Mastering Carvana Vending Machine Locations for Strategic

Guide to Carvana Vending Machine Locations

- Introduction: Navigating the Global Market for carvana vending machine locations

- Understanding carvana vending machine locations Types and Variations

- Key Industrial Applications of carvana vending machine locations

- Strategic Material Selection Guide for carvana vending machine locations

- In-depth Look: Manufacturing Processes and Quality Assurance for carvana vending machine locations

- Comprehensive Cost and Pricing Analysis for carvana vending machine locations Sourcing

- Spotlight on Potential carvana vending machine locations Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for carvana vending machine locations

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the carvana vending machine locations Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of carvana vending machine locations

- Strategic Sourcing Conclusion and Outlook for carvana vending machine locations

Introduction: Navigating the Global Market for carvana vending machine locations

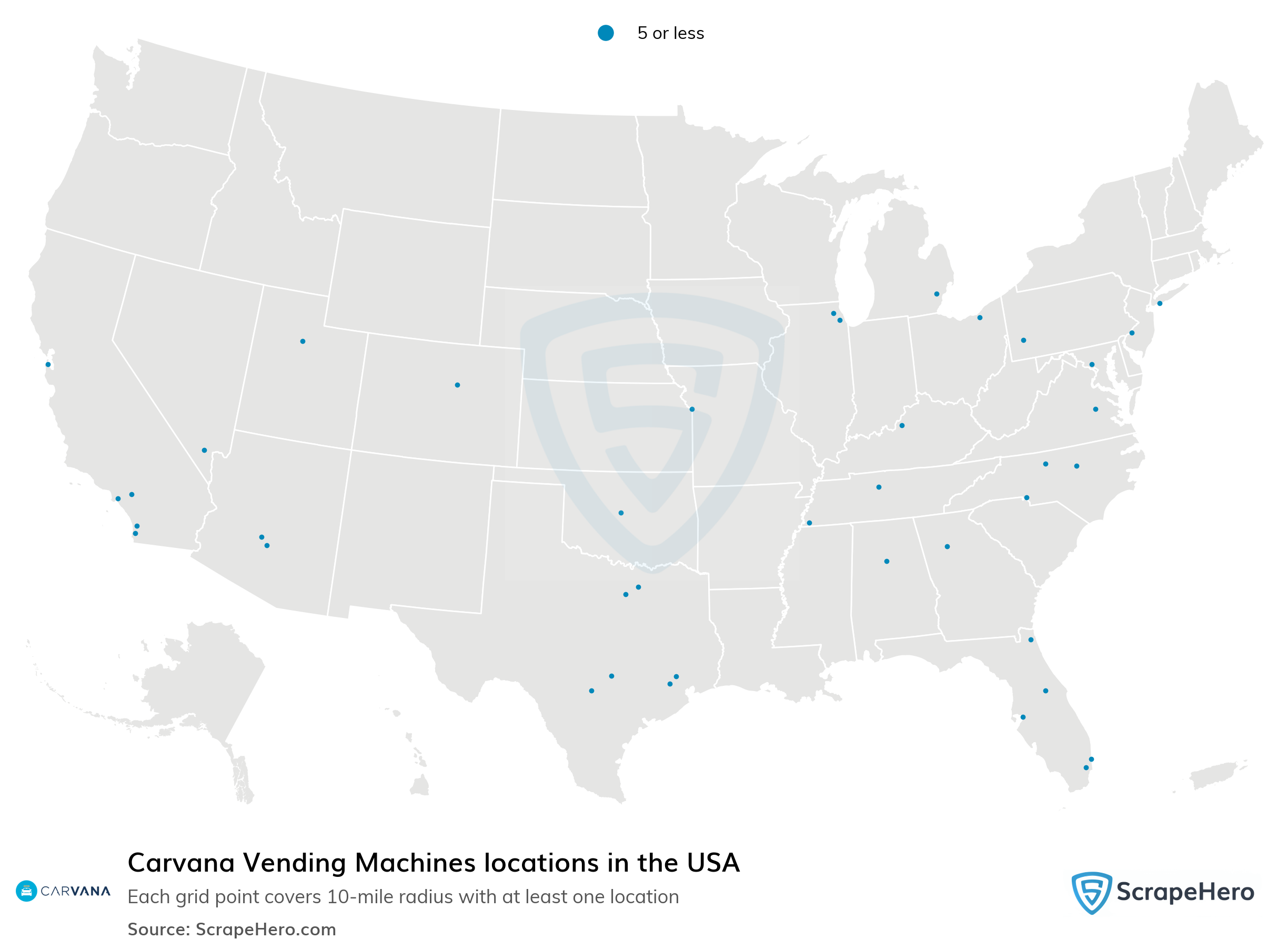

In today’s rapidly evolving automotive landscape, the demand for innovative vehicle purchasing solutions is on the rise. Carvana vending machines are at the forefront of this trend, offering a unique and efficient way to buy cars. For international B2B buyers, particularly those operating in emerging markets across Africa, South America, the Middle East, and Europe, understanding the nuances of these vending machine locations is critical for capitalizing on this lucrative opportunity.

This comprehensive guide delves into the essential aspects of carvana vending machine locations, providing valuable insights into various types, materials used in construction, manufacturing and quality control standards, and reliable suppliers. By exploring the cost structures associated with these vending machines, buyers can make informed decisions that align with their budget and operational goals.

Moreover, the guide addresses the dynamic market landscape, highlighting key trends and opportunities for international buyers. With a dedicated FAQ section, it aims to clarify common queries and concerns, ensuring that you navigate this market with confidence.

Empowering B2B buyers with actionable insights, this guide serves as a vital resource for those looking to enhance their business operations through innovative car vending solutions. By leveraging the information presented, you can strategically position your company to thrive in a competitive global market, ultimately driving growth and success in your region.

Understanding carvana vending machine locations Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Urban Vending Locations | High visibility, located in densely populated areas | Car sales and rentals | Pros: High foot traffic; Cons: Higher operational costs due to rent. |

| Suburban Vending Locations | Strategically placed near residential areas | Family vehicle sales | Pros: Lower competition; Cons: Limited customer reach compared to urban. |

| Corporate Partnerships | Vending machines located in corporate offices | Employee leasing programs | Pros: Direct access to employees; Cons: Limited to corporate clientele. |

| Event-Based Locations | Temporary setups at trade shows or expos | Promotional vehicle sales | Pros: High engagement; Cons: Short-term revenue potential. |

| Tourist Attractions | Situated near popular tourist spots | Rental services for tourists | Pros: Captures transient customers; Cons: Seasonal demand fluctuations. |

Urban Vending Locations

Urban vending locations are strategically positioned in high-traffic areas, making them ideal for attracting a diverse customer base. These sites benefit from significant footfall, which can lead to increased sales volumes. However, the operational costs associated with renting space in urban centers can be substantial. B2B buyers should consider the potential for higher sales against the backdrop of increased expenses, ensuring that their pricing models can accommodate these factors.

Suburban Vending Locations

Suburban vending locations cater primarily to family-oriented buyers and are often placed in areas with lower competition. These sites can be advantageous for B2B buyers looking to target specific demographics, such as families seeking reliable vehicles. While the competition may be less intense, these locations might not attract as many spontaneous buyers as urban sites. Buyers should evaluate local market conditions and demographic trends to determine the viability of establishing a presence in suburban areas.

Corporate Partnerships

Corporate partnerships involve placing vending machines within corporate offices, providing employees with convenient access to vehicle options. This approach can be particularly effective for companies looking to offer employee leasing programs or benefits. The primary advantage is direct access to a consistent customer base; however, the limitation lies in the confined market of corporate employees. B2B buyers should assess the size of the corporate clientele and the potential for long-term contracts when considering this model.

Event-Based Locations

Event-based locations, such as trade shows and expos, present unique opportunities for B2B buyers to engage with potential customers in a high-energy environment. These temporary setups can generate significant interest and lead to immediate sales. However, the challenge lies in the short-term nature of these events, which may not provide sustainable revenue streams. Buyers should weigh the benefits of increased visibility and engagement against the transient nature of such locations.

Tourist Attractions

Vending machines located near tourist attractions cater to a transient customer base, primarily tourists in need of rental vehicles. These locations can be highly lucrative during peak tourist seasons but may experience significant fluctuations in demand during off-peak periods. B2B buyers must consider seasonal trends and local tourism statistics when evaluating the potential return on investment for these vending machine placements. Understanding the local tourism landscape is critical for maximizing revenue opportunities.

Related Video: CARVANA | Car Vending Machine Experience | Full Walkthrough from online purchase to Delivery | 🇺🇸

Key Industrial Applications of carvana vending machine locations

| Industry/Sector | Specific Application of carvana vending machine locations | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Retail | Automated vehicle dispensing for used cars | Streamlined sales process, reduced overhead costs | Location accessibility, local regulations, and operational costs |

| Logistics and Delivery | Vehicle pick-up points for logistics companies | Enhanced efficiency in fleet management and delivery | Proximity to transport hubs, security measures, and technology integration |

| Real Estate Development | Innovative leasing options for residential properties | Attracts tech-savvy tenants, increases property value | Local market trends, zoning laws, and demographic analysis |

| E-commerce | Integration with online marketplaces for car sales | Expands sales channels, increases customer reach | Compatibility with e-commerce platforms, inventory management systems |

| Tourism and Travel | Rental vehicle dispensing for tourists | Convenient access for travelers, boosts local tourism | Location selection, partnerships with travel agencies, and service offerings |

Automotive Retail

Carvana vending machine locations serve as automated vehicle dispensing points, allowing customers to purchase used cars with minimal human interaction. This application addresses challenges such as long waiting times and high overhead costs associated with traditional dealerships. For international buyers, especially in regions like Africa and South America, understanding local consumer behavior and preferences is crucial. Buyers should consider the accessibility of locations and compliance with local automotive regulations to ensure a smooth operational flow.

Logistics and Delivery

In the logistics sector, Carvana vending machines can function as vehicle pick-up points for logistics companies, facilitating efficient fleet management. This application resolves common issues like delays in vehicle availability and the need for centralized vehicle storage. For B2B buyers in the Middle East and Europe, it’s essential to evaluate the proximity of these locations to transport hubs and ensure robust security measures are in place. Technology integration is also a key consideration to streamline operations.

Real Estate Development

Carvana vending machines can be integrated into residential properties as innovative leasing options. This application not only attracts tech-savvy tenants but also enhances the overall property value. Buyers from Europe and South America should analyze local market trends and zoning laws to ensure compliance and maximize tenant interest. Conducting a demographic analysis will help in tailoring the service offerings to meet the needs of potential residents.

E-commerce

The integration of Carvana vending machines with online marketplaces presents a significant opportunity for e-commerce businesses in the automotive sector. This application broadens sales channels and enhances customer reach, addressing the growing demand for online vehicle purchases. International B2B buyers should focus on the compatibility of these machines with various e-commerce platforms and the efficiency of inventory management systems. Understanding regional e-commerce trends will also be vital for success.

Tourism and Travel

In the tourism sector, Carvana vending machines can provide convenient access to rental vehicles for travelers. This application not only enhances the travel experience but also contributes to local tourism growth. Buyers in regions like Africa and South America should consider strategic location selection near popular tourist destinations and partnerships with travel agencies to maximize visibility and usage. Offering a variety of vehicle options will cater to different traveler needs and preferences.

Related Video: Carvana: The Making of a Vending Machine

Strategic Material Selection Guide for carvana vending machine locations

When selecting materials for Carvana vending machine locations, it is essential to consider the performance characteristics and environmental conditions specific to each region. The materials used in these machines must withstand various factors such as temperature fluctuations, humidity, and potential corrosion from environmental exposure. Below are analyses of four common materials used in the construction of vending machines, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength-to-weight ratio, and good temperature tolerance. It typically withstands temperatures ranging from -200°C to 800°C, depending on the grade.

Pros & Cons:

Stainless steel is highly durable and requires minimal maintenance, making it suitable for long-term use. However, it is more expensive than other materials like carbon steel, and its manufacturing process can be complex due to the need for specialized welding techniques.

Impact on Application:

Stainless steel is particularly effective in environments where the machines are exposed to moisture or corrosive elements, ensuring longevity and reliability.

Considerations for International Buyers:

Buyers should ensure compliance with local standards such as ASTM or DIN for stainless steel grades. In regions like Africa and South America, sourcing local suppliers can reduce costs and lead times.

Carbon Steel

Key Properties:

Carbon steel is strong and cost-effective, with a good temperature rating up to 500°C. However, it is susceptible to corrosion when exposed to moisture.

Pros & Cons:

The primary advantage of carbon steel is its affordability, making it an attractive option for large-scale deployments. On the downside, without proper protective coatings, it can rust and degrade over time, necessitating more frequent maintenance.

Impact on Application:

Carbon steel is suitable for internal components of vending machines that are not directly exposed to the elements, such as structural supports.

Considerations for International Buyers:

Buyers should be aware of local corrosion risks and consider protective coatings. Compliance with industry standards is also crucial, especially in Europe, where regulations may be stricter.

Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity, with a melting point of about 660°C.

Pros & Cons:

Aluminum’s light weight makes it easy to transport and install, while its corrosion resistance is beneficial in humid environments. However, it is generally less durable than stainless steel and can be more expensive than carbon steel.

Impact on Application:

Aluminum is ideal for external panels and components exposed to the elements, providing a balance between aesthetics and functionality.

Considerations for International Buyers:

In regions like the Middle East, where high temperatures and humidity can be challenging, selecting the right aluminum alloy is critical. Buyers should also check for compliance with local standards, particularly in Europe, where specific grades may be required.

Composite Materials

Key Properties:

Composite materials, often made from a combination of plastics and fibers, offer excellent corrosion resistance and can be engineered for specific thermal and mechanical properties.

Pros & Cons:

The main advantage of composites is their versatility and lightweight nature, which can reduce shipping costs. However, they may not be as strong as metals and can be more expensive to manufacture.

Impact on Application:

Composites are suitable for non-structural components and can be tailored to meet specific environmental conditions, such as high humidity.

Considerations for International Buyers:

Buyers should evaluate the sustainability of composite materials, as well as compliance with local environmental regulations. In regions like South America, where recycling may be a concern, choosing eco-friendly composites can enhance brand image.

Summary Table

| Material | Typical Use Case for carvana vending machine locations | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | External panels and structural components | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Carbon Steel | Internal structural supports | Cost-effective, good strength | Susceptible to corrosion | Low |

| Aluminum | External panels exposed to elements | Lightweight, good corrosion resistance | Less durable than stainless steel | Medium |

| Composite Materials | Non-structural components | Versatile and lightweight | May lack strength, higher manufacturing cost | Medium |

This guide provides a comprehensive overview of material options for Carvana vending machine locations, equipping international B2B buyers with the insights needed to make informed decisions tailored to their specific regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for carvana vending machine locations

Overview of Manufacturing Processes for Carvana Vending Machines

The manufacturing of Carvana vending machines involves several key stages that ensure both functionality and durability. Understanding these processes is crucial for international B2B buyers looking to source these unique automotive vending solutions.

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Common materials used in the construction of vending machines include:

- Steel and Aluminum: For structural integrity and durability.

- Glass: For visibility and aesthetics, usually tempered for safety.

- Electronic Components: Including displays, payment systems, and sensors.

Material selection is critical, as it directly impacts the machine’s longevity and performance. Suppliers often conduct tests to ensure materials meet specific standards before moving to the next stage.

2. Forming

In this stage, materials are shaped and cut into the required dimensions. Key techniques include:

- CNC Machining: Precision cutting of metal components to ensure exact specifications.

- Laser Cutting: For intricate designs and shapes, particularly in metal and glass.

- Bending and Welding: Forming the structure of the machine, ensuring joints are robust.

Each forming method must adhere to strict tolerances to guarantee that the final assembly is seamless and operates effectively.

3. Assembly

After forming, components are assembled into a complete vending machine. This process typically involves:

- Mechanical Assembly: Installing components such as motors, mechanisms for retrieving vehicles, and doors.

- Electrical Assembly: Integrating the control systems, payment processing units, and display screens.

Attention to detail in the assembly process is vital, as any oversight can lead to operational failures or safety issues.

4. Finishing

Finishing processes enhance both the aesthetic and protective qualities of the vending machines. This stage includes:

- Painting and Coating: Applying weather-resistant finishes to protect against environmental factors.

- Quality Checks: Each machine undergoes inspection for visual defects and operational functionality.

The finishing stage not only improves the appearance but also ensures the longevity of the vending machines in various climates.

Quality Assurance Standards

Quality assurance (QA) is crucial in the manufacturing of Carvana vending machines. B2B buyers must familiarize themselves with relevant international and industry-specific standards.

International Standards

- ISO 9001: This standard focuses on quality management systems (QMS) and is applicable across industries. Suppliers should be certified to ensure that their processes consistently meet customer requirements.

- CE Marking: Essential for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

Industry-Specific Standards

- API (American Petroleum Institute): Relevant for components that may interact with fuel or other automotive fluids, ensuring safety and reliability.

- UL (Underwriters Laboratories): Certification for electrical components, ensuring they meet safety standards.

Quality Control Checkpoints

Effective quality control (QC) checkpoints are integral to maintaining the standards of the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): Monitoring during the manufacturing process to identify defects early.

- Final Quality Control (FQC): Comprehensive testing and inspection of the finished product before shipment.

Common Testing Methods

To ensure the reliability and safety of the vending machines, various testing methods are employed:

- Functional Testing: Verifying that all components operate as intended.

- Stress Testing: Assessing the machine’s performance under extreme conditions, such as maximum load or adverse weather.

- Safety Testing: Ensuring compliance with safety standards, particularly for electrical components.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s QC processes is essential to mitigate risks. Here are actionable strategies:

- Conduct Audits: Regular audits of the manufacturing facility can reveal adherence to quality standards and operational efficiency.

- Request Reports: Suppliers should provide documentation of their quality control processes, including inspection and testing results.

- Third-Party Inspections: Engaging independent inspectors can provide an unbiased assessment of the manufacturing processes and quality control measures.

Quality Control Nuances for International Buyers

When sourcing from suppliers in different regions, B2B buyers should be aware of specific nuances:

- Cultural Differences: Understanding the local business practices and quality expectations can facilitate smoother negotiations and collaborations.

- Regulatory Compliance: Different countries have varying regulations regarding product safety and quality. Buyers must ensure that suppliers comply with local laws in addition to international standards.

- Logistics and Supply Chain Considerations: The geographical location can impact lead times and shipping costs. Buyers should factor in these elements when selecting suppliers.

Conclusion

Understanding the manufacturing processes and quality assurance standards for Carvana vending machines is crucial for international B2B buyers. By focusing on material preparation, forming, assembly, finishing, and robust quality control measures, buyers can make informed decisions that ensure they partner with reliable manufacturers. Verifying QC through audits, reports, and third-party inspections will further enhance the assurance of quality, ultimately leading to successful sourcing and operational success.

Comprehensive Cost and Pricing Analysis for carvana vending machine locations Sourcing

When considering the sourcing of Carvana vending machine locations, a thorough understanding of the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis delves into the various components that influence costs and pricing, alongside actionable insights tailored for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary cost driver is the materials used in the construction of the vending machines. This includes steel, glass, electronics, and other components. Sourcing high-quality materials can increase upfront costs but may reduce long-term maintenance expenses.

-

Labor: Labor costs vary significantly depending on the region. In locations with higher wage standards, labor costs can be a substantial portion of the overall expenditure. It is essential to consider both direct labor (assembly and installation) and indirect labor (management and support).

-

Manufacturing Overhead: This encompasses all costs related to the production process that are not directly tied to materials or labor, such as utilities, rent, and equipment depreciation. Understanding the overhead rates of potential suppliers can help in negotiating better pricing.

-

Tooling: Customization of vending machines often requires specialized tooling. The initial investment in tooling can be significant, but it is necessary for producing bespoke machines that meet specific buyer needs.

-

Quality Control (QC): Implementing strict QC measures ensures that the machines meet safety and operational standards. While this can add to initial costs, it is essential for minimizing defects and enhancing customer satisfaction.

-

Logistics: Shipping and handling costs vary based on the location of the supplier and the destination of the machines. Factors such as shipping mode, distance, and customs duties can significantly impact the total cost.

-

Margin: Suppliers will factor in their desired profit margin, which can vary based on market conditions and competition. Understanding the typical margins in the industry can aid in negotiations.

Price Influencers

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract lower per-unit costs. Buyers should assess their capacity to order in bulk to leverage volume discounts.

-

Specifications and Customization: Custom features can increase costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materials and Quality Certifications: Higher quality materials and certifications can elevate costs but are often worth the investment for durability and compliance with local regulations.

-

Supplier Factors: The reputation, reliability, and financial stability of suppliers can influence pricing. Conducting thorough due diligence is essential.

-

Incoterms: Understanding Incoterms is critical for clarifying cost responsibilities in shipping and delivery. This knowledge aids in avoiding unexpected expenses during the transaction.

Buyer Tips

-

Negotiation: Develop a clear understanding of the cost components to negotiate effectively. Presenting a well-researched counteroffer can lead to better pricing.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider maintenance, operating costs, and potential downtime.

-

Pricing Nuances for International Buyers: Factors such as currency fluctuations, import tariffs, and local economic conditions can affect pricing. Buyers should account for these variables in their budgeting.

-

Local Market Understanding: Familiarize yourself with regional market trends and competitor pricing strategies. This knowledge can empower buyers to make informed decisions.

Disclaimer

The prices and cost structures discussed herein are indicative and subject to change based on market conditions, supplier negotiations, and specific project requirements. Buyers are encouraged to conduct thorough market research and supplier evaluations to obtain accurate and current pricing.

Spotlight on Potential carvana vending machine locations Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for carvana vending machine locations.)*

Essential Technical Properties and Trade Terminology for carvana vending machine locations

Key Technical Properties for Carvana Vending Machines

Understanding the essential technical specifications of Carvana vending machines is crucial for B2B buyers, especially when considering installation and operational efficiency in diverse markets. Here are some critical properties to consider:

-

Material Grade: The construction of vending machines typically involves high-grade stainless steel or reinforced composite materials. These materials ensure durability and resistance to corrosion, which is particularly important in humid or harsh environments. Selecting the right material can reduce maintenance costs and enhance the longevity of the machines.

-

Tolerance Levels: Precision in manufacturing is vital, especially for the mechanical components that facilitate the vending process. Tolerances refer to the allowable deviations in dimensions, which affect the overall performance of the machine. Tight tolerances ensure that parts fit together seamlessly, reducing the risk of malfunction and minimizing service interruptions.

-

Power Specifications: Different regions have varying electrical standards. Understanding the power requirements—such as voltage, frequency, and phase—is crucial for ensuring that machines operate efficiently without damaging electrical components. This is particularly important for buyers in regions with inconsistent power supply.

-

Capacity and Size: The dimensions and storage capacity of the vending machines must align with local demand. Machines can vary in size, with some capable of holding multiple vehicle types. Assessing the space available at the intended location will help in selecting the right model that maximizes inventory turnover.

-

Software Integration: Modern vending machines often come equipped with advanced software systems for inventory management and sales tracking. Understanding the compatibility of these systems with existing software solutions is essential for seamless operations. This aspect can significantly impact operational efficiency and customer experience.

-

Safety Standards Compliance: Compliance with local and international safety standards is non-negotiable. Buyers should ensure that the machines adhere to regulations regarding electrical safety, mechanical safety, and user accessibility. This not only protects customers but also shields businesses from legal liabilities.

Common Trade Terminology

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Here are some key terms that buyers should know:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, understanding OEM relationships can help in sourcing quality components that ensure the reliability of vending machines.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for budgeting and inventory management, particularly for businesses looking to minimize upfront costs while ensuring sufficient supply.

-

RFQ (Request for Quotation): An RFQ is a document used to solicit price offers from suppliers. When entering new markets, crafting an effective RFQ can help buyers compare options and negotiate better terms, ensuring they receive competitive pricing for their purchases.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery responsibilities, which is crucial when importing equipment from overseas.

-

Lead Time: This term refers to the amount of time it takes from placing an order until it is delivered. Understanding lead times is essential for project planning, especially in regions where logistics can be unpredictable.

-

Warranty and Service Level Agreement (SLA): A warranty covers repairs or replacements for faulty equipment, while an SLA outlines the expected level of service from the supplier. Both are critical for risk management and ensuring that operational disruptions are minimized.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions that enhance their operational capabilities and market positioning.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the carvana vending machine locations Sector

Market Overview & Key Trends

The carvana vending machine locations sector is rapidly evolving, driven by a combination of technological advancements and changing consumer behaviors. The integration of automated technologies and digital platforms is reshaping how cars are sold and purchased globally. For B2B buyers from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is essential for making informed sourcing decisions.

One significant trend is the growing adoption of e-commerce in the automotive sector. As consumers increasingly favor online transactions, vending machine models that facilitate seamless digital experiences are becoming essential. This trend is particularly pronounced in emerging markets, where mobile penetration is high, and consumers seek convenience.

Furthermore, data analytics is playing a crucial role in optimizing inventory and enhancing customer experience. B2B buyers should look for suppliers that utilize advanced analytics to predict market demands and streamline operations. The shift towards contactless transactions and enhanced customer service capabilities is also a key factor in selecting partners in this sector.

Illustrative Image (Source: Google Search)

Another critical market driver is the focus on localization in supply chains. International buyers should prioritize suppliers that understand local regulations and consumer preferences, ensuring compliance and relevance in diverse markets. In regions like Argentina and Thailand, local partnerships can facilitate smoother market entry and enhance brand trust.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer an optional consideration; it is a vital component of modern business practices, particularly in the carvana vending machine locations sector. The environmental impact of automotive sales, from manufacturing to delivery, necessitates a commitment to sustainable practices. For B2B buyers, selecting partners who prioritize eco-friendly solutions is crucial for meeting regulatory standards and consumer expectations.

Ethical sourcing is integral to sustainability. Buyers should seek suppliers who demonstrate transparency in their supply chains and adhere to ethical labor practices. This commitment not only enhances brand reputation but also attracts environmentally conscious consumers.

The use of green certifications and sustainable materials is increasingly important. B2B buyers should look for suppliers that use recycled materials in their vending machines or have certifications such as LEED (Leadership in Energy and Environmental Design) or ISO 14001 (Environmental Management Systems). These certifications signal a commitment to reducing environmental impact and can differentiate a business in a competitive market.

Investing in sustainability not only mitigates risks associated with environmental regulations but also positions businesses favorably among stakeholders who prioritize corporate responsibility.

Brief Evolution/History

The concept of car vending machines emerged in the early 2010s, revolutionizing the traditional automotive sales model. Initially popularized by companies like Carvana in the United States, the model leverages automated technology to provide a unique, customer-centric purchasing experience.

As the model gained traction, international markets began to adopt similar concepts, adapting the technology to fit local consumer preferences and regulatory environments. Over the past decade, the focus has shifted from merely selling cars to enhancing customer experience and sustainability, reflecting broader global trends in e-commerce and ethical business practices.

Understanding this evolution is essential for B2B buyers aiming to navigate the complexities of sourcing and partnership in the carvana vending machine locations sector, ensuring they align with innovative and responsible suppliers.

Related Video: Can India-US Secure Trade Deal Soon? | Trump Tariffs War | Global Trade War | US News | News18

Frequently Asked Questions (FAQs) for B2B Buyers of carvana vending machine locations

-

What should I consider when vetting suppliers for Carvana vending machine locations?

When vetting suppliers, prioritize their track record in the automotive vending machine industry. Look for suppliers with experience in international trade, especially those familiar with regulations in your target market. Check references, review their portfolio, and assess their financial stability. It’s also beneficial to inquire about their supply chain reliability, after-sales support, and warranty terms. Conducting site visits or virtual tours can provide insights into their operations and quality control measures. -

Can I customize the vending machines to fit my brand?

Yes, customization options are often available. Many suppliers allow you to modify the design, color scheme, and branding elements of the vending machines to align with your corporate identity. Discuss your requirements with potential suppliers early in the negotiation process to ensure they can accommodate your requests. Additionally, inquire about the cost implications and lead times associated with customized orders to avoid any surprises during production. -

What are the typical minimum order quantities (MOQ) and lead times?

Minimum order quantities can vary significantly between suppliers, often ranging from a few units to several dozen. Larger orders may offer cost advantages, but it’s crucial to evaluate your market demand before committing. Lead times also depend on the complexity of the order and the supplier’s production capacity; expect anywhere from 8 to 16 weeks for standard machines. Always confirm these details upfront to plan your inventory and market launch effectively. -

What payment terms are commonly offered by suppliers?

Payment terms can vary widely among suppliers, so it’s essential to clarify these before finalizing any agreements. Common arrangements include a deposit upon order confirmation, followed by the balance before shipping. Some suppliers may offer flexible financing options or payment plans. Be mindful of currency fluctuations when negotiating terms, especially in international transactions, and consider using escrow services to mitigate risks. -

How can I ensure quality assurance and certifications for the vending machines?

Request detailed information about the supplier’s quality assurance processes and any relevant certifications. Look for compliance with international standards such as ISO 9001 for quality management systems. Suppliers should provide documentation regarding safety standards and testing results. Consider third-party inspections if necessary, particularly for large orders, to ensure that the products meet your specifications and regulatory requirements. -

What logistics considerations should I be aware of when importing vending machines?

Logistics is a critical factor in importing vending machines. Assess the supplier’s shipping capabilities and experience with international freight. Understand the shipping costs, customs duties, and potential delays in transit. It’s advisable to work with a logistics partner familiar with your region’s import regulations. Additionally, consider local storage solutions if you anticipate longer lead times to avoid congestion at your receiving facility. -

How should I handle disputes or issues with suppliers?

Establish clear communication channels and document all agreements to minimize disputes. In case of issues, address them promptly and professionally, preferably through direct communication with the supplier. If the situation escalates, consult the terms of your contract regarding dispute resolution mechanisms, such as mediation or arbitration. Maintaining a good relationship with your supplier can often help in resolving conflicts amicably, so aim for transparency and collaboration. -

What are the best practices for after-sales support and maintenance?

After-sales support is crucial for the long-term success of your vending machines. Ensure your supplier offers comprehensive maintenance services and training for your staff. Inquire about warranty coverage and the process for handling repairs or replacements. Establish a clear communication plan for reporting issues and obtaining support. Building a partnership with your supplier can facilitate quicker resolutions and ensure the longevity of your machines in the market.

Strategic Sourcing Conclusion and Outlook for carvana vending machine locations

In conclusion, the strategic sourcing of Carvana vending machine locations offers international B2B buyers significant opportunities for growth and innovation. By understanding local market dynamics, leveraging advanced technologies, and fostering strong supplier relationships, businesses can enhance their operational efficiency and customer satisfaction.

Key Takeaways:

– Market Analysis: Conduct thorough assessments of regional demand and competition to identify prime locations for vending machines.

– Supplier Partnerships: Establishing robust relationships with local suppliers can lead to more favorable terms and reliable service.

– Technology Utilization: Implementing data analytics and IoT technologies can streamline operations and improve customer experience.

As the automotive retail landscape continues to evolve, the potential for Carvana vending machines remains promising, especially in emerging markets across Africa, South America, the Middle East, and Europe. Now is the time for international B2B buyers to capitalize on these trends.

Call to Action: Engage with local stakeholders, invest in market research, and explore strategic partnerships to maximize the benefits of Carvana vending machine locations. Embrace the future of automotive retailing by positioning your business at the forefront of this innovative model.