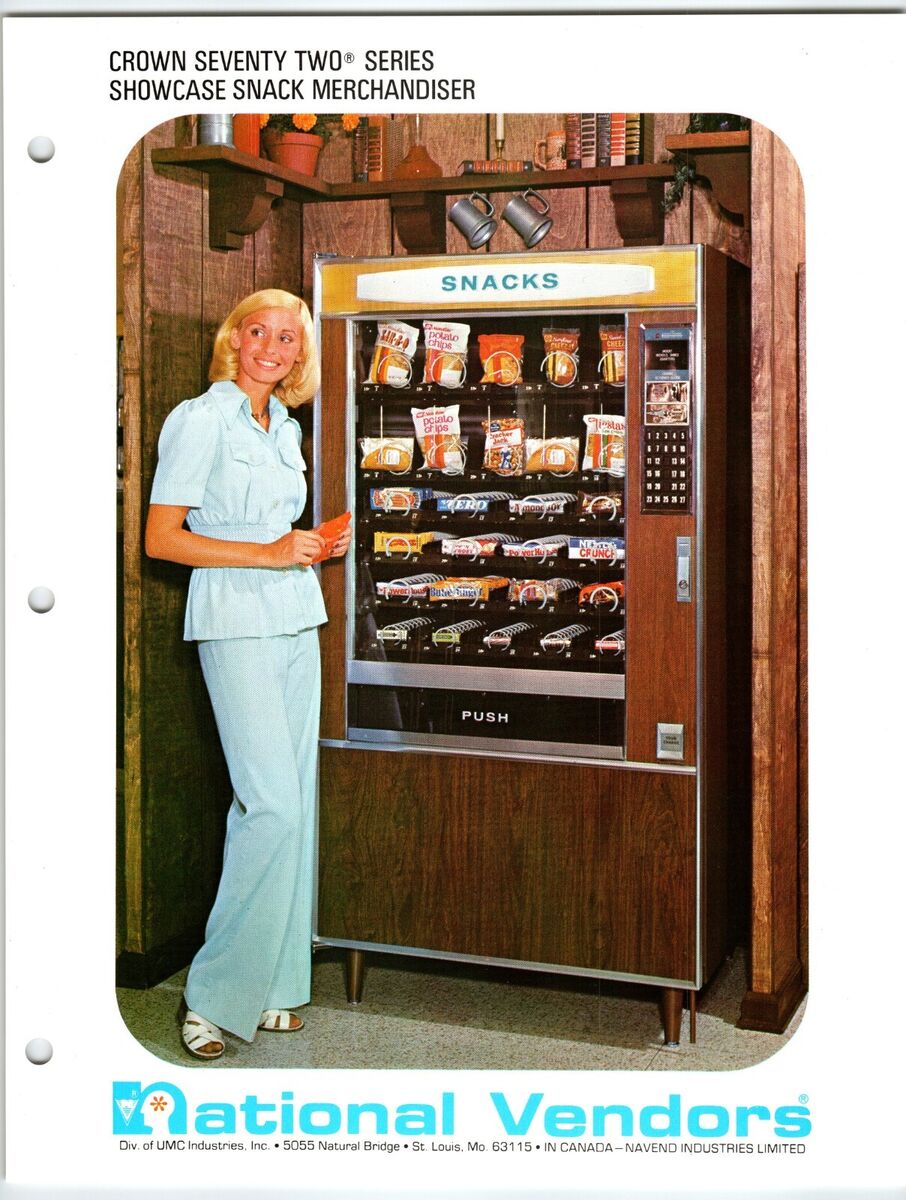

Illustrative Image (Source: Google Search)

-

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is crucial for budgeting and inventory management. Buyers should negotiate to align MOQs with their specific needs to avoid excess stock. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting price quotes for specific products or services.

– Importance: Issuing an RFQ is a strategic step in sourcing that allows buyers to compare prices and terms from multiple suppliers, ensuring competitive pricing. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers.

– Importance: Familiarity with Incoterms is essential for understanding shipping responsibilities, costs, and risks, particularly for international transactions. -

Lead Time

– Definition: The amount of time it takes for an order to be processed and delivered.

– Importance: Understanding lead times is vital for planning inventory and meeting customer demand. Buyers should clarify lead times during negotiations to ensure timely delivery. -

Warranty

– Definition: A guarantee provided by the manufacturer concerning the condition of the product and its repair or replacement under specific conditions.

– Importance: A robust warranty can reduce long-term costs and risks associated with equipment failure, making it a critical consideration for B2B buyers.

By comprehensively understanding these properties and terms, international B2B buyers can make informed decisions when investing in vintage snack vending machines, ultimately leading to enhanced operational success and customer satisfaction.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vintage snack vending machine Sector

Market Overview & Key Trends

The vintage snack vending machine sector is experiencing a renaissance driven by several global factors. The increasing consumer preference for nostalgic and artisanal products has led to a resurgence in demand for vintage-style vending machines that offer unique, high-quality snacks. B2B buyers in Africa, South America, the Middle East, and Europe must be aware of the growing trend of personalization and customization in vending offerings. Machines can now be tailored to reflect local tastes, accommodating regional flavors and health-conscious options, which is particularly important in diverse markets.

Emerging technologies are reshaping the sector, with innovations such as cashless payment systems, smart vending solutions, and IoT integration allowing for enhanced customer engagement and operational efficiency. These technologies not only facilitate easier transactions but also enable operators to gather valuable data on consumer preferences, which can inform inventory management and marketing strategies. For international buyers, investing in tech-savvy vending machines can provide a competitive edge in their respective markets.

Additionally, market dynamics such as urbanization and the shift towards on-the-go consumption are influencing the placement and operation of vintage snack vending machines. In densely populated urban areas, strategically placed machines can cater to busy lifestyles, while offering a touch of nostalgia that appeals to both younger consumers and adults seeking comfort in familiar flavors. As such, understanding local market dynamics and consumer behavior is critical for B2B buyers looking to optimize their vending machine investments.

Sustainability & Ethical Sourcing in B2B

In the context of vintage snack vending machines, sustainability and ethical sourcing are becoming increasingly pivotal. The environmental impact of manufacturing and operating vending machines can be significant, particularly regarding energy consumption and waste generation. B2B buyers should prioritize sourcing machines that are energy-efficient and constructed from sustainable materials. This not only reduces the carbon footprint but also aligns with the growing consumer demand for environmentally responsible products.

Moreover, implementing ethical supply chains is crucial. Buyers should seek suppliers that adhere to fair labor practices and sustainability certifications. This not only enhances brand reputation but also appeals to a conscientious consumer base. Certifications such as Fair Trade, Organic, and Forest Stewardship Council (FSC) can serve as key differentiators in the marketplace, demonstrating a commitment to social and environmental responsibility.

Utilizing “green” materials in the construction of vintage snack vending machines—such as recycled metals and biodegradable plastics—can further enhance sustainability efforts. Additionally, incorporating energy-efficient technology, such as solar panels for power, can minimize operational costs while promoting an eco-friendly brand image. For international B2B buyers, these considerations are not just ethical choices but also strategic advantages in a competitive market.

Brief Evolution/History

The vintage snack vending machine sector has evolved significantly since its inception in the early 20th century. Originally designed to dispense simple snacks, these machines have transformed into sophisticated devices that cater to diverse consumer preferences. The rise of retro aesthetics in marketing has revived interest in vintage-style machines, appealing to both nostalgia and modern sensibilities.

In recent years, the convergence of technology and design has redefined the vending experience, allowing for a blend of classic charm with contemporary convenience. This evolution has opened new avenues for B2B buyers to capitalize on emerging trends while honoring the historical significance of vintage vending machines. Understanding this evolution can provide valuable context for making informed sourcing decisions and positioning products effectively in the market.

Related Video: What Is International Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of vintage snack vending machine

-

What should I consider when vetting suppliers for vintage snack vending machines?

When vetting suppliers, prioritize their experience in manufacturing vintage snack vending machines and their reputation in international markets. Request references from previous clients, especially those in your region. Check for certifications related to safety and quality standards, which are crucial for compliance in your market. Additionally, assess their financial stability to ensure they can fulfill large orders. Look for suppliers who offer transparency in their processes and are responsive to inquiries, as this indicates a commitment to customer service. -

Can I customize the vintage snack vending machines to suit my market needs?

Yes, many manufacturers offer customization options for vintage snack vending machines. You can request specific designs, branding elements, and configurations tailored to your market’s preferences. However, be mindful that extensive customization may affect the minimum order quantity (MOQ) and lead times. Ensure you communicate your requirements clearly and consider requesting prototypes or samples before placing a larger order. This will help ensure the final product meets your expectations and resonates with your target audience. -

What are the typical minimum order quantities (MOQs) and lead times for these machines?

Minimum order quantities for vintage snack vending machines can vary significantly by supplier, generally ranging from 10 to 50 units. Lead times typically depend on the complexity of the machines and the level of customization required, usually spanning from 4 to 12 weeks. It’s advisable to discuss MOQs and lead times early in the negotiation process to avoid surprises. Additionally, consider the logistics involved in shipping to your region, as this can also impact delivery times. -

What payment options are commonly accepted by suppliers?

Most suppliers accept various payment methods, including bank transfers, letters of credit, and PayPal, depending on the transaction size and buyer’s location. For larger orders, letters of credit are often preferred, as they provide security for both parties. Be cautious about upfront payments; negotiate terms that allow for partial payments upon order confirmation and balance upon delivery. Ensure to clarify payment terms in the contract to avoid misunderstandings later. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should have robust quality assurance (QA) processes in place. Expect them to conduct thorough inspections during manufacturing and prior to shipment. Request information on their QA certifications, such as ISO standards, which can indicate a commitment to maintaining high-quality production. Additionally, inquire about warranty policies and post-sale support, as these can be crucial for addressing any defects or issues that may arise after purchase. -

How should I handle logistics and shipping for international orders?

When handling logistics, work closely with your supplier to determine the best shipping methods based on your budget and urgency. Consider using freight forwarders who specialize in international shipping to navigate customs and tariffs efficiently. Ensure that shipping terms (Incoterms) are clearly defined in your contract, specifying who is responsible for costs and risks at each stage of transport. It’s also wise to factor in potential delays due to customs clearance, especially when importing vintage machines. -

What steps can I take to resolve disputes with suppliers?

To effectively manage disputes, begin by addressing issues directly with the supplier through clear and open communication. Document all correspondence and agreements to have a record in case of escalations. If resolution is not achieved, refer to the dispute resolution clause in your contract, which may include mediation or arbitration. Familiarize yourself with international trade laws relevant to your transaction, as this knowledge can help in understanding your rights and responsibilities in cross-border disputes. -

What certifications should I look for in vintage snack vending machines?

Certifications to look for include CE marking in Europe, which indicates compliance with health, safety, and environmental protection standards, and relevant local certifications in your market. For buyers in Africa and South America, look for certifications that align with regional standards for electrical and mechanical safety. Additionally, inquire about any certifications related to the materials used, ensuring they are food-safe and environmentally friendly. These certifications are crucial for consumer safety and can enhance your product’s marketability.

Strategic Sourcing Conclusion and Outlook for vintage snack vending machine

In conclusion, the vintage snack vending machine market presents a unique opportunity for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. By leveraging strategic sourcing, businesses can not only capitalize on the growing demand for nostalgic products but also enhance customer engagement and brand loyalty. Key takeaways include the importance of understanding local market dynamics, ensuring compliance with regional regulations, and sourcing high-quality machines that reflect authenticity and reliability.

Investing in vintage snack vending machines can differentiate your business in a competitive landscape. Buyers should prioritize suppliers who offer customization options and robust after-sales support, which are critical for operational efficiency and customer satisfaction.

Looking ahead, the trend towards experiential retail will likely drive further interest in vintage machines, making now an ideal time to explore partnerships and expand your product offerings. By embracing strategic sourcing, you position your business for growth and innovation in a lucrative market. Engage with suppliers who share your vision and can support your journey towards success in this nostalgic yet evolving sector.