Master Vending Machine Dimensions to Optimize Your B2B

Guide to Vending Machine Dimensions

- Introduction: Navigating the Global Market for vending machine dimensions

- Understanding vending machine dimensions Types and Variations

- Key Industrial Applications of vending machine dimensions

- Strategic Material Selection Guide for vending machine dimensions

- In-depth Look: Manufacturing Processes and Quality Assurance for vending machine dimensions

- Comprehensive Cost and Pricing Analysis for vending machine dimensions Sourcing

- Spotlight on Potential vending machine dimensions Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for vending machine dimensions

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine dimensions Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vending machine dimensions

- Strategic Sourcing Conclusion and Outlook for vending machine dimensions

Introduction: Navigating the Global Market for vending machine dimensions

In today’s fast-paced global marketplace, understanding the dimensions of vending machines is crucial for B2B buyers aiming to make informed purchasing decisions. As businesses across Africa, South America, the Middle East, and Europe increasingly recognize the value of vending machines for enhancing customer experience and driving revenue, the need for precise specifications has never been more critical. Vending machine dimensions can significantly influence placement, user accessibility, and overall operational efficiency, making it essential for buyers to consider these factors carefully.

This comprehensive guide delves into various aspects of vending machine dimensions, offering insights into types, materials, manufacturing quality control, suppliers, cost considerations, and market trends. Each section is designed to equip international B2B buyers with the knowledge necessary to navigate the complexities of sourcing vending machines tailored to their specific needs.

By understanding the diverse range of dimensions and the implications of these choices, buyers can optimize their investments, ensuring that the selected machines fit seamlessly into their operational frameworks. Additionally, the guide addresses common FAQs, providing clarity on what to expect when integrating vending machines into different environments.

Arming yourself with this information not only streamlines the procurement process but also enhances your strategic positioning in a competitive landscape, allowing you to meet market demands with confidence and efficiency.

Understanding vending machine dimensions Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Snack Vending Machines | Standard size, typically 72″ H x 30″ W x 30″ D | Offices, schools, public spaces | Pros: Wide product variety, established technology. Cons: Limited to snacks and beverages, may require frequent restocking. |

| Compact Vending Machines | Smaller footprint, around 54″ H x 24″ W x 24″ D | Small offices, tight spaces | Pros: Space-efficient, ideal for low-traffic areas. Cons: Limited capacity, fewer product options. |

| Specialty Vending Machines | Customizable dimensions for specific products | High-end retail, niche markets | Pros: Tailored offerings, can accommodate unique items. Cons: Higher upfront costs, potential complexity in maintenance. |

| Outdoor Vending Machines | Weather-resistant design, larger size (up to 80″ H) | Parks, outdoor events | Pros: Robust build, can offer a variety of products. Cons: Requires additional security measures, higher installation costs. |

| Healthy Food Vending Machines | Dimensions vary, focus on fresh products | Gyms, hospitals, schools | Pros: Meets growing demand for healthy options, encourages wellness. Cons: May require specialized maintenance, higher product turnover. |

Traditional Snack Vending Machines

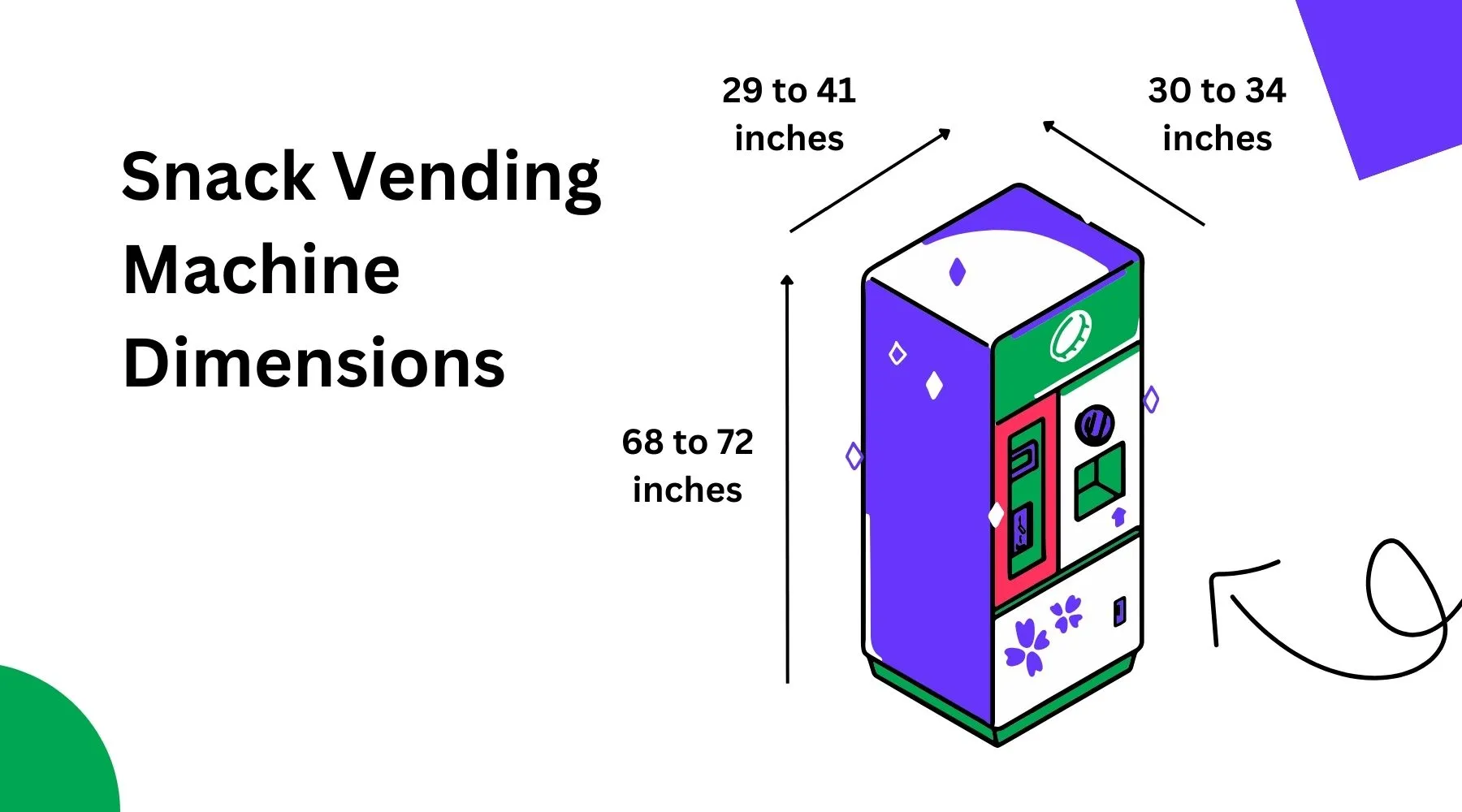

Traditional snack vending machines are the most recognizable type in the market, typically measuring around 72 inches in height, 30 inches in width, and 30 inches in depth. These machines are ideal for high-traffic areas such as offices, schools, and public spaces. They offer a wide variety of snacks and beverages, making them a staple for any vending operation. Buyers should consider the frequency of restocking and the potential for product variety, as these machines may require regular maintenance to keep up with demand.

Compact Vending Machines

Compact vending machines are designed for smaller spaces, with dimensions around 54 inches high, 24 inches wide, and 24 inches deep. They are particularly suitable for small offices or locations with limited foot traffic. While they save space and can fit into tight corners, they have a lower capacity and fewer product options than their larger counterparts. B2B buyers should assess their location’s traffic patterns to determine if a compact model will meet their needs without frequent restocking.

Illustrative Image (Source: Google Search)

Specialty Vending Machines

Specialty vending machines can be customized in terms of dimensions and features to accommodate specific products, such as electronics or gourmet food. These machines are commonly found in high-end retail environments and niche markets. The flexibility of design allows for tailored offerings, which can attract a unique customer base. However, buyers should be aware of the higher upfront costs and the potential complexity of maintenance due to the specialized nature of these machines.

Outdoor Vending Machines

Outdoor vending machines are built to withstand various weather conditions and often have larger dimensions, reaching up to 80 inches in height. They are ideal for parks, outdoor events, and other public spaces where traditional machines may not perform well. These machines can offer a wide range of products, but buyers should consider additional security measures to prevent vandalism or theft. Installation costs may also be higher due to the need for robust construction and safety features.

Healthy Food Vending Machines

Healthy food vending machines vary in size but are designed to offer fresh and nutritious options, catering to the growing demand for healthier lifestyles. They are typically placed in gyms, hospitals, and schools, appealing to health-conscious consumers. While these machines can boost sales in health-oriented environments, they may require specialized maintenance due to the perishable nature of the products. B2B buyers should evaluate the local market demand for healthy options before investing in this type of vending machine.

Key Industrial Applications of vending machine dimensions

| Industry/Sector | Specific Application of vending machine dimensions | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Customized vending solutions for urban areas | Increased foot traffic and sales through strategic placement | Local regulations, space constraints, and consumer behavior analysis |

| Education | Snack and beverage vending in schools and universities | Improved student satisfaction and convenience | Size suitability for high-traffic areas, health regulations |

| Healthcare | Medical supply vending machines in hospitals | Enhanced accessibility to essential supplies | Compliance with health standards, temperature control capabilities |

| Hospitality | Vending solutions in hotels for guests | 24/7 access to snacks and amenities, enhancing guest experience | Design aesthetics, product variety, and replenishment logistics |

| Corporate Offices | Snack and beverage stations in office environments | Boosted employee morale and productivity | Space optimization, user-friendly dimensions, and maintenance needs |

Retail Applications

In the retail sector, vending machine dimensions play a critical role in the design and placement of machines in urban environments. By customizing the size and shape of vending machines, businesses can maximize visibility and accessibility, attracting more customers. Key considerations for international buyers include local regulations governing vending operations, understanding space constraints in densely populated areas, and analyzing consumer behavior to optimize product offerings.

Education Sector

In educational institutions, vending machines are increasingly used to provide convenient access to snacks and beverages. The dimensions of these machines must be tailored to fit within busy hallways and cafeterias while ensuring they are accessible to students of all ages. International buyers should focus on compliance with health regulations regarding food safety and nutritional standards, ensuring that the machines can accommodate high traffic volumes without compromising service.

Healthcare Industry

Healthcare facilities utilize vending machines for medical supplies, offering quick access to essential items like bandages, gloves, and personal protective equipment. The dimensions of these machines are crucial to ensure they fit within designated areas, such as waiting rooms or nurse stations. Buyers should prioritize compliance with health standards, including the ability to maintain temperature control for sensitive items, and the design must facilitate easy restocking and maintenance.

Hospitality Sector

In the hospitality industry, vending machines in hotels provide guests with 24/7 access to snacks, beverages, and other amenities. The dimensions of these machines need to align with the aesthetic of the hotel while also being functional in terms of space utilization. International B2B buyers should consider design aesthetics that complement the hotel’s branding, product variety to cater to diverse preferences, and efficient replenishment logistics to maintain stock levels.

Corporate Offices

Vending machines in corporate offices serve as a convenient option for employees seeking snacks and beverages during work hours. The dimensions of these machines must be optimized for space in often limited break areas, ensuring they are user-friendly and easy to maintain. Buyers should focus on dimensions that allow for a variety of products, while also considering the maintenance needs and how the design can enhance the overall workplace environment.

Related Video: DIY Vending Machine – Arduino based Mechatronics Project

Strategic Material Selection Guide for vending machine dimensions

When selecting materials for vending machine dimensions, it is crucial to consider factors such as durability, manufacturing complexity, and cost-effectiveness. The materials used not only affect the machine’s performance but also its compliance with international standards. Below are analyses of four common materials used in vending machine construction, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. It typically has a pressure rating that makes it suitable for various environments, including humid and high-temperature areas.

Pros & Cons:

Stainless steel is highly durable and offers a long lifespan, making it an ideal choice for vending machines exposed to outdoor conditions. However, it is more expensive than other materials, which can impact overall project budgets. The manufacturing process can also be complex, requiring specialized equipment.

Impact on Application:

Stainless steel is compatible with a variety of media, including food and beverages, making it a preferred choice for vending machines that dispense consumables.

Considerations for International Buyers:

Buyers from regions like the Middle East and Europe should ensure compliance with standards such as ASTM A240 for stainless steel grades. Additionally, local preferences for finishes (e.g., brushed or polished) may influence material selection.

2. Carbon Steel

Key Properties:

Carbon steel is characterized by its high tensile strength and cost-effectiveness. However, it is susceptible to corrosion, particularly in humid environments, unless properly coated.

Pros & Cons:

The primary advantage of carbon steel is its low cost, making it an attractive option for budget-conscious projects. However, its susceptibility to rust and corrosion can lead to higher maintenance costs over time, especially in regions with high humidity, such as parts of Africa and South America.

Impact on Application:

Carbon steel is suitable for internal components of vending machines, where exposure to moisture is minimal.

Considerations for International Buyers:

Buyers should be aware of local regulations regarding corrosion protection and compliance with standards like ASTM A36. In regions like Turkey, where climate conditions can vary significantly, additional protective coatings may be required.

3. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It is often used in vending machines where weight reduction is a priority.

Pros & Cons:

The lightweight nature of aluminum allows for easier transportation and installation. However, it is less durable than steel and can be more expensive than carbon steel. Its lower strength may not be suitable for heavy-duty applications.

Impact on Application:

Aluminum is ideal for machines that require frequent relocation or are used in environments where weight is a critical factor. It is also compatible with a variety of media.

Considerations for International Buyers:

International buyers should consider the specific aluminum grades and their compliance with standards such as ASTM B221. In regions like Europe, the preference for lightweight materials may drive demand for aluminum vending machines.

4. Polycarbonate

Key Properties:

Polycarbonate is a high-impact, transparent plastic known for its excellent strength-to-weight ratio and UV resistance. It is often used for protective covers and panels.

Pros & Cons:

The main advantage of polycarbonate is its lightweight and shatter-resistant properties, making it ideal for safety applications. However, it is less heat resistant than metals and can be more expensive depending on the grade.

Impact on Application:

Polycarbonate is suitable for front panels and display areas of vending machines, where visibility and safety are paramount.

Considerations for International Buyers:

Buyers should verify compliance with relevant safety standards, such as EN 71 for plastic materials in Europe. In the Middle East, UV resistance is critical due to high sun exposure.

Summary Table

| Material | Typical Use Case for vending machine dimensions | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Exterior panels and structural components | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Carbon Steel | Internal components | Cost-effective and strong | Susceptible to corrosion | Low |

| Aluminum | Lightweight structures and panels | Lightweight and corrosion-resistant | Less durable than steel | Medium |

| Polycarbonate | Protective covers and display panels | Shatter-resistant and lightweight | Less heat resistant than metals | Medium |

This guide provides a clear understanding of material options for vending machine dimensions, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for vending machine dimensions

In the competitive landscape of vending machine production, understanding the manufacturing processes and quality assurance protocols is crucial for international B2B buyers. This section delves into the typical stages of manufacturing and the quality control measures that ensure compliance with global standards, providing actionable insights for buyers from Africa, South America, the Middle East, and Europe.

Illustrative Image (Source: Google Search)

Manufacturing Processes

1. Material Preparation

The first stage in manufacturing vending machines involves selecting and preparing materials. Common materials include steel, aluminum, plastics, and electronic components. Suppliers often utilize advanced technology like laser cutting and CNC machining to achieve precise dimensions, which are critical for functionality and aesthetics. Buyers should inquire about the sourcing of materials to ensure they meet sustainability and quality standards.

2. Forming

Once materials are prepared, the forming stage begins. This includes processes like stamping, bending, and welding to shape the machine’s structure. Techniques such as robotic welding may be employed to enhance consistency and reduce human error. Buyers should ensure that the manufacturers have the capabilities to produce machines that not only meet specifications but can also withstand the rigors of daily use.

3. Assembly

During the assembly phase, components such as the vending machine’s frame, dispensing mechanisms, and control systems are integrated. This stage often utilizes modular assembly techniques, allowing for scalability and customization based on client specifications. B2B buyers should assess the flexibility of manufacturers in accommodating unique requirements, such as additional payment systems or specialized shelving.

4. Finishing

The finishing stage involves applying coatings and treatments to enhance durability and aesthetics. This may include powder coating, painting, or applying anti-corrosion treatments. Quality finishing is essential not only for appearance but also for the longevity of the vending machine in various environments, particularly in regions with extreme weather conditions. Buyers should request information on the finishing processes used to ensure compatibility with their local climate.

Quality Assurance

International Standards

Compliance with international quality standards is non-negotiable for B2B buyers. The ISO 9001 certification is crucial as it signifies a commitment to quality management systems. Other relevant standards may include CE marking for European markets and API standards for specific electronic components. Buyers should prioritize suppliers who can demonstrate compliance with these standards through certifications and documentation.

Quality Control Checkpoints

Quality control is integral throughout the manufacturing process, typically segmented into several checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials and components upon arrival. It ensures that only materials meeting predefined standards proceed to the next stage.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC checks for adherence to specifications at various stages. This may involve measuring dimensions and ensuring proper assembly practices.

-

Final Quality Control (FQC): The final inspection before shipping, FQC ensures that the completed vending machines meet all design and quality standards. This includes functionality tests and a thorough visual inspection.

Buyers should request detailed QC reports from suppliers, which should outline the methodologies used at each checkpoint.

Common Testing Methods

To ensure product reliability, various testing methods are employed:

- Functional Testing: Verifies that all machine functions operate as intended, including payment systems and product dispensing.

- Durability Testing: Assesses how well the machine withstands physical stress and environmental factors.

- Safety Testing: Ensures compliance with safety regulations, particularly for electrical components.

B2B buyers should insist on seeing the results of these tests as part of their supplier evaluation process.

Verifying Supplier Quality Control

To mitigate risks associated with supplier quality, B2B buyers should take several proactive steps:

-

Supplier Audits: Conducting on-site audits allows buyers to assess manufacturing practices, quality control measures, and overall operational capabilities directly. This firsthand experience is invaluable for evaluating supplier reliability.

-

Requesting Reports: Suppliers should provide comprehensive reports detailing their quality assurance processes, including results from IQC, IPQC, and FQC. These documents should be routinely updated and easily accessible.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing quality. This is particularly important for buyers in regions with less stringent regulatory environments.

Quality Control Nuances for International Buyers

When sourcing vending machines from suppliers in different regions, international buyers must be aware of certain nuances:

-

Cultural Differences: Understanding cultural attitudes toward quality and business practices can influence supplier relationships. For example, some regions may prioritize speed over quality, impacting the final product.

-

Regulatory Compliance: Different countries have varying regulations that may affect product specifications. Buyers should ensure that their suppliers are knowledgeable about and compliant with the regulations in the buyer’s country.

-

Logistics and Supply Chain: Consider the implications of shipping and logistics on quality. For instance, machines must be properly packaged to prevent damage during transit. Buyers should discuss packaging standards with suppliers to minimize risk.

Conclusion

For international B2B buyers, a comprehensive understanding of manufacturing processes and quality assurance protocols is essential when sourcing vending machines. By focusing on material preparation, forming, assembly, and finishing, alongside rigorous quality control measures, buyers can ensure they partner with reliable suppliers. Taking proactive steps to verify supplier quality through audits, reports, and third-party inspections will further safeguard investments and enhance operational success.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for vending machine dimensions Sourcing

Understanding Cost Components in Vending Machine Dimensions Sourcing

When sourcing vending machines, a comprehensive understanding of the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials directly impacts both cost and quality. High-grade materials such as stainless steel and tempered glass may increase initial expenses but can enhance durability and reduce long-term maintenance costs.

-

Labor: Labor costs vary significantly based on the region of manufacturing. Countries with lower labor costs, such as some in Southeast Asia, may offer more competitive pricing, but this can affect the quality and craftsmanship of the final product.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities and rent. Efficient manufacturing processes can help minimize overhead, influencing the overall price.

-

Tooling: Custom tooling for specific dimensions can be a substantial initial investment. Buyers should consider whether the tooling costs can be amortized over a larger volume of machines to reduce the per-unit cost.

-

Quality Control (QC): Implementing stringent QC measures ensures that the machines meet specifications and regulations. While this may add to the cost, it can save expenses related to returns and repairs in the long run.

-

Logistics: Transportation costs are influenced by distance, mode of transport, and import/export tariffs. Understanding the logistics involved in shipping machines to your region is essential for accurate pricing.

-

Margin: Suppliers typically include a margin in their pricing to cover risks and profits. This can vary based on the supplier’s reputation, market demand, and the competitive landscape.

Key Price Influencers

Several factors can influence the price of vending machines, making it vital for buyers to understand these variables:

-

Volume/MOQ: Larger orders often lead to lower prices per unit due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to maximize cost savings.

-

Specifications/Customization: Customized machines with unique dimensions or features will generally cost more. Buyers should assess whether customization is essential or if standard models meet their needs.

-

Materials: The selection of materials not only affects the cost but also the machine’s longevity and aesthetic appeal. Buyers should evaluate the balance between cost and quality.

-

Quality/Certifications: Machines that comply with international standards may carry a premium price. However, investing in certified products can enhance brand reputation and reduce compliance risks.

-

Supplier Factors: The supplier’s location, reputation, and reliability can significantly affect pricing. Establishing relationships with reputable suppliers can provide better pricing and service terms.

-

Incoterms: Understanding Incoterms is critical for managing shipping responsibilities and costs. Buyers should clarify who bears the cost and risk at each stage of the shipping process.

Buyer Tips for Cost-Efficiency

To navigate the complexities of vending machine sourcing effectively, consider the following actionable insights:

-

Negotiate Terms: Always negotiate pricing, payment terms, and delivery schedules. Leverage multiple quotes to strengthen your bargaining position.

-

Evaluate Total Cost of Ownership (TCO): Beyond the purchase price, consider maintenance, operation, and potential downtime costs. A machine with a higher upfront cost may offer lower TCO over its lifespan.

-

Understand Pricing Nuances: Be aware that pricing can fluctuate based on regional economic conditions, currency exchange rates, and local demand. Buyers from Africa, South America, the Middle East, and Europe should stay informed about these factors to make strategic purchasing decisions.

-

Plan for Logistics: Factor in shipping times and costs when placing orders. Delays can lead to lost sales opportunities, so ensure logistics are well-coordinated with supplier timelines.

-

Consider Local Regulations: Different regions may have varying regulations regarding vending machines. Ensure compliance to avoid unexpected costs related to fines or modifications.

By understanding these components and influencing factors, international B2B buyers can make informed decisions that align with their budget and operational needs while optimizing their vending machine sourcing strategy.

Disclaimer: Prices mentioned herein are indicative and subject to change based on market conditions, supplier negotiations, and other variables. Always consult with suppliers for the most current pricing information.

Spotlight on Potential vending machine dimensions Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for vending machine dimensions.)*

Essential Technical Properties and Trade Terminology for vending machine dimensions

Vending machines are increasingly becoming a staple in various markets, and understanding their dimensions and technical specifications is crucial for international B2B buyers. This section provides insights into essential technical properties related to vending machine dimensions, along with key trade terminology that can facilitate informed purchasing decisions.

Essential Technical Properties

-

Material Grade

– Definition: The quality of materials used in vending machine construction, typically classified by standards such as stainless steel or powder-coated metal.

– B2B Importance: Material grade affects durability, maintenance, and aesthetic appeal. Buyers must select machines that can withstand local environmental conditions, particularly in regions with high humidity or extreme temperatures. -

Dimensions and Footprint

– Definition: The overall size of the vending machine, including height, width, and depth.

– B2B Importance: Understanding dimensions is critical for space planning in retail environments. Buyers should ensure that machines fit within designated areas while allowing for customer access and maintenance. -

Tolerance Levels

– Definition: The allowable variation in dimensions, which can affect the machine’s assembly and operation.

– B2B Importance: Tolerance affects compatibility with existing infrastructure and other equipment. Buyers should seek machines with precise tolerances to minimize installation issues. -

Capacity

– Definition: The volume of products that a vending machine can hold, often measured in the number of selections or items.

– B2B Importance: Capacity directly influences sales potential. Buyers must align machine capacity with expected product turnover rates to optimize inventory management. -

Weight Specifications

– Definition: The total weight of the vending machine, which can impact shipping, installation, and stability.

– B2B Importance: Knowing the weight is vital for transport logistics and ensuring that the floor can support the machine. It also affects the machine’s resistance to theft or vandalism. -

Energy Consumption Ratings

– Definition: Specifications that indicate the machine’s power usage, often expressed in kilowatt-hours (kWh).

– B2B Importance: Energy-efficient machines can significantly reduce operational costs. Buyers should consider energy ratings to enhance sustainability and comply with local regulations.

Key Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Significance: Understanding OEM relationships can help buyers source high-quality machines or components that meet specific industry standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Significance: Knowing the MOQ is essential for budgeting and inventory planning. Buyers should negotiate terms that align with their purchasing capabilities. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific products or services.

– Significance: An effective RFQ can streamline procurement processes and ensure competitive pricing. Buyers should detail their requirements clearly to receive accurate responses. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms that outline the responsibilities of buyers and sellers.

– Significance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risks, and costs. This knowledge is crucial for successful international transactions. -

Lead Time

– Definition: The amount of time between placing an order and receiving it.

– Significance: Understanding lead times is vital for inventory management and planning. Buyers must align lead times with their market demands to avoid stockouts. -

Customization Options

– Definition: The ability to modify vending machines to meet specific client needs, such as branding or additional features.

– Significance: Customization can enhance customer engagement and brand visibility. Buyers should explore available options to differentiate their offerings in competitive markets.

In summary, grasping these technical properties and trade terminologies will empower international B2B buyers to make informed decisions, ensuring that they select the right vending machines for their markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vending machine dimensions Sector

Market Overview & Key Trends

The vending machine dimensions sector is experiencing notable transformations driven by technological advancements, changing consumer preferences, and evolving market dynamics. One of the primary global drivers is the rise of smart vending machines, which integrate IoT technology to provide real-time data analytics, remote monitoring, and enhanced user experiences. This trend is particularly relevant for international B2B buyers in regions like Africa, South America, the Middle East, and Europe, where the demand for advanced solutions is rapidly increasing.

Furthermore, sustainability is becoming a critical factor influencing purchasing decisions. Buyers are increasingly seeking energy-efficient machines with lower environmental footprints, pushing manufacturers to innovate. In regions such as the UAE and Turkey, where environmental regulations are tightening, compliance with sustainable practices is essential. Additionally, the trend towards cashless payments is reshaping the landscape, with a growing preference for mobile payment options, which enhances convenience for consumers and operators alike.

In terms of sourcing, B2B buyers should be aware of the importance of establishing partnerships with suppliers who demonstrate agility in adapting to these market dynamics. Collaborating with manufacturers who utilize local materials and maintain flexible supply chains can provide a competitive advantage, especially in emerging markets. Ultimately, understanding these trends can help international buyers make informed decisions that align with both market demands and their organizational values.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer an option but a necessity for businesses in the vending machine dimensions sector. The environmental impact of manufacturing processes, energy consumption, and waste generation is significant, making it essential for B2B buyers to prioritize sustainable sourcing. This involves evaluating suppliers based on their commitment to reducing carbon footprints and utilizing eco-friendly materials.

Ethical supply chains are becoming increasingly important, particularly in regions with strict labor laws and ethical standards. Buyers should seek out suppliers who adhere to international certifications such as ISO 14001 for environmental management and Fair Trade practices to ensure responsible sourcing. This not only mitigates risks associated with unethical practices but also enhances brand reputation in the eyes of consumers who prioritize sustainability.

Moreover, incorporating green certifications and materials into product specifications can serve as a differentiator in the marketplace. For instance, opting for machines made from recycled materials or those that utilize energy-efficient technologies can significantly reduce operational costs and improve overall sustainability. By aligning purchasing strategies with environmental goals, B2B buyers can contribute to a more sustainable future while enhancing their competitiveness.

Brief Evolution/History

The vending machine industry has evolved considerably since its inception in the late 19th century. Originally designed for dispensing simple items like postcards and chewing gum, vending machines have transitioned into sophisticated systems capable of offering a wide range of products, including fresh food and beverages. The introduction of technology, such as credit card processing and touchscreen interfaces, has transformed consumer interactions and operational efficiencies.

In recent years, the focus has shifted toward creating machines that not only serve consumer needs but also address environmental concerns. This evolution reflects a growing awareness of sustainability and ethical sourcing, which are now pivotal in shaping the future of the vending machine dimensions sector. For international B2B buyers, understanding this historical context can provide valuable insights into current trends and future opportunities within the industry.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of vending machine dimensions

-

What dimensions should I consider when sourcing vending machines?

When sourcing vending machines, consider the height, width, and depth, as these dimensions impact placement and accessibility. Standard machines typically range from 5 to 7 feet tall and 2 to 3 feet wide. Ensure you also account for space for ventilation, user access, and maintenance. Additionally, local regulations in different regions may dictate specific requirements, so confirm these dimensions align with local standards to avoid compliance issues. -

How can I verify the credibility of a vending machine supplier?

To vet suppliers, start by checking their business credentials, including registration and licensing. Request references from other international B2B buyers, particularly those in your region. Review online ratings and feedback on trade platforms, and consider visiting their facilities if possible. Engaging in direct communication can also reveal their responsiveness and customer service quality, which are critical in international transactions. -

Are there customization options available for vending machines?

Many suppliers offer customization options for vending machines to meet specific business needs. This can include size adjustments, branding, and product configurations. When discussing customization, clearly outline your requirements and ask for examples of past projects. Ensure the supplier can accommodate changes without extending lead times significantly, as this can affect your operational timelines. -

What are the typical minimum order quantities (MOQ) and lead times?

Minimum order quantities can vary widely based on the supplier and the complexity of the machine. Generally, you may encounter MOQs ranging from 5 to 20 units. Lead times can also differ, often spanning from 4 to 12 weeks depending on customization and production schedules. Always confirm these details upfront to align your purchasing plans and avoid unexpected delays. -

What quality assurance certifications should I look for?

When sourcing vending machines, look for certifications that indicate compliance with international standards, such as ISO 9001 for quality management systems. Additionally, certifications specific to electrical and safety standards (e.g., CE marking in Europe or UL certification in the USA) can be crucial. Request documentation to verify these certifications, as they ensure the machines are built to last and operate safely. -

How should I approach logistics for importing vending machines?

Logistics can be complex when importing vending machines. First, determine the best shipping method based on your budget and urgency—options typically include sea freight for cost-effectiveness or air freight for speed. Collaborate with a logistics provider experienced in international shipments, and ensure they understand the specific requirements for transporting vending machines, including handling and customs clearance. -

What should I do in case of disputes with the supplier?

In the event of a dispute, maintain clear and professional communication with the supplier. Document all interactions and agreements to establish a clear record. Familiarize yourself with the terms of your contract, particularly regarding dispute resolution processes. If necessary, consider mediation or arbitration as alternatives to litigation, which can be costly and time-consuming, especially in international contexts. -

How can I ensure proper maintenance and support for my vending machines?

To ensure proper maintenance, discuss post-purchase support with your supplier, including warranty terms and service agreements. Request information about their support network, such as local technicians or service centers in your region. Additionally, establish a maintenance schedule to ensure the machines remain in optimal condition, which can help minimize downtime and enhance customer satisfaction in the long run.

Strategic Sourcing Conclusion and Outlook for vending machine dimensions

In conclusion, understanding vending machine dimensions is crucial for B2B buyers looking to optimize their investment in this growing market. Key takeaways include recognizing the importance of selecting the right size to match consumer demand and location constraints, as well as ensuring compliance with local regulations. Strategic sourcing enables businesses to identify suppliers who can provide machines that not only fit physical spaces but also cater to specific market needs, enhancing customer satisfaction.

As the vending machine industry continues to evolve, international buyers from Africa, South America, the Middle East, and Europe should remain vigilant about emerging trends, such as the integration of smart technology and sustainable designs. Investing in well-researched sourcing strategies will ensure your vending solutions are adaptable and future-proof.

Moving forward, take proactive steps to engage with manufacturers and suppliers who prioritize innovation and quality. By doing so, you can secure a competitive edge in your market and contribute to the transformation of the vending landscape in your region. The time to act is now—leverage strategic sourcing to align with the future of vending.