Mastering the Live Fish Vending Machine Market for B2B

Guide to Live Fish Vending Machine

- Introduction: Navigating the Global Market for live fish vending machine

- Understanding live fish vending machine Types and Variations

- Key Industrial Applications of live fish vending machine

- Strategic Material Selection Guide for live fish vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for live fish vending machine

- Comprehensive Cost and Pricing Analysis for live fish vending machine Sourcing

- Spotlight on Potential live fish vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for live fish vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the live fish vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of live fish vending machine

- Strategic Sourcing Conclusion and Outlook for live fish vending machine

Introduction: Navigating the Global Market for live fish vending machine

In an era where convenience and innovation redefine consumer habits, live fish vending machines are emerging as a transformative solution in the aquaculture and food retail sectors. These machines not only cater to the growing demand for fresh seafood but also offer an efficient and sustainable approach to fish distribution. By automating the process of live fish sales, businesses can minimize waste and enhance customer satisfaction, making them a compelling investment for international B2B buyers.

This guide serves as an essential resource for stakeholders across Africa, South America, the Middle East, and Europe, providing a comprehensive overview of the live fish vending machine market. Within these pages, you will find insights into various types of machines, the materials used in their construction, and the manufacturing and quality control standards that ensure reliability and safety. Furthermore, we explore key suppliers, cost considerations, and market trends that influence purchasing decisions.

By equipping B2B buyers with actionable insights, this guide empowers you to make informed sourcing decisions tailored to your specific market needs. Whether you are looking to enhance your retail offerings in Nigeria, explore new business avenues in Vietnam, or implement cutting-edge solutions in European markets, understanding the dynamics of live fish vending machines is crucial for success. Dive into this guide to unlock the potential of this innovative technology and elevate your business strategy in the global seafood market.

Understanding live fish vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automated Aquaculture Vending | Integrated filtration and oxygenation systems | Urban seafood markets, restaurants | Pros: Fresh fish, minimal labor; Cons: High initial cost. |

| Mobile Fish Vending Machine | Compact, transportable design for varied locations | Events, festivals, pop-up markets | Pros: Flexibility, easy setup; Cons: Limited stock capacity. |

| Smart Fish Vending Kiosks | IoT-enabled for remote monitoring and management | Supermarkets, convenience stores | Pros: Real-time data, reduced waste; Cons: Dependence on tech infrastructure. |

| High-Capacity Fish Dispensers | Large tanks with multiple species available | Wholesale distribution, fish farms | Pros: Bulk sales, diverse offerings; Cons: Requires significant space. |

| Specialty Species Vending | Focused on exotic or specific fish varieties | Niche markets, specialty restaurants | Pros: Unique offerings, higher margins; Cons: Limited customer base. |

Automated Aquaculture Vending

This type of vending machine features integrated filtration and oxygenation systems, ensuring that live fish remain healthy and vibrant until purchased. Ideal for urban seafood markets and restaurants, these machines provide a consistent supply of fresh fish. B2B buyers should consider the initial investment, which can be high, but the potential for reduced labor costs and increased customer satisfaction makes it a worthwhile consideration.

Mobile Fish Vending Machine

Mobile fish vending machines are designed for portability, allowing vendors to set up shop at various locations such as events, festivals, and pop-up markets. Their compact design makes them suitable for businesses looking to reach diverse consumer bases without the need for permanent infrastructure. Buyers should weigh the flexibility and ease of setup against the limited stock capacity, which may restrict sales opportunities during peak demand periods.

Smart Fish Vending Kiosks

Equipped with IoT technology, smart fish vending kiosks enable remote monitoring and management, providing real-time data on fish health and inventory levels. These machines are perfect for supermarkets and convenience stores that aim to enhance customer engagement while minimizing waste. B2B buyers must consider the technological requirements for implementation, as well as the potential benefits of reduced spoilage and improved operational efficiency.

High-Capacity Fish Dispensers

High-capacity fish dispensers accommodate larger tanks and multiple species, making them suitable for wholesale distribution and fish farms. They cater to businesses that require bulk sales and a diverse range of offerings. While the potential for increased sales volume is appealing, buyers should be aware of the significant space requirements and the associated costs of maintaining such systems.

Specialty Species Vending

Focusing on exotic or specific fish varieties, specialty species vending machines target niche markets and specialty restaurants. These machines can command higher margins due to their unique offerings. However, B2B buyers should consider the limited customer base and market demand, ensuring that their investment aligns with consumer interest in specialty seafood products.

Related Video: Buying Every Fish From the Live Fish Vending Machine… deadly fish

Key Industrial Applications of live fish vending machine

| Industry/Sector | Specific Application of live fish vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aquaculture | Direct sales to consumers | Increased revenue through direct-to-consumer sales | Machine capacity, species compatibility, regulatory compliance |

| Retail Food Services | Supplementing seafood offerings | Diversification of product range | Location suitability, machine maintenance, supply chain logistics |

| Hospitality | On-demand fresh fish supply | Enhanced customer experience with fresh options | Quality assurance, sourcing local fish, machine hygiene standards |

| Urban Farming | Sustainable fish farming solutions | Promoting eco-friendly practices | Environmental impact, local regulations, integration with urban systems |

| Event Catering | Mobile live fish vending for events | Unique selling proposition for catering services | Mobility features, capacity for large orders, quick setup time |

Aquaculture

In the aquaculture industry, live fish vending machines serve as a direct sales channel for farmers to reach consumers. This application helps eliminate intermediaries, enhancing profitability for fish producers. International buyers should consider machine compatibility with various fish species and ensure compliance with local health regulations to maximize operational efficiency.

Retail Food Services

Retail food services can leverage live fish vending machines to expand their seafood offerings. This innovative solution attracts customers seeking fresh and sustainable options, boosting sales and customer loyalty. Buyers in this sector should evaluate the machine’s location suitability, maintenance requirements, and the logistics of supply chain integration to ensure a seamless operation.

Hospitality

In the hospitality sector, live fish vending machines can provide hotels and restaurants with a reliable on-demand supply of fresh fish. This application not only enhances the dining experience by offering fresh seafood but also supports menu diversity. Key considerations for international buyers include ensuring quality assurance for the fish, sourcing from local fisheries, and adhering to hygiene standards to meet customer expectations.

Urban Farming

Urban farming initiatives can integrate live fish vending machines as part of sustainable food systems. These machines promote eco-friendly practices by providing fresh fish in urban areas, reducing transportation emissions and supporting local communities. Buyers should assess the environmental impact of the machines, comply with local regulations, and explore how the machines can integrate with existing urban agricultural systems for maximum effectiveness.

Event Catering

Event catering businesses can utilize mobile live fish vending machines to offer fresh seafood at various events. This unique selling proposition not only differentiates their services but also attracts clients looking for innovative catering options. Considerations for sourcing include the mobility features of the machines, their capacity to handle large orders, and the time required for quick setups to ensure they meet event demands efficiently.

Strategic Material Selection Guide for live fish vending machine

When selecting materials for live fish vending machines, it’s essential to consider the unique requirements of the aquatic environment, including temperature control, water exposure, and the need for hygiene. Below is an analysis of four common materials used in the construction of these machines, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, particularly in moist environments. It can withstand a wide range of temperatures and is durable under pressure, making it suitable for components that require structural integrity.

Pros & Cons:

The primary advantage of stainless steel is its longevity and resistance to corrosion, which reduces maintenance costs over time. However, it can be more expensive than other materials and may require specialized manufacturing techniques, which can complicate production.

Impact on Application:

Stainless steel is compatible with various aquatic media, ensuring that it does not leach harmful substances into the water. This is crucial for maintaining the health of live fish.

Considerations for International Buyers:

Buyers should be aware of different grades of stainless steel, such as 304 and 316, which offer varying levels of corrosion resistance. Compliance with international standards like ASTM and DIN is also essential, especially in regions like Europe and the Middle East.

Polycarbonate

Key Properties:

Polycarbonate is a lightweight, impact-resistant plastic that offers good thermal stability and transparency, allowing for visibility of the fish inside the vending machine.

Pros & Cons:

Its lightweight nature makes it easy to handle and install, while its transparency enhances customer engagement. However, polycarbonate is less durable than metals and can be susceptible to scratching and UV degradation over time.

Impact on Application:

Polycarbonate is suitable for viewing panels and protective covers, but it may not be ideal for structural components that require high strength.

Considerations for International Buyers:

Buyers should check for compliance with local regulations regarding food safety and plastics. In regions like Africa and South America, where UV exposure can be high, selecting UV-stabilized polycarbonate is advisable.

Aluminum

Key Properties:

Aluminum is lightweight, resistant to corrosion, and has good thermal conductivity. It is also relatively easy to machine and fabricate.

Pros & Cons:

The lightweight nature of aluminum makes it a cost-effective option for mobile vending machines. However, it may not provide the same level of strength as stainless steel and can be prone to denting and scratching.

Impact on Application:

Aluminum is suitable for structural components and frames, but care must be taken to ensure that it is adequately protected from prolonged water exposure.

Considerations for International Buyers:

Buyers should consider the alloy grade when selecting aluminum, as this can affect corrosion resistance. Compliance with local standards, such as JIS in Japan or EN in Europe, is also important.

Fiberglass Reinforced Plastic (FRP)

Key Properties:

FRP combines plastic with glass fibers, resulting in a strong, lightweight material that is highly resistant to corrosion and chemicals.

Pros & Cons:

The key advantage of FRP is its excellent resistance to a variety of environmental conditions, making it suitable for aquatic applications. However, it can be more expensive to manufacture and may require specialized skills for repairs.

Impact on Application:

FRP is ideal for tanks and structural components exposed to water, ensuring that the integrity of the fish habitat is maintained.

Considerations for International Buyers:

Buyers should ensure that the FRP used meets international standards for food safety and environmental impact, particularly in regions like the Middle East and Europe where regulations are stringent.

Summary Table

| Material | Typical Use Case for live fish vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components and tanks | Excellent corrosion resistance and durability | Higher cost and manufacturing complexity | High |

| Polycarbonate | Viewing panels and protective covers | Lightweight and transparent | Susceptible to scratching and UV degradation | Medium |

| Aluminum | Frames and structural components | Lightweight and cost-effective | Less durable and prone to denting | Medium |

| Fiberglass Reinforced Plastic (FRP) | Tanks and exposed components | Excellent corrosion resistance | Higher manufacturing costs and repair complexity | High |

This strategic material selection guide provides international B2B buyers with essential insights to make informed decisions when sourcing materials for live fish vending machines, ensuring compliance with local standards and suitability for their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for live fish vending machine

Manufacturing Processes for Live Fish Vending Machines

The production of live fish vending machines involves several critical stages, each requiring specific techniques and materials. Understanding these processes can help B2B buyers ensure they are sourcing high-quality, reliable machines.

Material Preparation

The manufacturing process begins with material selection and preparation. Common materials used include stainless steel, which is essential for corrosion resistance and hygiene, and high-quality plastics for internal components.

- Material Sourcing: Buyers should ensure that suppliers source materials from reputable vendors who adhere to international standards.

- Pre-processing: Materials undergo treatments such as cutting, bending, and surface cleaning to prepare them for the forming stage.

Forming

In this stage, the prepared materials are shaped into the desired components of the vending machine. Key techniques include:

- CNC Machining: This automated process ensures precision in cutting and shaping the metal components.

- Injection Molding: Used for plastic parts, this technique allows for complex shapes and ensures uniformity in production.

Assembly

Once the components are formed, the assembly process begins. This stage is crucial as it affects the machine’s overall functionality and reliability.

- Modular Assembly: Many manufacturers employ a modular approach, allowing for easier repairs and upgrades. This is particularly beneficial for international buyers who may need to service machines in remote locations.

- Integration of Technology: Advanced vending machines often include IoT technology for monitoring fish health and inventory management, which should be seamlessly integrated during assembly.

Finishing

The final stage in the manufacturing process involves surface treatment and quality checks.

- Surface Treatment: Processes like powder coating or electroplating enhance durability and aesthetic appeal.

- Final Inspection: Each machine undergoes a thorough inspection to ensure it meets design specifications and operational standards.

Quality Assurance Protocols

Quality assurance is critical in the manufacturing of live fish vending machines, ensuring they are safe, reliable, and compliant with international standards. B2B buyers should be well-versed in the following quality assurance processes.

International Standards

- ISO 9001: This standard focuses on quality management systems and ensures that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: Essential for products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For machines that interface with aquaculture systems, adherence to API standards can be crucial.

Quality Control Checkpoints

Effective quality control (QC) involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps catch defects early.

- Final Quality Control (FQC): A comprehensive check before shipment to confirm that the final product is defect-free and meets all specifications.

Common Testing Methods

B2B buyers should inquire about the following testing methods employed by manufacturers:

- Functional Testing: Ensures that the vending machine operates as intended.

- Durability Testing: Assesses the machine’s performance under simulated environmental conditions.

- Hygiene Testing: Particularly crucial for food-related machinery, this testing verifies that the machine meets health standards.

Verifying Supplier Quality Control

International buyers must take proactive steps to verify the quality control practices of potential suppliers:

- Supplier Audits: Conducting regular audits can provide insights into a supplier’s adherence to quality standards and processes.

- Requesting QC Reports: Buyers should request detailed quality control reports, including defect rates and compliance certifications.

- Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance regarding the quality of the machines being sourced.

Quality Control Nuances for International Buyers

When dealing with suppliers from different regions, especially Africa, South America, the Middle East, and Europe, several nuances must be considered:

- Cultural Differences: Understanding local business practices and communication styles can enhance negotiations and build stronger supplier relationships.

- Regulatory Compliance: Each region may have different regulatory requirements. It is crucial for buyers to ensure that the machines comply with local laws and standards.

- Logistics and Supply Chain: Consider the complexities of shipping and logistics when sourcing machines from overseas. Ensure that suppliers have robust shipping practices to avoid delays or damage.

Conclusion

A thorough understanding of the manufacturing processes and quality assurance practices for live fish vending machines is essential for B2B buyers. By focusing on material quality, manufacturing techniques, and comprehensive quality control measures, buyers can make informed decisions that ensure they acquire reliable, high-quality machines. Investing time in verifying supplier practices and understanding regional nuances will further enhance the procurement process, ultimately leading to successful business outcomes.

Comprehensive Cost and Pricing Analysis for live fish vending machine Sourcing

In the context of sourcing live fish vending machines, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This analysis will explore various cost components, pricing influencers, and actionable buyer tips, particularly relevant to stakeholders from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary materials for live fish vending machines include stainless steel, refrigeration units, and electronic components. High-quality materials are crucial for durability and compliance with health regulations. The choice of materials significantly impacts the overall cost, with premium options increasing both initial investment and long-term maintenance.

-

Labor: Labor costs can vary widely based on the manufacturing location. Countries with lower labor costs may offer cheaper products, but this can sometimes compromise quality. It’s essential to evaluate the skill level of the workforce and the associated costs in the context of the expected quality and reliability of the machines.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment used in production. A transparent breakdown of manufacturing overhead can help buyers understand the pricing structure and identify potential areas for negotiation.

-

Tooling: Custom tooling may be required for specialized designs or features, which can add significant upfront costs. Buyers should assess whether the tooling costs are justified by the expected returns and whether they can leverage existing designs to reduce expenses.

-

Quality Control (QC): Implementing rigorous QC processes is vital to ensure the machines meet industry standards. While these processes can add to the cost, they are essential for minimizing defects and ensuring customer satisfaction.

-

Logistics: Transportation costs, including shipping and customs duties, can vary greatly depending on the origin and destination of the machines. Understanding the logistics landscape and selecting the right Incoterms can help manage these costs effectively.

-

Margin: Supplier margins can vary based on market dynamics and competitive positioning. It’s important for buyers to understand the margin expectations of suppliers to negotiate effectively.

Price Influencers

-

Volume/MOQ: The quantity ordered often influences pricing. Larger orders can lead to bulk discounts, while minimum order quantities (MOQs) may limit sourcing options and increase unit costs.

-

Specifications/Customization: Customized machines tailored to specific needs or features can attract higher prices. Buyers should assess the necessity of these customizations against their budget constraints.

-

Materials and Quality/Certifications: The choice of materials and adherence to quality certifications can significantly affect pricing. Ensure that suppliers provide documentation of compliance with relevant standards, especially for health and safety.

-

Supplier Factors: The reputation and reliability of the supplier can also impact pricing. Established suppliers may charge a premium for their reputation, while newer entrants might offer competitive prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for managing shipping costs and responsibilities. Buyers should clarify these terms to avoid unexpected expenses.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers regarding costs and explore options for discounts based on order size or long-term contracts.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO), which includes not just the initial purchase price but also maintenance, operational costs, and potential downtime. This broader view can lead to more informed purchasing decisions.

-

Pricing Nuances: International buyers should be aware of currency fluctuations, import tariffs, and local taxes that can affect the final cost. Establishing clear contracts that outline pricing structures can mitigate risks.

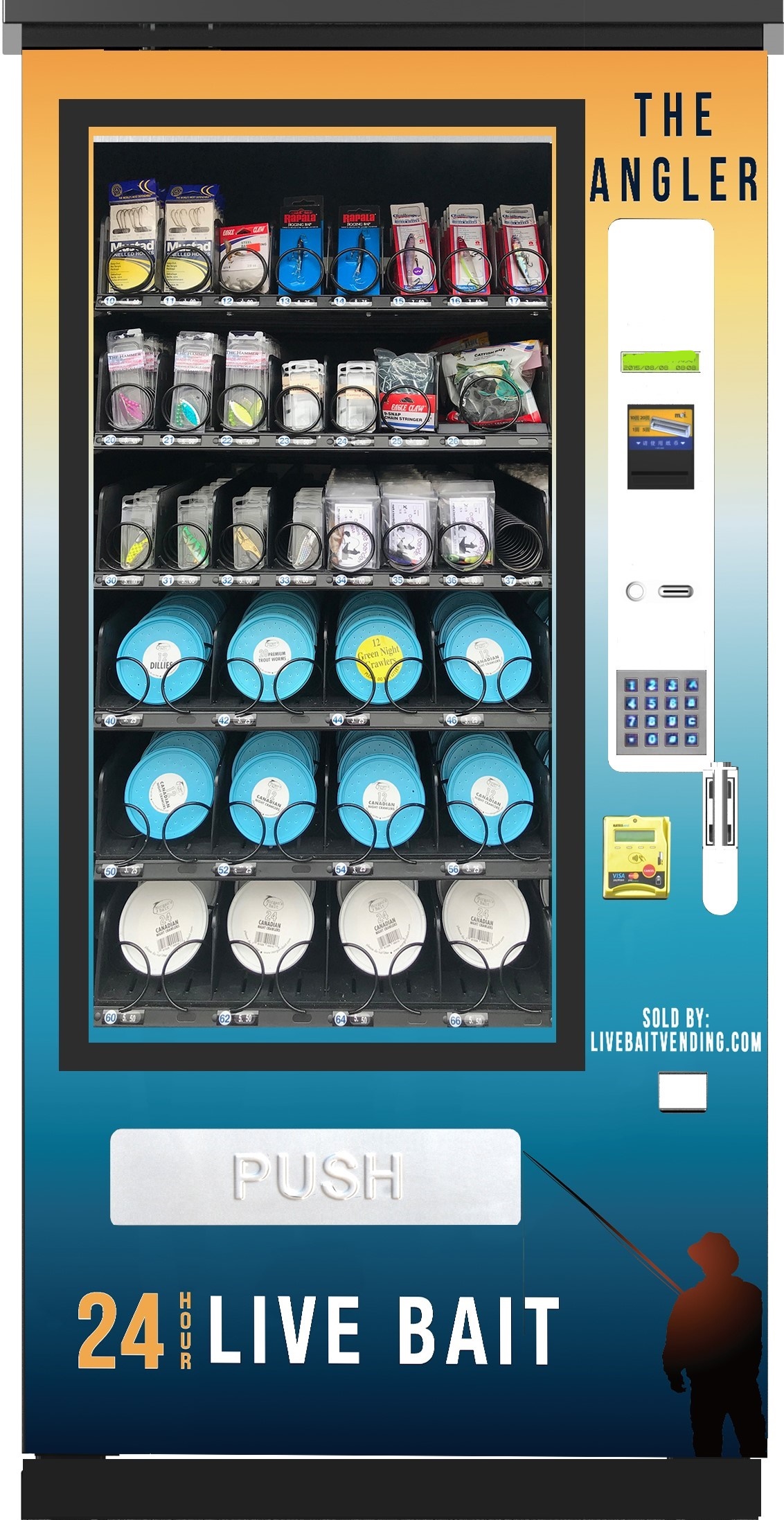

Illustrative Image (Source: Google Search)

- Local Partnerships: Consider collaborating with local distributors or agents who understand regional market dynamics and can help navigate cultural and regulatory challenges.

Disclaimer

The prices discussed in this analysis are indicative and can vary based on numerous factors, including market conditions, specific supplier agreements, and regional economic influences. Always conduct thorough due diligence and seek multiple quotes to ensure competitive pricing.

Spotlight on Potential live fish vending machine Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for live fish vending machine.)*

Essential Technical Properties and Trade Terminology for live fish vending machine

When considering the procurement of live fish vending machines, understanding their essential technical properties and trade terminology is crucial for making informed decisions. Here’s a comprehensive breakdown that will assist international B2B buyers in navigating this specialized market.

Key Technical Properties

-

Material Grade

– The materials used in the construction of live fish vending machines, such as stainless steel or food-grade plastics, are critical for ensuring durability and hygiene. Stainless steel is preferred for its corrosion resistance and easy cleaning, while food-grade plastics can reduce weight and cost. Buyers should ensure that materials meet local health regulations to avoid compliance issues. -

Temperature Control Range

– Maintaining optimal water temperatures is vital for the health of live fish. A machine should have a temperature control range that can accommodate the specific species being sold. For instance, tropical fish may require warmer temperatures than cold-water species. Buyers should verify that the machine can maintain consistent temperatures to prevent fish stress and mortality. -

Water Filtration System

– A robust water filtration system is essential for maintaining water quality and ensuring the health of the fish. Look for machines equipped with multi-stage filtration systems that can handle waste removal and chemical balance. This property impacts not only fish welfare but also the machine’s operational costs and maintenance frequency.

Illustrative Image (Source: Google Search)

-

Power Consumption

– Understanding the energy efficiency of the vending machine is crucial for long-term operational costs. Machines with low power consumption ratings can significantly reduce electricity bills, making them more sustainable for businesses. Buyers should evaluate the energy ratings and consider the total cost of ownership when assessing different models. -

User Interface and Payment System

– An intuitive user interface enhances customer experience, while a reliable payment system (supporting various payment methods) is essential for maximizing sales. Ensure that the machine is equipped with a user-friendly touchscreen, multilingual options, and secure payment processing capabilities. This will facilitate ease of use and attract a broader customer base.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. When sourcing live fish vending machines, understanding whether the supplier is an OEM can help buyers assess product quality and reliability. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This is particularly important for B2B buyers as it affects cash flow and inventory management. Buyers should negotiate MOQs that align with their sales forecasts to avoid excess inventory. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing and terms for specific products. For live fish vending machines, submitting an RFQ allows buyers to compare offers from multiple suppliers, ensuring competitive pricing and favorable terms. -

Incoterms (International Commercial Terms)

– These are predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for managing shipping costs and logistics. -

Lead Time

– This term refers to the time it takes from placing an order until delivery. Knowing the lead time is essential for inventory planning and ensuring that the vending machines are available when needed. Buyers should confirm lead times with suppliers to align with their business schedules. -

Warranty and Support Terms

– Warranties are essential for protecting investments in live fish vending machines. Understanding the duration and coverage of warranties, as well as the availability of technical support, is vital for ensuring long-term operational success. Buyers should inquire about warranty terms before finalizing any agreements.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make more informed decisions, ultimately enhancing their purchasing strategy in the live fish vending machine market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the live fish vending machine Sector

Market Overview & Key Trends

The live fish vending machine sector is experiencing significant growth, driven by increasing urbanization, changing consumer preferences, and a rising demand for fresh seafood. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of the following key trends:

-

Technological Advancements: Innovations in vending machine technology, such as IoT integration and mobile payment systems, are enhancing the user experience. This shift allows for better inventory management and real-time tracking, making it easier for businesses to operate efficiently.

-

Consumer Demand for Freshness: As consumers increasingly prioritize fresh and sustainable food sources, live fish vending machines provide an attractive option. This aligns with a broader trend toward health-conscious eating habits, particularly in urban areas where access to fresh fish may be limited.

-

Market Diversification: Buyers should note the diversification of product offerings in vending machines, which now include various fish species and value-added products. This trend caters to local tastes and preferences, making it essential for international buyers to understand regional market dynamics.

-

Regulatory Environment: Compliance with local and international food safety regulations is critical. Buyers must stay informed about the evolving regulations concerning seafood sales, as these can significantly impact sourcing and operational practices.

-

Sustainability Focus: The push for sustainable sourcing is reshaping the industry. B2B buyers are increasingly seeking suppliers who adhere to sustainable practices, reflecting a broader societal shift toward environmental consciousness.

Sustainability & Ethical Sourcing in B2B

Sustainability and ethical sourcing are vital components for B2B buyers in the live fish vending machine market. The environmental impact of seafood sourcing cannot be overstated, as overfishing and unsustainable practices threaten marine ecosystems. Here are key considerations for ensuring sustainable operations:

-

Ethical Supply Chains: Engaging with suppliers who prioritize ethical practices, such as responsible fishing methods and transparent supply chains, is essential. This not only reduces environmental impact but also enhances brand reputation among increasingly eco-conscious consumers.

-

Green Certifications: Buyers should look for suppliers with recognized sustainability certifications, such as the Marine Stewardship Council (MSC) or Aquaculture Stewardship Council (ASC). These certifications signal compliance with environmental standards and can provide a competitive edge in the market.

-

Sustainable Materials: In addition to sourcing live fish, B2B buyers should consider the materials used in vending machines. Opting for eco-friendly materials and energy-efficient machines can further minimize environmental footprints and appeal to sustainability-focused consumers.

-

Lifecycle Assessments: Conducting lifecycle assessments of vending machines can help identify areas for improvement in sustainability. This approach enables businesses to make informed decisions that reduce waste and energy consumption throughout the product’s life.

Brief Evolution/History

The concept of vending machines for live fish has evolved significantly over the past few decades. Initially, these machines were limited to specific markets, primarily in Asia, where seafood consumption is high. Over time, advancements in refrigeration and preservation technology have enabled the expansion of this model to other regions, including Europe and the Americas.

As consumer preferences shifted toward fresh and sustainable food sources, the live fish vending machine gained popularity in urban environments, where convenience and quality are paramount. This evolution reflects a broader trend in the food industry, where technology plays a crucial role in meeting the demands of modern consumers while promoting sustainability. International B2B buyers looking to enter this market should leverage this historical context to inform their sourcing strategies and product offerings.

Related Video: Buying Every Fish From the Live Fish Vending Machine… creepy fish

Frequently Asked Questions (FAQs) for B2B Buyers of live fish vending machine

-

What factors should I consider when vetting suppliers for live fish vending machines?

When vetting suppliers, prioritize their experience and reputation in the industry. Look for certifications that demonstrate compliance with international standards, such as ISO or CE certifications. Additionally, assess their production capabilities, including technology used and quality control processes. Reviews and testimonials from other B2B clients can provide insights into their reliability. Lastly, consider their geographical location and shipping logistics to ensure timely delivery and support. -

Can I customize the features of the live fish vending machine?

Yes, many suppliers offer customization options. Common customizations include size, design, technology integration (like payment systems), and specific fish species storage conditions. When discussing customizations, clearly outline your requirements and ensure that the supplier can meet them without compromising quality. Ask for prototypes or 3D models if available, and confirm that they have experience with similar custom projects to avoid future complications. -

What are the typical minimum order quantities (MOQs) and lead times?

MOQs can vary significantly depending on the supplier and the complexity of the machines. Generally, for live fish vending machines, MOQs may range from 1 to 10 units. Lead times are influenced by the supplier’s production schedule and customization requests, typically ranging from 4 to 12 weeks. Always confirm these details upfront and factor in additional time for shipping, especially for international orders, to avoid disruptions in your supply chain. -

What payment options are available for international orders?

Payment options vary by supplier but typically include bank transfers, letters of credit, and online payment platforms. For larger transactions, it’s advisable to use secure methods that provide buyer protection. Negotiate terms that suit both parties, such as partial upfront payments and the remainder upon delivery. Additionally, be aware of currency exchange rates and potential transaction fees, especially when dealing with suppliers from different regions. -

How can I ensure quality assurance and compliance with international standards?

Request detailed information about the supplier’s quality assurance processes. This includes documentation on inspections, certifications, and compliance with local and international regulations regarding live fish vending machines. It’s beneficial to conduct a factory visit or request third-party audits to verify these claims. Additionally, inquire about the warranty and after-sales support, as these can be indicators of the supplier’s commitment to quality. -

What logistics considerations should I keep in mind when sourcing from international suppliers?

Logistics is crucial when importing live fish vending machines. Consider shipping methods, costs, and estimated delivery times. Ensure that the supplier has experience with international shipping regulations and can handle customs clearance effectively. It’s also wise to discuss packaging methods to ensure the machines arrive in perfect condition. Collaborate with a reliable freight forwarder who understands the nuances of international trade to streamline the process. -

What steps should I take if I encounter a dispute with a supplier?

In case of a dispute, first, communicate your concerns directly with the supplier to seek resolution. Document all communications and agreements made during the negotiation process. If the issue remains unresolved, refer to the terms outlined in your contract, including arbitration clauses or mediation procedures. Engaging a legal expert familiar with international trade laws can provide guidance on your rights and options for resolving the dispute effectively. -

Are there specific certifications I should look for when sourcing live fish vending machines?

Yes, look for certifications that indicate compliance with health and safety standards, such as ISO 9001 for quality management systems and CE marking for compliance with European standards. Additionally, certifications related to environmental impact and sustainability can enhance your brand’s credibility. Verify that the supplier can provide documentation for these certifications, as they are essential for ensuring the machines meet regulatory requirements in your region.

Strategic Sourcing Conclusion and Outlook for live fish vending machine

The live fish vending machine market presents a unique opportunity for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Strategic sourcing in this sector is essential to capitalize on emerging trends and consumer demands. By prioritizing partnerships with reliable suppliers, buyers can ensure product quality, enhance operational efficiency, and align with local market preferences.

Key takeaways include the importance of understanding regional regulations, the necessity for sustainable sourcing practices, and the potential for technology integration to improve service delivery. Buyers should focus on evaluating suppliers based on their ability to provide innovative solutions that meet local needs while maintaining compliance with health and safety standards.

As the market for live fish vending machines continues to evolve, it is crucial for B2B buyers to stay informed about technological advancements and market dynamics. Embracing strategic sourcing will not only foster competitive advantage but also contribute to sustainable growth.

Looking ahead, we encourage buyers to engage actively with suppliers and explore collaborative opportunities that will shape the future of this industry. The potential for growth is immense—seize it now to ensure your business remains at the forefront of this exciting market.