Master Vending Machine Routes: Essential Insights for B2B

Guide to Vending Machine Routes

- Introduction: Navigating the Global Market for vending machine routes

- Understanding vending machine routes Types and Variations

- Key Industrial Applications of vending machine routes

- Strategic Material Selection Guide for vending machine routes

- In-depth Look: Manufacturing Processes and Quality Assurance for vending machine routes

- Comprehensive Cost and Pricing Analysis for vending machine routes Sourcing

- Spotlight on Potential vending machine routes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for vending machine routes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine routes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vending machine routes

- Strategic Sourcing Conclusion and Outlook for vending machine routes

Introduction: Navigating the Global Market for vending machine routes

The vending machine industry has evolved significantly, offering lucrative opportunities for international B2B buyers. As urbanization and consumer convenience become paramount, vending machine routes stand out as a vital component of this market. These routes not only provide essential access to products but also represent a strategic investment for businesses aiming to tap into diverse consumer bases across Africa, South America, the Middle East, and Europe, including key markets like Brazil and Saudi Arabia.

This comprehensive guide delves into the intricacies of vending machine routes, empowering buyers with the knowledge needed to make informed sourcing decisions. From understanding the various types of vending machines available to evaluating the materials used in their construction, we cover every essential aspect. Furthermore, we explore manufacturing and quality control practices, ensuring that buyers can assess suppliers’ reliability and product standards.

In addition to outlining the cost considerations and market dynamics, this guide addresses frequently asked questions that often arise during the purchasing process. By equipping B2B buyers with critical insights and actionable strategies, we aim to facilitate effective sourcing and foster successful partnerships. Whether you are looking to expand your vending operations or explore new markets, this guide serves as a valuable resource to navigate the global landscape of vending machine routes with confidence.

Understanding vending machine routes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Route | Fixed locations with regular service schedules | Offices, schools, hospitals | Pros: Reliable, predictable revenue. Cons: Higher operational costs due to travel time. |

| Micro-Market Route | Self-service kiosks with a variety of products | Corporate campuses, gyms, retail | Pros: Lower overhead, flexible inventory. Cons: Requires initial investment in technology. |

| Seasonal Route | Focus on specific products during peak seasons | Events, festivals, tourist areas | Pros: High sales potential during peak times. Cons: Limited operational periods. |

| Mobile Vending Route | Portable units that can serve multiple locations | Events, markets, fairs | Pros: High flexibility, low fixed costs. Cons: Weather-dependent, inconsistent sales. |

| Specialized Product Route | Focused on niche markets (e.g., healthy snacks) | Health clubs, schools, specialty shops | Pros: Targets specific customer needs, potential for high margins. Cons: Limited audience reach. |

Traditional Route

The traditional vending machine route is characterized by its fixed locations and regular service schedules. This model is widely used in offices, schools, and hospitals, where machines are stocked at consistent intervals. B2B buyers should consider the reliability of this model, as it generates predictable revenue streams. However, the operational costs can be higher due to travel time and logistics, making it essential to analyze the location density and potential sales volume before committing.

Micro-Market Route

Micro-markets feature self-service kiosks that offer a diverse range of products, often incorporating technology for inventory management and payment processing. These are ideal for corporate campuses, gyms, and retail environments where a variety of choices can drive sales. B2B buyers should weigh the benefits of lower overhead costs and flexible inventory management against the initial investment in technology and potential maintenance challenges. This model caters to the growing demand for convenience and variety.

Seasonal Route

The seasonal vending machine route focuses on specific products aligned with peak seasons or events, such as holidays or festivals. This approach is particularly beneficial in areas with high foot traffic during certain times, like tourist attractions or event venues. While the sales potential during peak periods can be significant, buyers must be prepared for limited operational periods and plan for inventory management during off-seasons. Understanding local market trends is crucial for success in this model.

Mobile Vending Route

Mobile vending routes utilize portable units that can serve multiple locations, making them ideal for events, markets, and fairs. This model offers high flexibility and low fixed costs, allowing businesses to adapt quickly to changing consumer demands. However, B2B buyers should consider the weather dependency and the potential for inconsistent sales due to varying foot traffic. Effective marketing and strategic location planning are essential for maximizing revenue in this route.

Specialized Product Route

This route focuses on niche markets, such as healthy snacks or specific dietary products, targeting particular customer segments like health clubs or specialty shops. The key advantage of this model is its ability to meet specific customer needs, which can lead to higher profit margins. However, B2B buyers must recognize the limited audience reach and ensure that there is sufficient demand for the specialized offerings. Conducting market research and understanding consumer preferences is vital for success in this niche.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of vending machine routes

| Industry/Sector | Specific Application of vending machine routes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Snack and beverage vending in hotels | Enhances guest experience, generates additional revenue | Machine placement options, product variety, payment systems |

| Education | Campus vending for students and staff | Provides convenient access to food, encourages healthy eating | Nutritional options, machine maintenance, payment flexibility |

| Corporate Offices | Office snack and beverage services | Increases employee satisfaction and productivity | Customization options, inventory management, service frequency |

| Manufacturing | Breakroom vending for factory workers | Reduces downtime, improves worker morale | Robustness of machines, product selection, service reliability |

| Healthcare | Vending for hospitals and clinics | Offers quick access to snacks and drinks for staff and visitors | Compliance with health regulations, product freshness, machine hygiene |

Hospitality

In the hospitality sector, vending machine routes are strategically placed in hotels to provide guests with convenient access to snacks and beverages. This not only enhances the guest experience but also serves as an additional revenue stream for hotel operators. For international buyers, especially in regions like Europe and the Middle East, it’s crucial to consider local preferences for products and payment systems that cater to a diverse clientele. Ensuring a variety of offerings, including healthy options, can significantly improve guest satisfaction.

Illustrative Image (Source: Google Search)

Education

Universities and schools utilize vending machine routes to cater to students and staff, providing quick access to food and beverages on campuses. This application can solve the problem of limited dining options, particularly during off-hours or in remote locations. B2B buyers in Africa and South America should focus on nutritional product offerings to promote healthy eating habits among students. Additionally, machine maintenance and the ability to accept various payment methods are critical considerations to keep operations running smoothly.

Corporate Offices

In corporate environments, vending machines serve as a convenient solution for employees seeking snacks and drinks throughout the workday. This application can enhance employee satisfaction and productivity by reducing the time spent away from work for food breaks. Buyers should consider customization options to align with corporate culture and dietary preferences, as well as effective inventory management systems to ensure consistent product availability. In regions like Brazil and Saudi Arabia, understanding local tastes can further optimize vending offerings.

Manufacturing

In manufacturing settings, vending machine routes are employed in breakrooms to provide workers with quick access to refreshments. This application addresses the need to minimize downtime during shifts while boosting morale among factory staff. B2B buyers should prioritize the robustness of machines to withstand industrial environments and ensure a diverse selection of products that cater to various dietary needs. Regular service and maintenance are also vital to keep machines operational and stocked.

Healthcare

Vending machines in healthcare facilities, such as hospitals and clinics, offer essential snacks and beverages for staff and visitors. This application addresses the need for quick and easy access to nourishment in high-demand settings. International buyers should be aware of compliance with health regulations and the importance of product freshness, as well as hygiene standards for vending machines. Tailoring offerings to include healthier choices can also enhance the overall experience for patients and healthcare professionals alike.

Related Video: How to Start a Vending Machine Business, Cost, Tips, How Much You Make

Strategic Material Selection Guide for vending machine routes

When selecting materials for vending machine routes, it’s essential to consider factors such as durability, cost, and compatibility with the intended media. Below are analyses of four common materials used in vending machine applications, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. It typically has a temperature rating of up to 800°F (427°C) and is resistant to many chemicals.

Pros & Cons:

The primary advantage of stainless steel is its durability and low maintenance requirements, making it ideal for high-traffic environments. However, it can be more expensive than other materials, which may affect budget considerations for some buyers. The manufacturing complexity is moderate, as stainless steel requires specialized processes for shaping and welding.

Impact on Application:

Stainless steel is compatible with a variety of media, including beverages and snacks, and is often used in vending machines that dispense food items. Its non-reactive nature ensures that it does not alter the taste or quality of the products.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with local food safety standards, such as those outlined by the European Food Safety Authority (EFSA). Additionally, ASTM and DIN standards may apply depending on the specific application.

Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has a good strength-to-weight ratio. It can withstand temperatures up to 600°F (316°C) and is often anodized for additional protection.

Pros & Cons:

One of the main advantages of aluminum is its low weight, which can reduce shipping costs and ease installation. However, it is less durable than stainless steel and may dent or scratch more easily. The manufacturing complexity is low, as aluminum can be easily machined and formed.

Impact on Application:

Aluminum is suitable for vending machines that require lightweight components, such as frames and panels. However, it may not be ideal for high-impact areas where durability is paramount.

Considerations for International Buyers:

Buyers in South America and Africa should consider the local availability of aluminum and any associated import tariffs. Compliance with local standards, such as JIS in Japan or ASTM in the U.S., may also be necessary.

Plastic (Polycarbonate)

Key Properties:

Polycarbonate is a strong, lightweight thermoplastic known for its high impact resistance and good thermal stability. It can operate effectively in temperatures ranging from -40°F to 240°F (-40°C to 116°C).

Pros & Cons:

The main advantage of polycarbonate is its excellent impact resistance, making it ideal for vending machine windows and components exposed to potential damage. However, it is less resistant to UV light, which can cause degradation over time. The manufacturing process is relatively straightforward, allowing for cost-effective production.

Impact on Application:

Polycarbonate is commonly used for transparent panels and protective covers in vending machines. Its clarity allows for visibility of the products inside, enhancing customer interaction.

Considerations for International Buyers:

Buyers should check for compliance with local safety regulations, especially in regions where UV exposure is high. Understanding the local market for plastics and any recycling requirements is also crucial.

Mild Steel

Key Properties:

Mild steel is known for its good tensile strength and ductility. It typically has a temperature rating of up to 400°F (204°C) and is prone to corrosion if not treated.

Pros & Cons:

Mild steel is cost-effective and easy to fabricate, making it a popular choice for structural components in vending machines. However, it requires protective coatings to prevent rust and corrosion, which can add to maintenance costs. The manufacturing complexity is low, allowing for quick production.

Impact on Application:

Mild steel is often used in the framework of vending machines and can support heavy loads. However, its susceptibility to corrosion limits its use in environments with high humidity or exposure to moisture.

Considerations for International Buyers:

Buyers in regions like Africa and South America should be aware of local climate conditions that may affect the longevity of mild steel components. Compliance with ASTM standards for structural steel may also be necessary.

Summary Table

| Material | Typical Use Case for vending machine routes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and beverage dispensing components | Excellent durability and corrosion resistance | Higher cost compared to alternatives | High |

| Aluminum | Lightweight frames and panels | Low weight reduces shipping costs | Less durable than stainless steel | Medium |

| Plastic (Polycarbonate) | Transparent panels and protective covers | High impact resistance | UV degradation over time | Low |

| Mild Steel | Structural components and frameworks | Cost-effective and easy to fabricate | Prone to corrosion without treatment | Low |

This guide provides a clear overview of material options for vending machine routes, helping international B2B buyers make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for vending machine routes

Manufacturing vending machines involves a series of intricate processes that ensure quality, durability, and functionality. Understanding these processes is crucial for B2B buyers from regions like Africa, South America, the Middle East, and Europe, as it directly impacts the reliability of vending machine routes. This section provides an in-depth look at the manufacturing processes and quality assurance measures that underpin the production of vending machines.

Manufacturing Processes

The manufacturing of vending machines typically involves four main stages: material preparation, forming, assembly, and finishing. Each stage is essential in ensuring that the final product meets the required specifications and standards.

1. Material Preparation

The first step involves sourcing and preparing materials that are suitable for vending machine production. Common materials include:

- Steel and Aluminum: Used for the machine chassis and exterior due to their strength and durability.

- Plastic Components: Utilized for internal parts and consumer interfaces to reduce weight and costs.

- Electronic Components: Sourced from specialized suppliers to ensure compatibility and reliability.

B2B buyers should consider suppliers who demonstrate a commitment to sustainable sourcing and use materials that comply with international environmental standards.

2. Forming

In this stage, raw materials are shaped into specific components using various techniques, such as:

- Stamping: Metal sheets are cut and shaped using high-pressure machines, ensuring precision in parts like doors and panels.

- Injection Molding: This technique is used for plastic components, allowing for complex shapes and designs that enhance user interaction.

- Laser Cutting: Offers high precision in cutting metal parts, crucial for maintaining the structural integrity of the vending machine.

Investing in suppliers who employ advanced forming technologies can lead to better-quality products and reduced lead times.

3. Assembly

The assembly process is where all components come together. Key steps include:

- Component Assembly: Individual parts are assembled into subassemblies, such as the refrigeration unit or the payment system.

- Integration of Electronics: Wiring and electronic components are integrated, requiring skilled labor to ensure proper functionality.

- Testing During Assembly: Initial testing of electronic systems is conducted at this stage to identify any issues early on.

B2B buyers should inquire about the training and expertise of assembly line workers, as skilled labor is critical for minimizing defects.

4. Finishing

Finishing processes enhance the aesthetics and durability of the vending machines. This stage includes:

- Painting and Coating: Protective coatings are applied to prevent rust and wear, while paint finishes improve the visual appeal.

- Final Assembly and Packaging: Once the finishing touches are complete, the machines are assembled for final inspection and prepared for shipping.

Buyers should seek suppliers that utilize environmentally friendly finishing techniques, as this can impact both product longevity and compliance with international regulations.

Quality Assurance

Quality assurance (QA) is paramount in the manufacturing of vending machines. It ensures that products meet specific standards and function reliably in various environments.

Relevant International Standards

B2B buyers should be aware of the following standards:

- ISO 9001: This international standard sets criteria for a quality management system, ensuring that suppliers maintain consistent quality in production.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: Relevant for components that may interact with food or beverages, ensuring safety and quality.

Understanding these standards can help buyers assess the credibility of suppliers and the quality of their products.

Quality Control Checkpoints

Quality control (QC) involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product to ensure it meets all functional and aesthetic criteria.

B2B buyers should request detailed QC reports that outline these checkpoints, providing transparency into the manufacturing process.

Common Testing Methods

Several testing methods are commonly employed to ensure quality, including:

- Functional Testing: Evaluates the operational effectiveness of vending machines, including payment processing and dispensing mechanisms.

- Durability Testing: Simulates long-term use to assess the machine’s performance under various conditions.

- Safety Testing: Ensures compliance with safety standards, particularly for electrical components.

Buyers should inquire about the specific testing methods employed by suppliers to gauge the reliability of their products.

Verifying Supplier Quality Control

To ensure that suppliers maintain high-quality standards, B2B buyers should consider the following verification strategies:

- Supplier Audits: Conducting regular audits of suppliers can help assess their compliance with quality standards and manufacturing processes.

- Requesting Quality Reports: Suppliers should provide documentation of their QC processes, including test results and compliance certificates.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing capabilities and quality assurance processes.

QC and Certification Nuances for International Buyers

International buyers must navigate various certification and compliance nuances:

- Regional Compliance: Different regions may have specific regulations; for instance, CE marking is essential for European markets, while compliance with local standards is crucial in Africa and South America.

- Language and Documentation: Ensure that all certifications and quality documentation are available in relevant languages to avoid misunderstandings.

- Cultural Differences: Understand the local business practices and expectations regarding quality assurance, which can vary significantly between regions.

By being informed about these nuances, B2B buyers can make better decisions when selecting suppliers for vending machine routes.

Conclusion

In summary, the manufacturing processes and quality assurance measures for vending machines play a vital role in ensuring product reliability and functionality. By understanding these processes, international B2B buyers can make informed decisions, ensuring that they partner with suppliers who prioritize quality and compliance. This knowledge not only enhances the efficiency of vending machine routes but also contributes to long-term business success.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for vending machine routes Sourcing

Understanding the Cost Structure of Vending Machine Routes

When sourcing vending machine routes, it is essential for international B2B buyers to grasp the comprehensive cost structure involved. This includes several critical components:

-

Materials: The quality and type of materials used in vending machines directly impact costs. Considerations should include the robustness of the machine casing, the technology used (e.g., touch screens, cashless payment systems), and the type of products dispensed (snacks, beverages, or specialized items).

-

Labor: Labor costs can vary significantly by region. In markets like Africa and South America, labor may be less expensive, but quality and skill levels must also be assessed. In contrast, European and Middle Eastern markets may have higher labor costs, reflecting different wage standards and operational efficiencies.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and administrative expenses. Buyers should inquire about the overhead allocation to better understand pricing.

-

Tooling and Quality Control (QC): Initial tooling costs for customizing machines can be substantial. Investing in quality control processes is crucial to ensure the reliability and durability of machines, which can save money in the long run by reducing maintenance and replacement needs.

-

Logistics: International shipping and transportation costs can significantly impact the total cost. This includes freight charges, customs duties, and potential tariffs that vary by region. Buyers should plan for these expenses, especially when sourcing from overseas suppliers.

-

Margin: Suppliers will typically include a profit margin in their pricing, which can vary based on competition, demand, and market dynamics. Understanding the typical margins in your region can help in negotiating better deals.

Key Price Influencers

Several factors can influence the pricing of vending machine routes:

-

Volume/MOQ: The minimum order quantity (MOQ) can significantly affect pricing. Higher volumes may lead to discounts, so it’s beneficial for buyers to consolidate orders when possible.

-

Specifications and Customization: Customizing machines to meet specific needs may incur additional costs. Buyers should weigh the benefits of tailored solutions against potential price increases.

-

Material Quality and Certifications: Machines built with higher-quality materials or those meeting specific certifications (e.g., energy efficiency, safety standards) may be priced higher but can offer long-term cost savings through durability and lower operational costs.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more but offer assurances of quality and service.

-

Incoterms: Understanding the agreed-upon Incoterms can clarify who bears responsibility for shipping costs, insurance, and risk. This knowledge is vital for accurate total cost calculations.

Buyer Tips for Cost-Efficiency

-

Negotiate: Leverage your buying power. Don’t hesitate to negotiate terms and prices, especially when dealing with larger suppliers or bulk orders.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Assess maintenance, energy consumption, and potential downtime costs to understand the full financial impact of your investment.

-

Consider Regional Variations: Pricing and costs can differ dramatically across regions. For instance, while sourcing in Brazil may offer lower labor costs, consider the logistics of shipping machines to remote areas.

-

Understand Pricing Nuances: Be aware of potential hidden costs, such as import duties and taxes, that could arise when importing machines into countries in the Middle East or Africa.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing, more favorable terms, and improved service. Suppliers often reward loyalty with discounts or priority service.

Disclaimer

The prices and cost components discussed here are indicative and can vary widely based on market conditions, supplier agreements, and specific buyer requirements. Always conduct thorough due diligence and obtain multiple quotes before making purchasing decisions.

Spotlight on Potential vending machine routes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for vending machine routes.)*

Essential Technical Properties and Trade Terminology for vending machine routes

Key Technical Properties for Vending Machine Routes

Understanding the essential technical properties of vending machines is crucial for international B2B buyers to make informed purchasing decisions. Here are some critical specifications that impact performance and longevity:

-

Material Grade: The grade of materials used in vending machines (e.g., stainless steel, high-grade plastics) is vital for durability and resistance to environmental factors such as humidity or temperature fluctuations. High-quality materials ensure that machines can withstand frequent use and maintain their aesthetic appeal, reducing the need for replacements or repairs.

-

Weight Capacity: This specification refers to the maximum weight a vending machine can support, including the products it dispenses. For buyers, understanding weight capacity is essential to ensure the machine can accommodate the specific types of products they intend to sell, especially in regions with diverse product preferences.

-

Energy Efficiency: Energy consumption ratings (such as Energy Star certification) indicate how much electricity a vending machine uses. This is particularly relevant for businesses looking to minimize operational costs and environmental impact. Energy-efficient machines can lead to significant savings over time, making them a wise investment.

-

Temperature Control Range: For machines that dispense perishable items (e.g., beverages or snacks), the temperature control range is critical. This specification ensures that products remain fresh and safe for consumption. Buyers should evaluate the temperature range to match the types of goods they plan to offer, particularly in warmer climates.

-

Connectivity Options: Modern vending machines often come with connectivity features such as cashless payment systems, remote monitoring, and inventory management tools. Understanding these options is crucial for businesses aiming to enhance user experience and streamline operations.

Common Trade Terminology in the Vending Machine Industry

Familiarity with industry jargon can significantly enhance communication and negotiation effectiveness in the vending machine sector. Here are some common terms:

-

OEM (Original Equipment Manufacturer): This refers to companies that produce components or machines that are then sold under another company’s brand. For buyers, partnering with reputable OEMs can ensure product quality and reliability.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory planning, especially for buyers in emerging markets who may have limited initial capital.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and other details for specific products. It is a crucial step in the procurement process, allowing buyers to compare options and negotiate better terms.

-

Incoterms (International Commercial Terms): These are a set of rules that define the responsibilities of sellers and buyers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers manage logistical risks and costs effectively.

-

Lead Time: This term refers to the amount of time from placing an order to receiving the goods. Understanding lead times is critical for inventory management and ensuring that vending machines are stocked and operational when needed.

-

Warranty Period: This is the duration during which a product is covered for repairs or replacements due to defects. Knowing the warranty period helps buyers assess the long-term value and reliability of their vending machine investments.

By grasping these essential technical properties and trade terminologies, B2B buyers can navigate the vending machine market more effectively, ensuring that they select products that meet their specific operational needs and market conditions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine routes Sector

Market Overview & Key Trends

The vending machine routes sector is experiencing significant transformation driven by several global factors. Increasing urbanization and fast-paced lifestyles in regions such as Africa, South America, the Middle East, and Europe are propelling demand for convenient, on-the-go food and beverage options. Additionally, the rise of e-commerce and technology integration is reshaping the landscape, with smart vending machines equipped with IoT capabilities enabling real-time inventory tracking and personalized consumer experiences. For B2B buyers, this represents an opportunity to tap into a growing market that values efficiency and innovation.

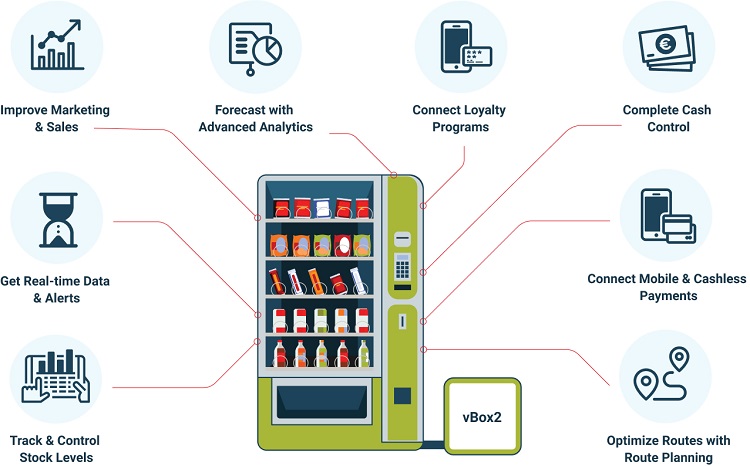

Emerging trends in sourcing include the use of data analytics to optimize product selection and placement. Companies are increasingly leveraging consumer insights to tailor offerings based on local preferences, enhancing both sales and customer satisfaction. Furthermore, the adoption of cashless payment systems is gaining traction, particularly in regions like Europe and the Middle East, where contactless transactions have become the norm. As a B2B buyer, investing in technology that supports these trends can improve operational efficiency and customer engagement.

Another critical dynamic is the competitive landscape, with both established players and new entrants vying for market share. This competition is pushing companies to differentiate themselves through unique product offerings and superior service delivery. International buyers should focus on partnerships with suppliers who demonstrate agility and innovation in their approaches to meet evolving market demands.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of the vending machine routes sector, with increasing pressure from consumers and regulators for environmentally responsible practices. B2B buyers must consider the environmental impact of their sourcing decisions, from the materials used in vending machine construction to the products offered within them. Companies are now prioritizing suppliers who utilize sustainable practices, such as reduced packaging waste and energy-efficient machines.

The importance of ethical supply chains cannot be overstated. Businesses that prioritize transparency in sourcing and production are better positioned to build trust with consumers and partners alike. Certifications such as Fair Trade, Rainforest Alliance, and ISO 14001 for environmental management can enhance a company’s reputation and appeal in the marketplace. B2B buyers should actively seek out vendors who hold these certifications, as they signify a commitment to ethical practices and sustainability.

Moreover, the use of ‘green’ materials, including biodegradable and recyclable components, is gaining traction. By incorporating such materials into their supply chain, companies not only minimize their environmental footprint but also align themselves with the growing consumer demand for sustainable options. For international buyers, aligning with suppliers focused on sustainability can lead to competitive advantages and stronger market positioning.

Brief Evolution/History

The vending machine industry has evolved significantly since its inception in the early 20th century. Initially offering simple snacks and drinks, vending machines have transformed into sophisticated retail solutions equipped with advanced technology. The introduction of cashless payment systems and smart technology has propelled the sector into a new era, allowing for real-time data collection and enhanced consumer interaction. This evolution reflects broader trends in retail and consumer behavior, emphasizing convenience and personalization. For B2B buyers, understanding this history is crucial for recognizing the current dynamics and future potential of the vending machine routes market.

Related Video: EU Ready for U.S. Trade Deal, Warns of Fallout If Ukraine Aid Falters | N18G

Frequently Asked Questions (FAQs) for B2B Buyers of vending machine routes

-

What key factors should I consider when vetting suppliers for vending machine routes?

When vetting suppliers, prioritize their experience and reputation in the vending machine industry. Look for suppliers with a proven track record in your target region, as they will be familiar with local regulations and market demands. Request references from previous clients and verify their ability to provide ongoing support. Additionally, assess their financial stability to ensure they can fulfill long-term commitments. Conducting site visits, if feasible, can also provide valuable insights into their operations and product quality. -

Can I customize the vending machines and products for my target market?

Yes, customization is often possible and can be crucial for success in diverse markets. Many suppliers offer options to tailor vending machines to suit local tastes and preferences, including product selection and branding. Engage with potential suppliers to discuss your specific needs, including machine size, payment methods, and product offerings that align with cultural preferences. Ensure that customization capabilities are clearly defined in the contract to avoid any misunderstandings later. -

What are the typical minimum order quantities (MOQs) and lead times for vending machine routes?

MOQs can vary significantly based on the supplier and the specific products being ordered. Generally, suppliers may require a minimum order of several machines or a bulk quantity of products. Lead times also depend on the complexity of the order and the supplier’s production capacity, typically ranging from a few weeks to several months. It is essential to discuss these factors upfront and incorporate them into your planning to ensure timely delivery and market entry. -

What payment terms should I expect when sourcing vending machine routes?

Payment terms can differ by supplier, but typical arrangements include upfront payments, installment plans, or letters of credit, especially for international transactions. It is important to negotiate terms that are manageable for your cash flow while ensuring the supplier is protected. Be aware of potential currency exchange issues and international transaction fees that may affect the overall cost. Always clarify payment terms in the contract to prevent disputes down the line. -

How can I ensure quality assurance and compliance with industry standards?

To ensure quality assurance, request certifications from suppliers that demonstrate compliance with international safety and health standards, such as ISO 9001. Conducting regular audits and inspections can help maintain quality over time. Additionally, inquire about the supplier’s quality control processes, including testing procedures for products and machines. Establishing a clear quality assurance protocol in your agreement will help mitigate risks and ensure product reliability. -

What logistics considerations should I keep in mind when sourcing vending machine routes?

Logistics is a critical aspect of sourcing vending machines, especially for international buyers. Consider shipping methods, costs, and potential customs regulations in your target market. Collaborate with suppliers who have experience in international shipping to facilitate smoother transactions. Additionally, plan for storage and distribution once the machines arrive, as this can impact your overall operational efficiency. Understanding local logistics challenges can also help you avoid delays. -

What steps should I take in case of disputes with suppliers?

In the event of a dispute, the first step is to refer to the terms outlined in your contract, which should specify dispute resolution procedures. Open communication with the supplier can often lead to a mutual agreement. If necessary, consider mediation or arbitration as alternative dispute resolution methods, which can be less costly and time-consuming than litigation. Maintain detailed records of all communications and transactions to support your case and ensure clarity during discussions. -

Are there any specific regulations or compliance issues I should be aware of in my target market?

Each region has unique regulations governing the operation of vending machines, including health and safety standards, taxation, and product labeling requirements. Research local laws thoroughly or consult with legal experts to ensure compliance. In Africa and South America, for instance, regulations may vary significantly between countries. Understanding these legal frameworks will help you avoid penalties and ensure a smoother market entry, thereby safeguarding your investment.

Strategic Sourcing Conclusion and Outlook for vending machine routes

In conclusion, strategic sourcing in vending machine routes is pivotal for optimizing operational efficiency and enhancing profitability. International B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe, should prioritize establishing robust supplier relationships and leveraging data analytics for informed decision-making. By focusing on local consumer preferences, businesses can select products that resonate well, thereby driving higher sales and customer satisfaction.

Investing in technology for route optimization and inventory management can significantly reduce costs and improve service delivery. Key takeaways include:

- Local Market Understanding: Tailor product offerings to meet regional tastes and demands.

- Supplier Collaboration: Foster partnerships with reliable suppliers to ensure quality and consistency.

- Data-Driven Decisions: Utilize analytics to enhance route efficiency and inventory turnover.

Looking ahead, the vending machine industry is poised for growth, especially as consumer behavior shifts toward convenience and automation. B2B buyers are encouraged to stay ahead of market trends and explore innovative solutions that can streamline operations and elevate customer experiences. By embracing these strategies, companies can position themselves for success in a competitive landscape.