Unlock Profits with the Ultimate Bait Vending Machine

Guide to Bait Vending Machine

- Introduction: Navigating the Global Market for bait vending machine

- Understanding bait vending machine Types and Variations

- Key Industrial Applications of bait vending machine

- Strategic Material Selection Guide for bait vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for bait vending machine

- Comprehensive Cost and Pricing Analysis for bait vending machine Sourcing

- Spotlight on Potential bait vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for bait vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the bait vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of bait vending machine

- Strategic Sourcing Conclusion and Outlook for bait vending machine

Introduction: Navigating the Global Market for bait vending machine

In today’s dynamic business landscape, the bait vending machine represents a unique convergence of convenience and efficiency, catering to anglers and outdoor enthusiasts worldwide. As the demand for fishing gear and live bait grows, particularly in regions rich in aquatic biodiversity such as Africa, South America, the Middle East, and Europe, investing in a bait vending machine can significantly enhance your business’s competitive edge. These machines not only streamline the purchasing process for customers but also maximize operational efficiency and minimize overhead costs.

This comprehensive guide delves into the diverse types of bait vending machines available in the market, highlighting their construction materials, manufacturing quality control standards, and leading suppliers. We will also explore cost considerations, market trends, and frequently asked questions to equip you with the essential knowledge needed for informed sourcing decisions.

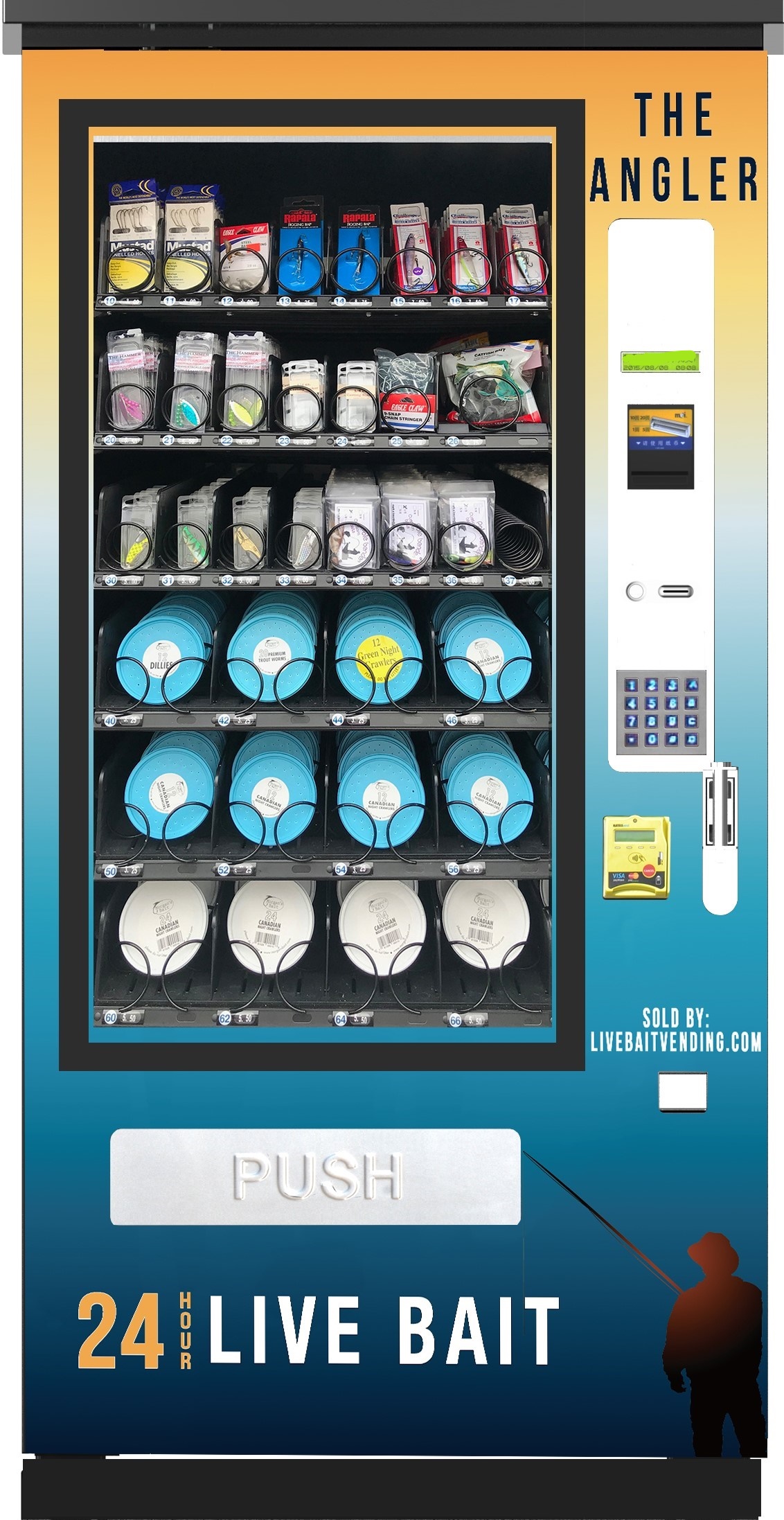

Illustrative Image (Source: Google Search)

Whether you are a retailer looking to diversify your offerings or a distributor seeking innovative solutions for your clientele, understanding the intricacies of bait vending machines is crucial. This guide empowers international B2B buyers, particularly from emerging markets in Africa, South America, the Middle East, and established markets in Europe like Spain and Argentina, to navigate the complexities of this niche market. By leveraging the insights provided, you can enhance your procurement strategy and foster strong partnerships that drive growth and customer satisfaction.

Understanding bait vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Bait Vending Machine | Mechanical dispensing mechanism with coin or card payment | Fishing tackle shops, marinas | Pros: Simple operation, low maintenance. Cons: Limited product range, may require frequent restocking. |

| Smart Bait Vending Machine | Digital interface with real-time inventory tracking | Large retail chains, tourist hotspots | Pros: Enhanced customer experience, remote management. Cons: Higher initial investment, requires internet connectivity. |

| Mobile Bait Vending Machine | Portable design, battery-operated or solar-powered | Events, fishing competitions, outdoor festivals | Pros: Flexibility in location, easy to transport. Cons: Limited capacity, may require frequent refilling. |

| Customizable Bait Vending Machine | Tailored designs for specific bait types or branding | Specialty fishing stores, local markets | Pros: Unique offerings, brand visibility. Cons: Higher cost, longer lead times for production. |

| Hybrid Bait Vending Machine | Combines traditional and smart features | Urban areas, convenience stores | Pros: Versatile functionality, appeals to tech-savvy customers. Cons: Complexity in operation, potential for technical issues. |

Traditional Bait Vending Machine

The traditional bait vending machine operates through a straightforward mechanical dispensing system, usually accepting coins or cards for payment. These machines are commonly found in fishing tackle shops and marinas, making them ideal for immediate access to bait. When considering this type, B2B buyers should evaluate the machine’s durability and ease of maintenance, as these aspects directly impact operational efficiency and customer satisfaction. Although they are cost-effective, their limited product range necessitates regular restocking, which can affect profitability.

Smart Bait Vending Machine

Smart bait vending machines integrate advanced technology, featuring digital interfaces for real-time inventory tracking and management. These machines are well-suited for large retail chains and tourist hotspots, where customer engagement is crucial. B2B buyers looking for scalability and enhanced customer experience will find these machines appealing. However, the higher initial investment and reliance on internet connectivity may pose challenges for some businesses, particularly in regions with limited infrastructure.

Mobile Bait Vending Machine

Designed for portability, mobile bait vending machines are battery-operated or solar-powered, making them perfect for events, fishing competitions, and outdoor festivals. Their flexibility allows businesses to reach diverse customer bases in various locations. B2B buyers should consider the operational logistics, such as transportation and refilling, as these machines typically have limited capacity. While they offer unique opportunities for sales, the need for frequent maintenance can be a downside.

Customizable Bait Vending Machine

Customizable bait vending machines allow businesses to tailor designs for specific bait types or branding, catering to niche markets. They are particularly beneficial for specialty fishing stores and local markets, where unique offerings can attract more customers. When purchasing, B2B buyers should weigh the advantages of brand visibility against the higher costs and longer lead times for production. Customization can enhance customer loyalty, but it requires careful planning and investment.

Hybrid Bait Vending Machine

Hybrid bait vending machines combine traditional mechanical features with smart technology, offering versatility in urban areas and convenience stores. These machines can appeal to a broad customer base, including those who prefer digital interactions. B2B buyers should assess the complexity of operation and potential technical issues that may arise. While they provide a comprehensive solution, the intricate design may require more training for staff, impacting operational efficiency.

Related Video: Buying Every Fish From the Live Fish Vending Machine… creepy fish

Key Industrial Applications of bait vending machine

| Industry/Sector | Specific Application of Bait Vending Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fishing & Aquaculture | On-site bait dispensing for commercial fishing | Increased operational efficiency and reduced waste | Durability in marine environments, ease of maintenance |

| Wildlife Management | Bait distribution for wildlife control programs | Effective pest management and enhanced safety | Compliance with local regulations, bait type selection |

| Recreational Fishing | Vending solutions at fishing locations and events | Improved customer satisfaction and convenience | Location accessibility, payment system integration |

| Environmental Research | Bait provision for ecological studies | Reliable data collection and research accuracy | Customization options for bait types, durability |

| Tourism & Recreation | Vending machines in parks and tourist areas | Enhanced visitor experience and additional revenue | Aesthetic design, local wildlife considerations |

Fishing & Aquaculture

In the fishing and aquaculture sector, bait vending machines provide an efficient solution for distributing bait directly at fishing sites. This application minimizes the need for fishermen to transport live bait, reducing waste and ensuring freshness. International buyers need to consider factors such as machine durability in marine environments and ease of maintenance to ensure long-term functionality. Additionally, understanding local fishing regulations regarding bait types is crucial to compliance and operational success.

Wildlife Management

Bait vending machines are increasingly used in wildlife management for the controlled distribution of bait in pest control programs. These machines can dispense specific types of bait that target particular species, thereby enhancing the effectiveness of wildlife control efforts. For B2B buyers, it’s essential to ensure that the machines comply with local environmental regulations and that the bait types are appropriate for the intended use. Additionally, sourcing machines that are robust and can withstand various outdoor conditions is vital.

Recreational Fishing

In recreational fishing, bait vending machines serve as a convenient solution for anglers at lakes, rivers, and fishing events. By providing easy access to bait, these machines significantly improve customer satisfaction and can lead to increased sales for operators. Buyers in this sector should focus on location accessibility to ensure machines are placed in high-traffic areas. Integrating modern payment systems, like contactless payments, can further enhance user experience and drive sales.

Environmental Research

For ecological studies, bait vending machines can play a crucial role in providing researchers with reliable access to bait for sampling and data collection. This application is particularly beneficial in conducting studies on fish populations and ecosystem health. International buyers must consider customization options for different bait types and the machine’s durability to withstand various environmental conditions. Ensuring that the machines are equipped with data logging capabilities can also enhance research outcomes.

Tourism & Recreation

In parks and tourist areas, bait vending machines can enhance the visitor experience by providing easy access to bait for recreational fishing. This not only improves customer satisfaction but also generates additional revenue streams for park operators. When sourcing these machines, buyers should prioritize aesthetic design to ensure they blend well with the natural environment. Additionally, understanding local wildlife considerations is important to avoid negative impacts on local ecosystems.

Related Video: DIY Vending Machine – Arduino based Mechatronics Project

Strategic Material Selection Guide for bait vending machine

When selecting materials for bait vending machines, it is crucial to consider the specific operational environments and requirements that will impact performance, durability, and compliance with international standards. Below is an analysis of four common materials used in the construction of bait vending machines, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. It is often rated for high-pressure applications, making it suitable for environments where durability is essential.

Pros & Cons: The primary advantage of stainless steel is its longevity and resistance to rust and corrosion, which is particularly beneficial in humid or wet environments. However, it tends to be more expensive than other materials and may require specialized manufacturing processes, which can increase lead times.

Impact on Application: Stainless steel is compatible with various media, including saltwater and freshwater, making it ideal for bait vending machines used in diverse aquatic environments.

Considerations for International Buyers: Compliance with standards such as ASTM A240 (for stainless steel) is essential. Buyers in regions like Europe and the Middle East should ensure that the material meets local regulations regarding food safety and hygiene.

Aluminum

Key Properties: Aluminum is lightweight and has good corrosion resistance, particularly when anodized. It can handle moderate temperatures and pressures, making it suitable for less demanding applications.

Pros & Cons: The lightweight nature of aluminum makes it easier to transport and install. However, it is less durable than stainless steel and can be prone to dents and scratches. Additionally, aluminum may require protective coatings to enhance its resistance to corrosion.

Impact on Application: Aluminum is suitable for freshwater environments but may not perform as well in highly corrosive conditions, such as saltwater.

Considerations for International Buyers: Buyers should check compliance with standards such as ASTM B221 for aluminum extrusions. In regions like South America, where humidity can be high, selecting anodized aluminum can mitigate some corrosion risks.

Polycarbonate

Key Properties: Polycarbonate is a thermoplastic known for its impact resistance and transparency. It can withstand moderate temperatures and is often used in applications requiring visibility.

Pros & Cons: The primary advantage of polycarbonate is its lightweight nature and high impact resistance, making it ideal for protective covers and windows in vending machines. However, it is less resistant to UV radiation and may degrade over time if exposed to direct sunlight without proper treatment.

Impact on Application: Polycarbonate is suitable for environments where visibility of the bait is essential, but it may not be suitable for direct exposure to harsh chemicals or extreme temperatures.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM D635 for flammability. In regions like Africa and the Middle East, UV stabilization treatments can enhance the material’s longevity.

Mild Steel

Key Properties: Mild steel is a low-carbon steel that provides good weldability and machinability. It is often used in structural applications but has limited corrosion resistance unless properly coated.

Pros & Cons: Mild steel is cost-effective and offers good strength, making it a popular choice for structural components. However, it is highly susceptible to corrosion if not adequately protected, which can lead to increased maintenance costs.

Impact on Application: Mild steel is suitable for internal components of bait vending machines but requires protective coatings (e.g., powder coating) for external applications, especially in humid environments.

Considerations for International Buyers: Compliance with standards like ASTM A36 is important. Buyers should consider the local climate and potential exposure to corrosive elements when selecting mild steel for their machines.

Summary Table

| Material | Typical Use Case for bait vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, external casing | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Aluminum | Lightweight parts, internal components | Lightweight and easy to transport | Less durable, may require coatings | Medium |

| Polycarbonate | Protective covers, visibility panels | High impact resistance | UV degradation over time | Medium |

| Mild Steel | Structural elements, internal supports | Cost-effective, good strength | Susceptible to corrosion | Low |

This guide should assist international B2B buyers in making informed decisions regarding material selection for bait vending machines, ensuring that they choose the best option for their specific operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for bait vending machine

The production of bait vending machines involves several intricate manufacturing processes, each designed to ensure the final product meets industry standards and customer expectations. These processes can be broken down into four main stages: material preparation, forming, assembly, and finishing. Understanding these stages is essential for B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe.

Manufacturing Processes

Material Preparation

The first stage involves selecting and preparing the necessary materials, primarily metals and plastics. Common materials include stainless steel for durability and resistance to corrosion, and high-density polyethylene (HDPE) for its lightweight yet robust properties. Suppliers often source these materials from certified vendors to ensure quality. Buyers should inquire about the origin of materials and request certifications that guarantee compliance with international standards.

Forming

Once materials are prepared, they undergo forming processes such as cutting, bending, and molding. Techniques like laser cutting and CNC machining are commonly used for precision and efficiency. These methods allow for intricate designs and the customization of components to meet specific requirements. For B2B buyers, understanding the forming techniques used can provide insights into the machine’s longevity and performance.

Assembly

After forming, components are assembled into the final product. This stage typically involves both manual and automated processes. Automation can enhance consistency and reduce labor costs, while skilled labor is crucial for tasks requiring precision, such as wiring and the installation of electronic components. Buyers should evaluate the assembly processes employed by suppliers, as this stage significantly impacts the machine’s operational reliability.

Finishing

The final stage of manufacturing involves finishing processes such as painting, coating, and surface treatment. These processes not only enhance the aesthetic appeal of the bait vending machine but also improve its resistance to environmental factors such as moisture and UV exposure. Buyers should ensure that suppliers follow best practices in finishing to guarantee a longer lifespan for the machines.

Quality Assurance

Quality assurance (QA) is critical in manufacturing, ensuring that products meet established standards and customer expectations. For bait vending machines, this involves adhering to both international and industry-specific standards.

International Standards

ISO 9001 is the most recognized international standard for quality management systems. Compliance with ISO 9001 indicates that a supplier has implemented a robust quality management framework. B2B buyers should look for suppliers who hold ISO 9001 certification, as this demonstrates a commitment to continuous improvement and customer satisfaction.

Illustrative Image (Source: Google Search)

Industry-Specific Standards

In addition to ISO standards, industry-specific certifications such as CE marking in Europe and API standards in the Middle East may apply. The CE mark indicates compliance with safety, health, and environmental protection standards for products sold within the European Economic Area (EEA). Buyers in Europe, especially in Spain, should ensure that their suppliers are compliant with these regulations to avoid legal and safety issues.

QC Checkpoints

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage verifies the quality of raw materials and components before production begins. Buyers can request IQC reports to ensure that only high-quality materials are used.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC checks are conducted to monitor the production process. This ensures that any deviations from specifications are identified and addressed promptly.

-

Final Quality Control (FQC): After assembly, FQC involves comprehensive testing of the finished product. This might include performance tests, safety checks, and functional evaluations. Buyers should ask for detailed FQC reports to verify that the machines meet all operational standards.

Common Testing Methods

Several testing methods are commonly employed to ensure the quality of bait vending machines:

-

Functional Testing: This checks whether the machine operates as intended, including the dispensing mechanism and payment systems.

-

Durability Testing: Machines are subjected to stress tests to evaluate their resistance to wear and tear over time.

-

Compliance Testing: This ensures that the machines meet all regulatory requirements, including electrical safety and environmental impact.

Verifying Supplier QC

B2B buyers can take several steps to verify the quality control processes of suppliers:

-

Audits: Conducting supplier audits can provide insights into their manufacturing processes and quality management systems. This could be a part of a broader vendor assessment.

-

Requesting Reports: Buyers should ask suppliers for documentation related to IQC, IPQC, and FQC results. Reviewing these reports helps validate the supplier’s claims about quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s QC processes. This is particularly beneficial for businesses operating in regions where they cannot physically inspect the manufacturing facilities.

QC and Certification Nuances for International Buyers

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is essential. Different regions may have varying regulatory requirements and standards, which can impact the importation and usability of bait vending machines. Buyers should be aware of local regulations and ensure that suppliers provide the necessary documentation to comply with these standards.

Additionally, cultural differences may influence the interpretation of quality standards. Effective communication with suppliers about expectations and requirements is crucial to avoid misunderstandings.

Conclusion

In summary, understanding the manufacturing processes and quality assurance measures for bait vending machines is vital for international B2B buyers. By focusing on material preparation, forming, assembly, finishing, and adhering to international and industry-specific quality standards, buyers can ensure they procure reliable and high-quality machines. Engaging in thorough due diligence, including audits and verification of certifications, will further safeguard their investments and enhance operational success.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for bait vending machine Sourcing

Understanding the cost structure and pricing dynamics associated with sourcing bait vending machines is essential for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. This section provides a detailed analysis of cost components, price influencers, and actionable buyer tips to enhance sourcing strategies.

Cost Components

-

Materials: The primary materials used in bait vending machines include metal, plastics, and electronic components. Prices can vary significantly based on the quality and source of these materials. For instance, sourcing metals from local suppliers may reduce costs compared to importing from overseas.

-

Labor: Labor costs can fluctuate based on the manufacturing location. Regions with lower labor costs, such as parts of South America and Asia, may offer significant savings. However, consider the trade-off in terms of quality and expertise, especially when precision manufacturing is required.

-

Manufacturing Overhead: This includes all indirect costs related to production, such as utilities, rent, and administrative expenses. Understanding the overhead structure of suppliers is crucial, as it can significantly impact the final pricing of the machines.

-

Tooling: Custom tooling for specific machine designs can add to initial costs. Buyers should weigh the benefits of custom solutions against the potential for higher upfront investment. Standardized tools may reduce costs but could limit customization options.

-

Quality Control (QC): Ensuring quality through rigorous QC processes is essential, especially for machines meant for outdoor use. Investing in quality control can prevent costly defects and ensure reliability, which is critical for customer satisfaction.

-

Logistics: Shipping costs, including freight, insurance, and customs duties, can vary widely based on the geographic location of the buyer and the supplier’s shipping practices. Incoterms play a crucial role in defining who bears these costs, impacting the total price.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the standard margins in the industry can help buyers negotiate better deals. Margins often vary based on market conditions and competition.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Higher volumes often lead to lower per-unit costs, so buyers should consider consolidating orders to maximize savings.

-

Specifications/Customization: Custom features and specifications can lead to increased costs. Buyers should assess whether the additional features are essential or if standard models suffice for their needs.

-

Quality/Certifications: Machines that meet specific industry standards or certifications may come at a premium. However, these certifications often justify higher prices by ensuring reliability and safety.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their track record but often provide better assurance of quality and service.

-

Incoterms: Understanding the responsibilities defined by Incoterms (e.g., FOB, CIF) is vital for cost management. The choice of Incoterms can affect freight costs and risk management, impacting the overall cost structure.

Buyer Tips

-

Negotiation: Always approach negotiations with a clear understanding of the market rates and be prepared to discuss pricing based on volume, delivery times, and payment terms.

-

Cost-Efficiency: Evaluate total costs, including shipping and customs, rather than just the machine’s base price. This holistic view can uncover hidden expenses and more cost-effective options.

-

Total Cost of Ownership (TCO): Consider the long-term costs associated with maintenance, energy consumption, and potential downtime. Machines with a higher initial price but lower operating costs can be more economical over time.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and trade agreements that could affect pricing. Establishing relationships with local agents or distributors can provide insights into regional market conditions and pricing strategies.

Disclaimer

The prices discussed in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough market research and supplier evaluations to obtain accurate pricing.

Spotlight on Potential bait vending machine Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for bait vending machine.)*

Essential Technical Properties and Trade Terminology for bait vending machine

Key Technical Properties of Bait Vending Machines

Understanding the technical specifications of bait vending machines is crucial for B2B buyers. Here are the essential properties to consider:

-

Material Grade

– Bait vending machines are primarily constructed from stainless steel or high-grade plastics. Stainless steel offers durability and corrosion resistance, essential for machines exposed to moisture and environmental elements. High-grade plastics provide lightweight options and can reduce overall costs. For B2B buyers, selecting the right material ensures longevity and minimizes maintenance, which translates to lower operational costs. -

Capacity

– The capacity of a bait vending machine refers to the volume of bait it can hold. This is typically measured in liters or kilograms. A higher capacity is advantageous for businesses that experience high demand, as it reduces the frequency of restocking. Buyers should assess the expected usage rates to determine the optimal capacity that aligns with their operational needs. -

Power Supply

– Most bait vending machines operate on either AC or DC power. Understanding the power requirements is essential for ensuring compatibility with local electrical standards. International buyers must consider voltage differences in their regions, as this can impact the machine’s performance and safety. Proper alignment with local regulations is crucial to avoid operational disruptions. -

User Interface

– The user interface includes the controls and display systems that customers interact with. Advanced models may feature touch screens, while simpler versions might use buttons. A user-friendly interface can improve customer satisfaction and reduce the need for extensive training. Buyers should prioritize machines with intuitive designs that cater to their target market’s tech-savviness. -

Payment Systems

– Payment options can significantly impact the usability of bait vending machines. Modern machines often support multiple payment methods, including cash, credit/debit cards, and mobile payments. Understanding the payment preferences of the target market is vital. Offering diverse payment options can enhance customer convenience and drive sales.

Common Trade Terminology

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B environment. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces components that are used in another company’s end product. In the context of bait vending machines, buyers may source critical parts from OEMs to ensure quality and compatibility. Engaging with reputable OEMs can lead to better pricing and more reliable supply chains. -

MOQ (Minimum Order Quantity)

– MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budget planning and inventory management. Buyers should negotiate MOQs that align with their business models to avoid excess capital tied up in unsold inventory. -

RFQ (Request for Quotation)

– An RFQ is a formal process where buyers request pricing and terms from suppliers. This step is critical for obtaining competitive pricing and understanding the terms of sale. An effective RFQ can lead to better deals and more favorable contract terms. -

Incoterms

– Incoterms (International Commercial Terms) are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for managing shipping, insurance, and customs clearance. Familiarity with Incoterms can prevent disputes and streamline international operations. -

Lead Time

– Lead time refers to the period from placing an order to receiving the product. For bait vending machines, lead times can vary based on manufacturing processes, customization requirements, and shipping logistics. Buyers should factor lead times into their planning to ensure timely availability of products for their customers.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, fostering successful partnerships and optimizing their supply chain strategies in the bait vending machine market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the bait vending machine Sector

Market Overview & Key Trends

The bait vending machine sector is experiencing a dynamic transformation driven by various global factors. Key drivers include the increasing popularity of recreational fishing, which has surged in regions such as Africa and South America, leading to a growing demand for convenient access to bait. Additionally, technological advancements are reshaping the market landscape. The integration of IoT and mobile payment solutions into vending machines enhances user experience and operational efficiency, appealing to tech-savvy consumers across Europe and the Middle East.

International B2B buyers should be aware of emerging sourcing trends, particularly the shift towards direct partnerships with manufacturers. This approach not only streamlines the supply chain but also allows buyers to customize offerings based on regional preferences. For instance, in Spain, the demand for specific bait types is growing due to local fishing practices, prompting manufacturers to adapt their product lines accordingly.

Moreover, sustainability is becoming a paramount concern. B2B buyers are increasingly prioritizing vendors who demonstrate a commitment to eco-friendly practices, such as using recyclable materials and minimizing waste. The adoption of digital platforms for monitoring inventory and sales data is also enhancing market responsiveness, enabling businesses to swiftly adapt to changing consumer demands.

Sustainability & Ethical Sourcing in B2B

In the bait vending machine sector, sustainability is not merely a trend but a necessity. The environmental impact of fishing practices and bait production can be significant, leading to overfishing and habitat destruction. As such, B2B buyers must prioritize ethical sourcing to ensure the sustainability of their supply chains. This involves collaborating with suppliers who adhere to responsible fishing practices and can provide transparency regarding the sourcing of their bait products.

Furthermore, the utilization of ‘green’ certifications and materials is gaining traction in the industry. Buyers should look for vendors who offer bait made from biodegradable or sustainably sourced components, as these products not only reduce environmental impact but also appeal to a growing consumer base that values sustainability. Certifications such as the Marine Stewardship Council (MSC) can serve as indicators of a supplier’s commitment to ethical practices.

By emphasizing sustainability, buyers can not only enhance their corporate responsibility but also position themselves favorably within their markets. As consumers, especially in Europe and the Middle East, increasingly demand eco-friendly options, businesses that align with these values can gain a competitive edge.

Brief Evolution/History

The bait vending machine sector has evolved significantly since its inception. Originally designed for convenience, these machines have transitioned from basic models dispensing live bait to sophisticated units equipped with smart technology. The introduction of digital payment options and real-time inventory tracking systems has modernized the user experience.

Historically, the sector catered primarily to local fishing communities; however, with the globalization of fishing tourism, international B2B buyers now have access to a wider array of products and services. This evolution reflects broader trends in consumer behavior, where convenience, technology integration, and sustainability are becoming essential components of business strategy in the bait vending machine industry.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of bait vending machine

-

What should I consider when vetting suppliers for bait vending machines?

When vetting suppliers, prioritize their experience and specialization in vending machines, specifically in the bait sector. Request references and case studies from previous clients, particularly those in your region. Evaluate their production capabilities and quality assurance processes. Additionally, check for certifications relevant to your market, such as CE for Europe or ISO standards, which demonstrate compliance with international regulations. -

Can bait vending machines be customized for specific needs?

Yes, many suppliers offer customization options for bait vending machines. Buyers can request features such as size, design, payment systems, and even the types of bait dispensed. Clearly outline your requirements in the initial discussions to ensure the supplier can meet your specifications. This customization can enhance user experience and boost sales, particularly in diverse markets like Africa and South America. -

What are the typical minimum order quantities (MOQs) and lead times for bait vending machines?

MOQs can vary significantly based on the supplier and the complexity of the machines. Generally, expect MOQs to range from 5 to 50 units. Lead times can also differ; anticipate 4 to 16 weeks from order confirmation to delivery, depending on customization and production schedules. Always discuss these factors upfront to align expectations and plan your inventory accordingly. -

What payment terms should I expect when ordering from international suppliers?

Payment terms can vary widely among suppliers. Common options include upfront payment, a deposit followed by the balance upon delivery, or payment through letters of credit. For international transactions, consider using secure payment methods that protect your investment. Establish clear terms in your contract to avoid misunderstandings, and ensure compliance with local regulations in both your country and the supplier’s. -

How can I ensure quality assurance and certification for my purchase?

Request documentation of quality assurance practices from suppliers, including details on testing and inspection processes. Certifications such as ISO 9001 or specific safety certifications relevant to your market can indicate a commitment to quality. Before finalizing your order, consider asking for samples or test machines to evaluate performance and durability, ensuring they meet your standards. -

What logistical considerations should I be aware of when importing bait vending machines?

Logistics can be complex, especially when importing machinery. Consider the total landed cost, including shipping, customs duties, and taxes. Engage with logistics providers experienced in handling machinery to streamline the process. Additionally, verify that the supplier can provide necessary shipping documents and ensure compliance with customs regulations in your country to avoid delays. -

How should I handle disputes with suppliers?

To handle disputes effectively, establish a clear communication channel with your supplier from the outset. Include dispute resolution clauses in your contract, outlining steps for mediation or arbitration. If issues arise, document all communications and agreements related to the dispute. Engaging a legal professional familiar with international trade laws can also be beneficial in resolving conflicts amicably. -

What are the warranty and after-sales support options available for bait vending machines?

Most reputable suppliers will offer a warranty covering manufacturing defects for a specified period, typically from one to three years. Inquire about the terms of the warranty, including what it covers and how to claim it. Additionally, assess the supplier’s after-sales support, such as technical assistance, spare parts availability, and maintenance services, to ensure ongoing support for your investment.

Strategic Sourcing Conclusion and Outlook for bait vending machine

In conclusion, the strategic sourcing of bait vending machines presents a unique opportunity for international B2B buyers across Africa, South America, the Middle East, and Europe. By prioritizing key factors such as supplier reliability, product quality, and local market trends, businesses can enhance their competitive advantage. Establishing strong partnerships with vendors not only ensures a consistent supply of high-quality bait but also fosters innovation and adaptability to changing customer demands.

Key Takeaways:

- Market Understanding: Conduct thorough market research to identify regional preferences and seasonal trends in fishing activities.

- Supplier Evaluation: Focus on suppliers who demonstrate sustainability practices and can provide comprehensive support, including maintenance and operational training.

- Cost-Effectiveness: Analyze total cost of ownership, including procurement, logistics, and potential revenue generation through strategic placement of machines.

As the demand for innovative and convenient fishing solutions grows, international B2B buyers should act decisively to leverage these insights. Embrace strategic sourcing as a pathway to not only meet current market needs but also to anticipate future trends. Engage with suppliers who share your vision for growth and sustainability, ensuring your business remains at the forefront of this evolving industry.