Maximize Revenue with the Best Gum Vending Machine

Guide to Gum Vending Machine

- Introduction: Navigating the Global Market for gum vending machine

- Understanding gum vending machine Types and Variations

- Key Industrial Applications of gum vending machine

- Strategic Material Selection Guide for gum vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for gum vending machine

- Comprehensive Cost and Pricing Analysis for gum vending machine Sourcing

- Spotlight on Potential gum vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for gum vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the gum vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of gum vending machine

- Strategic Sourcing Conclusion and Outlook for gum vending machine

Introduction: Navigating the Global Market for gum vending machine

Navigating the global market for gum vending machines presents a unique opportunity for international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe. These machines not only provide a simple and effective means of generating revenue but also enhance customer experience by offering convenience and accessibility to a popular consumer product. As the demand for automated retail solutions continues to rise, understanding the intricacies of the gum vending machine market becomes critical.

This comprehensive guide delves into various types of gum vending machines, exploring their materials, manufacturing processes, and quality control measures. It also highlights key suppliers and the factors influencing costs, ensuring you make informed decisions that align with your business needs. Additionally, market trends and insights will be discussed, providing a contextual backdrop for your sourcing strategy.

By addressing frequently asked questions and common concerns, this guide empowers you to navigate the complexities of sourcing gum vending machines effectively. Whether you are a distributor looking to expand your product offerings or a retailer seeking to enhance your service portfolio, this resource is designed to equip you with the knowledge and tools necessary for successful procurement in a competitive landscape. Engage with the insights presented here to optimize your purchasing strategy and maximize your investment in gum vending solutions.

Understanding gum vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Spiral Vending | Spiral shelves for product dispensing | Schools, offices, public spaces | Pros: Low maintenance, familiar design. Cons: Limited product variety. |

| Electronic Touchscreen | Digital interface with customizable selections | Shopping malls, airports, high-traffic areas | Pros: Interactive, can offer promotions. Cons: Higher initial cost, requires power. |

| Dual-Product Dispenser | Dispenses two types of products simultaneously | Convenience stores, event venues | Pros: Maximizes space, appeals to diverse preferences. Cons: More complex mechanics can lead to jams. |

| Bulk Candy Dispenser | Allows customers to fill bags with loose products | Amusement parks, fairs, specialty shops | Pros: High product turnover, customizable offerings. Cons: Requires regular refills, potential messiness. |

| Specialty Gumball Machine | Unique designs, often themed; can dispense multiple flavors | Children’s entertainment centers, arcades | Pros: Eye-catching, engages children. Cons: Seasonal demand, niche market appeal. |

Classic Spiral Vending

The classic spiral vending machine is a staple in many environments. Its design features spiral shelves that allow for easy dispensing of products such as gum and candies. This type is particularly suitable for schools, offices, and public spaces where quick and straightforward access to snacks is desired. When considering a purchase, buyers should note its low maintenance requirements and familiar design, but they may find it limiting in terms of product variety.

Electronic Touchscreen

Electronic touchscreen vending machines represent a modern evolution in the vending industry. These machines feature digital interfaces that allow users to make selections through a touchscreen, often showcasing customizable options. They are well-suited for high-traffic areas like shopping malls and airports. While they provide an interactive experience and the ability to run promotions, buyers should be aware of the higher initial costs and the necessity for a reliable power source.

Dual-Product Dispenser

The dual-product dispenser is designed to cater to diverse consumer preferences by offering two types of products at once. This machine is commonly found in convenience stores and event venues, where space efficiency is crucial. Its ability to maximize product offerings can attract a wider customer base. However, buyers should consider that the more complex mechanics may lead to jams, requiring more frequent maintenance.

Bulk Candy Dispenser

Bulk candy dispensers allow customers to fill bags with loose products, providing an engaging experience. They are typically found in amusement parks, fairs, and specialty shops where high product turnover is desired. This type of machine offers the advantage of customizable product offerings, appealing to various tastes. However, it requires regular refills and can create messiness, which buyers need to manage.

Specialty Gumball Machine

Specialty gumball machines often feature unique designs and themes, catering primarily to children. These machines can dispense multiple flavors and are popular in children’s entertainment centers and arcades. Their eye-catching designs can engage young customers, making them a fun addition to any venue. However, potential buyers should consider the seasonal demand and niche appeal, which may affect sales consistency.

Related Video: How to Make MULTI Chewing Gum Vending Machine from Cardboard at Home DIY

Key Industrial Applications of gum vending machine

| Industry/Sector | Specific Application of gum vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Convenience stores and supermarkets | Increases impulse purchases, enhances customer experience | Location analysis, machine capacity, product variety |

| Education | Schools and universities | Offers students quick access to snacks, promotes healthy eating | Compliance with health regulations, payment options |

| Transportation | Airports and train stations | Provides travelers with easy access to snacks during transit | Durability, payment system integration, product freshness |

| Entertainment Venues | Movie theaters and amusement parks | Captures foot traffic, increases revenue from snacks | Space optimization, branding opportunities, machine aesthetics |

| Corporate Offices | Office buildings | Convenient snack options for employees, boosts morale | Customization options, machine maintenance, supply chain logistics |

Retail Sector

In retail environments such as convenience stores and supermarkets, gum vending machines serve as an effective tool to increase impulse purchases. These machines can be strategically placed near checkout counters or high-traffic areas to attract customers. For international buyers, it’s crucial to consider local consumer preferences and purchasing habits when selecting products for these machines. Additionally, ensuring the machine is capable of handling various payment methods, including mobile payments, can enhance customer satisfaction and drive sales.

Education Sector

In educational institutions, gum vending machines can provide students with quick access to snacks between classes. This not only promotes healthy eating habits but also caters to the busy lifestyle of students. Buyers from this sector should focus on compliance with health regulations, ensuring that the products offered meet nutritional standards. Additionally, it’s important to consider machine placement in high-traffic areas to maximize visibility and usage.

Transportation Sector

Airports and train stations present an ideal setting for gum vending machines, offering travelers convenient access to snacks during transit. This application addresses the common problem of hunger during travel, providing a quick solution. International buyers must prioritize durability and reliability in their machines, as they will be subjected to heavy use. Furthermore, integration with various payment systems, including contactless options, can enhance user experience and facilitate faster transactions.

Entertainment Venues

In movie theaters and amusement parks, gum vending machines can capitalize on foot traffic by providing snacks to guests. This not only increases revenue but also enhances the overall experience of visitors. Buyers in this industry should consider space optimization and branding opportunities when selecting vending machines. A visually appealing design that aligns with the venue’s theme can attract more customers and encourage impulse buys.

Corporate Offices

Gum vending machines in corporate offices offer employees convenient snack options, fostering a positive work environment and boosting morale. These machines can be customized to include healthier snack alternatives, catering to the diverse preferences of employees. When sourcing for this application, it’s essential to consider machine maintenance and supply chain logistics to ensure that products remain fresh and readily available. Additionally, providing a variety of payment options can further enhance convenience for employees.

Related Video: How To Make A Chewing Gum Vending Machine At Home DIY

Strategic Material Selection Guide for gum vending machine

When selecting materials for gum vending machines, it is essential to consider their properties, advantages, disadvantages, and suitability for specific applications. Below is an analysis of four common materials used in the construction of gum vending machines, tailored for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. It typically has a temperature rating of up to 800°F (427°C) and is resistant to oxidation, making it ideal for environments with varying humidity and temperature.

Pros & Cons:

Stainless steel is durable and easy to clean, which is crucial for vending machines that handle food products. However, it is more expensive than other materials like carbon steel. Manufacturing complexity can also be higher due to the need for specialized tools and techniques.

Impact on Application:

Stainless steel is compatible with various media, including food products, and does not impart any flavors or contaminants. Its durability ensures longevity, making it a preferred choice for high-traffic areas.

Considerations for International Buyers:

Compliance with food safety standards is critical. Buyers should ensure that the material meets standards such as ASTM A240 for stainless steel. In regions like Europe, adherence to EU regulations on food contact materials is also necessary.

2. Carbon Steel

Key Properties:

Carbon steel offers good strength and toughness, with a typical temperature rating of up to 400°F (204°C). However, it is susceptible to corrosion if not properly coated or treated.

Pros & Cons:

This material is cost-effective and easy to manufacture, making it a popular choice for budget-sensitive projects. The main drawback is its vulnerability to rust and corrosion, which can lead to increased maintenance costs over time.

Impact on Application:

Carbon steel is suitable for non-corrosive environments. If the vending machine is exposed to moisture or harsh conditions, additional protective coatings are necessary to prolong its lifespan.

Considerations for International Buyers:

Buyers should be aware of the need for protective coatings and treatments to comply with local regulations regarding corrosion resistance. Standards like ASTM A36 for structural steel may be relevant, depending on the application.

3. Polycarbonate

Key Properties:

Polycarbonate is a high-performance thermoplastic known for its impact resistance and clarity. It can withstand temperatures up to 240°F (116°C) and has excellent UV resistance.

Pros & Cons:

This material is lightweight and offers good insulation properties, making it suitable for transparent components of vending machines. However, it can be more expensive than other plastics and may not be as durable under extreme conditions.

Impact on Application:

Polycarbonate is ideal for protective covers and transparent panels, allowing visibility of the product inside the vending machine. Its impact resistance ensures that it can withstand vandalism or accidental damage.

Considerations for International Buyers:

Buyers should check for compliance with safety standards such as ASTM D5767 for polycarbonate materials. Additionally, understanding local regulations regarding plastic use is essential, especially in regions with strict environmental laws.

4. Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, with a temperature rating of up to 600°F (316°C). It is also highly malleable, allowing for various shapes and designs.

Pros & Cons:

Aluminum is cost-effective and easy to work with, making it suitable for complex shapes in vending machines. However, it may not be as strong as stainless steel and can be prone to denting.

Impact on Application:

Aluminum is suitable for components that require lightweight construction without sacrificing durability. It is often used in frames and structural elements of vending machines.

Considerations for International Buyers:

Buyers should ensure that the aluminum used meets standards such as ASTM B221 for extruded aluminum. Additionally, understanding the local market’s preferences for material choices can influence purchasing decisions.

Summary Table

| Material | Typical Use Case for gum vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, food contact areas | Excellent corrosion resistance, durable | Higher cost, complex manufacturing | High |

| Carbon Steel | Structural frames, non-corrosive areas | Cost-effective, good strength | Susceptible to corrosion, requires coating | Low |

| Polycarbonate | Transparent panels, protective covers | Lightweight, impact-resistant | Higher cost, less durable under extreme conditions | Medium |

| Aluminum | Frames, structural elements | Lightweight, easy to work with | Less strength than stainless steel, prone to denting | Medium |

This guide provides a comprehensive overview of material options for gum vending machines, helping international B2B buyers make informed decisions based on their specific needs and regional regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for gum vending machine

The manufacturing of gum vending machines involves several intricate processes and stringent quality assurance measures. Understanding these processes is vital for international B2B buyers seeking to procure reliable and efficient machines. Below is a detailed overview of the manufacturing stages, key techniques, and quality control protocols that should be considered.

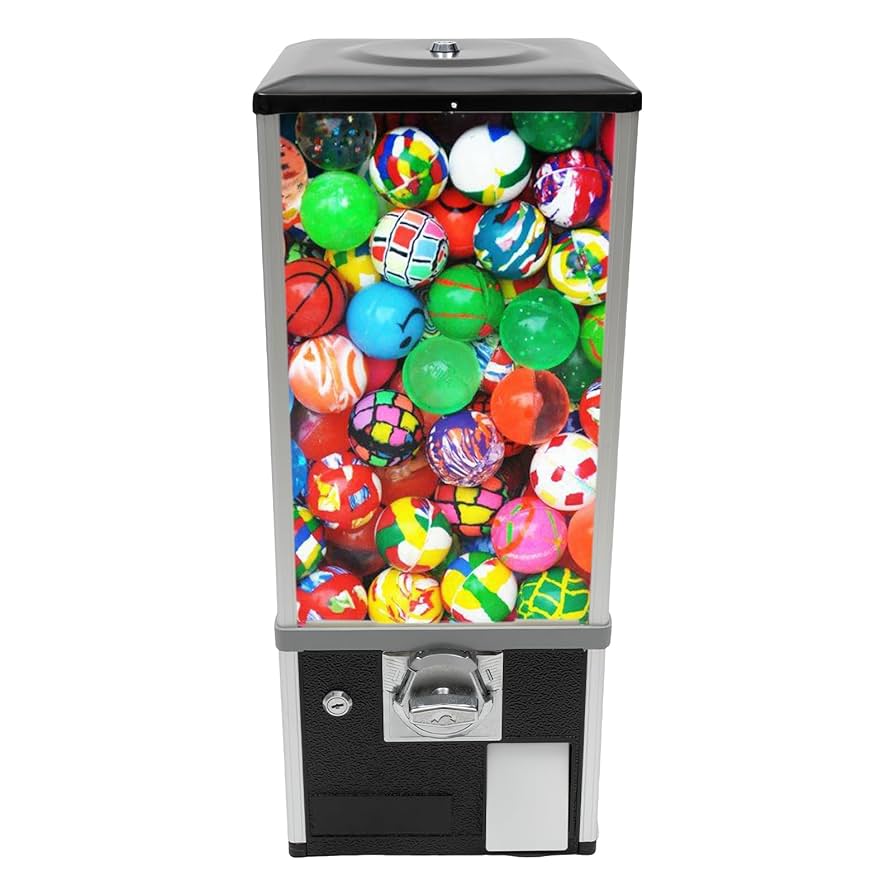

Illustrative Image (Source: Google Search)

Manufacturing Processes

1. Material Preparation

The first step in the manufacturing process involves sourcing and preparing high-quality materials. Common materials used in gum vending machines include:

- Metal Components: Steel and aluminum for structural integrity.

- Plastic Parts: High-density polyethylene (HDPE) or polycarbonate for durability and transparency.

- Electronic Components: Circuit boards, sensors, and motors for operational functionality.

Suppliers should ensure that materials comply with international standards, such as RoHS (Restriction of Hazardous Substances), to avoid harmful substances.

2. Forming

Once materials are prepared, they undergo various forming processes:

- Metal Fabrication: Techniques such as laser cutting, bending, and welding are employed to shape metal components. Precision is crucial to ensure proper fit and functionality.

- Injection Molding: Plastic parts are created using injection molding techniques, which allow for high-volume production with consistent quality.

- Surface Treatment: Metal surfaces are often treated with powder coating or galvanization to prevent rust and enhance aesthetic appeal.

3. Assembly

The assembly process is where all components come together:

- Sub-assembly: Individual components like the coin mechanism, gum dispenser, and control panel are assembled separately.

- Final Assembly: All sub-assemblies are integrated into the main body of the vending machine. This stage includes the installation of electronic components and ensuring all mechanical parts operate seamlessly.

Automated assembly lines may be used to enhance efficiency, though manual assembly is common for more complex installations.

4. Finishing

Finishing processes ensure that the vending machines are visually appealing and functional:

- Quality Checks: Each machine undergoes a series of inspections to verify the accuracy of assembly and functionality.

- Painting and Branding: Machines are painted and branded according to client specifications. This can include custom colors and logos.

- Final Testing: Before shipment, each machine is tested for functionality, durability, and performance under simulated usage conditions.

Quality Assurance

Quality assurance (QA) is a critical aspect of manufacturing gum vending machines, ensuring that the final product meets both company and customer expectations.

Relevant International Standards

For international B2B buyers, understanding compliance with industry standards is essential. Key standards include:

- ISO 9001: This standard focuses on quality management systems and ensures a consistent level of quality in products and services.

- CE Marking: Required for products sold in the European Economic Area (EEA), CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: These may be relevant if the vending machine incorporates any specialized technology or materials that require certification.

Quality Control Checkpoints

Quality control involves various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during production to catch defects early. This includes checks on dimensions, assembly accuracy, and functionality.

- Final Quality Control (FQC): A comprehensive evaluation of the finished product, including performance tests and visual inspections.

Common Testing Methods

Several testing methods are employed to ensure quality:

- Functional Testing: Ensures that all mechanical and electronic components operate correctly.

- Durability Testing: Assesses the machine’s ability to withstand operational stress and environmental conditions.

- Safety Testing: Verifies compliance with safety standards, including electrical safety and material safety.

Verifying Supplier Quality Control

International B2B buyers must take proactive steps to verify the quality control measures of their suppliers:

- Supplier Audits: Conducting regular audits of the manufacturing facilities can provide insight into the supplier’s quality management practices. This includes checking for certifications and compliance with international standards.

- Quality Reports: Requesting detailed quality reports, including records of testing and inspection results, can help assess the reliability of the supplier.

- Third-Party Inspections: Engaging independent third-party inspectors can offer unbiased evaluations of the manufacturing processes and final products.

QC and Certification Nuances for International Buyers

For buyers in regions such as Africa, South America, the Middle East, and Europe, it is crucial to understand the specific regulatory and certification requirements that may vary by region:

- Local Regulations: Some countries may have additional regulations that impact the importation and use of vending machines. Buyers should familiarize themselves with these to ensure compliance.

- Cultural Preferences: Different regions may have unique preferences for vending machine designs and functionalities, which can affect the choice of suppliers and manufacturing specifications.

- Logistics and Supply Chain: Considerations around shipping, tariffs, and duties can influence the total cost of ownership and should be factored into the supplier selection process.

By understanding the manufacturing processes and quality assurance protocols involved in gum vending machines, international B2B buyers can make informed purchasing decisions that align with their operational needs and market demands.

Related Video: Parle-G Biscuits Manufacturing process – Food Factory Tour- Modern Food factory, Mega Factory II

Comprehensive Cost and Pricing Analysis for gum vending machine Sourcing

Cost Structure of Gum Vending Machines

When sourcing gum vending machines, international B2B buyers must understand the various cost components involved in manufacturing and procurement. The primary cost elements include:

-

Materials: The type of materials used significantly impacts the overall cost. High-quality plastics, metals, and electronic components can elevate expenses but may also enhance durability and functionality.

-

Labor: Labor costs can vary widely based on geographical location and skill level. Regions with lower labor costs may provide more competitive pricing, but this can sometimes affect quality.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment depreciation. Efficient manufacturing processes can help reduce overhead, leading to lower prices.

-

Tooling: Custom tooling may be required for specific designs, adding to initial costs. However, these costs can be amortized over larger production runs, making them more manageable.

-

Quality Control (QC): Ensuring that machines meet quality standards incurs additional expenses. Rigorous QC processes can prevent costly recalls and enhance brand reputation.

-

Logistics: Shipping costs, including freight and insurance, must be factored into the total cost. The choice of transport mode (air, sea, land) will influence these expenses.

-

Margin: Suppliers will include their profit margins in the pricing, which can vary based on market demand and competition.

Price Influencers

Several factors influence the pricing of gum vending machines:

-

Volume/MOQ: Bulk orders often lead to lower unit prices due to economies of scale. Buyers should negotiate Minimum Order Quantities (MOQ) to optimize costs.

-

Specifications/Customization: Custom designs or specific features can increase costs. It’s essential to balance the need for customization with budget constraints.

-

Materials and Quality: Higher quality materials and certifications (e.g., CE, ISO) can justify higher prices. Buyers should assess the long-term benefits of investing in quality versus initial costs.

-

Supplier Factors: Supplier reputation, reliability, and history of delivery can affect pricing. Established suppliers may charge a premium for their perceived value.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for managing logistics costs and risks associated with shipping and delivery.

Buyer Tips for Cost Efficiency

To navigate the complexities of sourcing gum vending machines, buyers should consider the following strategies:

-

Negotiation: Leverage volume purchases to negotiate better pricing. Building long-term relationships with suppliers can also yield favorable terms.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, operational costs, and expected lifespan. A lower initial cost may lead to higher long-term expenses.

-

Pricing Nuances: Be aware that prices may fluctuate due to currency exchange rates, tariffs, and regional market conditions. It is advisable to stay informed about economic trends in both the sourcing and purchasing countries.

-

Due Diligence: Research multiple suppliers to compare prices and quality. Attend trade shows or industry conferences to gain insights into market standards and innovations.

Disclaimer

The prices mentioned in any sourcing discussions are indicative and can vary significantly based on the aforementioned factors. Always conduct thorough market research and consult with suppliers for accurate quotations tailored to your specific requirements.

Spotlight on Potential gum vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘gum vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for gum vending machine

Key Technical Properties of Gum Vending Machines

When selecting gum vending machines for your business, understanding the technical specifications is crucial for ensuring reliability, efficiency, and customer satisfaction. Here are some essential properties to consider:

-

Material Grade

– Definition: This refers to the quality of materials used in the construction of the vending machine, often categorized by durability, corrosion resistance, and weight.

– Importance: High-grade materials ensure longevity and reduce maintenance costs, which is particularly important in high-traffic environments. Buyers should inquire about the specific materials used, such as stainless steel for durability or high-density plastics for weight savings. -

Capacity

– Definition: This indicates the number of gum packets or items the machine can hold at one time.

– Importance: Understanding capacity helps in planning inventory and service intervals. A higher capacity can lead to fewer refills and increased sales, making it vital for busy locations. -

Power Supply

– Definition: Refers to the electrical requirements of the vending machine, including voltage and current ratings.

– Importance: Knowing the power supply specifications is essential for ensuring compatibility with the location’s electrical system. Misalignment can lead to operational issues or increased installation costs. -

Dimensions and Weight

– Definition: The physical size and weight of the vending machine.

– Importance: These factors influence placement options, transport logistics, and the stability of the machine. For instance, heavier machines may require reinforced surfaces, while compact models are suitable for smaller spaces. -

Tolerance Levels

– Definition: This refers to the allowable variations in the machine’s dimensions and operational performance.

– Importance: Understanding tolerance levels is crucial for ensuring that the machine operates correctly within its designed parameters, which can affect both functionality and customer experience. -

Security Features

– Definition: These include locks, tamper-proof designs, and electronic payment protection.

– Importance: Enhanced security features protect against theft and vandalism, which is particularly vital in public areas. Buyers should evaluate the security measures to ensure the safety of their investment.

Common Trade Terminology in the Vending Machine Industry

Familiarizing yourself with industry-specific terminology can enhance communication with suppliers and streamline the purchasing process. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships is essential for buyers looking for specific components or custom machines, as it affects pricing and warranty considerations. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ helps in budgeting and inventory planning, particularly for new businesses. Negotiating lower MOQs can facilitate initial stocking without excessive upfront costs. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price quotes from suppliers for specific products or services.

– Relevance: Issuing an RFQ can help buyers compare offers and negotiate better terms, ensuring they get the best value for their investment. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers.

– Relevance: Understanding Incoterms is crucial for international transactions, as they dictate aspects like shipping costs, risk transfer, and insurance responsibilities. -

Lead Time

– Definition: The time it takes from placing an order to receiving the product.

– Relevance: Knowing the lead time helps in planning inventory and sales strategies, particularly for seasonal businesses that require timely stock replenishment.

- Warranty

– Definition: A guarantee provided by the manufacturer covering repairs or replacements for a specified period.

– Relevance: Evaluating warranty options is vital for risk management, as it affects long-term costs and operational reliability.

Understanding these technical properties and trade terms will empower B2B buyers in making informed decisions, facilitating smoother transactions, and ultimately enhancing operational efficiency in their vending machine ventures.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the gum vending machine Sector

Market Overview & Key Trends

The gum vending machine sector is witnessing significant transformation, driven by several global factors. First, the shift towards cashless transactions is reshaping how consumers interact with vending machines, especially in regions like Europe and South America. Innovations such as mobile payment systems and contactless technology are becoming standard, catering to a tech-savvy consumer base. Furthermore, the growing demand for convenience is propelling the installation of vending machines in diverse locations, from airports to corporate offices.

In terms of sourcing trends, international B2B buyers are increasingly focusing on automation and IoT (Internet of Things) integration. Smart vending machines equipped with real-time inventory management systems allow operators to optimize stock levels and reduce waste. This technology is particularly beneficial for markets in Africa and the Middle East, where logistical challenges can hinder supply chain efficiency. Additionally, the emergence of eco-friendly materials in machine construction and packaging is gaining traction, aligning with global sustainability initiatives.

Market dynamics also reveal a rising competitive landscape, with manufacturers striving for differentiation through custom branding and user-friendly interfaces. Buyers should be aware of local regulations that may impact machine design and operation, as compliance can vary significantly across regions. Understanding these factors will enable B2B buyers to make informed decisions and capitalize on emerging opportunities.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly crucial in the gum vending machine sector. The environmental impact of traditional vending machines, particularly concerning energy consumption and waste generation, is prompting buyers to seek more sustainable solutions. This includes machines that use energy-efficient components and those that minimize plastic waste through eco-friendly packaging options.

Ethical sourcing of materials is also becoming a priority. Buyers should consider suppliers who provide transparency in their supply chains, ensuring that materials are sourced responsibly and sustainably. Certifications such as Forest Stewardship Council (FSC) for wood products or ISO 14001 for environmental management systems can serve as indicators of a supplier’s commitment to sustainability.

Moreover, the demand for “green” certifications is growing, as consumers are more likely to support brands that prioritize environmental responsibility. For B2B buyers, aligning with suppliers that adhere to these standards not only enhances brand reputation but also meets the expectations of increasingly conscious consumers.

Brief Evolution/History

The evolution of the gum vending machine dates back to the late 19th century, when the first machines were introduced in the United States. Initially designed to dispense simple products like gum and candy, these machines have significantly evolved over the decades. The introduction of electronic payment systems in the late 20th century marked a pivotal shift, enabling cashless transactions that cater to modern consumer preferences.

In recent years, technological advancements have further revolutionized the sector. Today’s machines are equipped with smart technology that allows for remote monitoring and management, enhancing operational efficiency. This evolution reflects broader trends in consumer behavior and technological innovation, positioning the gum vending machine sector as a dynamic and evolving market for international B2B buyers. Understanding this history provides context for current trends and future developments in the industry.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of gum vending machine

-

What criteria should I use to vet suppliers of gum vending machines?

When vetting suppliers, prioritize their experience and reputation in the industry. Check for certifications such as ISO or CE that indicate adherence to quality standards. Request references from previous clients to gauge reliability and service levels. Additionally, assess their financial stability and production capacity to ensure they can meet your demands consistently. -

Can gum vending machines be customized to fit my brand?

Yes, many manufacturers offer customization options for gum vending machines. You can request branding elements such as logos, colors, and designs that align with your company’s image. Discuss the specific features you want, like product selections or payment methods, to ensure that the machine meets your business needs and customer preferences. -

What is the typical minimum order quantity (MOQ) for gum vending machines?

The MOQ for gum vending machines varies by supplier, usually ranging from 5 to 50 units. It’s essential to communicate your needs upfront to the supplier, as some may allow smaller orders for first-time buyers. Larger orders may also yield better pricing, so consider your market demand before placing an order. -

What are the common lead times for delivery after placing an order?

Lead times can vary significantly based on the supplier’s location and production capacity. Typically, you can expect lead times of 4 to 12 weeks. Always confirm with the supplier for specific timelines and potential delays, especially if customization is involved. Planning ahead can help mitigate risks associated with unexpected delays. -

What quality assurance processes should I expect from suppliers?

Reputable suppliers should have robust quality assurance processes in place, including regular inspections and testing of machines during production. Ask for details on their QA protocols and whether they provide certifications for compliance with international standards. This ensures that you receive a product that meets quality expectations and minimizes operational issues. -

What payment terms are generally accepted for international orders?

Common payment terms for international orders include letters of credit, bank transfers, or payment through escrow services. Discuss options with your supplier, as some may require a deposit upfront, followed by the balance upon delivery. Understanding the payment terms is crucial to avoid disputes and ensure a smooth transaction process. -

How should I handle logistics and shipping for my order?

Logistics can be complex, especially for international shipments. Coordinate with your supplier to understand their shipping methods and options. Consider using a freight forwarder who specializes in international shipping to navigate customs and tariffs efficiently. Ensure that you have insurance coverage for the shipment to protect against loss or damage during transit. -

What steps can I take if there is a dispute with the supplier?

In the event of a dispute, first communicate directly with the supplier to attempt resolution amicably. Document all correspondence and agreements. If necessary, refer to the contract for terms regarding dispute resolution, which may include mediation or arbitration. Legal counsel may also be required if the issue escalates, so ensure that you understand your legal rights and obligations.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for gum vending machine

In conclusion, strategic sourcing for gum vending machines presents an invaluable opportunity for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. By understanding market trends, supplier capabilities, and regional consumer preferences, businesses can make informed decisions that enhance operational efficiency and profitability.

Key Takeaways:

– Market Analysis: Conduct thorough research to identify emerging trends and customer demands in your region.

– Supplier Relationships: Foster strong partnerships with reliable suppliers to ensure product quality and supply chain stability.

– Cost Management: Leverage strategic sourcing to optimize costs while maintaining high standards in service delivery.

As the vending machine market continues to evolve, businesses must remain agile and responsive to shifting consumer behaviors. By embracing strategic sourcing practices, you can position your company to capitalize on future growth opportunities in this dynamic sector.

Now is the time to take action—explore new suppliers, enhance your product offerings, and engage in meaningful partnerships that will drive your business forward. Embrace the future of vending with confidence!