Optimize Your Investment in Vending Machine Refrigeration

Guide to Vending Machine Refrigeration

- Introduction: Navigating the Global Market for vending machine refrigeration

- Understanding vending machine refrigeration Types and Variations

- Key Industrial Applications of vending machine refrigeration

- Strategic Material Selection Guide for vending machine refrigeration

- In-depth Look: Manufacturing Processes and Quality Assurance for vending machine refrigeration

- Comprehensive Cost and Pricing Analysis for vending machine refrigeration Sourcing

- Spotlight on Potential vending machine refrigeration Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for vending machine refrigeration

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine refrigeration Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vending machine refrigeration

- Strategic Sourcing Conclusion and Outlook for vending machine refrigeration

Introduction: Navigating the Global Market for vending machine refrigeration

Vending machine refrigeration is a pivotal element in the evolving landscape of automated retail, ensuring product freshness and consumer satisfaction. As international B2B buyers increasingly recognize the value of quality refrigeration, understanding the nuances of this market becomes essential. The right refrigeration solutions not only extend the shelf life of beverages and snacks but also enhance operational efficiency, reduce energy costs, and comply with health regulations.

This guide delves into the comprehensive aspects of vending machine refrigeration, covering various types and materials used in manufacturing, stringent quality control measures, and an overview of leading suppliers in the industry. Additionally, we will explore cost implications and market trends that impact sourcing decisions. By providing answers to frequently asked questions, this resource aims to equip buyers with the knowledge necessary to make informed purchasing decisions.

For businesses in regions such as Africa, South America, the Middle East, and Europe, understanding the intricacies of vending machine refrigeration is crucial. The insights presented herein empower buyers to navigate the complexities of international procurement, ensuring they select products that meet both operational needs and budget constraints. With this guide, B2B buyers will be better positioned to capitalize on the lucrative opportunities within the vending machine market, ultimately driving business success.

Understanding vending machine refrigeration Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Glass Front Refrigerators | Transparent glass door, high visibility of products | Retail environments, convenience stores | Pros: Attractive display, easy access; Cons: Higher energy consumption, potential for condensation issues. |

| Closed Front Refrigerators | Solid doors, often insulated, better energy efficiency | Office break rooms, vending locations | Pros: Energy-efficient, maintains temperature; Cons: Limited visibility of products. |

| Reach-In Refrigerators | Typically larger, allows for bulk storage of products | Supermarkets, restaurants | Pros: High capacity, easy to organize; Cons: Requires more space, higher initial investment. |

| Compact Refrigerators | Smaller footprint, designed for limited space | Small offices, gyms, dormitories | Pros: Space-saving, portable; Cons: Limited storage capacity, may not accommodate larger items. |

| Mobile Vending Refrigerators | Portable units, often battery-operated for mobility | Events, festivals, outdoor markets | Pros: Versatile and adaptable; Cons: Battery life limitations, may require frequent charging. |

Glass Front Refrigerators

These refrigerators feature transparent glass doors that allow customers to view products without opening the unit. This design is particularly effective in retail environments and convenience stores, where product visibility can drive sales. When considering a purchase, buyers should evaluate energy efficiency, as these units can consume more energy due to frequent door openings and potential condensation issues.

Closed Front Refrigerators

Closed front refrigerators are characterized by solid, insulated doors that enhance energy efficiency and temperature stability. They are commonly used in office break rooms and vending locations where product visibility is less critical. B2B buyers should weigh the benefits of lower energy costs against the potential drawback of limited product visibility, which may impact impulse purchases.

Reach-In Refrigerators

Reach-in refrigerators are larger units designed for bulk storage of perishable items. They are ideal for supermarkets and restaurants, providing easy access to a wide range of products. Buyers should consider the space requirements and initial investment, as these units can be more costly and necessitate a larger footprint compared to other types of refrigeration.

Compact Refrigerators

Compact refrigerators are designed for environments with limited space, such as small offices, gyms, or dormitories. Their smaller footprint makes them portable and easy to fit into various settings. However, B2B buyers should be mindful of their limited storage capacity, which may not accommodate larger items or high-volume needs.

Mobile Vending Refrigerators

These are portable refrigeration units, often battery-operated, designed for use at events, festivals, and outdoor markets. Their versatility allows businesses to adapt to various locations and customer demands. Buyers should consider battery life and charging requirements, as these units may need regular recharging to maintain optimal performance during extended use.

Related Video: 1. Risk Communication. Models. Definitions

Key Industrial Applications of vending machine refrigeration

| Industry/Sector | Specific Application of vending machine refrigeration | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Snack and beverage vending machines | Increased sales through convenient access to chilled products | Energy efficiency, reliability, and temperature control |

| Healthcare | Pharmaceutical dispensing machines | Ensures medication integrity through proper temperature maintenance | Compliance with health regulations, energy efficiency |

| Hospitality | Hotel mini-bars | Enhances guest experience with easy access to refreshments | Compact design, energy consumption, and aesthetic appeal |

| Retail | Automated retail kiosks for groceries | Streamlines inventory management and reduces labor costs | Durability, ease of maintenance, and supply chain logistics |

| Education | Campus vending machines for students | Promotes healthy eating options and convenience for students | Customization options, energy efficiency, and reliability |

Food & Beverage

Vending machine refrigeration plays a vital role in the food and beverage industry by maintaining the optimal temperature for snacks and drinks. This technology helps businesses increase sales by providing customers with convenient access to chilled products, especially in high-traffic areas. International buyers should consider energy efficiency and reliability when sourcing these machines, as they can significantly impact operational costs and product quality.

Healthcare

In the healthcare sector, refrigerated vending machines are crucial for the safe dispensing of pharmaceuticals and medical supplies. These machines ensure that medications are stored at the required temperatures, preserving their efficacy and integrity. Buyers in this industry must prioritize compliance with health regulations and seek machines that demonstrate energy efficiency to minimize operational costs while maintaining strict temperature controls.

Hospitality

In hotels, mini-bars equipped with refrigeration technology enhance the guest experience by providing easy access to refreshments. This convenience can lead to increased revenue through impulse purchases. When sourcing these machines, businesses should focus on compact designs that fit various room sizes, as well as energy-efficient models that align with sustainability goals while appealing to guests’ aesthetic preferences.

Retail

Automated retail kiosks, particularly those selling groceries, utilize vending machine refrigeration to keep products fresh and appealing. This application streamlines inventory management and reduces labor costs by allowing consumers to purchase items without staff assistance. Key considerations for B2B buyers include the durability of refrigeration units, ease of maintenance, and the logistics of supply chains to ensure consistent product availability.

Education

On campuses, vending machines with refrigeration capabilities provide students with convenient access to healthy food options. These machines can promote better eating habits while catering to busy schedules. Buyers should look for customization options to meet specific dietary needs, energy-efficient designs to keep operational costs low, and reliable performance to ensure consistent availability of products.

Related Video: Industrial Refrigeration system Basics – Ammonia refrigeration working principle

Strategic Material Selection Guide for vending machine refrigeration

When selecting materials for vending machine refrigeration, international B2B buyers must consider various factors, including the material’s properties, performance, and compliance with regional standards. Below, we analyze four common materials used in vending machine refrigeration systems.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures and pressures. It typically has a temperature rating of up to 800°C and can handle pressures of 2000 psi, depending on the grade.

Pros & Cons: The durability of stainless steel makes it ideal for long-term use in refrigeration applications. However, it tends to be more expensive than other materials like carbon steel or aluminum. Manufacturing complexity can also be higher due to the need for specialized welding techniques.

Impact on Application: Stainless steel is compatible with a wide range of refrigerants, making it a versatile choice for various vending machine designs. Its non-reactive nature ensures that it does not contaminate the stored products.

Considerations for International Buyers: Buyers from regions like South Africa and Colombia should ensure compliance with local standards such as SANS and ASTM, as well as consider the availability of specific grades like 304 or 316, which are commonly used in food-grade applications.

Aluminum

Key Properties: Aluminum is lightweight, has good thermal conductivity, and offers decent corrosion resistance. Its temperature rating is generally lower than stainless steel, typically around 300°C.

Pros & Cons: The primary advantage of aluminum is its low weight, making it easier to transport and install. However, it is less durable than stainless steel and can be prone to denting and scratching. Additionally, its cost is moderate compared to stainless steel.

Impact on Application: Aluminum is suitable for applications involving non-corrosive refrigerants. However, it may not be the best choice for environments with high humidity or exposure to aggressive chemicals.

Considerations for International Buyers: Buyers in Europe and the Middle East should check compliance with EU regulations regarding food safety and material certification. Preference for aluminum may vary based on local market trends and the specific requirements of vending machine designs.

Carbon Steel

Key Properties: Carbon steel is known for its high strength and ability to withstand mechanical stress. It is generally rated for temperatures up to 400°C and pressures similar to stainless steel.

Pros & Cons: Carbon steel is cost-effective and provides good structural integrity. However, it is susceptible to corrosion if not properly coated or treated, which can limit its lifespan in refrigeration applications.

Impact on Application: While suitable for structural components, carbon steel is less compatible with moisture-laden environments unless adequately protected. It is often used in frames and supports rather than in direct contact with refrigerants.

Considerations for International Buyers: Buyers in South America should be aware of local corrosion risks and consider protective coatings. Compliance with ASTM standards is essential for ensuring quality and safety in applications.

Copper

Key Properties: Copper has excellent thermal conductivity and is highly malleable, making it ideal for heat exchangers in refrigeration systems. Its temperature rating can exceed 200°C, and it can handle high pressures.

Pros & Cons: The primary advantage of copper is its superior thermal properties, which enhance the efficiency of refrigeration systems. However, copper is more expensive than aluminum and carbon steel, and its susceptibility to corrosion can be a drawback in certain environments.

Impact on Application: Copper is widely used in heat exchange applications within vending machines, especially for cooling coils. Its compatibility with various refrigerants makes it a preferred choice for many manufacturers.

Considerations for International Buyers: Buyers from the Middle East should consider the impact of high temperatures on copper’s performance and ensure compliance with local standards. The cost of copper may also fluctuate based on global market conditions.

Summary Table

| Material | Typical Use Case for vending machine refrigeration | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, food-safe applications | Excellent corrosion resistance, durability | Higher cost, complex manufacturing | High |

| Aluminum | Lightweight frames, non-corrosive refrigerants | Low weight, good thermal conductivity | Less durable, prone to damage | Medium |

| Carbon Steel | Structural supports, frames | Cost-effective, high strength | Susceptible to corrosion | Low |

| Copper | Heat exchangers, cooling coils | Superior thermal conductivity | Expensive, corrosion risk | High |

This guide provides a comprehensive overview of material options for vending machine refrigeration, allowing international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for vending machine refrigeration

Manufacturing Processes for Vending Machine Refrigeration

The manufacturing of vending machine refrigeration units involves several critical stages that ensure the final product meets quality, efficiency, and safety standards. Understanding these processes is essential for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

1. Material Preparation

The manufacturing process begins with the careful selection and preparation of materials. Common materials include:

- Steel and Aluminum: Used for structural components due to their durability and resistance to corrosion.

- Insulation Materials: Such as polyurethane foam, which is crucial for energy efficiency.

- Refrigerants: Compliant with international environmental standards (e.g., R134a, R600a) that minimize ozone depletion and global warming potential.

Key Techniques:

– Material Testing: Prior to use, materials undergo testing for tensile strength, thermal conductivity, and resistance to corrosion.

– Sourcing: Reliable suppliers are critical; buyers should evaluate suppliers based on their material certifications and environmental compliance.

2. Forming

Once materials are prepared, the next step is forming components through processes such as:

- Stamping: Used for creating metal parts like panels and brackets.

- Injection Molding: For producing plastic components that house electronic controls.

- Cutting and Bending: Essential for custom-fit designs that meet specific vending machine configurations.

Key Techniques:

– CNC Machining: Offers precision in creating complex shapes and parts, enhancing the quality of the final assembly.

– Laser Cutting: Provides high accuracy and clean edges, reducing the need for further finishing work.

3. Assembly

The assembly stage involves integrating all components into a functional refrigeration unit. This includes:

- Mechanical Assembly: Installing compressors, evaporators, condensers, and fans.

- Electrical Assembly: Wiring the control systems, sensors, and displays.

- Insulation Installation: Ensuring that insulation is properly fitted to minimize energy loss.

Key Techniques:

– Robotic Assembly: Increases efficiency and reduces human error during the assembly process.

– Modular Design: Allows for easier assembly and maintenance, providing flexibility for different vending machine configurations.

4. Finishing

Finishing processes enhance the durability and aesthetic appeal of vending machines. This includes:

- Surface Treatment: Such as powder coating or painting to provide a protective layer against scratches and corrosion.

- Quality Control Testing: Units undergo rigorous testing for functionality, including temperature checks and energy consumption assessments.

Key Techniques:

– Automated Painting Systems: Ensure uniform coverage and reduce waste.

– Final Assembly Check: A thorough inspection to confirm that all components are correctly installed and functioning.

Quality Assurance in Vending Machine Refrigeration

Quality assurance (QA) is paramount in manufacturing, particularly for products that must meet stringent international standards.

International and Industry Standards

B2B buyers should be aware of the following standards that govern the manufacturing of vending machine refrigeration:

- ISO 9001: Focuses on quality management systems and ensuring consistent quality in production.

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- UL Certification: For safety and performance in North America.

- API Standards: Relevant for components that require adherence to specific performance criteria.

Quality Control Checkpoints

Effective quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspects raw materials upon delivery to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing assessments during production to identify defects early.

- Final Quality Control (FQC): Comprehensive testing of finished products to verify performance against specifications.

Common Testing Methods:

– Thermal Testing: Evaluating cooling efficiency under various conditions.

– Electrical Testing: Ensuring that electrical components operate correctly and safely.

– Durability Testing: Simulating long-term use to assess the lifespan of components.

Verifying Supplier Quality Control

B2B buyers can implement several strategies to verify the quality control practices of their suppliers:

- Supplier Audits: Conducting on-site evaluations of manufacturing processes and QA systems.

- Reviewing Quality Reports: Analyzing documentation that outlines past quality issues and resolutions.

- Third-Party Inspections: Engaging independent inspectors to assess compliance with industry standards.

Considerations for International Buyers

For buyers from Africa, South America, the Middle East, and Europe, several nuances should be kept in mind:

- Local Standards Compliance: Ensure that products meet local regulations in addition to international standards.

- Cultural and Market Differences: Understand that customer preferences may vary, necessitating adjustments in product design or features.

- Logistics and Supply Chain: Evaluate the supplier’s ability to meet delivery timelines and manage shipping costs effectively.

By comprehensively understanding the manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions, ensuring they source reliable and efficient vending machine refrigeration solutions that align with their operational needs.

Related Video: How It’s Made Air Conditioner In Factories | Air Conditioner Manufacturing Process @Techmachine_

Comprehensive Cost and Pricing Analysis for vending machine refrigeration Sourcing

Understanding the Cost Structure of Vending Machine Refrigeration

When sourcing vending machine refrigeration units, understanding the cost structure is essential for international B2B buyers. The main components that contribute to the overall cost include:

- Materials: The choice of materials significantly impacts cost. High-quality insulation, compressors, and refrigerants are crucial for efficiency and longevity but can increase initial expenses.

- Labor: Labor costs vary by region and can influence pricing. It’s important to consider the local labor market when negotiating with suppliers.

- Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses. Suppliers with efficient production processes may offer lower prices.

- Tooling: Custom tooling for specific designs can be a significant upfront cost. Buyers should evaluate whether their specifications justify this investment.

- Quality Control (QC): Implementing rigorous QC processes ensures product reliability but adds to manufacturing costs. Certifications (like ISO) might also affect pricing.

- Logistics: Shipping costs can vary widely based on the distance from the manufacturer, mode of transport, and local tariffs. Understanding Incoterms is vital to gauge responsibility for shipping costs.

- Margin: Supplier margins can fluctuate depending on market conditions, competition, and product demand.

Price Influencers in Vending Machine Refrigeration

Several factors can influence pricing for vending machine refrigeration, particularly for international buyers:

- Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Negotiating for favorable terms based on volume can yield significant savings.

- Specifications and Customization: Customized units with specific features or designs generally come at a premium. Buyers should weigh the benefits of customization against costs.

- Materials and Quality Certifications: Higher-quality materials and certifications can increase costs but may offer better performance and durability, leading to lower total costs over time.

- Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a proven track record may charge more but offer better service and support.

- Incoterms: Understanding the responsibilities defined by Incoterms can help buyers avoid unexpected costs related to shipping and insurance.

Tips for International Buyers

For buyers from Africa, South America, the Middle East, and Europe, consider the following strategies to enhance cost-efficiency:

- Negotiate Terms: Leverage your purchasing power by negotiating better terms, especially if placing large orders or establishing long-term relationships.

- Evaluate Total Cost of Ownership (TCO): Focus not just on the initial purchase price but also on operational costs, maintenance, and energy efficiency over the product’s lifecycle.

- Understand Pricing Nuances: Be aware that pricing can vary based on local economic conditions, currency fluctuations, and trade policies. Conduct thorough market research to inform your negotiations.

- Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms, as well as priority service and support.

Disclaimer on Pricing

Please note that prices for vending machine refrigeration units can fluctuate based on market conditions, and the insights provided here should be considered indicative. Always request quotes directly from suppliers to obtain accurate pricing tailored to your specific needs and circumstances.

Spotlight on Potential vending machine refrigeration Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘vending machine refrigeration’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for vending machine refrigeration

In the realm of vending machine refrigeration, understanding the essential technical properties and trade terminology is crucial for international B2B buyers. This knowledge not only aids in making informed purchasing decisions but also enhances communication with suppliers and manufacturers. Below, we outline key specifications and terms that buyers should familiarize themselves with.

Critical Technical Properties

-

Material Grade

– The material used in vending machine refrigeration units, often stainless steel or high-grade plastics, affects durability and efficiency. Stainless steel is preferred for its resistance to corrosion and ease of cleaning, which is essential in food safety. -

Cooling Capacity

– Measured in BTUs (British Thermal Units), this specification indicates the amount of heat a refrigeration unit can remove in an hour. A higher BTU rating is necessary for larger machines or those in hotter climates, ensuring products remain at safe temperatures. -

Energy Efficiency Rating (EER)

– This rating assesses the efficiency of a refrigeration unit in converting electrical energy into cooling power. Higher EER values indicate lower operating costs, which is vital for long-term profitability, especially in regions with high energy costs. -

Temperature Range

– The operational temperature range specifies the lowest and highest temperatures a vending machine can maintain. This is crucial for ensuring that perishable goods are stored at safe temperatures, particularly in tropical climates found in parts of Africa and South America. -

Noise Level

– Measured in decibels (dB), noise level is an important consideration for vending machines located in quiet environments, such as offices or libraries. Units with lower dB ratings provide a more pleasant user experience. -

Insulation Thickness

– The thickness of the insulation material affects energy efficiency and cooling performance. Greater insulation thickness helps maintain internal temperatures and reduces energy consumption, which is particularly beneficial in warmer regions.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers for specific components of vending machines. -

MOQ (Minimum Order Quantity)

– This term indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, particularly for smaller businesses or startups. -

RFQ (Request for Quotation)

– A formal document used by buyers to solicit price offers from suppliers. Crafting a precise RFQ is important for obtaining competitive pricing and ensuring that all necessary specifications are addressed. -

Incoterms (International Commercial Terms)

– These standardized trade terms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms can streamline negotiations and reduce misunderstandings. -

Lead Time

– The time taken from placing an order to receiving the goods. Understanding lead times is crucial for planning inventory levels and ensuring that vending machines are stocked and operational promptly. -

Warranty Period

– The duration for which a product is guaranteed against defects. A longer warranty period can indicate higher product quality and provides buyers with peace of mind regarding their investment.

By equipping themselves with knowledge of these technical properties and trade terms, B2B buyers can navigate the complexities of vending machine refrigeration more effectively, fostering better supplier relationships and ensuring optimal product performance.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine refrigeration Sector

Market Overview & Key Trends

The vending machine refrigeration sector is experiencing significant growth, driven by increasing consumer demand for convenient access to beverages and snacks, coupled with technological advancements. Key market dynamics include the rise of smart vending machines that integrate IoT technology, allowing for remote monitoring and inventory management. This trend is particularly relevant for B2B buyers from regions like Africa and South America, where logistics and supply chain efficiency are critical.

Emerging trends in sourcing emphasize energy-efficient refrigeration units that comply with global energy standards. International buyers should consider manufacturers offering innovative cooling solutions, such as eco-friendly refrigerants and energy-efficient compressors, which not only reduce operational costs but also align with sustainability goals. Additionally, the adoption of contactless payment systems has become essential, enhancing customer convenience and safety, especially in the wake of the pandemic.

The market is also witnessing a shift towards modular vending solutions, which can be easily adapted to various locations and consumer preferences. For buyers in the Middle East and Europe, understanding local market nuances—such as consumer preferences for healthier snack options—can help in selecting the right vending solutions that cater to diverse demographics.

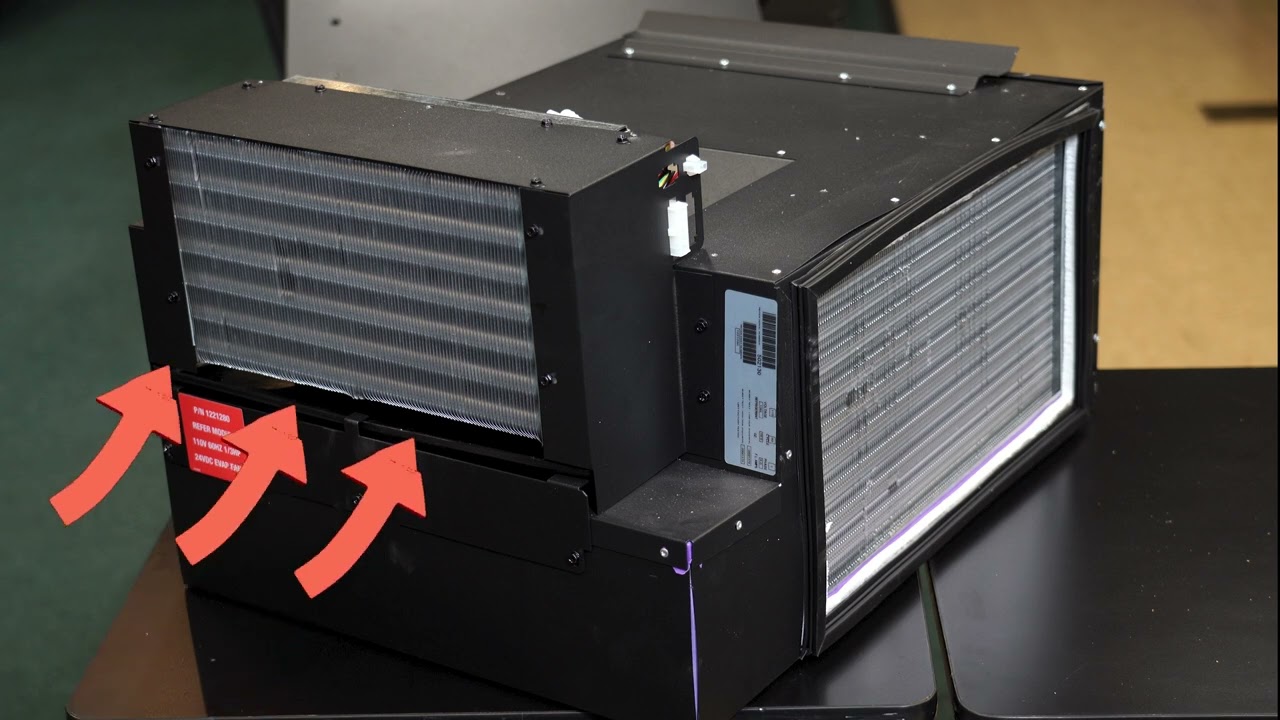

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability is a key consideration for B2B buyers in the vending machine refrigeration sector. The environmental impact of traditional refrigerants, such as HFCs, is prompting a transition to greener alternatives like natural refrigerants (e.g., CO2 and ammonia) that have a lower global warming potential. Buyers should prioritize vendors who demonstrate commitment to sustainable practices through certifications such as ISO 14001 and compliance with the F-Gas Regulation in Europe.

Ethical sourcing is equally important, as it encompasses not only the environmental aspects but also the social responsibility of suppliers. Buyers are encouraged to engage with manufacturers who maintain transparent supply chains and adhere to fair labor practices. This can enhance brand reputation and foster customer loyalty, particularly in markets like South Africa and Colombia, where consumers are increasingly aware of and sensitive to corporate responsibility.

Investing in refrigeration units made from sustainable materials can also contribute to a circular economy, where products are designed for longevity and recyclability. B2B buyers should seek suppliers who provide eco-friendly packaging and promote recycling programs, ensuring that their vending solutions align with broader sustainability objectives.

Brief Evolution/History

The evolution of vending machine refrigeration has been marked by technological advancements and changing consumer behaviors. Initially, vending machines primarily offered canned beverages and snacks without any refrigeration. Over time, the introduction of electric refrigeration transformed these machines, enabling the storage of perishable items and expanding product offerings.

In recent years, the shift towards smart technologies has revolutionized the sector. Today’s vending machines are equipped with sensors, smart payment options, and remote monitoring capabilities, allowing operators to optimize inventory and enhance user experience. As international markets continue to evolve, understanding the historical context of these changes can provide valuable insights into future innovations and consumer expectations in the vending machine refrigeration landscape.

Related Video: Global trade will never be the same again, says Christine Lagarde | Power & Politics

Frequently Asked Questions (FAQs) for B2B Buyers of vending machine refrigeration

-

What factors should I consider when vetting suppliers for vending machine refrigeration?

When vetting suppliers, focus on their industry experience, client testimonials, and product quality certifications. Verify their manufacturing capabilities and ensure they comply with international standards, such as ISO or CE certifications. It’s also beneficial to request samples to assess product quality firsthand. Additionally, consider the supplier’s ability to provide customized solutions tailored to your specific needs, as this can enhance your competitive edge in the market. -

Can I customize vending machine refrigeration units to fit my specific requirements?

Yes, many manufacturers offer customization options for vending machine refrigeration units. You can request specific sizes, colors, and features like energy efficiency and temperature ranges. Discuss your requirements with potential suppliers during the initial negotiations to ensure they can meet your specifications. Keep in mind that customization may impact lead times and costs, so clarify these aspects upfront. -

What are the typical minimum order quantities (MOQs) and lead times for vending machine refrigeration?

Minimum order quantities (MOQs) can vary significantly depending on the supplier and the complexity of the product. Generally, MOQs for vending machine refrigeration units range from 50 to 200 units. Lead times also depend on customization levels and current production schedules, typically ranging from 4 to 12 weeks. Always confirm these details with suppliers before placing an order to avoid unexpected delays. -

What payment terms should I expect when sourcing vending machine refrigeration?

Payment terms can vary by supplier, but common practices include a deposit (usually 30-50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer flexible terms, such as net 30 or net 60 days. It’s crucial to negotiate clear payment terms that protect your interests and ensure you are comfortable with the supplier’s financial credibility. -

How can I ensure quality assurance and certifications for vending machine refrigeration?

Request detailed information about the quality assurance processes employed by the supplier, including inspection procedures and testing protocols. Ensure that the products meet relevant international certifications, such as CE, UL, or RoHS, which indicate compliance with safety and environmental standards. A reliable supplier should be willing to provide documentation verifying these certifications. -

What logistics considerations should I keep in mind when importing vending machine refrigeration?

Logistics is crucial when importing vending machine refrigeration units. Consider shipping methods (air vs. sea), customs regulations in your country, and associated costs like duties and taxes. Collaborate with a reputable freight forwarder who understands the complexities of international shipping. Additionally, ensure that the supplier can accommodate your logistics needs, including packaging and delivery timelines. -

What should I do in case of disputes with my vending machine refrigeration supplier?

In the event of a dispute, first attempt to resolve the issue through direct communication with the supplier. If that fails, refer to your contract for dispute resolution procedures, which may include mediation or arbitration. It’s advisable to maintain thorough documentation of all communications and agreements to support your position. Consider seeking legal advice if the dispute cannot be resolved amicably. -

How do I handle warranty and after-sales service for vending machine refrigeration units?

Ensure that the supplier offers a clear warranty policy that covers defects in materials and workmanship. Understand the duration of the warranty and any specific conditions that may apply. Establish the process for claiming warranty service, including response times and support channels. After-sales service is critical; confirm that the supplier provides reliable support for maintenance and repairs to minimize downtime for your vending operations.

Strategic Sourcing Conclusion and Outlook for vending machine refrigeration

In conclusion, effective strategic sourcing in vending machine refrigeration is essential for international B2B buyers seeking to enhance their operational efficiency and competitiveness. Key takeaways emphasize the importance of understanding local market conditions, leveraging supplier relationships, and prioritizing energy-efficient technologies. By adopting a strategic sourcing approach, businesses can not only reduce costs but also mitigate risks associated with supply chain disruptions.

As we look to the future, the demand for innovative vending solutions is expected to grow, particularly in emerging markets across Africa, South America, the Middle East, and Europe. B2B buyers should stay informed about the latest technological advancements and sustainability practices in refrigeration to capitalize on new opportunities.

Engaging with reliable suppliers who prioritize quality and compliance will be crucial in navigating the complexities of the global market. Now is the time to invest in strategic sourcing strategies that align with your business goals and regional needs. Embrace the future of vending machine refrigeration—your strategic advantage awaits.