Master the Market with Hair Vending Machines: A B2B Buyer’s

Guide to Hair Vending Machines

- Introduction: Navigating the Global Market for hair vending machines

- Understanding hair vending machines Types and Variations

- Key Industrial Applications of hair vending machines

- Strategic Material Selection Guide for hair vending machines

- In-depth Look: Manufacturing Processes and Quality Assurance for hair vending machines

- Comprehensive Cost and Pricing Analysis for hair vending machines Sourcing

- Spotlight on Potential hair vending machines Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for hair vending machines

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the hair vending machines Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of hair vending machines

- Strategic Sourcing Conclusion and Outlook for hair vending machines

Introduction: Navigating the Global Market for hair vending machines

In an increasingly globalized market, hair vending machines have emerged as a transformative solution for businesses catering to the beauty and personal care sectors. These innovative machines provide a convenient, automated way to purchase high-quality hair products, catering to the growing demand for accessibility and efficiency among consumers. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to capitalize on this trend, understanding the intricacies of hair vending machines becomes critical.

This comprehensive guide delves into various aspects of hair vending machines, including types, materials, manufacturing processes, quality control standards, and supplier options. We will explore the cost implications and market dynamics, equipping buyers with the insights needed to navigate this evolving landscape effectively. Additionally, frequently asked questions will address common concerns and operational challenges, ensuring that buyers are well-informed.

By leveraging this guide, international B2B buyers will gain the knowledge necessary to make strategic sourcing decisions, ultimately enhancing their competitive edge in the marketplace. Whether you are in Italy, Nigeria, or beyond, understanding the value and functionality of hair vending machines will empower you to meet consumer needs more efficiently, paving the way for growth and innovation in your business.

Understanding hair vending machines Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Hair Vending Machine | Standard design, typically offers packaged hair products like wigs and extensions | Salons, beauty supply stores | Pros: Familiarity, straightforward operation. Cons: Limited product variety. |

| Smart Hair Vending Machine | Digital interface, inventory tracking, payment options (credit/debit, mobile payments) | High-traffic areas (airports, malls) | Pros: Enhanced customer engagement, real-time inventory updates. Cons: Higher initial investment. |

| Customized Hair Vending Machine | Allows personalization (color, length), often includes a touchscreen interface | Fashion events, trade shows | Pros: Unique offering, caters to specific customer preferences. Cons: Maintenance complexity. |

| Eco-Friendly Hair Vending Machine | Uses sustainable materials, promotes organic or ethically sourced hair products | Eco-conscious markets | Pros: Appeals to environmentally aware consumers. Cons: Potentially higher costs for products. |

| Mobile Hair Vending Unit | Portable design, can be relocated for events or seasonal sales | Festivals, pop-up shops | Pros: Flexibility in location, can target specific demographics. Cons: Limited capacity for stock. |

Traditional Hair Vending Machine

Traditional hair vending machines are the most common type, offering a straightforward selection of packaged hair products such as wigs and extensions. They are typically found in salons and beauty supply stores. B2B buyers should consider their target market’s familiarity with this type of machine, as it provides a reliable and simple operation. However, the limited product variety may restrict appeal in a competitive market.

Smart Hair Vending Machine

Smart hair vending machines incorporate advanced technology, featuring digital interfaces, inventory tracking, and multiple payment options including credit, debit, and mobile payments. These machines are ideal for high-traffic areas such as airports and shopping malls. B2B buyers should weigh the benefits of enhanced customer engagement and real-time inventory updates against the higher initial investment required for such technology.

Customized Hair Vending Machine

Customized hair vending machines offer a unique selling proposition by allowing customers to personalize their selections based on color and length, often through a touchscreen interface. This type is particularly suited for fashion events and trade shows where consumers seek tailored experiences. While they can attract niche markets, buyers must consider the potential complexity in maintenance and operation.

Eco-Friendly Hair Vending Machine

Eco-friendly hair vending machines focus on sustainability, using environmentally friendly materials and promoting organic or ethically sourced hair products. They cater to eco-conscious consumers and are best suited for markets that prioritize sustainability. B2B buyers should evaluate the appeal of these machines against potentially higher product costs, which may affect profit margins.

Mobile Hair Vending Unit

Mobile hair vending units provide flexibility, allowing businesses to relocate their offerings to festivals or pop-up shops. This type of machine can target specific demographics based on location and event type. B2B buyers should consider the advantages of this mobility, but also recognize that limited stock capacity may restrict sales potential.

Key Industrial Applications of hair vending machines

| Industry/Sector | Specific Application of hair vending machines | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Beauty & Personal Care | Retail distribution of hair products | Increased accessibility and convenience for consumers | Machine reliability, product compatibility, payment integration |

| Hospitality | In-room vending for hair care products | Enhanced guest experience and additional revenue stream | Product selection, machine maintenance, customer support |

| Events & Exhibitions | On-site vending at beauty events | Immediate product availability, increased sales opportunities | Mobility of machines, branding options, inventory management |

| E-commerce | Automated fulfillment of hair products online | Streamlined order processing, reduced labor costs | Software integration, inventory tracking, machine scalability |

| Education & Training | Hairdressing schools for student supplies | Cost-effective supply access, supports practical training | Product quality, safety compliance, machine durability |

Beauty & Personal Care

In the beauty and personal care sector, hair vending machines serve as retail distribution points for a variety of hair products, such as shampoos, conditioners, and styling tools. These machines increase accessibility for consumers, allowing them to purchase products conveniently in high-traffic areas, such as malls and salons. For international B2B buyers, considerations include ensuring machine reliability to avoid downtime, compatibility with various product types, and seamless payment integration to facilitate transactions.

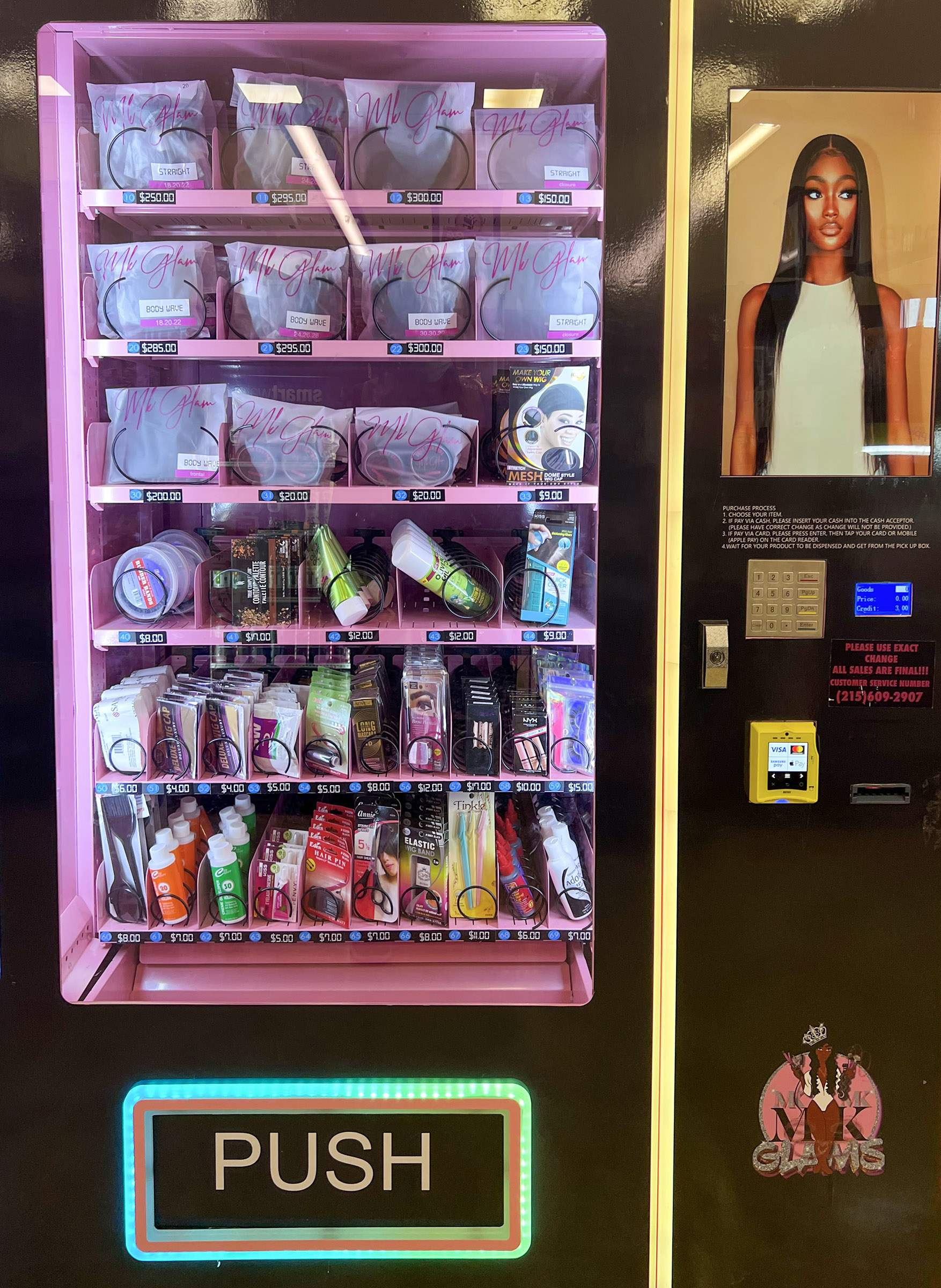

Illustrative Image (Source: Google Search)

Hospitality

In the hospitality industry, hair vending machines can be installed in hotel rooms or lobbies to provide guests with hair care products. This not only enhances the guest experience by offering convenience but also creates an additional revenue stream for hotels. Buyers in this sector should focus on product selection that caters to diverse guest needs, machine maintenance for ongoing service quality, and customer support to address any issues promptly.

Events & Exhibitions

Hair vending machines are increasingly utilized at beauty events and exhibitions, providing on-site access to hair products for attendees. This application solves the problem of immediate product availability, allowing vendors to capitalize on sales opportunities during events. Key sourcing considerations include the mobility of machines for easy transport, branding options to promote the event or company, and effective inventory management to ensure products are always available.

E-commerce

For e-commerce businesses, hair vending machines can automate the fulfillment of hair products ordered online. This application streamlines order processing and reduces labor costs associated with traditional fulfillment methods. International buyers should prioritize software integration capabilities to connect the vending machines with their online platforms, inventory tracking systems to manage stock levels efficiently, and scalability options to accommodate future growth.

Education & Training

In educational settings, such as hairdressing schools, hair vending machines provide students with easy access to essential supplies at a cost-effective price. This application supports practical training by ensuring that students have the necessary products on hand. Buyers in this sector must consider product quality to ensure safety and effectiveness, compliance with educational standards, and the durability of machines to withstand frequent use.

Related Video: LABORATORY APPARATUS AND THEIR USES

Strategic Material Selection Guide for hair vending machines

When selecting materials for hair vending machines, it’s crucial to consider their properties, advantages, and limitations in relation to the specific demands of the application. This guide analyzes four common materials used in the manufacturing of hair vending machines, providing insights that are particularly relevant for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high tensile strength, and ability to withstand high temperatures. It typically has a temperature rating of up to 800°C and can handle pressures of up to 50 bar, depending on the grade.

Pros & Cons: The durability of stainless steel makes it ideal for long-term use in vending machines, especially in humid or wet environments. However, it can be more expensive than other materials and may require specialized manufacturing processes. Additionally, while it is resistant to rust, it can still corrode if exposed to harsh chemicals.

Impact on Application: Stainless steel is suitable for vending machines that dispense hair products, as it does not react with the contents and maintains hygiene standards.

Considerations for Buyers: Buyers should ensure compliance with international standards such as ASTM or DIN, particularly regarding food safety if the machine dispenses products for human use. In regions like Nigeria or Brazil, local regulations may also dictate specific material requirements.

2. Aluminum

Key Properties: Aluminum is lightweight, has good corrosion resistance, and can be anodized for additional protection. It typically has a temperature rating of up to 600°C and can handle moderate pressure.

Pros & Cons: The primary advantage of aluminum is its low weight, which facilitates easier transport and installation. It is also cost-effective compared to stainless steel. However, aluminum is less durable than steel and may not withstand heavy impacts or extreme conditions.

Impact on Application: Aluminum is suitable for the outer casing of vending machines, where weight savings are essential, but it may not be ideal for internal components that require higher durability.

Considerations for Buyers: Buyers should consider the local availability of aluminum and its recyclability, which may be a factor in sustainability-focused markets in Europe. Compliance with local environmental regulations is also critical.

3. Polycarbonate

Key Properties: Polycarbonate is a high-performance plastic known for its impact resistance and transparency. It can withstand temperatures up to 120°C and is resistant to UV radiation.

Pros & Cons: The transparency of polycarbonate allows for visibility of the products inside the vending machine, enhancing consumer engagement. It is lightweight and easy to mold into various shapes. However, it may not be as durable as metals and can scratch easily.

Impact on Application: Polycarbonate is ideal for the front panels of vending machines, allowing customers to see the products while providing adequate protection.

Considerations for Buyers: Buyers should ensure that polycarbonate meets relevant safety standards, especially in regions with stringent consumer protection laws. Additionally, they should consider the environmental impact of plastic use, particularly in markets that prioritize sustainability.

4. Carbon Steel

Key Properties: Carbon steel is strong and cost-effective, with a temperature rating of up to 400°C. However, it is prone to corrosion if not properly treated.

Pros & Cons: Its strength makes it suitable for structural components of vending machines. The lower cost compared to stainless steel is a significant advantage. However, its susceptibility to rust and corrosion limits its use in environments with high moisture or chemical exposure.

Impact on Application: Carbon steel can be used in non-visible structural parts of the vending machine, where strength is required but exposure to moisture is limited.

Considerations for Buyers: Buyers should be aware of the need for protective coatings to prevent corrosion, especially in humid climates like those found in parts of Africa and South America. Compliance with local manufacturing standards is also essential.

Summary Table

| Material | Typical Use Case for hair vending machines | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Internal components, product storage | Excellent corrosion resistance | Higher cost, requires specialized manufacturing | High |

| Aluminum | Outer casing, lightweight structures | Lightweight, cost-effective | Less durable, may not withstand heavy impacts | Medium |

| Polycarbonate | Front panels, visibility of products | Impact-resistant, transparent | Scratches easily, less durable than metals | Medium |

| Carbon Steel | Non-visible structural components | Strong and cost-effective | Prone to corrosion without treatment | Low |

This guide aims to assist B2B buyers in making informed decisions regarding material selection for hair vending machines, ensuring compliance with local standards and suitability for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for hair vending machines

Manufacturing Processes for Hair Vending Machines

Manufacturing hair vending machines involves several crucial stages, each with its own set of techniques and considerations. Understanding these processes can help B2B buyers from various regions, including Africa, South America, the Middle East, and Europe, make informed purchasing decisions.

Material Preparation

The first stage in manufacturing hair vending machines is material preparation. This involves selecting the right materials that will ensure durability and functionality. Common materials include:

- Metal Components: Steel or aluminum is often used for the frame and housing due to their strength and resistance to wear.

- Electronics: High-quality electronic components are essential for the vending mechanism and payment systems. This includes circuit boards, sensors, and display screens.

- Finishing Materials: Plastics or composites may be used for aesthetic elements or internal components that require lightweight properties.

B2B buyers should ensure that suppliers source materials from reputable vendors, as the quality of materials directly impacts the machine’s performance and lifespan.

Forming

Forming is the process where raw materials are shaped into parts of the vending machine. Key techniques include:

- Metal Stamping: This technique is used to create the outer shell and structural components. It involves pressing metal sheets into specific shapes using dies.

- Injection Molding: Used for producing plastic parts, this technique allows for complex shapes and is highly efficient for large volumes.

- CNC Machining: Computer Numerical Control (CNC) machining is employed for precision parts, ensuring that components fit together accurately.

Buyers should inquire about the forming technologies used by suppliers, as advanced techniques can lead to better quality and reduced production costs.

Assembly

The assembly stage is where all individual components are brought together to create the final product. This involves:

- Sub-Assembly: Components like electronic boards and mechanical parts are often assembled separately before being integrated into the main machine.

- Quality Checks: During assembly, it is vital to conduct in-process quality checks to ensure that each part meets the required specifications.

B2B buyers should assess whether suppliers have standardized assembly procedures and if they employ trained personnel to minimize errors.

Finishing

Finishing processes enhance the aesthetic appeal and durability of hair vending machines. Common techniques include:

- Painting and Coating: Protective coatings and paint not only improve appearance but also protect against corrosion and wear.

- Surface Treatments: Processes such as anodizing or galvanizing can be applied to metal parts to enhance their resistance to environmental factors.

Understanding the finishing processes can help buyers evaluate the longevity of the machines in different climates, particularly in regions like Africa and the Middle East, where environmental factors can impact equipment.

Quality Assurance

Quality assurance (QA) is critical in ensuring that hair vending machines operate reliably and meet customer expectations. Effective QA processes include adherence to international standards and implementing thorough testing methodologies.

International Standards

B2B buyers should be aware of the following relevant standards:

- ISO 9001: This international standard focuses on quality management systems and is essential for ensuring consistent product quality.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For electronic components, API (Application Programming Interface) standards ensure that software systems interact correctly.

Understanding these certifications helps buyers assess the credibility of suppliers and the quality of their products.

QC Checkpoints

Quality control checkpoints are integrated throughout the manufacturing process:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet quality specifications.

- In-Process Quality Control (IPQC): Regular checks during the assembly process help identify defects early, reducing the risk of faulty products reaching the market.

- Final Quality Control (FQC): Before shipping, a comprehensive inspection of the final product is conducted to verify functionality and compliance with specifications.

B2B buyers should inquire about the specific QC checkpoints that suppliers implement and any statistical methods used to analyze defects.

Common Testing Methods

Testing methods employed during QA can include:

- Functional Testing: Ensures that the machine operates as intended, including all electronic features.

- Durability Testing: Assess how well the machine withstands wear and tear over time.

- Environmental Testing: Evaluates performance under different environmental conditions, crucial for machines deployed in varied climates.

Buyers should request detailed testing reports from suppliers to verify the effectiveness of their QA processes.

Verifying Supplier Quality Control

To ensure that suppliers maintain high-quality standards, B2B buyers should consider the following strategies:

-

Supplier Audits: Conduct regular audits of suppliers to assess their manufacturing processes and quality assurance practices. This may include on-site visits to observe operations.

-

Quality Reports: Request comprehensive quality reports that outline the results of IQC, IPQC, and FQC processes, along with any corrective actions taken for defects.

-

Third-Party Inspections: Engage third-party inspection services to provide an unbiased evaluation of the supplier’s manufacturing capabilities and quality control measures.

-

Certifications and Accreditations: Verify that suppliers hold relevant certifications and accreditations that demonstrate their commitment to quality.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for hair vending machines is essential for B2B buyers looking to make informed purchasing decisions. By focusing on material quality, advanced manufacturing techniques, and stringent quality control measures, buyers can ensure that they invest in reliable and durable machines that meet their operational needs.

Related Video: Most Satisfying Factory Production Processes And Heavy-Duty Factory Machines!

Comprehensive Cost and Pricing Analysis for hair vending machines Sourcing

When sourcing hair vending machines, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This section outlines the key components that influence costs, factors affecting pricing, and strategic tips for effective negotiations.

Cost Components

-

Materials: The primary materials in hair vending machines include metal for the chassis, electronic components for the vending mechanism, and display technology. The cost of these materials can vary significantly based on quality, sourcing location, and market fluctuations.

-

Labor: Labor costs are influenced by the region where the manufacturing occurs. For instance, factories in developing countries may offer lower labor costs compared to those in Europe or North America. However, the skill level of the workforce can impact the quality of the final product.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, such as utilities, rent, and administrative expenses. Efficient operations can help minimize these overheads, contributing to overall cost savings.

-

Tooling: Initial tooling costs can be significant, especially for customized machines. This includes molds and dies necessary for the production of specific components. Buyers should inquire about these costs early in the negotiation process.

-

Quality Control (QC): Implementing stringent QC measures ensures that the machines meet safety and performance standards. While this may increase upfront costs, it can prevent costly defects and returns in the long run.

-

Logistics: Shipping costs are a critical aspect, particularly for international buyers. These costs can fluctuate based on fuel prices, distance, and the chosen shipping method. It’s essential to consider both import duties and local taxes when calculating total logistics expenses.

-

Margin: Suppliers typically include a profit margin within their pricing structure, which can vary widely based on competition, market demand, and the unique value proposition of their machines.

Price Influencers

-

Volume/MOQ: Minimum Order Quantities (MOQ) can significantly affect pricing. Larger orders often qualify for discounts, making it beneficial for buyers to consolidate purchases.

-

Specifications/Customization: Custom features or specifications can drive up costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials: The choice of materials can impact both the initial cost and the durability of the machine. Opting for higher-quality materials may incur higher costs but can enhance longevity and reduce maintenance needs.

-

Quality/Certifications: Machines that meet international safety and quality standards may command higher prices. Certifications such as ISO or CE can also be a selling point, ensuring compliance in various markets.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but often provide better quality assurance and customer support.

-

Incoterms: Understanding the implications of different Incoterms (International Commercial Terms) is essential. They define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs, which can affect the total cost.

Buyer Tips

-

Negotiation: Leverage the total order volume to negotiate better terms and pricing. Suppliers may offer discounts for larger commitments or long-term contracts.

-

Cost Efficiency: Assess total cost of ownership rather than just initial purchase price. This includes maintenance, operational costs, and potential resale value.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, costs may vary between Europe and Africa due to currency fluctuations, local demand, and supply chain logistics.

-

Local Regulations: Research local regulations regarding vending machines in your target market. Compliance may add costs but is necessary for successful market entry.

Disclaimer

Prices discussed are indicative and can vary based on market conditions, specific supplier negotiations, and other external factors. It’s advisable to conduct thorough market research and supplier evaluations to obtain accurate pricing information tailored to your needs.

Spotlight on Potential hair vending machines Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘hair vending machines’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for hair vending machines

Key Technical Properties of Hair Vending Machines

When considering hair vending machines, international B2B buyers should familiarize themselves with several critical technical specifications. Understanding these properties is essential for ensuring product quality, operational efficiency, and compliance with industry standards.

Illustrative Image (Source: Google Search)

-

Material Grade

The construction materials of hair vending machines significantly affect durability and performance. Common materials include stainless steel for the casing and high-grade plastics for internal components. Buyers should seek machines made from corrosion-resistant materials, particularly in humid climates typical of regions like Africa and South America. -

Tolerance Levels

Tolerance refers to the allowable deviation from specified dimensions during manufacturing. High tolerance levels are crucial for ensuring parts fit correctly and operate smoothly, which directly impacts the machine’s reliability. A tolerance of ±0.5 mm is often acceptable in mechanical components of vending machines, promoting longevity and reducing maintenance costs. -

Power Consumption

Efficiency in power consumption is a vital consideration, especially for businesses operating in regions with unstable electricity supplies. Machines designed with energy-efficient technologies can help reduce operational costs. Specifications should indicate average power consumption in watts, allowing buyers to estimate monthly energy expenses. -

Capacity

The capacity of a vending machine, measured in the number of hair products it can hold, is essential for meeting customer demand. Machines typically range from 50 to 200 units. Selecting a model with appropriate capacity ensures that businesses can serve their target market without frequent restocking. -

User Interface

A user-friendly interface is vital for customer satisfaction. Touchscreen interfaces with multilingual support can enhance user experience, particularly in diverse markets. Features like product information displays and payment options (e.g., mobile payments) should also be considered to cater to local preferences. -

Security Features

Vending machines must incorporate robust security features to prevent theft and vandalism. Look for specifications indicating the type of locking mechanisms, alarms, and surveillance capabilities. Machines with advanced security features can provide peace of mind for operators, particularly in high-traffic areas.

Common Trade Terms in the Hair Vending Machine Industry

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several key terms that buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components or products that are marketed by another company under its brand name. For buyers, partnering with an OEM can lead to better pricing and customization options, particularly for machines tailored to specific regional needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for managing inventory and ensuring that initial orders are economically viable, especially for startups or smaller businesses. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. This is particularly important in B2B contexts, as it allows buyers to compare prices and terms from multiple vendors, ensuring competitive pricing and favorable conditions. -

Incoterms (International Commercial Terms)

These are a set of predefined international rules that clarify the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms, such as FOB (Free On Board) and CIF (Cost, Insurance, and Freight), is essential for understanding shipping costs and responsibilities, which can significantly impact overall pricing. -

Lead Time

This term refers to the time it takes from placing an order to receiving the product. Understanding lead times helps buyers plan their inventory and manage customer expectations effectively, particularly in fast-paced markets. -

Warranty Period

The warranty period specifies the duration during which the manufacturer is responsible for repairs or replacements due to defects. A longer warranty period can indicate a supplier’s confidence in their product and provide buyers with greater assurance regarding their investment.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions when purchasing hair vending machines, ultimately enhancing their business operations and customer satisfaction.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the hair vending machines Sector

Market Overview & Key Trends

The hair vending machines market is experiencing significant growth driven by several global factors. Increasing demand for convenience and accessibility in beauty products, particularly in urban areas, is a key driver. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are capitalizing on this trend, recognizing the potential for hair vending machines to cater to on-the-go consumers. The rise of e-commerce has also fueled this demand, as businesses seek innovative ways to reach customers outside traditional retail environments.

Emerging technologies are reshaping the landscape of hair vending machines. For instance, the integration of contactless payment systems and mobile app connectivity enables enhanced user experiences, fostering customer loyalty. Additionally, the use of AI and machine learning in inventory management ensures that businesses can adapt to changing consumer preferences swiftly. B2B buyers should focus on suppliers who offer these technological advancements, as they provide a competitive edge.

Market dynamics are also influenced by regional preferences and cultural trends. In Africa and South America, there is a growing appreciation for locally sourced and culturally relevant hair products. B2B buyers should explore partnerships with local suppliers to enhance their offerings and build brand loyalty. Meanwhile, European markets show a strong inclination towards premium products, making it essential for international buyers to align their product selections with regional consumer expectations.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming increasingly important in the hair vending machine sector. As consumers become more environmentally conscious, B2B buyers must prioritize ethical sourcing and sustainable practices in their supply chains. The environmental impact of hair products, particularly those involving synthetic materials, necessitates a shift towards greener alternatives. Suppliers who utilize biodegradable packaging and sustainable sourcing methods are becoming increasingly attractive to businesses looking to enhance their brand image.

Ethical supply chains are essential for maintaining consumer trust and loyalty. B2B buyers should seek certifications such as Fair Trade or organic to ensure that their products meet ethical standards. Collaborating with suppliers who can provide transparency in sourcing practices not only mitigates risks but also resonates well with consumers who value corporate responsibility.

Moreover, adopting ‘green’ materials in hair vending machines, such as recycled plastics or sustainably sourced hair, can differentiate a brand in a competitive marketplace. Buyers should consider how these sustainable practices can be communicated effectively to consumers, enhancing brand reputation and driving sales.

Brief Evolution/History

The concept of vending machines has evolved significantly over the decades, transitioning from traditional snacks and beverages to niche markets like beauty products. The introduction of hair vending machines began gaining traction in the early 2010s, as entrepreneurs recognized the potential to serve a growing demand for hair extensions and beauty products in a convenient format.

Initially, these machines offered limited product ranges, but advancements in technology and consumer preferences have led to a more diverse selection. Today, hair vending machines can provide a variety of products, from wigs to hair care items, enabling businesses to cater to a broader audience. This evolution underscores the importance of adaptability in the B2B market, as suppliers and buyers alike must remain attuned to consumer trends and technological advancements.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of hair vending machines

-

What should I look for when vetting suppliers of hair vending machines?

When vetting suppliers, consider their industry experience, client testimonials, and product quality. Request samples to evaluate the hair quality and machine functionality. Check for certifications like ISO or CE, indicating compliance with international standards. Conduct background checks on their manufacturing capabilities, lead times, and customer service responsiveness. Additionally, inquire about their after-sales support and warranty terms to ensure you are partnering with a reliable supplier. -

Can hair vending machines be customized to fit my brand?

Yes, many manufacturers offer customization options for hair vending machines. You can typically request personalized branding, such as logos and color schemes, to align with your business identity. Some suppliers may also allow modifications in machine size, product selection, and interface design. It’s important to communicate your specific requirements early in the negotiation process to ensure they can meet your expectations. -

What are the typical minimum order quantities (MOQs) and lead times?

Minimum order quantities vary by supplier but can range from 10 to 50 units for hair vending machines. Lead times depend on the complexity of customization and the supplier’s production capacity, generally ranging from 4 to 12 weeks. Always confirm these details before placing an order to avoid delays in your supply chain. Establishing a good relationship with suppliers can sometimes lead to more flexible MOQs and expedited production. -

What payment methods are commonly accepted by suppliers?

Common payment methods include bank transfers, PayPal, and letters of credit, depending on the supplier’s policies and your location. Some suppliers may offer payment plans, especially for larger orders. It’s advisable to negotiate payment terms that protect your investment, such as partial payment upfront and the remainder upon delivery. Always ensure that any payment method used is secure and provides recourse in case of disputes. -

How can I ensure quality assurance and certification compliance?

Request detailed information about the supplier’s quality assurance processes, including inspections and testing protocols for both the machines and the hair products. Certifications such as ISO 9001 or specific industry-related certifications can indicate adherence to quality standards. It is beneficial to ask for documentation proving compliance with health and safety regulations, especially if exporting to regions with strict import laws. -

What logistics considerations should I keep in mind when sourcing from international suppliers?

Consider the logistics involved in shipping hair vending machines, including shipping costs, customs duties, and potential delays. Work with suppliers who have experience in international shipping and can provide options for freight forwarding. Ensure they can handle documentation for customs clearance. It’s also wise to discuss insurance options for your shipment to protect against loss or damage during transit. -

How should I handle disputes with suppliers?

To manage disputes effectively, maintain clear communication with your supplier throughout the purchasing process. Establish a written contract outlining expectations, deliverables, and remedies for non-compliance. If issues arise, attempt to resolve them amicably through direct dialogue first. If necessary, consider mediation or arbitration as a means of resolving disputes without resorting to litigation, which can be costly and time-consuming. -

What are the common challenges faced in international trade of hair vending machines?

Common challenges include navigating different regulations, import/export tariffs, and varying quality standards across countries. Language barriers and cultural differences can also complicate negotiations and communications. Additionally, fluctuations in currency exchange rates may impact pricing. To mitigate these challenges, work with knowledgeable intermediaries or trade specialists who can provide insights into local markets and legal requirements.

Strategic Sourcing Conclusion and Outlook for hair vending machines

In conclusion, strategic sourcing for hair vending machines represents a significant opportunity for international B2B buyers, especially in emerging markets across Africa, South America, the Middle East, and Europe. By leveraging data-driven insights, buyers can identify reliable suppliers, negotiate favorable terms, and ultimately enhance their market presence. Key takeaways include the importance of understanding regional market dynamics, evaluating supplier credentials, and considering the total cost of ownership rather than just upfront pricing.

As the demand for convenient access to quality hair products continues to grow, investing in hair vending machines can offer a competitive edge. These machines not only cater to the evolving consumer preferences but also provide an innovative channel for distribution.

Looking forward, B2B buyers are encouraged to act decisively in sourcing strategies that align with their business goals. Embrace technological advancements and consumer trends to position your brand for success. Engage with suppliers who prioritize sustainability and quality, and explore partnerships that can drive mutual growth in this dynamic market. The future of hair vending machines is bright, and now is the time to invest in this promising sector.