Master Vending Machine Price Labels: A Strategic B2B

Guide to Vending Machine Price Labels

- Introduction: Navigating the Global Market for vending machine price labels

- Understanding vending machine price labels Types and Variations

- Key Industrial Applications of vending machine price labels

- Strategic Material Selection Guide for vending machine price labels

- In-depth Look: Manufacturing Processes and Quality Assurance for vending machine price labels

- Comprehensive Cost and Pricing Analysis for vending machine price labels Sourcing

- Spotlight on Potential vending machine price labels Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for vending machine price labels

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine price labels Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vending machine price labels

- Strategic Sourcing Conclusion and Outlook for vending machine price labels

Introduction: Navigating the Global Market for vending machine price labels

In today’s rapidly evolving marketplace, the significance of vending machine price labels cannot be overstated. These labels are essential for conveying pricing information clearly and accurately, ensuring that customers make informed purchasing decisions. For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of vending machine price labels is crucial for optimizing operations and enhancing customer satisfaction.

This comprehensive guide delves into various facets of vending machine price labels, covering key aspects such as types of labels, materials used in manufacturing, quality control measures, and insights into reputable suppliers. Additionally, it provides a detailed analysis of cost considerations and explores current market trends. By addressing frequently asked questions, this guide equips buyers with the knowledge needed to navigate the complexities of sourcing the right labels for their vending machines.

Armed with this information, B2B buyers can make informed decisions that not only enhance their operational efficiency but also contribute to a seamless customer experience. Whether you are looking to streamline your supply chain or ensure compliance with local regulations, this guide serves as a vital resource for making strategic sourcing decisions in the global market for vending machine price labels.

Understanding vending machine price labels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Static Price Labels | Non-digital, fixed pricing, often adhesive | Retail, snacks, beverages | Pros: Low cost, easy to apply; Cons: No flexibility, requires reprinting for price changes. |

| Digital Price Displays | Electronic screens, programmable pricing | High-end vending machines | Pros: Dynamic pricing, easy updates; Cons: Higher initial cost, requires power supply. |

| QR Code Labels | Scannable codes for pricing and promotions | Promotions, seasonal products | Pros: Interactive, can link to online content; Cons: Requires customer engagement, may not be effective for all demographics. |

| Customizable Labels | Tailored designs with branding and pricing info | Specialty items, brand awareness | Pros: Enhances brand identity, flexible; Cons: Higher production costs, longer lead times. |

| Tamper-Proof Labels | Security features to prevent price alteration | High-value items, security-focused | Pros: Increases security, protects revenue; Cons: More expensive, may complicate label changes. |

Static Price Labels

Static price labels are the most traditional form of labeling used in vending machines. They are typically adhesive and feature fixed pricing, making them suitable for products with stable prices. B2B buyers find these labels appealing due to their low cost and ease of application. However, the lack of flexibility to change prices without reprinting can be a drawback, particularly for businesses that frequently adjust their pricing strategies.

Digital Price Displays

Digital price displays represent a modern advancement in vending machine labeling. These electronic screens allow for programmable pricing, enabling businesses to update prices dynamically. Ideal for high-end vending machines, these displays can attract tech-savvy customers. While they offer significant advantages in terms of flexibility and real-time updates, the initial investment and ongoing power supply requirements can be a barrier for some buyers.

QR Code Labels

QR code labels integrate technology with traditional labeling, allowing customers to scan codes for pricing and promotional information. This type is particularly effective for seasonal products or promotions, as they can link customers to online content or special offers. B2B buyers appreciate the interactive nature of QR code labels, though their effectiveness may depend on customer engagement and technological familiarity.

Customizable Labels

Customizable labels provide businesses with the opportunity to tailor designs that reflect their brand identity. These labels can include unique graphics along with pricing information, enhancing brand awareness in competitive markets. While they offer flexibility and a personalized touch, the production costs and longer lead times can be significant considerations for B2B buyers looking for cost-effective solutions.

Tamper-Proof Labels

Tamper-proof labels are designed with security features that prevent unauthorized alterations to pricing information. These labels are particularly relevant for high-value items and businesses focused on security. While they provide increased protection for revenue and pricing integrity, the higher costs associated with these labels can deter some buyers, especially those with budget constraints.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of vending machine price labels

| Industry/Sector | Specific Application of vending machine price labels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Pricing for snack and beverage vending machines | Enhances customer experience through clear pricing | Durability, visibility in various lighting conditions |

| Retail | Price labeling for retail vending machines | Facilitates quick purchasing decisions | Customization options, compliance with local regulations |

| Transportation | Ticket vending machines for public transport | Streamlines fare collection and reduces wait times | Integration with payment systems, weather resistance |

| Healthcare | Medical supplies vending machines | Ensures accurate billing and inventory management | Material safety, ease of readability |

| Education | Campus vending machines for student supplies | Supports convenience and accessibility for students | Multi-language options, adaptability to different environments |

Food & Beverage

In the food and beverage sector, vending machine price labels are critical for informing customers about product prices, nutritional information, and promotions. Clear pricing enhances the customer experience, encouraging impulse purchases and reducing the likelihood of disputes at the point of sale. Buyers should consider durability and visibility of labels, especially in environments with varying lighting conditions. Additionally, labels must comply with local health regulations regarding food labeling, which can vary significantly across regions such as Africa and Europe.

Retail

Vending machines in retail settings utilize price labels to display the cost of items, thus facilitating a seamless shopping experience. These labels can be customized to reflect promotions or discounts, driving sales and enhancing customer engagement. For international buyers, it is essential to ensure that the labels meet local regulations regarding pricing transparency and consumer rights. Customization options should also be evaluated to align with branding strategies and marketing initiatives.

Transportation

In the transportation industry, ticket vending machines rely on price labels to communicate fare information effectively. This clear communication is vital for streamlining fare collection and minimizing wait times for passengers. International buyers must consider the integration of these labels with various payment systems, including cash, credit, and mobile payments. Additionally, sourcing labels that are resistant to weather conditions is crucial, especially in regions with extreme climates, to ensure longevity and reliability.

Healthcare

Healthcare vending machines, which dispense medical supplies, leverage price labels to ensure accurate billing and inventory management. These labels not only inform patients and medical staff of costs but also aid in maintaining compliance with healthcare regulations. Buyers in this sector should prioritize material safety and ease of readability, as these factors are essential in medical environments where clarity is critical. Furthermore, labels may need to accommodate multiple languages to serve diverse populations effectively.

Education

Campus vending machines that provide student supplies and snacks benefit from well-placed price labels that enhance convenience and accessibility. Clear labeling helps students make quick purchasing decisions during busy schedules. Buyers should consider multi-language options for labels to cater to international students and ensure adaptability to different environments, such as indoor and outdoor locations. Compliance with educational institution policies regarding pricing and promotions is also a key consideration for sourcing.

Related Video: How to Start a Vending Machine Business, Cost, Tips, How Much You Make

Strategic Material Selection Guide for vending machine price labels

When selecting materials for vending machine price labels, it is crucial to consider properties that affect durability, visibility, and overall performance in various environments. Below, we analyze four common materials used for price labels, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Vinyl

Key Properties:

Vinyl is a synthetic plastic polymer known for its flexibility and resistance to moisture. It can withstand a temperature range of -40°C to 70°C, making it suitable for various climates.

Pros & Cons:

Vinyl labels are durable and resistant to tearing, which is advantageous in high-traffic areas. They are also waterproof and UV-resistant, ensuring longevity outdoors. However, vinyl can be more expensive than paper alternatives and may not be recyclable, raising environmental concerns.

Impact on Application:

Vinyl is compatible with a variety of inks and adhesives, allowing for vibrant colors and clear printing. It is ideal for labels that require frequent changes, as it adheres well without leaving residue.

Considerations for International Buyers:

Buyers should ensure compliance with local regulations regarding plastic use and disposal. Common standards such as ASTM D-1000 for adhesive properties may apply, and preferences for sustainable materials are increasing in regions like Europe.

2. Paper

Key Properties:

Paper labels are made from cellulose fibers, offering a lightweight and cost-effective solution. They are generally rated for temperatures up to 60°C and are best used in dry environments.

Pros & Cons:

The primary advantage of paper labels is their low cost and ease of printing, making them suitable for short-term use. However, they are susceptible to moisture and fading when exposed to sunlight, which limits their durability in outdoor settings.

Impact on Application:

Paper labels are best suited for indoor vending machines or temporary promotions. They are easily customizable and can be produced in various finishes, including glossy or matte.

Considerations for International Buyers:

International buyers should be aware of local paper recycling guidelines and standards like ISO 14001 for environmental management. In regions like South America, where humidity can be high, paper labels may require additional protective coatings.

3. Polypropylene

Key Properties:

Polypropylene is a thermoplastic polymer known for its strength and resistance to chemical exposure. It can endure temperatures ranging from -20°C to 100°C, making it suitable for diverse applications.

Pros & Cons:

The durability of polypropylene labels is a significant advantage, as they resist tearing and are waterproof. However, they can be more expensive than paper and vinyl, which may deter cost-sensitive buyers.

Impact on Application:

Polypropylene labels are ideal for vending machines located in humid or outdoor environments due to their moisture resistance. They can also be printed with high-quality graphics, enhancing visibility.

Considerations for International Buyers:

Buyers should check for compliance with local safety and environmental regulations, particularly in the Middle East and Africa, where standards may vary. ASTM D-4956 is a relevant standard for reflective materials that may apply to certain label types.

4. Polyester

Key Properties:

Polyester is a robust synthetic material known for its high tensile strength and resistance to chemicals and moisture. It can withstand temperatures from -40°C to 120°C.

Pros & Cons:

Polyester labels are extremely durable and resistant to fading, making them suitable for long-term use. However, they are typically more expensive than other materials, which can impact budget considerations.

Impact on Application:

These labels are ideal for vending machines that are exposed to harsh environmental conditions, such as high temperatures or moisture. Their durability ensures that they remain legible and intact over time.

Considerations for International Buyers:

International buyers should consider the recyclability of polyester and check compliance with local environmental regulations. Standards such as DIN EN 13432 for biodegradable materials may also be relevant in certain European markets.

Summary Table

| Material | Typical Use Case for vending machine price labels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vinyl | Outdoor and high-traffic vending machines | Durable, waterproof, UV-resistant | Higher cost, non-recyclable | High |

| Paper | Indoor and temporary promotions | Low cost, easy to print | Susceptible to moisture and fading | Low |

| Polypropylene | Humid or outdoor environments | Durable, waterproof | Higher cost compared to paper | Medium |

| Polyester | Harsh environmental conditions | Extremely durable, chemical-resistant | Higher cost, less common | High |

This guide provides a comprehensive overview of material options for vending machine price labels, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for vending machine price labels

The manufacturing process for vending machine price labels is a critical aspect that directly impacts their functionality, durability, and overall effectiveness in a retail environment. Understanding the various stages of production and the quality assurance measures in place can help B2B buyers make informed decisions when sourcing these products. Below, we explore the main stages of manufacturing, key techniques employed, and quality control standards relevant for international buyers, particularly from Africa, South America, the Middle East, and Europe.

Manufacturing Processes

Material Preparation

The first step in the production of vending machine price labels is material selection. Common materials include vinyl, polyester, and paper. Each material has unique properties that affect durability, print quality, and resistance to environmental factors such as moisture and UV light.

- Material Sourcing: Suppliers should provide certifications regarding the quality and origin of materials to ensure compliance with international standards.

- Pre-Treatment: Materials may undergo pre-treatment processes to enhance adhesion and printing capabilities. This could involve cleaning or applying a primer coat.

Forming

After preparing the materials, the next step involves shaping them into labels. This can be achieved through various techniques:

- Die-Cutting: This method allows for precise cuts in various shapes and sizes, catering to different vending machine designs. It is essential for producing labels that fit specific spaces.

- Digital Cutting: Utilizing advanced digital cutting technology can increase efficiency and reduce waste, particularly for smaller production runs.

Assembly

Once the labels are formed, they proceed to the assembly stage, where additional components may be added:

- Adhesive Application: Depending on the intended use, labels may be coated with adhesive on one side for easy application to vending machines.

- Layering: For labels requiring durability (e.g., water-resistant or tear-proof), multiple layers may be laminated together. This enhances the labels’ lifespan and usability in high-traffic environments.

Finishing

The final stage of manufacturing involves finishing processes that enhance the aesthetic and functional qualities of the labels:

- Printing: High-resolution printing techniques, such as digital or flexographic printing, are used to ensure clarity and vibrancy of the text and graphics. This is crucial for effective communication of pricing and product information.

- Quality Inspection: After printing, labels are inspected for color accuracy, alignment, and overall quality. Defective labels are removed from the production line.

Quality Assurance

Quality assurance is paramount in the manufacturing of vending machine price labels, ensuring that they meet international standards and customer expectations. Key quality control practices include:

Relevant International Standards

International standards such as ISO 9001 provide a framework for quality management systems that can enhance operational efficiency and customer satisfaction. In addition, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may apply depending on the market and application.

Quality Control Checkpoints

Quality control is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This involves the inspection of raw materials upon arrival at the manufacturing facility. Buyers should verify that suppliers have stringent IQC processes to ensure material quality.

-

In-Process Quality Control (IPQC): During production, continuous monitoring is conducted to identify any deviations from quality standards. This might include regular checks of cutting precision, adhesive strength, and print clarity.

- Final Quality Control (FQC): Before shipment, a final inspection ensures that all labels meet the specified criteria. This includes checking for defects, ensuring labels are correctly packaged, and that documentation is complete.

Common Testing Methods

Various testing methods can be employed to assess the quality and durability of vending machine price labels:

- Adhesion Testing: Evaluates how well the labels stick to surfaces under different conditions.

- Environmental Testing: Exposes labels to extreme temperatures, humidity, and UV light to determine their longevity and resistance.

- Print Quality Testing: Checks for smudging, fading, and color accuracy under various lighting conditions.

Verification of Supplier Quality Control

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. Here are some actionable strategies:

-

Supplier Audits: Conducting regular audits of suppliers can help assess their quality management systems. Buyers should look for adherence to international standards and proper documentation of processes.

-

Quality Reports: Requesting detailed quality reports and testing results can provide insights into the supplier’s performance over time.

-

Third-Party Inspections: Engaging independent inspection services can provide unbiased assessments of supplier quality and compliance with international standards.

Quality Control and Certification Nuances for International Buyers

For buyers from diverse regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is essential:

-

Regional Compliance: Buyers should be aware of specific regulations and standards applicable in their regions. For instance, CE marking may be required for products sold within the European market.

-

Cultural Considerations: Different regions may have varying expectations regarding quality and durability. It is advisable to communicate these expectations clearly with suppliers.

-

Documentation: Maintaining thorough documentation of all quality assurance processes is crucial, especially for international transactions. This includes certificates of compliance, test results, and quality audit reports.

By understanding the manufacturing processes and quality assurance measures involved in the production of vending machine price labels, international B2B buyers can make informed decisions, ensuring they select reliable suppliers who deliver high-quality products tailored to their specific needs.

Related Video: Inspection and Quality control in Manufacturing

Comprehensive Cost and Pricing Analysis for vending machine price labels Sourcing

When sourcing vending machine price labels, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis will help you navigate the complexities involved in procurement, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary cost driver is the type of materials used in the labels. Common options include paper, vinyl, and synthetic materials. Each material has different durability and print quality, which can affect pricing.

-

Labor: Labor costs vary significantly based on the region. In countries with lower labor costs, such as certain parts of Africa and South America, you may find more competitive pricing. However, consider the trade-offs in quality and reliability.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help keep these costs down, impacting the final price.

-

Tooling: Custom tooling for specific label designs can be a substantial upfront cost. If your order involves unique shapes or sizes, be prepared for these additional expenses.

-

Quality Control (QC): Implementing rigorous quality checks can increase costs but is essential for ensuring that the labels meet industry standards and customer expectations.

-

Logistics: Shipping and handling costs can fluctuate based on the distance and mode of transport. Be mindful of any import duties or tariffs that may apply when sourcing from overseas suppliers.

-

Margin: Suppliers will typically add a profit margin to cover their costs and risks. This margin can vary depending on the supplier’s market position and the volume of the order.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly impact pricing. Higher volume orders often lead to lower per-unit costs, making it advantageous for buyers who can commit to larger quantities.

-

Specifications/Customization: Custom labels tailored to specific branding or functional needs usually come at a premium. Clearly define your requirements to avoid unnecessary costs.

-

Materials and Quality/Certifications: Labels that require specific certifications (e.g., eco-friendly materials) may have higher costs. Ensure you communicate your quality requirements upfront.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers may charge more due to their track record and assurances of quality.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital. They dictate who is responsible for shipping, insurance, and tariffs, which can affect overall costs.

Buyer Tips

-

Negotiation: Always negotiate pricing and terms. Suppliers may have flexibility, especially for larger orders or long-term partnerships.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO), not just the purchase price. Consider logistics, storage, and potential wastage when calculating TCO.

-

Pricing Nuances: Be aware that pricing strategies can differ significantly by region. For example, suppliers in Europe may have different pricing structures compared to those in Africa or South America due to local economic conditions and market dynamics.

-

Supplier Relationships: Establish strong relationships with suppliers. Good communication can lead to better pricing and priority service.

Disclaimer

Prices for vending machine price labels can vary widely based on the aforementioned factors. It is advisable to obtain quotes from multiple suppliers and consider all cost components and influencers when making procurement decisions.

Spotlight on Potential vending machine price labels Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘vending machine price labels’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for vending machine price labels

In the vending machine industry, selecting the right price labels is crucial for effective operations. Understanding the technical properties and trade terminology associated with these labels can significantly impact purchasing decisions for B2B buyers.

Key Technical Properties of Vending Machine Price Labels

-

Material Grade

– Definition: This refers to the quality and type of material used for the price labels, such as vinyl, paper, or polyester.

– Importance: Higher-grade materials enhance durability and resistance to environmental factors like moisture and temperature changes, which is essential for outdoor vending machines. -

Adhesive Strength

– Definition: The force required to remove the label from a surface without tearing or leaving residue.

– Importance: A strong adhesive ensures that labels stay affixed during machine operation, reducing the need for frequent replacements and maintaining a professional appearance. -

Print Quality

– Definition: This encompasses the resolution and clarity of the text and images printed on the labels.

– Importance: High print quality ensures that prices and product information are easily readable, improving customer experience and reducing confusion.

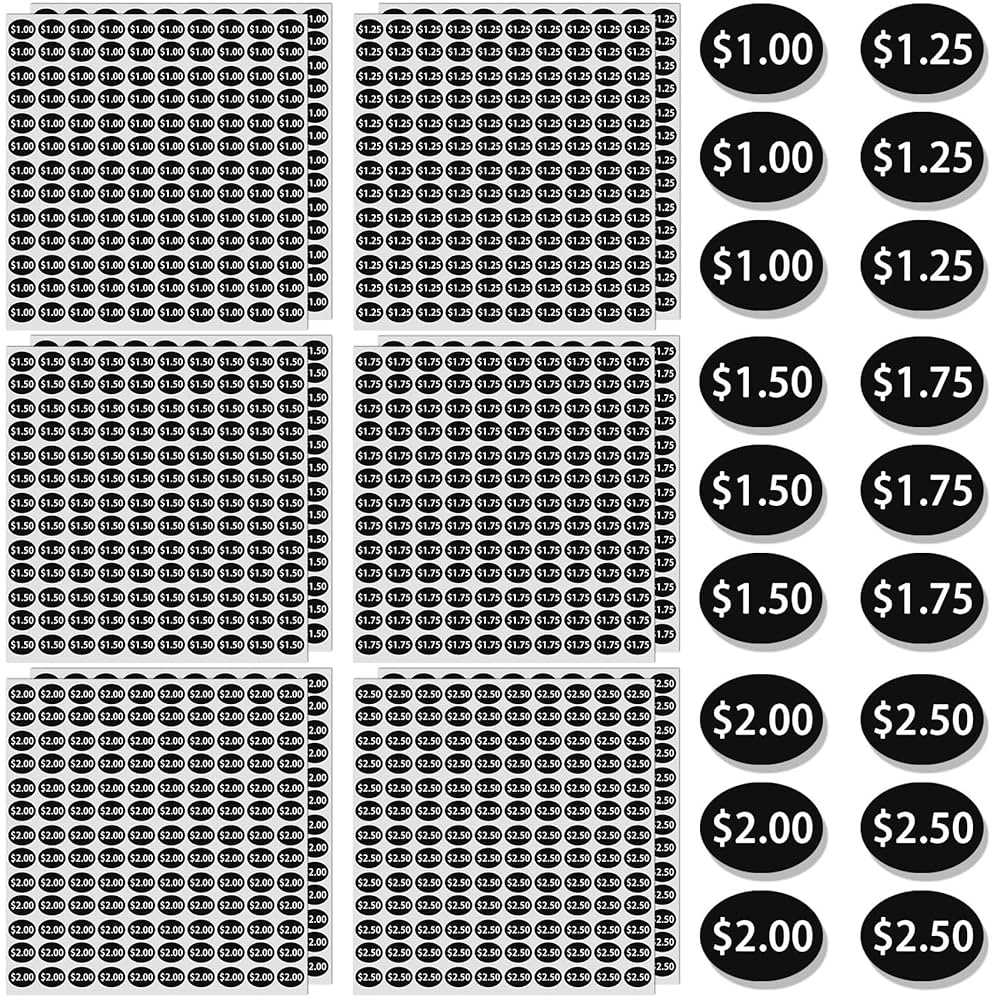

Illustrative Image (Source: Google Search)

-

Tolerance

– Definition: The allowable variation in label dimensions, including size and shape.

– Importance: Precise tolerances ensure that labels fit correctly in designated slots on vending machines, preventing jams and ensuring efficient operation. -

UV Resistance

– Definition: The ability of the label material to withstand fading or degradation when exposed to sunlight.

– Importance: UV-resistant labels maintain their appearance over time, which is especially important for machines located in bright, outdoor environments. -

Temperature Range

– Definition: The range of temperatures in which the labels can perform optimally without losing adhesion or integrity.

– Importance: Labels that can withstand a wide temperature range are essential for machines operating in various climates, ensuring longevity and reliability.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Significance: Understanding OEM relationships helps buyers identify trusted manufacturers for high-quality labels that meet their specifications. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Significance: Knowing the MOQ helps buyers plan their purchasing strategies and inventory management effectively, especially when entering new markets. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to request pricing and terms from suppliers for specific products.

– Significance: An RFQ process allows buyers to compare offers from different suppliers, ensuring they secure the best possible price and terms. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of buyers and sellers in international transactions.

– Significance: Familiarity with Incoterms helps buyers understand shipping costs, responsibilities, and risks associated with transporting labels from suppliers, which is crucial for budgeting. -

Lead Time

– Definition: The time taken from placing an order to the delivery of the product.

– Significance: Understanding lead times is vital for inventory management and ensuring that vending machines are stocked with the necessary labels in a timely manner. -

Customization Options

– Definition: The ability to tailor labels to specific sizes, colors, or designs as per client requirements.

– Significance: Customization allows companies to enhance brand visibility and meet specific operational needs, making it a valuable consideration for B2B buyers.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that enhance the efficiency and effectiveness of their vending machine operations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine price labels Sector

Market Overview & Key Trends

The global vending machine price labels market is witnessing significant transformation driven by technological advancements and evolving consumer preferences. With the rise of digitalization, international B2B buyers are increasingly adopting electronic price labels, which offer real-time pricing updates, reduced manual labor, and enhanced customer engagement. This trend is particularly prominent in regions like Europe and South America, where retailers seek to optimize operational efficiency and improve the shopping experience.

Another key driver is the growing demand for customization. Businesses are gravitating towards suppliers that offer bespoke labeling solutions tailored to their branding and informational needs. Additionally, integration with inventory management systems is becoming crucial, allowing for automatic updates of prices as stock levels fluctuate. This interconnectedness is a vital consideration for buyers from Africa and the Middle East, where efficiency and adaptability are paramount in competitive markets.

Emerging technologies such as QR codes and NFC (Near Field Communication) are also reshaping the landscape, enabling interactive customer experiences and seamless payments. For buyers, understanding these technological trends can facilitate better sourcing decisions that align with market demands. Moreover, as e-commerce continues to expand, the need for versatile labeling solutions that cater to both physical and online retail spaces is becoming increasingly critical.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer a mere trend but a necessity in the vending machine price labels sector. B2B buyers are increasingly aware of the environmental impact of their procurement choices, prompting a shift towards eco-friendly materials and practices. Suppliers are being evaluated not only on price and quality but also on their commitment to sustainable sourcing. This includes the use of biodegradable or recyclable materials in price labels, which can significantly reduce waste in landfills.

Ethical supply chains are crucial in ensuring that materials are sourced responsibly. Buyers should look for vendors who provide transparency regarding their sourcing practices and who hold certifications such as FSC (Forest Stewardship Council) or ISO 14001, which indicate a commitment to environmental management. By prioritizing suppliers with strong sustainability credentials, businesses can enhance their corporate social responsibility (CSR) profile, appealing to environmentally conscious consumers.

Additionally, implementing sustainable practices within the supply chain can result in cost savings over time. For instance, utilizing digital labels can decrease the need for paper-based materials, which not only cuts costs but also minimizes deforestation. Therefore, embracing sustainability is not just beneficial for the environment but can also yield long-term financial advantages for B2B buyers.

Brief Evolution/History

The vending machine price labels sector has evolved significantly over the past few decades. Initially dominated by static paper labels, the industry has gradually shifted towards more dynamic solutions with the advent of technology. The introduction of electronic shelf labels (ESLs) in the early 2000s marked a pivotal point, allowing for real-time price changes and reducing the need for manual updates.

This evolution has been propelled by advancements in digital technology and the increasing need for efficiency in retail operations. Today, B2B buyers can access a diverse range of labeling solutions that not only enhance operational efficiency but also improve customer engagement through interactive features. As the market continues to innovate, understanding its historical context can provide valuable insights into future trends and opportunities for international buyers.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of vending machine price labels

-

What should I consider when vetting suppliers for vending machine price labels?

When vetting suppliers, prioritize those with proven experience in producing vending machine price labels. Check for certifications such as ISO 9001, which indicates quality management systems. Review their portfolio and request samples to assess print quality and material durability. Additionally, look for suppliers who understand local regulations in your region, as compliance can impact your business operations. -

Can I customize vending machine price labels to fit my branding needs?

Yes, most suppliers offer customization options. You can specify dimensions, colors, and materials that align with your branding. Ensure you provide the necessary design files and guidelines to your supplier. It’s beneficial to ask for digital proofs before final production to confirm that the labels meet your specifications.

-

What is the typical minimum order quantity (MOQ) for vending machine price labels?

The MOQ can vary significantly based on the supplier and your customization requirements. Generally, MOQs range from 500 to 5,000 labels. It’s advisable to discuss your needs with potential suppliers to negotiate terms that suit your business size and budget. Smaller quantities may be available but could incur higher per-unit costs. -

What are the lead times for receiving my order of vending machine price labels?

Lead times depend on factors such as order volume, customization complexity, and the supplier’s production capacity. Typically, expect a timeframe of 2 to 4 weeks for standard orders. For custom designs, additional time may be required for proofs and adjustments. Always confirm lead times upfront to plan your inventory management effectively. -

How can I ensure the quality of the vending machine price labels I order?

To ensure quality, request samples before placing a full order. Discuss quality assurance practices with your supplier, including their printing technology and materials used. Inquire about any certifications that validate their quality standards. Establish clear specifications and include quality checkpoints in your contract to mitigate risks. -

What certifications should I look for in a vending machine price label supplier?

Look for suppliers with relevant industry certifications, such as ISO 9001 for quality management and ISO 14001 for environmental management. Certifications like FSC (Forest Stewardship Council) indicate sustainable sourcing of materials. These certifications not only enhance credibility but also ensure that the supplier adheres to international standards.

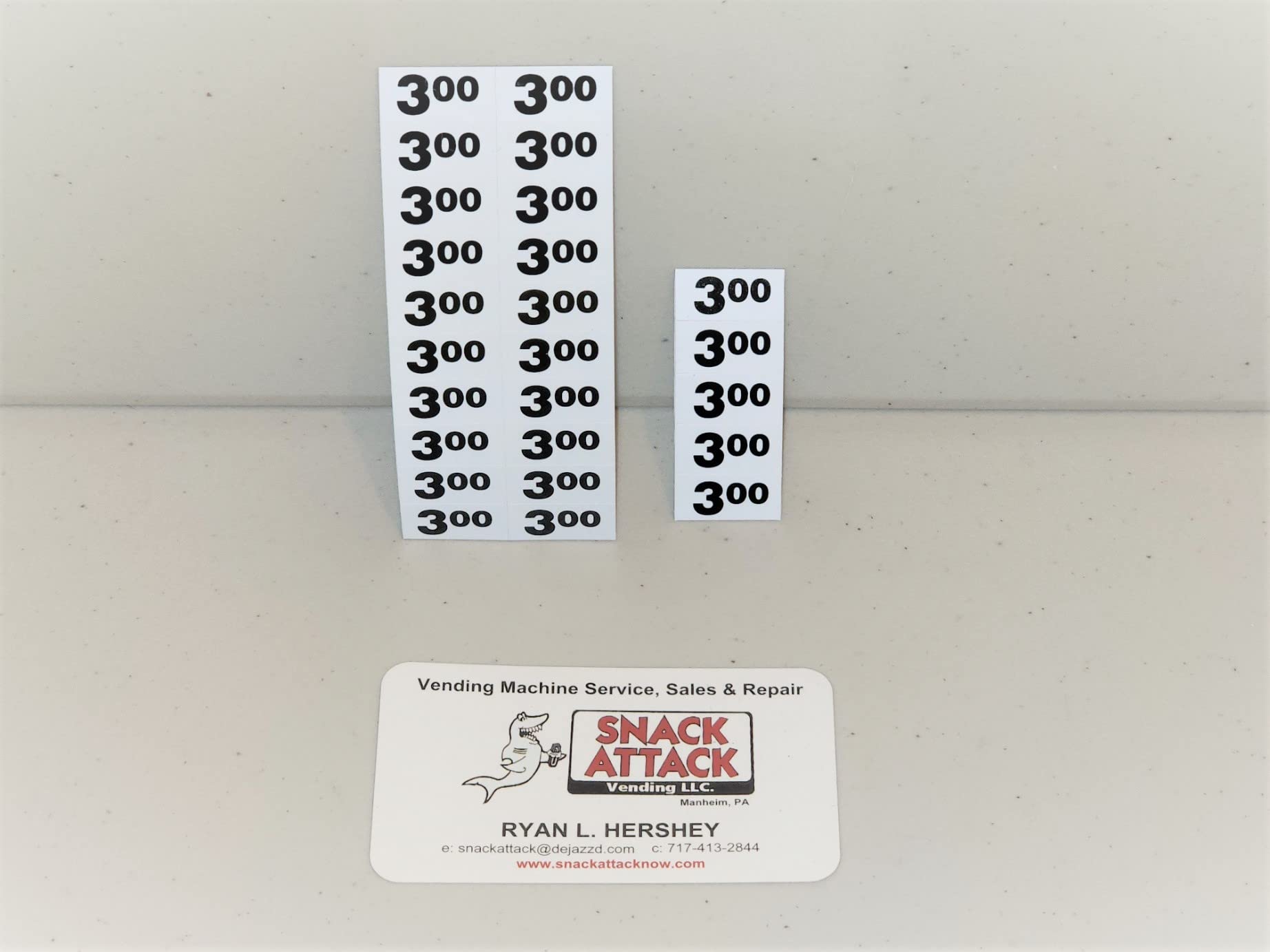

Illustrative Image (Source: Google Search)

-

What logistics considerations should I be aware of when importing vending machine price labels?

When importing, consider shipping options, customs duties, and lead times. Choose a reliable logistics partner familiar with international trade regulations in your region. Factor in potential delays due to customs inspections and ensure proper documentation accompanies your shipment to avoid complications. It’s wise to discuss these aspects with your supplier to coordinate logistics effectively. -

How can I handle disputes with my supplier over vending machine price labels?

To manage disputes effectively, establish clear terms in your contract regarding quality, delivery timelines, and payment conditions. Maintain open communication with your supplier to address issues promptly. If disputes arise, refer to your contract’s resolution procedures, and consider mediation or arbitration as a means of resolution before escalating to legal action.

Strategic Sourcing Conclusion and Outlook for vending machine price labels

In summary, strategic sourcing of vending machine price labels is essential for optimizing operational efficiency and enhancing customer engagement. By focusing on quality, durability, and adaptability, international B2B buyers can ensure that their labeling solutions meet diverse market demands across regions such as Africa, South America, the Middle East, and Europe.

Key takeaways include the importance of selecting suppliers that understand local regulations and cultural nuances, as well as those who can provide customized solutions tailored to specific business needs. Leveraging technology in sourcing processes can further streamline operations and reduce costs, offering a competitive edge in the fast-evolving vending industry.

As we look ahead, the global market for vending machine price labels is poised for growth, driven by increased consumer reliance on automated retail solutions. International buyers are encouraged to explore partnerships with innovative suppliers who can support sustainability and product differentiation. By doing so, businesses can not only enhance their offerings but also contribute to a more resilient supply chain. Engage now to secure your place in the future of vending solutions.