Master Your B2B Strategy with the PSA 10 Vending Machine

Guide to Psa 10 Vending Machine

- Introduction: Navigating the Global Market for psa 10 vending machine

- Understanding psa 10 vending machine Types and Variations

- Key Industrial Applications of psa 10 vending machine

- Strategic Material Selection Guide for psa 10 vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for psa 10 vending machine

- Comprehensive Cost and Pricing Analysis for psa 10 vending machine Sourcing

- Spotlight on Potential psa 10 vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for psa 10 vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the psa 10 vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of psa 10 vending machine

- Strategic Sourcing Conclusion and Outlook for psa 10 vending machine

Introduction: Navigating the Global Market for psa 10 vending machine

The PSA 10 vending machine represents a pivotal advancement in automated retail solutions, offering B2B buyers a unique opportunity to enhance their product distribution and customer engagement. These machines, renowned for their reliability and efficiency, cater to a diverse market by dispensing high-quality items, from snacks to electronics, with minimal human intervention. As the global market increasingly shifts towards automation, understanding the nuances of PSA 10 vending machines becomes essential for businesses aiming to remain competitive.

This guide serves as a comprehensive resource, meticulously detailing the various types of PSA 10 vending machines available, the materials used in their construction, and the critical aspects of manufacturing and quality control. Additionally, it outlines potential suppliers across different regions, providing insights into cost considerations and market dynamics that can influence purchasing decisions.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe (notably in countries like Poland and the UAE), this guide empowers informed sourcing decisions. By addressing common FAQs and offering strategic insights, it equips businesses with the knowledge necessary to navigate the complexities of acquiring PSA 10 vending machines. Ultimately, leveraging this information can significantly enhance operational efficiency and customer satisfaction, paving the way for sustained growth in an increasingly automated retail landscape.

Understanding psa 10 vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Vending Machine | Standard design with coin and bill acceptors | Retail, offices, schools | Pros: Widely recognized, easy to maintain. Cons: Limited payment options and slower transaction speeds. |

| Smart Vending Machine | Internet connectivity, touch screens, app integration | Tech-savvy environments, airports | Pros: Enhanced user experience, real-time inventory tracking. Cons: Higher initial investment and maintenance costs. |

| Healthy Snack Vending Machine | Focus on nutritious options, often refrigerated | Gyms, schools, health-focused businesses | Pros: Meets growing demand for healthy options, attracts health-conscious customers. Cons: Limited product variety compared to traditional machines. |

| Automated Retail Kiosks | Larger footprint, integrated technology for self-service | Airports, shopping malls, events | Pros: Can offer a wider range of products, 24/7 availability. Cons: Requires more space and potentially higher operational costs. |

| Customized Vending Solutions | Tailored product offerings and branding | Corporate offices, promotional events | Pros: Unique offerings can enhance brand visibility, personalized customer experience. Cons: Development and setup can be time-consuming and costly. |

Traditional Vending Machine

Traditional vending machines are the most common type, featuring simple coin and bill acceptors. They are primarily used in retail environments, offices, and schools, making them accessible to a broad audience. When considering a purchase, buyers should evaluate the machine’s reliability and ease of maintenance. While these machines are cost-effective and easy to operate, they may lack modern payment options like mobile wallets, which could deter tech-savvy consumers.

Smart Vending Machine

Smart vending machines leverage technology to enhance the user experience, incorporating touch screens and internet connectivity. These machines are ideal for tech-savvy environments such as airports and modern offices. They allow for real-time inventory management and can integrate with mobile apps for seamless transactions. Buyers should consider the higher initial investment and ongoing maintenance costs, but the potential for increased sales and customer engagement can justify the expense.

Healthy Snack Vending Machine

With a focus on nutritious offerings, healthy snack vending machines are gaining popularity in gyms, schools, and health-focused businesses. These machines often include refrigerated sections to keep items fresh. B2B buyers interested in promoting wellness within their organizations should consider these machines, as they cater to the growing demand for healthy options. However, the selection may be limited compared to traditional machines, which could affect customer satisfaction.

Automated Retail Kiosks

Automated retail kiosks represent a more advanced vending solution, featuring larger footprints and integrated technology for self-service. Commonly found in airports, shopping malls, and events, these kiosks can offer a wider range of products, including electronics and apparel. Buyers should assess the space requirements and operational costs, as these kiosks can be more expensive to install and maintain. Nonetheless, their 24/7 availability can significantly enhance revenue potential.

Customized Vending Solutions

Customized vending solutions allow businesses to tailor product offerings and branding to meet specific market needs. This type of vending machine is often deployed in corporate offices and during promotional events. Buyers should consider the benefits of enhanced brand visibility and a personalized customer experience. However, the development and setup process can be time-consuming and costly, requiring careful planning and investment to ensure a successful implementation.

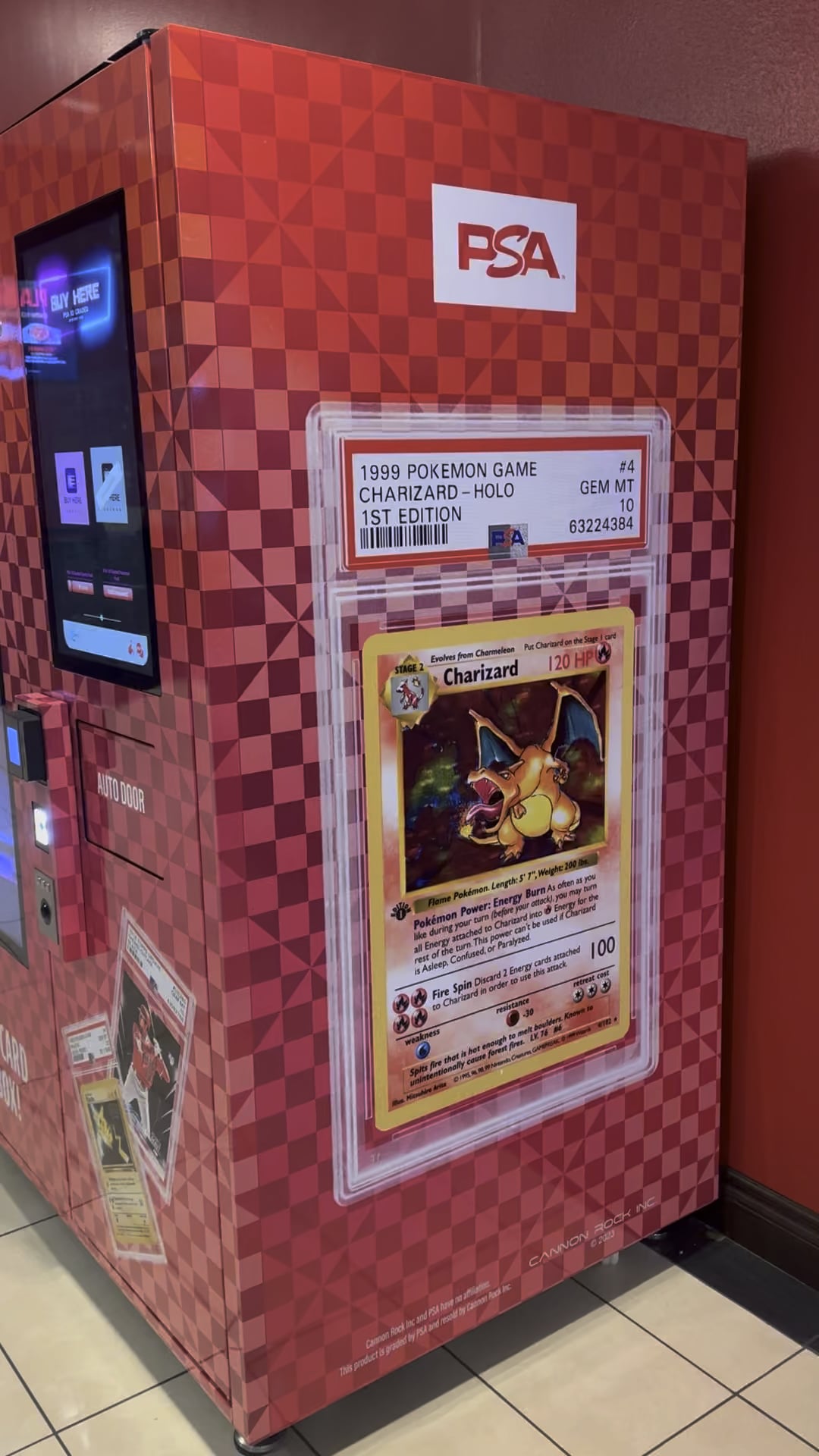

Related Video: Pokemon PSA 10 vending machine in Las Vegas with a bonus booster pack! Did we win or lose money? 👀

Key Industrial Applications of psa 10 vending machine

| Industry/Sector | Specific Application of psa 10 vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Automated merchandise sales | Increased customer engagement and sales volume | Location suitability, payment system integration |

| Healthcare | Dispensing medical supplies | Improved access to essential supplies | Regulatory compliance, inventory management |

| Hospitality | 24/7 snack and beverage service | Enhanced guest experience and convenience | Product selection, maintenance support |

| Education | Campus vending solutions | Increased revenue from student and staff purchases | Machine durability, product variety |

| Transportation | Ticketing and travel passes | Streamlined ticket purchasing process | Software compatibility, user interface design |

Retail

In the retail sector, the psa 10 vending machine serves as an automated point-of-sale for merchandise, allowing customers to browse and purchase products without the need for a cashier. This technology enhances customer engagement by providing a convenient shopping experience, especially in high-traffic areas. For international buyers, especially in regions like Africa and South America, factors such as local product preferences and payment system compatibility are critical to consider during sourcing.

Healthcare

In healthcare, psa 10 vending machines are utilized to dispense medical supplies, such as bandages, gloves, and other essential items. This application ensures that healthcare professionals have immediate access to necessary supplies, particularly in emergency situations. Buyers in this sector must prioritize regulatory compliance and inventory management systems to track usage and maintain supply levels, ensuring that the vending machines are stocked with the right items at all times.

Hospitality

The hospitality industry benefits from psa 10 vending machines by providing 24/7 access to snacks and beverages for guests. This service not only enhances the guest experience but also generates additional revenue for hotels and resorts. When sourcing these machines, businesses should consider the variety of products offered, machine maintenance support, and the integration of cashless payment options to cater to modern consumer preferences.

Education

Educational institutions leverage psa 10 vending machines to offer a range of snacks and drinks on campus. This application increases revenue from students and staff while providing convenient access to food and beverages during long hours of study. International buyers in the education sector should focus on machine durability and product variety to meet diverse dietary needs, ensuring that the vending solutions are sustainable and appealing to the student demographic.

Transportation

In the transportation sector, psa 10 vending machines are used for ticketing and the sale of travel passes. This application streamlines the purchasing process for travelers, reducing queues and enhancing customer satisfaction. For buyers in this industry, key considerations include software compatibility with existing systems and user interface design to ensure a seamless customer experience across various platforms.

Related Video: DIY Vending Machine – Arduino based Mechatronics Project

Strategic Material Selection Guide for psa 10 vending machine

When selecting materials for the PSA 10 vending machine, it is essential to consider the specific performance requirements and environmental conditions in which the machine will operate. The following analysis covers four common materials used in the construction of vending machines, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength-to-weight ratio, and ability to withstand a wide range of temperatures. It typically has a temperature rating of up to 800°F (427°C) and can handle pressures exceeding 150 psi, depending on the grade.

Pros & Cons:

Stainless steel is highly durable and offers a modern aesthetic, making it suitable for various environments, including humid or outdoor settings. However, it is generally more expensive than other materials, and the manufacturing process can be complex due to its hardness.

Impact on Application:

This material is ideal for vending machines that dispense food and beverages, as it maintains hygiene and prevents contamination. Its corrosion resistance is particularly beneficial in coastal areas or regions with high humidity.

Considerations for International Buyers:

Buyers should ensure compliance with food safety standards relevant to their region, such as the FDA in the U.S. or EFSA in Europe. Common grades like 304 and 316 are recognized globally, but local regulations may dictate specific requirements.

2. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has a melting point of around 1,220°F (660°C). It can withstand moderate pressures and is often used in applications where weight is a critical factor.

Pros & Cons:

The primary advantage of aluminum is its low cost and ease of manufacturing, which allows for rapid production and customization. However, it is less durable than stainless steel and can be prone to denting and scratching.

Impact on Application:

Aluminum is suitable for vending machines that require portability or frequent relocation. Its resistance to corrosion makes it a good choice for outdoor applications, although it may not be ideal for high-traffic areas due to its susceptibility to damage.

Considerations for International Buyers:

Buyers should be aware of the varying quality standards for aluminum in different regions, such as ASTM in the U.S. and EN in Europe. Ensuring that the aluminum used meets these standards can help avoid issues with structural integrity.

3. Carbon Steel

Key Properties:

Carbon steel is strong and durable, with a temperature rating of up to 1,500°F (815°C). However, it is susceptible to corrosion if not properly treated or coated.

Pros & Cons:

This material is cost-effective and provides excellent strength, making it suitable for structural components of vending machines. The downside is its vulnerability to rust, which necessitates protective coatings, increasing maintenance costs.

Impact on Application:

Carbon steel is best suited for internal components where exposure to moisture is limited. Its strength makes it ideal for supporting heavy loads, but its corrosion risk limits its use in exposed areas.

Considerations for International Buyers:

Buyers should consider local environmental conditions when selecting carbon steel. In humid regions, additional coatings or treatments may be necessary to prevent rust, which can lead to increased operational costs.

4. Polycarbonate

Key Properties:

Polycarbonate is a high-performance thermoplastic known for its impact resistance and clarity. It has a temperature rating of about 250°F (121°C) and can withstand moderate pressures.

Pros & Cons:

The material is lightweight and offers excellent transparency, making it ideal for display panels on vending machines. However, it can be more expensive than other plastics and is less durable than metals.

Impact on Application:

Polycarbonate is particularly useful for vending machines that require visibility of products, enhancing customer engagement. Its impact resistance helps protect against vandalism or accidental damage.

Considerations for International Buyers:

Buyers should ensure that the polycarbonate used complies with relevant safety standards, such as those set by ASTM or ISO. Additionally, regional preferences for materials can influence purchasing decisions, especially in markets that prioritize sustainability.

| Material | Typical Use Case for psa 10 vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | External casing and structural components | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Portable vending machines | Lightweight and cost-effective | Less durable, prone to dents | Medium |

| Carbon Steel | Internal structural components | Cost-effective and strong | Susceptible to corrosion | Low |

| Polycarbonate | Display panels and windows | Impact-resistant and transparent | Less durable than metals | Medium |

This strategic material selection guide provides international B2B buyers with crucial insights into the materials suitable for PSA 10 vending machines, helping them make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for psa 10 vending machine

Manufacturing Processes for PSA 10 Vending Machines

Understanding the manufacturing processes of PSA 10 vending machines is crucial for B2B buyers looking to ensure quality and reliability in their procurement. The production of these machines typically involves several key stages, each with its own techniques and considerations.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Materials: High-quality materials are essential for the durability and functionality of vending machines. Common materials include stainless steel for structural components, high-grade plastics for internal parts, and electronic components sourced from reputable suppliers.

– Pre-Processing: Materials undergo pre-processing, which includes cutting, shaping, and treating to enhance their properties. This step ensures that the materials meet specific standards for strength and resistance. -

Forming

– Fabrication Techniques: Various fabrication techniques such as laser cutting, stamping, and bending are employed to shape the components of the vending machine. Precision in this stage is vital to ensure that parts fit together seamlessly.

– Component Manufacturing: Key components like the coin mechanism, product dispensing system, and control panels are manufactured separately. This modular approach allows for easier assembly and maintenance. -

Assembly

– Integration of Components: The assembly process involves the integration of all manufactured components. Automated assembly lines may be used for efficiency, although manual assembly is also common to ensure quality in complex parts.

– Wiring and Electronics: The electronic systems are installed during assembly, including the control interface and payment systems. This requires skilled technicians to ensure correct installation and functionality. -

Finishing

– Surface Treatment: Finishing processes such as painting, powder coating, or plating are applied to enhance aesthetics and protect against corrosion. These treatments also provide a smooth surface for easy cleaning.

– Final Assembly and Inspection: After finishing, the machines undergo a final assembly where all parts are checked for fit and functionality. This stage is crucial for identifying any potential issues before the machine is shipped.

Quality Assurance in Manufacturing

Quality assurance (QA) is paramount in the manufacturing of PSA 10 vending machines. Implementing rigorous QA processes ensures that the machines meet international standards and perform reliably in various environments.

Relevant International Standards

- ISO 9001: This is a global standard that outlines the criteria for a quality management system. Compliance with ISO 9001 demonstrates a commitment to quality and customer satisfaction.

- CE Marking: For products sold in the European market, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: Depending on the components used, adherence to American Petroleum Institute (API) standards may be required, especially for machines that handle products in sensitive environments.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– Material Inspection: All raw materials are inspected upon arrival at the manufacturing facility. This includes checking specifications, certifications, and conducting physical tests to ensure compliance with standards. -

In-Process Quality Control (IPQC)

– Ongoing Inspections: Throughout the manufacturing process, regular inspections are conducted at various stages to monitor quality. This involves checking tolerances, dimensions, and the integrity of components during fabrication and assembly. -

Final Quality Control (FQC)

– Comprehensive Testing: Before shipment, each vending machine undergoes a thorough testing process. This includes functionality tests, safety checks, and performance evaluations to ensure that the machine operates as intended.

Common Testing Methods

- Functional Testing: Verifies that all features of the vending machine operate correctly, including the payment system and product dispensing mechanism.

- Durability Testing: Simulates real-world usage to assess the machine’s resilience to wear and tear.

- Environmental Testing: Ensures the machine can withstand various environmental conditions, such as humidity and temperature fluctuations.

Verification of Supplier Quality Control

For B2B buyers, verifying the quality control measures of suppliers is essential. Here are several strategies to ensure compliance and reliability:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control practices. This includes reviewing their adherence to international standards and internal quality procedures.

-

Quality Reports: Requesting detailed quality reports, including testing results and certifications, can help buyers assess the reliability of the supplier’s products.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the manufacturing quality. These agencies can conduct inspections at different stages of production and provide certificates of compliance.

QC/Cert Nuances for International B2B Buyers

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification:

-

Regulatory Compliance: Different regions may have varying regulatory requirements. It is essential to ensure that the vending machines comply with local regulations regarding safety, emissions, and energy efficiency.

-

Cultural Considerations: Understanding the cultural context and business practices in different regions can influence quality expectations. For example, buyers from the UAE may prioritize advanced technological features, while those from Poland may focus more on durability and maintenance.

-

Logistics and Supply Chain: Quality assurance extends beyond manufacturing. Buyers should consider the entire supply chain, including shipping and handling practices, as these can impact the final product’s quality upon delivery.

By understanding the manufacturing processes and quality assurance practices for PSA 10 vending machines, international B2B buyers can make informed decisions that align with their quality standards and business needs. Engaging with suppliers who prioritize quality at every stage will ensure that they receive reliable, high-performance vending machines suited to their market demands.

Related Video: Inspection and Quality control in Manufacturing

Comprehensive Cost and Pricing Analysis for psa 10 vending machine Sourcing

When sourcing PSA 10 vending machines, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. Here is a comprehensive analysis of the key components influencing costs and pricing, as well as actionable insights for effective procurement.

Cost Components

-

Materials: The materials used in the manufacturing of PSA 10 vending machines, such as metal, glass, electronics, and plastic, significantly impact the overall cost. High-quality materials may raise the price but can enhance durability and functionality.

-

Labor: Labor costs vary by region. Countries with lower wage rates may offer cheaper labor but could affect the quality of craftsmanship. Consider the labor market conditions in the supplier’s location when assessing costs.

-

Manufacturing Overhead: This includes indirect costs like utilities, rent, and equipment maintenance. Efficient manufacturing processes can reduce overhead, which may be reflected in the pricing.

-

Tooling: Initial setup costs for manufacturing tooling can be substantial, particularly for custom designs. Understanding these costs is essential, especially if you require specific features or modifications.

-

Quality Control (QC): Investing in rigorous QC processes ensures that the machines meet international standards. However, this adds to the cost. Buyers should weigh the benefits of quality assurance against the potential risks of subpar products.

-

Logistics: Transporting vending machines involves freight costs, customs duties, and potential tariffs, which can vary significantly based on the shipping route and Incoterms used.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can be influenced by market demand and competition.

Price Influencers

-

Volume/MOQ: Minimum Order Quantities (MOQ) can affect pricing. Higher volumes often lead to discounts, making it economically viable for buyers looking for bulk purchases.

-

Specifications/Customization: Custom designs or features can increase costs. Clearly defining requirements can help suppliers provide accurate quotes.

-

Materials: The choice of materials can also lead to price fluctuations. More sustainable or innovative materials may have premium pricing.

-

Quality/Certifications: Machines with certifications for safety or energy efficiency may come at a higher price point but can offer long-term savings and compliance with local regulations.

-

Supplier Factors: Supplier reputation, reliability, and past performance can influence costs. Established suppliers may charge higher prices due to their track record of quality and service.

-

Incoterms: Understanding Incoterms is critical, as they define responsibilities for shipping, insurance, and tariffs. This affects the total cost of ownership.

Buyer Tips

-

Negotiate Wisely: Leverage your knowledge of market prices and competitor offerings when negotiating. Establishing a good relationship with suppliers can also lead to better terms and pricing.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider operational costs, maintenance, and potential downtime when assessing value.

-

Understand Pricing Nuances: Different regions may have unique pricing structures due to local economic conditions. For buyers from Africa, South America, the Middle East, and Europe, being aware of these nuances can aid in making informed purchasing decisions.

-

Request Samples: Before committing to a bulk order, request samples to assess quality and functionality. This minimizes the risk of large-scale purchases of substandard products.

Disclaimer

The prices and costs discussed herein are indicative and subject to change based on market conditions, supplier negotiations, and other variables. Always conduct thorough due diligence when evaluating potential suppliers and their offerings.

Spotlight on Potential psa 10 vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘psa 10 vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for psa 10 vending machine

When considering the procurement of a PSA 10 vending machine, understanding its essential technical properties and industry terminology is crucial for international B2B buyers. This knowledge not only aids in making informed decisions but also enhances negotiation strategies and supplier relationships.

Key Technical Properties

-

Material Grade

The material grade refers to the type of materials used in the construction of the vending machine, typically stainless steel or high-impact plastic. Stainless steel is preferred for its durability and resistance to corrosion, making it ideal for various environments, particularly in humid regions such as parts of Africa and the Middle East. A high-grade material ensures longevity and reduces maintenance costs. -

Tolerance Levels

Tolerance levels denote the permissible limits of variation in dimensions and weight of components. For vending machines, precise tolerances are critical to ensure proper functioning, such as the smooth operation of dispensing mechanisms. Understanding these specifications can help buyers evaluate the quality and reliability of the machine, which is particularly important in regions where service and repair may be less accessible.

-

Power Consumption

Power consumption metrics indicate the energy efficiency of the vending machine. Machines that consume less energy can significantly reduce operational costs, making them more appealing for businesses in regions with high electricity prices. Buyers should assess the power rating (in watts) and consider potential energy-saving features to optimize their investment. -

Capacity

The capacity refers to the volume and variety of products the vending machine can hold. This is particularly important for B2B buyers looking to target specific markets, such as snacks in schools or beverages in corporate offices. A higher capacity can lead to fewer restocking trips, which is crucial for maintaining efficient operations in remote areas. -

Connectivity Features

Modern vending machines often come equipped with connectivity options, such as IoT capabilities for real-time inventory tracking and remote management. Understanding these features can be beneficial for businesses aiming to streamline operations and improve customer experience through data-driven insights.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of vending machines, understanding the OEM can help buyers identify quality standards and potential warranty coverage, ensuring they are sourcing reliable products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is vital for B2B buyers as it impacts budgeting and inventory management. Knowing the MOQ helps businesses plan their purchases effectively, especially in markets with fluctuating demand. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. Crafting a well-defined RFQ can streamline the procurement process and ensure that suppliers provide accurate quotes based on the buyer’s requirements. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms can help B2B buyers negotiate shipping costs and responsibilities, minimizing risks associated with international trade. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. This is particularly important in industries where timing is critical. Understanding lead times can assist buyers in planning their inventory and ensuring they meet customer demands without delay.

Conclusion

Being well-versed in the technical properties and trade terminology associated with PSA 10 vending machines equips B2B buyers with the tools needed for effective procurement. This knowledge not only aids in selecting the right machine but also facilitates smoother negotiations and strategic planning in international markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the psa 10 vending machine Sector

Market Overview & Key Trends

The global market for PSA 10 vending machines is experiencing significant growth, driven by increased consumer demand for convenient retail solutions and advancements in technology. The rise of cashless transactions and mobile payment systems is reshaping how vending machines operate, making them more appealing to both businesses and consumers. In regions such as Africa and South America, there is a burgeoning middle class with rising disposable incomes, which is further propelling the demand for automated retail solutions.

Emerging trends include the integration of Internet of Things (IoT) technology, which allows for real-time inventory management and data analytics to enhance operational efficiency. Additionally, the use of artificial intelligence (AI) is gaining traction, enabling vending machines to personalize user experiences based on purchase history. For international B2B buyers, particularly in Europe (e.g., Poland) and the Middle East (e.g., UAE), understanding these technological advancements is crucial for making informed sourcing decisions.

Market dynamics are also influenced by the ongoing shift towards e-commerce and omnichannel retailing. As businesses look to diversify their sales channels, PSA 10 vending machines are becoming an attractive option for companies seeking to expand their reach without significant overhead costs. Furthermore, the competitive landscape is evolving, with traditional vending machine manufacturers adapting to new market demands by offering customizable and innovative solutions.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a pivotal concern in the PSA 10 vending machine sector, particularly as consumers and businesses alike prioritize environmental responsibility. The environmental impact of manufacturing, operating, and disposing of vending machines necessitates a focus on sustainable practices throughout the supply chain. International B2B buyers should consider suppliers that demonstrate a commitment to sustainability through the use of eco-friendly materials and energy-efficient technologies.

Ethical sourcing is also vital in ensuring that the components of vending machines are produced under fair labor practices and with minimal environmental degradation. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to ethical sourcing. Buyers should actively seek out manufacturers that prioritize these certifications, as this not only enhances their brand reputation but also aligns with the growing consumer demand for socially responsible products.

Additionally, utilizing recyclable and biodegradable materials in the production of vending machines can significantly reduce their carbon footprint. For B2B buyers, collaborating with suppliers that adhere to these sustainability principles will not only fulfill corporate social responsibility goals but also appeal to an increasingly eco-conscious market.

Brief Evolution/History

The vending machine industry has evolved significantly since its inception in the late 19th century, transitioning from simple mechanical devices to sophisticated, tech-driven solutions. Initially, vending machines offered basic items such as snacks and beverages, but over the decades, they have adapted to consumer preferences and technological advancements. The introduction of digital payment systems and touchless interfaces in the 21st century marked a pivotal shift, allowing for more seamless transactions and enhanced user experiences. Today, PSA 10 vending machines stand at the forefront of this evolution, combining convenience with cutting-edge technology to meet the diverse needs of global consumers and businesses alike.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of psa 10 vending machine

-

What should I consider when vetting suppliers of PSA 10 vending machines?

When vetting suppliers, assess their reputation, certifications, and experience in the industry. Check for customer reviews and testimonials, and ensure they have a proven track record in delivering quality products. Request references and verify their financial stability to mitigate risks. Additionally, consider their after-sales service, warranty provisions, and the availability of spare parts to ensure long-term support. -

Can I customize the PSA 10 vending machine to suit my business needs?

Yes, many suppliers offer customization options for PSA 10 vending machines. You can request features such as branding, size adjustments, payment systems, and product selections tailored to your target market. Discuss your specific requirements with potential suppliers to understand the extent of customization they can provide and any associated costs. Always ensure that modifications comply with local regulations. -

What are the typical minimum order quantities (MOQ) and lead times for PSA 10 vending machines?

Minimum order quantities can vary significantly by supplier, typically ranging from 5 to 50 units. Lead times also depend on the order size, customization, and supplier location, generally taking anywhere from 4 to 12 weeks. It’s essential to communicate your needs clearly and confirm these details upfront to avoid delays and ensure timely delivery. -

What payment methods are commonly accepted, and what should I be cautious about?

Most suppliers accept various payment methods, including bank transfers, letters of credit, and PayPal. Be cautious of suppliers requesting full payment upfront, as this can be a red flag. It’s advisable to negotiate terms that allow for partial payments based on milestones, such as deposits before production and final payments upon delivery. Ensure that payment terms are documented in the contract. -

How can I ensure quality assurance and certifications for PSA 10 vending machines?

Request documentation of quality assurance processes and certifications, such as ISO standards, from your suppliers. Ask for product samples or conduct factory visits if possible to assess quality firsthand. It is also wise to inquire about their testing procedures and warranties to ensure that the machines meet the required safety and operational standards in your region. -

What logistics considerations should I keep in mind when importing PSA 10 vending machines?

Consider logistics factors such as shipping methods, costs, and timelines when importing vending machines. Work with a reliable freight forwarder who understands the complexities of international shipping, including customs clearance. Ensure that you factor in import duties and taxes into your overall cost, and confirm that the supplier provides necessary shipping documentation to facilitate smooth transport.

Illustrative Image (Source: Google Search)

-

How should I handle disputes with a supplier?

To manage disputes effectively, establish clear communication channels with your supplier from the outset. Include dispute resolution procedures in your contract, such as mediation or arbitration, to streamline the process. If issues arise, document all communications and agreements related to the dispute. Consider engaging legal counsel experienced in international trade to guide you through more complex disputes. -

What are the best practices for maintaining my PSA 10 vending machines post-purchase?

Regular maintenance is crucial for the longevity of your vending machines. Develop a routine maintenance schedule that includes cleaning, software updates, and inspections of mechanical parts. Keep a log of maintenance activities and any repairs made. Additionally, establish a good relationship with the supplier for ongoing support and access to spare parts, which can help minimize downtime and ensure efficient operation.

Strategic Sourcing Conclusion and Outlook for psa 10 vending machine

In conclusion, the strategic sourcing of PSA 10 vending machines presents a significant opportunity for international B2B buyers looking to enhance their market offerings. Key takeaways include the importance of understanding local market dynamics, leveraging supplier relationships, and investing in high-quality machines that meet regulatory standards. By prioritizing these aspects, businesses can ensure a sustainable supply chain that not only reduces costs but also enhances customer satisfaction.

As the demand for vending solutions grows, particularly in regions like Africa, South America, the Middle East, and Europe, buyers are encouraged to adopt a proactive sourcing strategy. This includes evaluating multiple suppliers, assessing technological advancements, and considering environmentally sustainable options that resonate with modern consumers.

Illustrative Image (Source: Google Search)

Looking ahead, the evolving landscape of vending solutions necessitates agility and innovation. International buyers are urged to stay informed about market trends and emerging technologies that can provide a competitive edge. By doing so, they can position themselves to capitalize on new opportunities and drive growth in their respective markets. Engage with trusted suppliers today to explore how PSA 10 vending machines can transform your business operations and meet the demands of an ever-changing marketplace.