Unlock Profits with Underpants Vending Machine Japan: A B2B

Guide to Underpants Vending Machine Japan

- Introduction: Navigating the Global Market for underpants vending machine japan

- Understanding underpants vending machine japan Types and Variations

- Key Industrial Applications of underpants vending machine japan

- Strategic Material Selection Guide for underpants vending machine japan

- In-depth Look: Manufacturing Processes and Quality Assurance for underpants vending machine japan

- Comprehensive Cost and Pricing Analysis for underpants vending machine japan Sourcing

- Spotlight on Potential underpants vending machine japan Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for underpants vending machine japan

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the underpants vending machine japan Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of underpants vending machine japan

- Strategic Sourcing Conclusion and Outlook for underpants vending machine japan

Introduction: Navigating the Global Market for underpants vending machine japan

In recent years, the demand for innovative retail solutions has surged globally, and the underpants vending machine from Japan stands at the forefront of this trend. These machines not only provide a unique shopping experience but also cater to the growing need for convenience in urban environments. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding this niche market is essential for making informed procurement decisions.

This comprehensive guide delves into various aspects of underpants vending machines, including types and designs, materials used, and the manufacturing and quality control processes that ensure product reliability. Additionally, we will explore potential suppliers, cost considerations, and market dynamics that are crucial for navigating this unique segment.

By equipping yourself with actionable insights, you will be better prepared to assess opportunities and challenges within this innovative retail space. This guide aims to empower you with the knowledge needed to capitalize on the growing demand for convenience-driven products. Whether you are looking to enhance your product offerings or enter a new market, understanding the underpants vending machine landscape in Japan can unlock significant business potential and elevate your competitive edge.

Understanding underpants vending machine japan Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Underpants Vending | Offers a range of sizes and styles | Convenience stores, train stations | Pros: Easy to stock, widely accepted; Cons: Limited customization options. |

| High-Tech Smart Vending | Integrates cashless payment and touchscreen | Airports, upscale retail environments | Pros: Enhanced user experience; Cons: Higher initial investment. |

| Luxury Underpants Vending | Premium brands and materials available | Hotels, high-end shopping districts | Pros: Attracts affluent customers; Cons: Higher operational costs. |

| Eco-Friendly Vending | Focuses on sustainable materials | Eco-conscious retailers, events | Pros: Appeals to green consumers; Cons: May have limited product range. |

| Customizable Vending | Offers branding and product customization | Corporate gifting, promotional events | Pros: Tailored marketing opportunities; Cons: Longer lead times for setup. |

Standard Underpants Vending

Standard underpants vending machines are characterized by their straightforward design and functionality, offering a variety of sizes and styles. These machines are typically found in convenience stores and train stations, providing quick access for consumers in need. For B2B buyers, the ease of stocking and maintenance makes them a practical choice. However, they may lack the customization options that some businesses desire, limiting their appeal in niche markets.

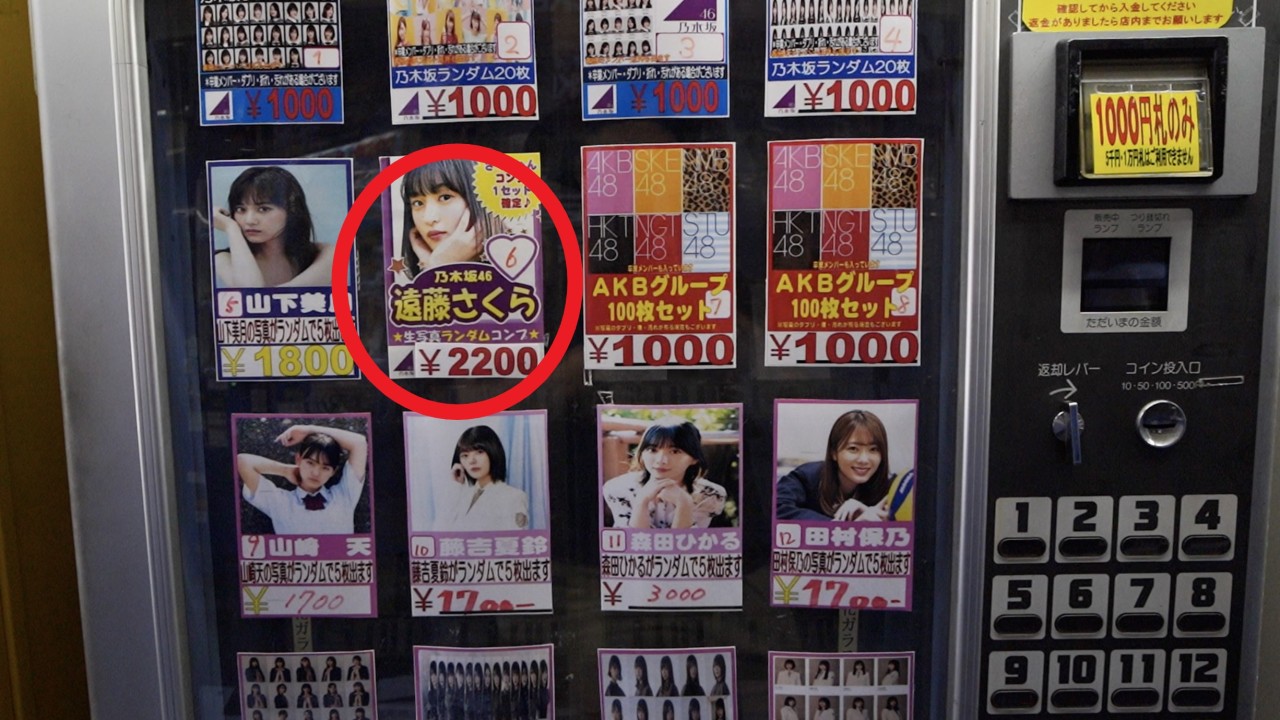

Illustrative Image (Source: Google Search)

High-Tech Smart Vending

High-tech smart vending machines incorporate advanced technologies such as cashless payment systems and touchscreens. These machines are ideal for locations like airports and upscale retail environments where customer experience is paramount. B2B buyers should consider the higher initial investment required for these models, but the enhanced user experience can lead to increased sales and customer satisfaction, making them a worthwhile investment in the long run.

Luxury Underpants Vending

Luxury underpants vending machines offer premium brands and high-quality materials, catering to affluent customers in locations such as hotels and high-end shopping districts. These machines can enhance brand image and customer loyalty for businesses looking to attract a more discerning clientele. However, B2B buyers must be aware of the higher operational costs associated with stocking and maintaining luxury products, which may impact profit margins.

Eco-Friendly Vending

Eco-friendly vending machines focus on sustainability, using environmentally friendly materials and products. They are particularly appealing to eco-conscious retailers and event organizers who want to align with green consumer trends. While they can attract a dedicated customer base, B2B buyers should note that the product range may be limited compared to standard machines, which could restrict sales opportunities.

Customizable Vending

Customizable vending machines allow businesses to personalize branding and product offerings, making them ideal for corporate gifting and promotional events. This flexibility can create unique marketing opportunities and enhance brand visibility. However, B2B buyers should consider the longer lead times for setup and potential higher costs associated with customization, which could affect project timelines and budgets.

Related Video: USED PANTY VENDING MACHINES in JAPAN?!

Key Industrial Applications of underpants vending machine japan

| Industry/Sector | Specific Application of underpants vending machine japan | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Guest convenience in hotels and resorts | Enhances guest experience and satisfaction | Machine reliability, payment options, and stock variety |

| Transportation | Airports and train stations | Provides travelers with essential comfort items | Space efficiency, machine size, and maintenance support |

| Retail | Standalone retail environments | Attracts foot traffic, increases impulse purchases | Location analysis, customer demographics, and branding |

| Sports and Recreation | Gyms and sports facilities | Offers convenience for athletes and gym-goers | Durability, machine placement, and product variety |

| Educational Institutions | Schools and universities | Addresses student needs and promotes hygiene | Compliance with regulations, machine accessibility, and product quality |

Hospitality

In the hospitality sector, underpants vending machines are strategically placed in hotels and resorts to enhance guest convenience. These machines provide quick access to essential clothing items for travelers who may have forgotten to pack extra undergarments. By offering this service, hotels can significantly improve guest satisfaction and loyalty. International buyers should consider the reliability of the machines, the variety of products offered, and the ease of payment systems to ensure a seamless guest experience.

Transportation

Airports and train stations are ideal environments for underpants vending machines, catering to the needs of travelers who require immediate access to personal items. These machines can alleviate discomfort during long journeys, providing a solution for unexpected delays or travel mishaps. For B2B buyers in this sector, key considerations include the machine’s space efficiency, size, and the availability of maintenance support to ensure continuous operation in high-traffic areas.

Retail

In retail environments, underpants vending machines serve as a unique attraction that can increase foot traffic and boost impulse purchases. Positioned in malls or shopping centers, they offer a convenient option for shoppers looking for quick solutions. For international buyers, understanding customer demographics and conducting thorough location analysis is essential for maximizing sales potential. Additionally, branding opportunities on the machines can enhance visibility and customer engagement.

Sports and Recreation

Gyms and sports facilities benefit from underpants vending machines by providing athletes and gym-goers with convenient access to undergarments post-workout. This service addresses a common need for hygiene and comfort, encouraging repeat visits to the facility. When sourcing these machines, buyers should prioritize durability, optimal machine placement, and a diverse product offering to cater to different customer preferences.

Educational Institutions

Schools and universities can implement underpants vending machines to meet the needs of students, particularly in high-traffic areas like dormitories or student unions. These machines promote hygiene and convenience, addressing situations where students may find themselves in need of extra undergarments. Compliance with local regulations, accessibility for all students, and ensuring product quality are critical factors for international B2B buyers considering this application.

Related Video: Japan’s Biggest Retro Vending Machine Wonderland – Over 100 Machines 🍔 🍭 🍜 🥤

Strategic Material Selection Guide for underpants vending machine japan

When selecting materials for underpants vending machines in Japan, it’s essential to consider various factors that influence product performance, durability, and overall cost-effectiveness. Here, we analyze four common materials used in the construction of these machines, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It typically has a temperature rating up to 800°C and pressure ratings depending on the specific grade.

Pros & Cons:

Stainless steel is durable and requires minimal maintenance, making it ideal for high-traffic environments. However, it tends to be more expensive compared to other materials, and its manufacturing can be complex due to the need for specialized welding techniques.

Impact on Application:

Stainless steel is compatible with a variety of media, including moisture and temperature fluctuations, making it suitable for vending machines that dispense underpants in various climates.

Considerations for International Buyers:

Buyers from regions like Saudi Arabia and Turkey should ensure compliance with local standards such as ASTM or DIN. The aesthetic appeal of stainless steel also aligns with modern design preferences in Europe and the Middle East.

2. Powder-Coated Steel

Key Properties:

Powder-coated steel offers a protective layer that enhances corrosion resistance and provides a variety of color options. It can withstand temperatures up to 200°C, making it suitable for indoor applications.

Pros & Cons:

This material is cost-effective and visually appealing, allowing for customization. However, it can be less durable than stainless steel and may chip or scratch over time, exposing the underlying steel to corrosion.

Impact on Application:

Powder-coated surfaces are generally suitable for indoor vending machines but may not hold up as well in humid or outdoor environments.

Considerations for International Buyers:

Buyers should consider the local climate when selecting powder-coated steel. Compliance with environmental regulations regarding coatings is also crucial, especially in Europe.

3. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has a good strength-to-weight ratio. It can handle temperatures up to 600°C and is non-magnetic, which can be beneficial in certain applications.

Pros & Cons:

Aluminum is easy to manufacture and can be anodized for additional protection, making it a versatile option. However, it is generally less durable than stainless steel and may be more susceptible to dents and scratches.

Impact on Application:

Aluminum is suitable for vending machines that require mobility or frequent relocation. Its lightweight nature makes it easier to transport and install.

Considerations for International Buyers:

International buyers should be aware of the varying grades of aluminum and their specific properties. Additionally, they should ensure compliance with local standards, especially in regions with stringent regulations like Europe.

4. High-Density Polyethylene (HDPE)

Key Properties:

HDPE is a thermoplastic known for its high strength-to-density ratio and resistance to impact and moisture. It operates effectively in temperatures ranging from -40°C to 80°C.

Pros & Cons:

HDPE is lightweight, cost-effective, and resistant to many chemicals, making it ideal for vending machine applications. However, it may not provide the same level of aesthetic appeal as metal options and can be less durable under heavy use.

Impact on Application:

This material is particularly suitable for vending machines in humid environments, as it does not corrode and is easy to clean.

Considerations for International Buyers:

Buyers should verify the recyclability of HDPE in their region and ensure that it meets local safety and quality standards.

Summary Table

| Material | Typical Use Case for underpants vending machine japan | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-traffic, outdoor environments | Excellent durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Powder-Coated Steel | Indoor environments | Cost-effective and customizable | Less durable; can chip or scratch | Medium |

| Aluminum | Mobile or frequently relocated machines | Lightweight and easy to manufacture | Less durable; susceptible to dents | Medium |

| High-Density Polyethylene (HDPE) | Humid or moisture-prone environments | Resistant to corrosion and easy to clean | Less aesthetic appeal and lower durability | Low |

This guide provides a comprehensive overview of material options for underpants vending machines, enabling international B2B buyers to make informed decisions tailored to their specific market needs and regulatory environments.

In-depth Look: Manufacturing Processes and Quality Assurance for underpants vending machine japan

Overview of Manufacturing Processes for Underpants Vending Machines

The manufacturing of underpants vending machines in Japan is characterized by a systematic approach that integrates advanced technology with traditional craftsmanship. The main stages of the manufacturing process include material preparation, forming, assembly, and finishing. Understanding these stages is crucial for international B2B buyers seeking to source high-quality vending machines.

Material Preparation

The first step involves selecting and preparing raw materials. Manufacturers typically use high-grade metals, plastics, and electronic components to ensure durability and functionality. Key considerations include:

- Material Quality: Sourcing materials from reputable suppliers is essential. Look for certifications that indicate compliance with international standards.

- Sustainability: Increasingly, manufacturers are focusing on eco-friendly materials, which could be a selling point in markets with strong environmental regulations.

Forming

This stage involves shaping the materials into the required components of the vending machine. Techniques commonly used include:

- Metal Stamping: For creating the machine’s chassis and structural components, ensuring precision and strength.

- Injection Molding: Used for plastic parts, allowing for complex shapes and lightweight designs.

- CNC Machining: Employed for high-precision parts, ensuring that all components fit together seamlessly.

Assembly

After forming, the components are assembled into a complete vending machine. Key aspects include:

- Automation: Many manufacturers employ automated assembly lines to enhance efficiency and reduce labor costs.

- Skilled Labor: Despite automation, skilled technicians are essential for quality assembly, particularly for electronic components and programming.

- Modular Design: Many machines are designed modularly, allowing for easier upgrades and repairs.

Finishing

The finishing stage enhances the aesthetic and functional qualities of the vending machine. This includes:

- Painting and Coating: Protective coatings are applied to prevent corrosion and wear. High-quality finishes also enhance the machine’s appearance.

- Quality Control Checks: Before moving to the next phase, several quality checks are performed to ensure all components meet specified standards.

Quality Assurance in Manufacturing

Quality assurance (QA) is critical in ensuring that the underpants vending machines meet both domestic and international standards. The following aspects are essential for B2B buyers to understand:

International Standards

Buyers should be aware of relevant international standards that govern manufacturing processes:

- ISO 9001: This standard focuses on quality management systems. Suppliers who are ISO 9001 certified demonstrate a commitment to quality and continuous improvement.

- CE Marking: Required for products sold within the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Standards: Although more common in other industries, understanding API guidelines can be beneficial for specific components used in the vending machines.

Quality Control Checkpoints

Quality control is integrated at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Materials and components are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects early.

- Final Quality Control (FQC): Completed machines undergo thorough testing to ensure functionality and safety before shipping.

Common Testing Methods

Testing methods vary but typically include:

- Functional Testing: Ensuring that the machine operates correctly, including payment processing and product dispensing.

- Durability Testing: Assessing how well the machine withstands wear and tear over time.

- Safety Testing: Ensuring compliance with electrical safety standards, particularly for machines equipped with electronic components.

Verifying Supplier Quality Control

For B2B buyers, ensuring that suppliers maintain rigorous quality control processes is paramount. Here are actionable steps to verify supplier QC:

- Supplier Audits: Conduct regular audits of suppliers to assess their manufacturing processes and quality assurance practices. Look for documented procedures and adherence to standards.

- Request Quality Reports: Ask suppliers for detailed quality reports that outline their QC processes and results of recent tests.

- Engage Third-Party Inspectors: Consider hiring third-party inspection services to evaluate supplier facilities and processes. This adds an additional layer of assurance regarding quality.

Quality Control Nuances for International Buyers

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific nuances:

- Cultural Differences: Understanding the cultural context can aid in negotiations and ensure effective communication regarding quality expectations.

- Regulatory Compliance: Different regions have varying regulations affecting product safety and quality. Buyers should familiarize themselves with local laws that may impact the importation of vending machines.

- Logistics and Supply Chain Considerations: Ensure that suppliers can navigate the complexities of international shipping and customs, which can impact delivery timelines and product integrity.

Conclusion

The manufacturing processes and quality assurance practices for underpants vending machines in Japan reflect a commitment to quality and innovation. By understanding these processes, international B2B buyers can make informed decisions when sourcing these machines, ensuring they meet both their operational needs and the expectations of their markets. Through rigorous supplier verification and awareness of international standards, buyers can mitigate risks and secure high-quality products that will succeed in their respective markets.

Related Video: Honda factory tour – Production in Japan plant

Comprehensive Cost and Pricing Analysis for underpants vending machine japan Sourcing

In the sourcing of underpants vending machines from Japan, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis provides insights into the various cost components, price influencers, and practical tips to enhance negotiation strategies and overall cost efficiency.

Cost Components

-

Materials: The primary materials involved in manufacturing vending machines include metal for the frame, plastic for the casing, and electronic components for the vending mechanism. The quality and origin of these materials significantly impact the overall cost. For instance, using high-grade steel may raise initial costs but can enhance durability and reduce long-term maintenance.

-

Labor: Labor costs in Japan can be relatively high compared to other manufacturing countries. However, the efficiency and skill level of the workforce often lead to superior product quality and reduced defect rates, which can be a critical factor for B2B buyers seeking reliability.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and administrative expenses. Japanese manufacturers often have advanced production technologies, which may increase overhead but also lead to better efficiency and lower defect rates.

-

Tooling: Custom tooling can be a significant upfront cost, particularly if the vending machines require unique designs or specifications. Buyers should account for these costs when estimating the total investment.

-

Quality Control (QC): Japanese manufacturers are renowned for their rigorous quality control processes. While this can add to the overall cost, it ensures that the final product meets high standards, which is particularly important for international buyers who may face stricter regulations in their home markets.

-

Logistics: Shipping costs can vary widely based on the destination, volume, and shipping method. Buyers should consider both freight charges and potential tariffs or import duties when calculating total costs.

-

Margin: Supplier margins can fluctuate based on competition, demand, and the exclusivity of the product. Negotiating the margin is often a key component of the purchasing process.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should assess their demand carefully to negotiate favorable terms.

-

Specifications/Customization: Custom features, such as branding or unique functionalities, can increase costs. Clear communication about requirements can help prevent unexpected expenses.

-

Materials: The choice of materials can drastically influence the price. Buyers should evaluate the balance between cost and quality to ensure they meet their operational needs without overspending.

-

Quality/Certifications: Certifications for safety and quality can add costs but are often necessary for compliance in various markets. Buyers should inquire about these certifications upfront to avoid future liabilities.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established manufacturers may charge a premium but offer better after-sales support and warranty options.

-

Incoterms: Understanding the Incoterms agreed upon in the contract is essential, as they define the responsibilities of buyers and sellers in shipping, insurance, and tariffs. This understanding can prevent unexpected costs upon delivery.

Buyer Tips

-

Negotiation: Leverage market knowledge and competitor pricing to negotiate better terms. Building a relationship with suppliers can also lead to more favorable pricing.

-

Cost-Efficiency: Consider total cost of ownership (TCO) instead of just the purchase price. Factors like energy consumption, maintenance, and potential downtime should be factored into overall cost assessments.

-

Pricing Nuances: Be aware of regional pricing strategies. Suppliers may offer different terms based on the buyer’s location, reflecting local market conditions and competition.

-

Research and Benchmarking: Conduct thorough market research and benchmark against similar products and suppliers to ensure competitive pricing. This is particularly important for buyers from Africa, South America, the Middle East, and Europe, where market dynamics can vary significantly.

Disclaimer

Prices and cost structures are indicative and can fluctuate based on market conditions, supplier negotiations, and geopolitical factors. It is advisable for buyers to conduct due diligence and seek multiple quotes to ensure the best pricing strategy.

Spotlight on Potential underpants vending machine japan Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for underpants vending machine japan.)*

Essential Technical Properties and Trade Terminology for underpants vending machine japan

When considering the procurement of underpants vending machines from Japan, international B2B buyers must familiarize themselves with essential technical properties and relevant trade terminology. Understanding these elements is crucial for making informed purchasing decisions and ensuring smooth transactions.

Key Technical Properties

-

Material Grade

– Definition: The quality and type of materials used in the construction of the vending machine, often specified in terms of durability and resistance to environmental factors.

– B2B Importance: High-grade materials ensure longevity and reliability, reducing maintenance costs. For buyers in regions with extreme weather conditions, selecting machines made from weather-resistant materials can lead to better performance and customer satisfaction. -

Capacity

– Definition: The number of items (in this case, underpants) that the vending machine can hold at one time.

– B2B Importance: Understanding capacity is vital for inventory management and sales forecasting. Buyers should assess the expected foot traffic in their locations to determine the optimal capacity for maximizing sales without overstocking. -

Power Requirements

– Definition: The electrical specifications needed for the vending machine to operate effectively, including voltage and frequency.

– B2B Importance: Different regions have varying power standards. Buyers must ensure that the machines they import are compatible with local electrical systems to avoid costly modifications or operational failures. -

User Interface

– Definition: The design and functionality of the machine’s display and payment systems, which may include touchscreen controls, payment card readers, and mobile payment options.

– B2B Importance: A user-friendly interface can significantly impact customer experience and sales. Buyers should prioritize machines that offer multiple payment options, especially in markets where cashless transactions are prevalent. -

Security Features

– Definition: Mechanisms designed to protect the machine from theft or vandalism, such as reinforced locks, alarms, and surveillance cameras.

– B2B Importance: Security is a major concern for vending machine operators. Investing in machines with robust security features can prevent losses and protect the investment, particularly in high-risk areas.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify reliable suppliers and manufacturers for maintenance or replacement parts, ensuring continued operation of their vending machines. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is essential for budgeting and inventory planning. Buyers from Africa or South America may need to balance between meeting MOQs and managing cash flow. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price quotes from suppliers for specific products or services.

– Importance: An RFQ allows buyers to compare prices, terms, and specifications from different manufacturers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international rules governing the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand their obligations regarding shipping, insurance, and tariffs, which is crucial for effective cost management and risk assessment. -

Lead Time

– Definition: The amount of time it takes from placing an order to receiving the goods.

– Importance: Knowing the lead time is vital for planning inventory and sales strategies. Buyers should consider lead times when assessing the urgency of their needs and potential market fluctuations.

Understanding these technical properties and trade terms will empower B2B buyers to navigate the complexities of sourcing underpants vending machines from Japan, ensuring they make strategic, cost-effective decisions that align with their business objectives.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the underpants vending machine japan Sector

Market Overview & Key Trends

The underpants vending machine sector in Japan is witnessing dynamic growth, driven by several global factors. The increasing demand for convenience and hygiene, particularly in urban areas, has led to a surge in vending machine installations. This trend is further fueled by a shift in consumer preferences towards automated retail solutions, which provide quick access to essential items. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, should note that this market is characterized by rapid technological advancements. Innovations such as cashless payment options and smart vending machines equipped with IoT capabilities are becoming prevalent, enhancing user experience and operational efficiency.

Emerging trends indicate a growing interest in customization and personalization within the vending machine offerings. This shift allows businesses to cater to diverse consumer preferences and cultural nuances, making it crucial for B2B buyers to consider local market insights. Moreover, the integration of AI for inventory management and consumer behavior analysis is reshaping supply chain strategies, allowing companies to optimize their operations effectively. Buyers from regions like Saudi Arabia and Turkey can benefit from understanding these technological advancements to ensure their sourcing strategies align with market demands.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming an essential criterion for B2B buyers in the underpants vending machine sector. The environmental impact of production and waste management is under scrutiny, making it imperative for companies to adopt sustainable practices. Ethical sourcing not only enhances brand reputation but also meets the growing consumer demand for environmentally friendly products. This is particularly relevant for international buyers looking to establish credibility in markets that prioritize corporate social responsibility.

To align with sustainability goals, businesses should explore sourcing materials certified by recognized environmental standards, such as organic cotton or recycled fabrics. These materials not only reduce ecological footprints but also appeal to eco-conscious consumers. Additionally, incorporating energy-efficient vending machines can significantly lower operational costs and environmental impact. Buyers should seek suppliers who prioritize sustainability in their operations, ensuring that their supply chains reflect a commitment to ethical practices.

Brief Evolution/History

The concept of vending machines in Japan has evolved significantly since their inception in the early 20th century. Initially serving simple needs, the vending machine landscape has transformed into a sophisticated market that caters to various consumer demands, including clothing. The introduction of underpants vending machines reflects Japan’s innovative spirit and understanding of consumer behavior, particularly in urban environments where convenience is paramount. As global interest in this unique vending machine category grows, B2B buyers can leverage historical insights to inform their market entry strategies and product offerings, ensuring they meet both local and international expectations.

Related Video: IMF: Trade Tariffs Could Slow Sri Lanka’s Economic Recovery | WION Business Watch

Frequently Asked Questions (FAQs) for B2B Buyers of underpants vending machine japan

-

What factors should I consider when vetting suppliers of underpants vending machines from Japan?

When vetting suppliers, prioritize their experience in the vending machine industry, particularly with underpants. Look for suppliers with a proven track record in international trade and positive testimonials from other B2B buyers. Ensure they have the necessary certifications and compliance with safety and quality standards specific to your region. Request samples to evaluate the product quality firsthand and check their responsiveness in communication, as this can indicate reliability in future transactions. -

Can I customize the underpants vending machines to suit my market needs?

Yes, many Japanese suppliers offer customization options for their underpants vending machines. This may include branding, machine size, color, and product selection tailored to your target audience’s preferences. Discuss your specific requirements early in the negotiation process to ensure the supplier can accommodate your needs. Keep in mind that extensive customization may impact lead times and pricing, so factor these into your planning. -

What is the typical minimum order quantity (MOQ) for underpants vending machines, and how do lead times vary?

The MOQ for underpants vending machines can vary significantly among suppliers but often starts at 10-20 units. Factors influencing MOQ include customization requests and the supplier’s production capacity. Lead times typically range from 4 to 12 weeks, depending on order size, customization complexity, and the supplier’s current workload. Always confirm these details upfront to align your inventory and sales strategy with the supplier’s capabilities. -

What payment terms are commonly offered by Japanese suppliers for B2B transactions?

Payment terms vary among suppliers, but common arrangements include a 30% deposit upon order confirmation and the remaining 70% prior to shipment. Some suppliers may offer net payment terms, such as net 30 or net 60 days, especially for established relationships. It’s crucial to discuss and agree on payment methods (such as wire transfer or credit terms) and ensure they align with your financial capabilities and risk management strategies. -

How can I ensure quality assurance and compliance with certifications?

To ensure quality assurance, request documentation of certifications from the supplier, such as ISO 9001 or product-specific safety standards. Implement a quality control process that includes pre-shipment inspections and testing samples. Consider hiring a third-party inspection service to verify product quality before shipment, especially if you are unfamiliar with the supplier’s production standards. This step is vital to mitigate risks associated with defective products.

Illustrative Image (Source: Google Search)

-

What logistics considerations should I keep in mind when importing vending machines from Japan?

Logistics play a critical role in the successful importation of vending machines. Assess shipping options, such as air freight for faster delivery versus sea freight for cost-effectiveness. Ensure your supplier can handle export documentation and customs clearance. Familiarize yourself with import regulations in your country, including tariffs and taxes. Collaborating with a logistics provider experienced in international trade can streamline the shipping process and reduce potential delays. -

How do I handle disputes with suppliers regarding product quality or delivery issues?

Establish clear communication channels and maintain documentation of all transactions, including contracts and correspondence. In the event of a dispute, initiate dialogue with the supplier to address the issue directly. If resolution is not achieved, refer to the terms outlined in your contract regarding mediation or arbitration. Engaging a legal expert familiar with international trade laws can provide guidance and support in navigating complex disputes. -

What are the potential risks of sourcing underpants vending machines from Japan, and how can I mitigate them?

Risks include quality discrepancies, shipping delays, and potential cultural misunderstandings. To mitigate these risks, conduct thorough due diligence on suppliers and establish clear contracts that outline expectations and responsibilities. Consider diversifying your supplier base to avoid over-reliance on a single source. Additionally, staying informed about geopolitical developments and economic conditions in Japan can help you anticipate and navigate any challenges that may arise.

Strategic Sourcing Conclusion and Outlook for underpants vending machine japan

In summary, the market for underpants vending machines in Japan presents a unique opportunity for international B2B buyers seeking innovative retail solutions. Key takeaways include understanding local consumer behavior, leveraging Japan’s technological advancements, and recognizing the cultural significance of convenience in retail. Strategic sourcing is essential, enabling businesses to navigate the complexities of supply chain management, quality assurance, and compliance with local regulations.

Actionable Insights:

– Research Local Preferences: Tailor product offerings to match the tastes and preferences of Japanese consumers, ensuring cultural relevance.

– Evaluate Suppliers: Partner with reputable manufacturers who understand the nuances of the Japanese market, emphasizing quality and innovation.

– Leverage Technology: Utilize advanced vending technology that enhances user experience and operational efficiency.

As we look to the future, the demand for automated retail solutions like underpants vending machines is poised to grow, driven by urbanization and changing consumer habits. International buyers from Africa, South America, the Middle East, and Europe are encouraged to explore this niche market actively. By embracing strategic sourcing, you can position your business to capitalize on emerging trends and drive profitable growth in Japan’s vibrant vending landscape.