Master Vending Machine Measurements for Optimal Sourcing

Guide to Vending Machine Measurements

- Introduction: Navigating the Global Market for vending machine measurements

- Understanding vending machine measurements Types and Variations

- Key Industrial Applications of vending machine measurements

- Strategic Material Selection Guide for vending machine measurements

- In-depth Look: Manufacturing Processes and Quality Assurance for vending machine measurements

- Comprehensive Cost and Pricing Analysis for vending machine measurements Sourcing

- Spotlight on Potential vending machine measurements Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for vending machine measurements

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine measurements Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vending machine measurements

- Strategic Sourcing Conclusion and Outlook for vending machine measurements

Introduction: Navigating the Global Market for vending machine measurements

- (Content generation for module ‘Introduction: Navigating the Global Market for vending machine measurements’ encountered an issue: ChatGPT failed after 3 attempts: ‘str’ object has no attribute ‘choices’)*

Understanding vending machine measurements Types and Variations

- (Content generation for module ‘Understanding vending machine measurements Types and Variations’ encountered an issue: ChatGPT failed after 3 attempts: ‘str’ object has no attribute ‘choices’)*

Key Industrial Applications of vending machine measurements

- (Content generation for module ‘Key Industrial Applications of vending machine measurements’ encountered an issue: ChatGPT failed after 3 attempts: ‘str’ object has no attribute ‘choices’)*

Strategic Material Selection Guide for vending machine measurements

- (Content generation for module ‘Strategic Material Selection Guide for vending machine measurements’ encountered an issue: ChatGPT failed after 3 attempts: ‘str’ object has no attribute ‘choices’)*

In-depth Look: Manufacturing Processes and Quality Assurance for vending machine measurements

- (Content generation for module ‘In-depth Look: Manufacturing Processes and Quality Assurance for vending machine measurements’ encountered an issue: ChatGPT failed after 3 attempts: ‘str’ object has no attribute ‘choices’)*

Comprehensive Cost and Pricing Analysis for vending machine measurements Sourcing

In the realm of vending machine measurements sourcing, understanding the cost structure and pricing dynamics is critical for international B2B buyers. This section delves into the essential components that influence costs, pricing strategies, and actionable insights to optimize sourcing decisions.

Cost Components

-

Materials: The primary costs associated with vending machine measurements arise from the materials used. This includes sensors, mechanical components, and electronic parts. Prices can vary significantly based on material quality and supplier location. For instance, sourcing materials from regions with lower labor costs may reduce expenses but could affect quality.

-

Labor: Labor costs encompass the wages paid to workers involved in production, assembly, and quality control. Countries with higher wage standards, such as those in Western Europe, may present higher labor costs compared to regions in Africa or South America. However, consider the trade-off between cost and skill level, as experienced labor can lead to fewer defects and lower long-term costs.

-

Manufacturing Overhead: This includes costs related to utilities, factory maintenance, and administrative expenses. Efficient manufacturing practices can help mitigate these overhead costs, but buyers should ensure that suppliers maintain adequate production capacity and quality standards.

-

Tooling: The cost of tools and equipment required for production can be substantial, especially if custom tooling is needed for specific measurements. Buyers should inquire about tooling costs upfront, as these can significantly impact the overall price.

-

Quality Control (QC): Implementing a robust QC process is essential to ensure that the measurements meet specified standards. While this adds to the cost, it is a necessary investment to prevent costly recalls or replacements.

-

Logistics: Transportation and warehousing costs are critical in the overall pricing structure. International shipping, customs duties, and local distribution can add considerable expenses. Buyers should assess logistics options carefully to optimize delivery times and costs.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure profitability. Understanding the standard margins in the industry can help buyers negotiate better terms.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs. Buyers should assess their needs carefully and consider bulk purchasing for cost savings.

-

Specifications/Customization: Customized measurements may incur additional costs due to the need for specialized tooling or materials. Clear communication of specifications can help mitigate these costs.

-

Material Quality/Certifications: Higher quality materials and certifications (e.g., ISO standards) often come at a premium but can significantly enhance the durability and reliability of the vending machines.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their experience and quality assurance processes.

-

Incoterms: Understanding the Incoterms agreed upon can affect pricing. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can alter the total cost of ownership.

Buyer Tips

-

Negotiation: Cultivating relationships with suppliers can yield better pricing and terms. Regular communication and negotiation can help secure advantageous deals.

-

Cost-Efficiency: Buyers should consider the total cost of ownership (TCO), which includes purchase price, operational costs, and maintenance over the product’s lifespan. This holistic view can lead to more informed purchasing decisions.

-

Pricing Nuances for International Buyers: International buyers, especially from Africa, South America, the Middle East, and Europe, should be aware of currency fluctuations, local tariffs, and taxes that can impact overall costs. Engaging with local experts can help navigate these complexities.

Disclaimer

Pricing information provided is indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. Buyers are encouraged to conduct thorough market research and engage with multiple suppliers to ensure competitive pricing.

Spotlight on Potential vending machine measurements Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘vending machine measurements’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for vending machine measurements

Key Technical Properties of Vending Machine Measurements

When sourcing vending machines, understanding specific technical properties is crucial for making informed purchasing decisions. Here are some critical specifications to consider:

-

Material Grade

– Definition: This refers to the quality and type of materials used in the construction of the vending machine, such as stainless steel, aluminum, or plastic composites.

– Importance: Higher-grade materials often enhance durability and resistance to wear and tear, which is essential for machines operating in high-traffic environments. For buyers, this translates to lower long-term maintenance costs and extended machine lifespan. -

Tolerance

– Definition: Tolerance is the allowable variation in dimensions during the manufacturing process. It ensures that parts fit together correctly and function as intended.

– Importance: Precise tolerances are vital for the mechanical operation of vending machines. Poor tolerances can lead to operational failures, affecting product dispensing and customer satisfaction. Buyers should ensure that manufacturers adhere to strict tolerance standards. -

Power Consumption

– Definition: This measures the amount of electrical energy the vending machine consumes during operation, typically expressed in watts.

– Importance: For international buyers, especially in regions with high energy costs, understanding power consumption helps in estimating operational expenses. Machines with lower energy consumption can significantly reduce utility bills over time. -

Capacity

– Definition: This refers to the number of items a vending machine can hold and dispense, often specified in volume or number of slots.

– Importance: Selecting the right capacity is crucial for meeting customer demand. Insufficient capacity can lead to stockouts and lost sales, while excessive capacity may result in wasted space and resources. -

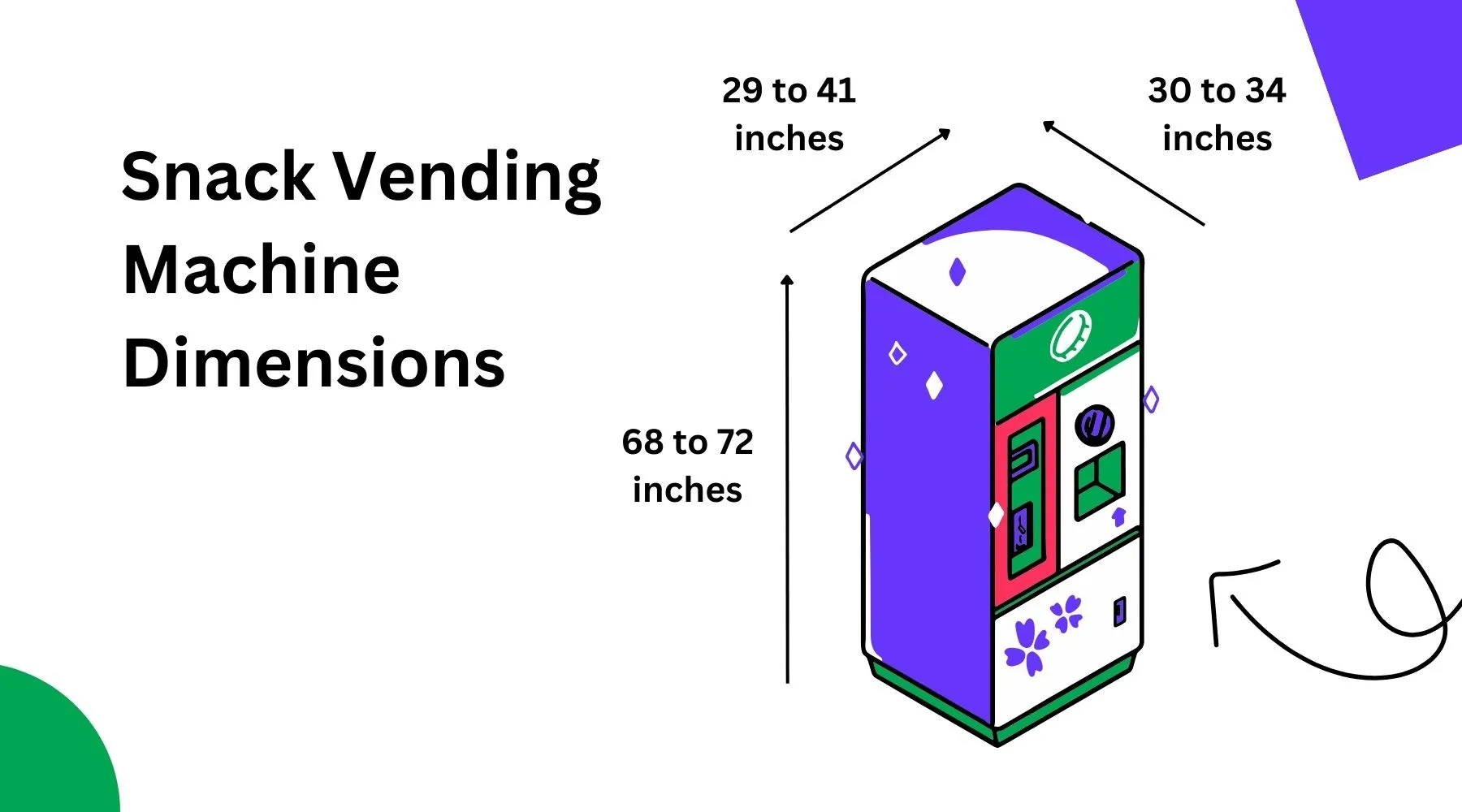

Dimensions

– Definition: The physical size of the vending machine, including height, width, and depth.

– Importance: Understanding the dimensions is essential for ensuring that the machine fits in the designated location. For international buyers, shipping costs and logistics can also be affected by the size of the machine.

Common Trade Terms in the Vending Machine Industry

Familiarity with industry jargon can enhance communication and negotiation in the B2B purchasing process. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Working with OEMs can ensure high-quality components that meet specific standards. Buyers should verify the OEM’s reputation to ensure reliability and support. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding MOQ helps buyers manage inventory costs and ensure they are not over-committing to purchases that exceed their needs. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting a quote for specific products or services.

– Importance: An RFQ can help buyers compare prices and terms from multiple suppliers, facilitating informed decision-making and negotiation. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms published by the International Chamber of Commerce (ICC).

– Importance: These terms clarify the responsibilities of buyers and sellers regarding shipping costs, risk transfer, and customs clearance. Understanding Incoterms is crucial for international transactions to avoid misunderstandings and financial losses.

Illustrative Image (Source: Google Search)

- Lead Time

– Definition: The amount of time from the placement of an order until it is fulfilled.

– Importance: Knowing the lead time is essential for planning inventory and ensuring that vending machines are available when needed. Longer lead times can disrupt business operations, especially in competitive markets.

By understanding these technical properties and trade terms, international B2B buyers can make more informed decisions when purchasing vending machines, ultimately leading to better operational efficiency and customer satisfaction.

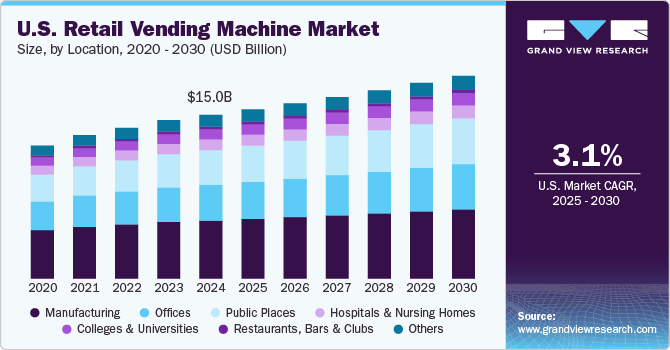

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine measurements Sector

Market Overview & Key Trends

The vending machine measurements sector is witnessing robust growth driven by technological advancements and changing consumer behaviors. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly focused on integrating smart vending solutions that utilize IoT (Internet of Things) technology. These innovations enable real-time inventory tracking, remote diagnostics, and enhanced customer interaction through mobile payment solutions.

Emerging trends such as cashless transactions and contactless services are reshaping the vending landscape. For instance, the COVID-19 pandemic accelerated the adoption of touchless payment systems and remote management capabilities, making it essential for businesses to consider these features when sourcing vending machines. Furthermore, energy efficiency is becoming a critical factor, with machines designed to minimize electricity consumption while maximizing performance, which is particularly appealing to buyers in regions facing energy shortages or high costs.

Market dynamics also indicate a shift towards customization and personalization in vending machine offerings. B2B buyers are looking for suppliers that can provide tailored solutions, from machine design to product selection, catering to local tastes and preferences. This trend is especially relevant in diverse markets where cultural and dietary preferences vary significantly.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly paramount in the vending machine measurements sector. As global awareness of environmental issues rises, B2B buyers are prioritizing suppliers that demonstrate a commitment to sustainable practices. This includes the use of environmentally friendly materials, energy-efficient technologies, and responsible waste management practices.

Ethical sourcing is essential, as buyers seek to ensure that their supply chains are free from exploitation and environmental harm. Certifications such as ISO 14001 for environmental management and Fair Trade for ethical sourcing are becoming critical criteria in vendor selection. Suppliers that can provide transparent sourcing processes and sustainability certifications are more likely to attract international B2B buyers looking to align with socially responsible practices.

Furthermore, the incorporation of recyclable materials in vending machine components, such as casings and internal structures, reflects a growing trend toward circular economy practices. This shift not only mitigates environmental impact but also resonates with consumers who prefer brands that prioritize sustainability, thus enhancing the marketability of B2B buyers’ offerings.

Brief Evolution/History

The vending machine industry has evolved significantly over the last century, transitioning from simple mechanical devices to sophisticated, technology-driven systems. Early vending machines primarily dispensed snacks and beverages through manual mechanisms, which limited their operational efficiency and product range.

The introduction of electronic vending machines in the late 20th century marked a pivotal shift, allowing for better inventory management and payment options. The rise of digital technology in the 21st century further transformed the sector, paving the way for smart vending solutions equipped with IoT capabilities. This evolution has not only improved operational efficiency but also enhanced customer engagement, making vending machines a viable channel for businesses across various industries, from retail to hospitality.

As B2B buyers navigate this evolving landscape, understanding these historical advancements can provide valuable insights into future trends and opportunities for growth in the vending machine measurements sector.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of vending machine measurements

-

What should I look for when vetting suppliers of vending machines?

When vetting suppliers, prioritize their experience in the industry, reputation, and customer feedback. Check their certifications and compliance with international standards, especially if you’re sourcing from different continents. Request references and verify their operational capabilities, including manufacturing capacity and technology used. Consider suppliers who offer transparent communication and support throughout the sourcing process to build a reliable partnership. -

Can I customize vending machines to fit my specific needs?

Yes, many suppliers offer customization options for vending machines. This may include size adjustments, branding, product selection, and technological features like cashless payment systems. When negotiating, clearly outline your requirements and ensure the supplier can accommodate them within your budget and timeline. It’s advisable to request samples or prototypes before finalizing the order to ensure they meet your expectations. -

What are typical minimum order quantities (MOQ) and lead times for vending machines?

MOQs can vary widely based on the supplier and the complexity of the vending machines. Generally, MOQs may range from 10 to 100 units. Lead times typically range from 4 to 12 weeks, depending on the customization requirements and supplier location. Always clarify these terms upfront to avoid unexpected delays and ensure your project timeline aligns with your business needs. -

What payment methods are accepted by vending machine suppliers?

Payment methods can vary by supplier, but common options include wire transfers, letters of credit, and payment platforms like PayPal. Ensure that you understand the payment terms, including deposits and final payments. Additionally, inquire about any available financing options or discounts for bulk purchases, as this can significantly impact your cash flow and overall costs.

-

How can I ensure quality assurance and certification for vending machines?

Request documentation of quality assurance processes from your supplier, including ISO certifications and compliance with local safety standards. It’s important to conduct pre-shipment inspections or audits, especially for large orders. Establish clear quality expectations in your contract and consider third-party quality assurance services to verify that the machines meet your specifications before they are shipped. -

What logistics considerations should I keep in mind when sourcing vending machines internationally?

Logistics is crucial when importing vending machines. Consider shipping methods (air vs. sea), customs regulations, and potential tariffs that may apply. Work closely with your supplier to ensure proper packaging to avoid damage during transit. Additionally, utilize freight forwarders experienced in handling such equipment to streamline the process and mitigate risks associated with international shipping. -

How can I handle disputes with vending machine suppliers?

Dispute resolution should be clearly outlined in your contract, including preferred methods such as mediation or arbitration. Maintain clear documentation of all communications and agreements to support your position in case of a dispute. Open and honest communication is key; address issues promptly with your supplier to find mutually agreeable solutions, as maintaining a good relationship can often lead to better outcomes. -

What are the best practices for after-sales support and maintenance of vending machines?

After-sales support is essential for the longevity of your vending machines. Ensure your supplier offers comprehensive warranties and maintenance services. Establish a clear maintenance schedule and training for your staff on how to operate and troubleshoot the machines. Consider local service partners for ongoing support, and maintain a direct line of communication with the supplier for any technical issues that may arise.

Strategic Sourcing Conclusion and Outlook for vending machine measurements

As we conclude our exploration of vending machine measurements, it’s crucial to recognize the significance of strategic sourcing in enhancing operational efficiency and profitability. By leveraging accurate measurements, businesses can optimize inventory management, reduce waste, and improve customer satisfaction.

Illustrative Image (Source: Google Search)

Key takeaways for international B2B buyers include:

- Precision Matters: Accurate measurements ensure the right products are stocked, minimizing loss and maximizing sales.

- Adaptability: With varying market demands across regions such as Africa, South America, the Middle East, and Europe, flexibility in sourcing strategies is essential.

- Cost Efficiency: Investing in the right measuring technologies can lead to long-term savings, ensuring your vending operations remain competitive.

Looking ahead, the vending machine industry is poised for growth, driven by technological advancements and evolving consumer preferences. International buyers should seize this opportunity to refine their sourcing strategies and invest in innovative solutions that will enhance their market position. By prioritizing strategic sourcing, businesses can not only meet current demands but also anticipate future trends, positioning themselves for sustained success in a dynamic marketplace.