Master the Market with Fao Schwarz Vending Machine Insights

Guide to Fao Schwarz Vending Machine

- Introduction: Navigating the Global Market for fao schwarz vending machine

- Understanding fao schwarz vending machine Types and Variations

- Key Industrial Applications of fao schwarz vending machine

- Strategic Material Selection Guide for fao schwarz vending machine

- In-depth Look: Manufacturing Processes and Quality Assurance for fao schwarz vending machine

- Comprehensive Cost and Pricing Analysis for fao schwarz vending machine Sourcing

- Spotlight on Potential fao schwarz vending machine Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for fao schwarz vending machine

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the fao schwarz vending machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fao schwarz vending machine

- Strategic Sourcing Conclusion and Outlook for fao schwarz vending machine

Introduction: Navigating the Global Market for fao schwarz vending machine

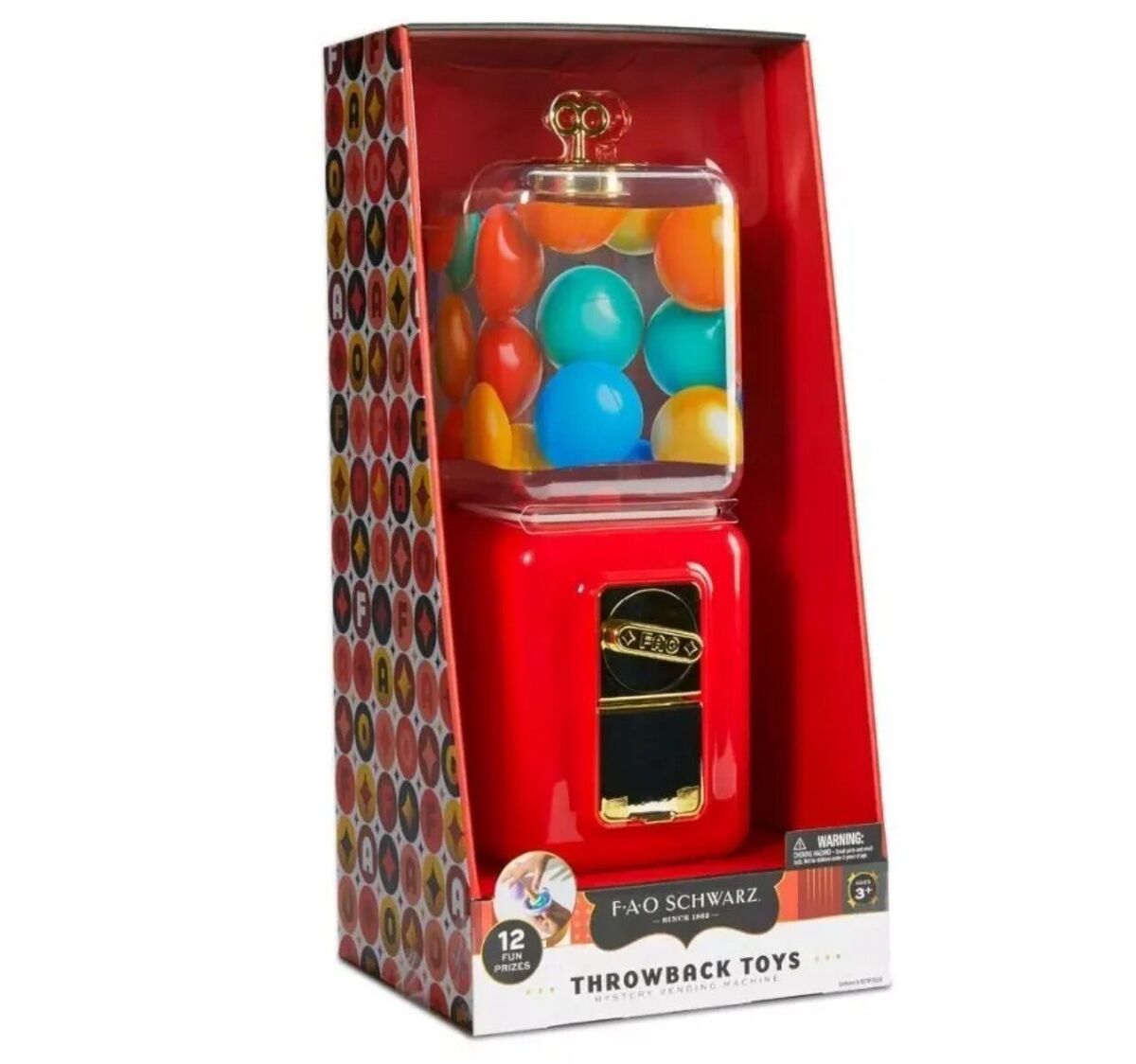

The global market for Fao Schwarz vending machines is a dynamic and evolving landscape that presents lucrative opportunities for B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. These vending machines, known for their unique and engaging product offerings, serve not just as retail points but also as brand ambassadors that enhance customer experiences. As international buyers seek innovative solutions to meet their customers’ demands, understanding the nuances of Fao Schwarz vending machines becomes critical.

This guide provides a comprehensive overview of the Fao Schwarz vending machine sector, covering essential topics such as types, materials, manufacturing and quality control, suppliers, and cost considerations. Additionally, it addresses market trends and provides answers to frequently asked questions, enabling buyers to navigate this niche effectively. By leveraging insights from this guide, businesses can make informed sourcing decisions that align with their strategic goals.

For buyers in diverse markets—from the bustling streets of Spain to the vibrant cities of Nigeria—this guide is designed to empower decision-making processes. It highlights the importance of selecting the right vending machines that not only fit their operational needs but also resonate with their target audiences. With the right knowledge and resources, international B2B buyers can capitalize on the unique opportunities presented by Fao Schwarz vending machines, ensuring a competitive edge in their respective markets.

Understanding fao schwarz vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Toy Vending Machine | Offers a mix of traditional toys and collectibles | Retail stores, amusement parks | Pros: Wide appeal, nostalgic value. Cons: Limited product range may not attract all demographics. |

| Interactive Digital Vending Machine | Touchscreen interface with games and product displays | Shopping malls, entertainment venues | Pros: Engages customers, potential for upselling. Cons: Higher initial investment and maintenance costs. |

| Specialty Merchandise Vending Machine | Focuses on branded merchandise and exclusive items | Events, conventions, specialty stores | Pros: Attracts fans and collectors, boosts brand visibility. Cons: Requires effective marketing to drive traffic. |

| Snack & Beverage Combo Machine | Combines toys with snacks or beverages | Family entertainment centers, cinemas | Pros: Increases sales through impulse buying. Cons: Space constraints may limit product variety. |

| Seasonal Theme Vending Machine | Rotates products based on holidays or events | Seasonal markets, fairs, festivals | Pros: Creates excitement and urgency, tailored offerings. Cons: Requires frequent inventory changes and management. |

Classic Toy Vending Machine

The Classic Toy Vending Machine is characterized by its assortment of traditional toys and collectibles, appealing to both children and nostalgic adults. Commonly found in retail stores and amusement parks, these machines serve as an accessible entry point for businesses looking to engage a broad audience. When considering this option, B2B buyers should evaluate the machine’s location and target market to ensure a steady flow of customers, as the limited product range may not attract all demographics.

Interactive Digital Vending Machine

This type features a touchscreen interface, allowing users to interact with games and product displays. Ideal for shopping malls and entertainment venues, it offers an engaging customer experience that can lead to increased sales through upselling opportunities. B2B buyers must weigh the higher initial investment and ongoing maintenance costs against the potential for higher customer engagement and revenue generation.

Specialty Merchandise Vending Machine

Focusing on branded merchandise and exclusive items, Specialty Merchandise Vending Machines cater to events, conventions, and specialty stores. They attract fans and collectors, providing businesses with a unique opportunity to boost brand visibility. Buyers should consider the effectiveness of their marketing strategies to drive traffic to these machines, as their success largely depends on consumer interest in the offered products.

Snack & Beverage Combo Machine

Combining toys with snacks or beverages, this machine is designed for family entertainment centers and cinemas. It capitalizes on impulse buying, increasing sales opportunities by offering complementary products. B2B buyers should be aware of space constraints, as these machines may limit the variety of products offered, potentially impacting customer satisfaction.

Seasonal Theme Vending Machine

Seasonal Theme Vending Machines rotate their offerings based on holidays or events, making them a popular choice for seasonal markets, fairs, and festivals. By creating excitement and urgency with tailored offerings, these machines can significantly boost sales during peak times. However, buyers must be prepared for the challenges of frequent inventory changes and management to keep the offerings fresh and relevant.

Related Video: Machine Learning in 2024 – Beginner’s Course

Key Industrial Applications of fao schwarz vending machine

| Industry/Sector | Specific Application of fao schwarz vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Toy and novelty item vending in shopping malls | Increased foot traffic, diversified revenue streams | Product assortment, machine capacity, and payment system integration |

| Education | After-school program vending for snacks and toys | Enhances student engagement and convenience | Health regulations, product variety, and replenishment logistics |

| Hospitality | In-room vending for guests in hotels | Improved guest satisfaction, additional revenue source | Machine design aesthetics, product selection, and maintenance support |

| Events and Exhibitions | Vending at trade shows for promotional items | Direct marketing opportunities, brand visibility | Custom branding options, ease of setup, and operational support |

| Healthcare | Child-friendly vending in pediatric wards | Comfort for young patients, distraction during visits | Compliance with health regulations, product safety, and variety |

Retail Applications

In retail environments, fao schwarz vending machines can be strategically placed in shopping malls to offer toys and novelty items. This not only attracts families and children but also increases foot traffic. The machines can be stocked with a variety of merchandise tailored to local tastes, which is crucial for international buyers in diverse markets such as Nigeria and Spain. Considerations for sourcing include the machine’s capacity to hold various products and the integration of payment systems that cater to local preferences.

Educational Settings

In schools and educational institutions, these vending machines can serve as after-school snack and toy dispensers. They provide a convenient option for students, enhancing their engagement during breaks. For international buyers, especially in South America and Africa, it’s essential to ensure compliance with health regulations regarding food items. Additionally, the selection of products must be appealing to children while also meeting nutritional standards.

Illustrative Image (Source: Google Search)

Hospitality Industry

In the hospitality sector, placing fao schwarz vending machines in hotel rooms can significantly boost guest satisfaction. They offer convenience by providing snacks and toys, making stays more enjoyable for families. For B2B buyers, aesthetics and machine design are key factors, as they need to align with the hotel’s branding. Moreover, sourcing should include considerations for product selection that caters to diverse guest preferences and effective maintenance support.

Events and Exhibitions

At trade shows and exhibitions, these vending machines can be utilized for distributing promotional items and novelty products. This direct marketing approach enhances brand visibility and engages potential customers effectively. For international buyers, sourcing considerations include the ability to customize branding on the machines and ensuring ease of setup and operational support during events.

Healthcare Environments

In healthcare settings, especially pediatric wards, fao schwarz vending machines can provide child-friendly snacks and toys. This helps in comforting young patients and distracting them during medical visits. Buyers in this sector must prioritize compliance with health regulations and product safety. Additionally, offering a variety of appealing options can significantly enhance the experience for children and their families, making it an attractive investment for healthcare facilities.

Related Video: FANUC Industrial Robots | AUDI Case Study

Strategic Material Selection Guide for fao schwarz vending machine

When selecting materials for the FAO Schwarz vending machine, it’s essential to consider the unique requirements of the vending environment, including durability, aesthetic appeal, and compliance with international standards. Below, we analyze four common materials used in vending machines, focusing on their properties, advantages, disadvantages, and implications for international buyers, particularly from Africa, South America, the Middle East, and Europe.

1. Stainless Steel

Key Properties: Stainless steel is known for its exceptional corrosion resistance and strength, making it suitable for environments where moisture and cleaning agents are prevalent. It can withstand temperature variations and has good structural integrity.

Pros & Cons: Stainless steel is highly durable and easy to clean, which is crucial for maintaining hygiene in vending machines. However, it is more expensive than other materials and can be challenging to machine, potentially increasing manufacturing complexity.

Impact on Application: Stainless steel is compatible with a wide range of media, including food and beverages, making it an ideal choice for vending machines. Its resistance to rust and staining ensures long-term performance in various environments.

Considerations for International Buyers: Buyers should ensure compliance with food safety standards such as FDA regulations in the U.S. or EFSA standards in Europe. Additionally, understanding local sourcing options can help mitigate costs.

2. Powder-Coated Steel

Key Properties: Powder-coated steel offers a protective layer that enhances corrosion resistance while allowing for a variety of colors and finishes. It is less expensive than stainless steel and provides a good balance of strength and aesthetics.

Pros & Cons: This material is cost-effective and visually appealing, making it suitable for branding. However, it can chip or scratch, exposing the underlying steel to corrosion, which may reduce its lifespan.

Impact on Application: Powder-coated steel is suitable for indoor applications but may not perform well in harsh outdoor environments. Its compatibility with various media is generally good, but care must be taken to avoid damage to the coating.

Considerations for International Buyers: Buyers should verify that the powder coating meets local environmental regulations regarding VOC emissions. Additionally, understanding the durability requirements based on regional climates can influence material choice.

3. Acrylic

Key Properties: Acrylic is a lightweight, shatter-resistant plastic that offers excellent clarity and UV resistance. It is often used for display panels and windows in vending machines.

Pros & Cons: Acrylic is easy to fabricate and can be molded into complex shapes, providing design flexibility. However, it is less durable than metals and can scratch easily, which may affect its appearance over time.

Impact on Application: Acrylic is ideal for showcasing products due to its transparency, but it may not be suitable for high-impact areas. Its chemical resistance is moderate, so compatibility with certain cleaning agents should be assessed.

Considerations for International Buyers: Buyers should check for compliance with local safety standards, especially regarding the use of plastics in food-related applications. Understanding the recycling options for acrylic in different regions can also be beneficial.

4. Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and possesses good thermal and electrical conductivity. It can be anodized for enhanced surface protection and aesthetic appeal.

Pros & Cons: Aluminum is relatively inexpensive and easy to work with, making it a popular choice for many applications. However, it may not be as strong as stainless steel, which could limit its use in high-stress areas.

Impact on Application: Aluminum is suitable for various media, including food and beverages, and its lightweight nature makes it ideal for portable vending machines. However, care must be taken to avoid exposure to harsh chemicals that could degrade the material.

Considerations for International Buyers: Buyers should ensure that aluminum products comply with relevant international standards, such as ASTM or DIN. Additionally, understanding the local market for aluminum can help in sourcing and cost management.

Summary Table

| Material | Typical Use Case for fao schwarz vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components and exterior panels | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Powder-Coated Steel | Exterior panels and branding elements | Cost-effective and visually appealing | Susceptible to chipping and scratching | Medium |

| Acrylic | Display panels and product windows | Lightweight and shatter-resistant | Scratches easily and less durable | Medium |

| Aluminum | Structural components and lightweight parts | Lightweight and corrosion-resistant | Lower strength compared to stainless steel | Low |

This guide provides a comprehensive overview of material options for the FAO Schwarz vending machine, aiding international B2B buyers in making informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for fao schwarz vending machine

Manufacturing Processes for FAO Schwarz Vending Machines

Understanding the manufacturing processes for FAO Schwarz vending machines is essential for international B2B buyers seeking quality, durability, and compliance with global standards. The manufacturing journey typically involves several key stages, each incorporating specific techniques to ensure the final product meets the high standards expected by consumers and retailers alike.

1. Material Preparation

The first stage in the manufacturing process involves sourcing and preparing the materials. Common materials used in vending machines include:

- Metal: Steel and aluminum are often used for structural components due to their strength and durability.

- Plastics: High-quality polymers are selected for parts like the vending windows and internal mechanisms, ensuring resistance to wear and tear.

- Electronics: Components such as circuit boards and sensors are sourced from certified suppliers to ensure reliability.

During this phase, suppliers must adhere to strict quality standards to ensure all materials meet safety and performance criteria.

2. Forming

Once the materials are prepared, the next step is forming. This includes:

- Cutting: Metals and plastics are cut to size using precision machinery.

- Molding: Plastic components are often created through injection molding, which allows for intricate designs and consistency across parts.

- Fabrication: Metal parts may undergo processes such as welding or bending to achieve the required shapes.

Key techniques during this stage include CNC (Computer Numerical Control) machining, which enhances precision, and laser cutting, known for its accuracy and clean edges.

3. Assembly

The assembly stage is critical, as it brings together all manufactured components. This typically involves:

- Mechanical Assembly: Skilled workers or automated systems assemble the frame, doors, and internal mechanisms.

- Electrical Integration: Wiring and electronic components are installed, ensuring proper connections for operational functionality.

- Quality Checks: During assembly, initial quality checks (IPQC – In-Process Quality Control) are performed to catch defects early.

Efficient assembly lines, often guided by Lean Manufacturing principles, help minimize waste and optimize productivity.

4. Finishing

Finishing processes enhance the aesthetic and functional qualities of the vending machines. This includes:

- Painting and Coating: Protective coatings are applied to prevent corrosion and enhance appearance. Powder coating is a common technique that provides a durable finish.

- Quality Assurance Testing: Final inspections are conducted to ensure that all components operate correctly and meet safety standards.

This stage culminates in the final quality check (FQC – Final Quality Control) before products are packaged and prepared for shipment.

Quality Assurance in Manufacturing

Quality assurance (QA) is a cornerstone of the manufacturing process for FAO Schwarz vending machines. Adherence to international standards is crucial, especially for B2B buyers who prioritize reliability and safety.

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems, ensuring consistent product quality and customer satisfaction. Manufacturers must implement processes that align with these principles.

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Compliance: For electronic components, adherence to the Application Programming Interface (API) standards ensures interoperability and reliability.

Quality Control Checkpoints

Quality control is embedded at various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint examines raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during assembly help identify and rectify issues in real-time.

- Final Quality Control (FQC): A comprehensive review of the finished product ensures all specifications are met before shipment.

Common Testing Methods

Manufacturers employ various testing methods to validate the quality and functionality of vending machines:

- Functional Testing: Verifies that all electronic components work correctly.

- Stress Testing: Assesses the machine’s performance under extreme conditions to gauge durability.

- Safety Testing: Ensures compliance with safety standards, preventing potential hazards.

Verifying Supplier Quality Control

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is critical. Here are actionable steps to ensure supplier reliability:

- Conduct Audits: Regular audits of suppliers can help assess their adherence to quality standards and operational efficiency.

- Request Reports: Suppliers should provide documented evidence of their quality control processes, including IQC, IPQC, and FQC results.

- Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased evaluation of the manufacturing process and product quality.

Quality Control Nuances for International Buyers

Understanding the nuances of quality control when dealing with international suppliers is vital. Here are key considerations:

- Cultural Differences: Different regions may have varying approaches to quality assurance. Buyers should familiarize themselves with local practices and standards.

- Regulatory Compliance: Buyers must ensure that products comply with both local regulations and those of the markets they intend to serve.

- Communication: Clear communication regarding quality expectations and standards is essential to avoid misunderstandings and ensure product alignment.

By navigating these aspects of manufacturing and quality assurance, international B2B buyers can secure high-quality FAO Schwarz vending machines that meet their operational needs and regulatory requirements.

Related Video: The Production Planning Process

Comprehensive Cost and Pricing Analysis for fao schwarz vending machine Sourcing

The cost structure and pricing of the Fao Schwarz vending machine are influenced by various components and factors, particularly relevant to international B2B buyers. Understanding these elements can help buyers make informed decisions while sourcing these machines.

Cost Components

-

Materials: The quality and type of materials used in the vending machines significantly impact the overall cost. High-quality plastics, metals, and electronic components tend to increase the price. Buyers should assess the durability and aesthetics of materials, as these can affect the machine’s longevity and appeal.

-

Labor: Labor costs vary by region and can be a substantial part of the manufacturing expense. Countries with higher labor costs, such as those in Western Europe, may see higher prices compared to regions with lower wages. Understanding the labor market in the supplier’s country can provide insight into potential pricing.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and other operational expenses necessary for production. Overhead can vary significantly based on the location of the manufacturing facility. Buyers should consider suppliers who optimize their overhead costs to offer competitive pricing.

-

Tooling: Customization of vending machines requires specific tooling, which can be a significant upfront cost. This is particularly relevant if the buyer is looking for bespoke designs or features. Understanding tooling costs can help buyers negotiate better deals.

-

Quality Control (QC): Ensuring the machines meet quality standards incurs additional costs. Suppliers with rigorous QC processes may charge more, but this can lead to better reliability and customer satisfaction in the long run.

-

Logistics: Shipping and handling fees can vary widely based on the destination, shipping method, and the volume of the order. Buyers should account for these costs in their total budget and consider suppliers with efficient logistics to minimize expenses.

-

Margin: Suppliers typically add a margin to cover their profit and risk. This margin can vary based on the supplier’s position in the market and their operational efficiency.

Price Influencers

-

Volume and Minimum Order Quantity (MOQ): Bulk orders generally reduce the per-unit price. Buyers looking to source multiple machines should negotiate MOQ terms to maximize cost efficiency.

-

Specifications and Customization: Custom features can increase costs. Buyers should clearly outline their needs to avoid unexpected expenses associated with modifications.

-

Materials and Quality Certifications: Machines built with premium materials or that possess quality certifications (like ISO or CE) may command higher prices. Buyers must weigh the benefits of these features against their budgets.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Well-established suppliers might charge more but offer better service and quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for cost management. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. This can significantly impact the total cost of ownership.

Buyer Tips

-

Negotiation: Always negotiate pricing and terms, especially when ordering in bulk. Building a long-term relationship with suppliers can lead to better deals.

-

Cost-Efficiency: Assess the total cost of ownership, including maintenance and operational costs, rather than just the initial purchase price. This approach can lead to better financial decisions.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and import tariffs that can affect the final cost. It’s advisable to engage local experts or consultants to navigate these complexities.

Disclaimer

Prices can vary widely based on market conditions, material availability, and supplier negotiations. The information provided is indicative and should be verified with suppliers for accurate pricing.

Spotlight on Potential fao schwarz vending machine Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘fao schwarz vending machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for fao schwarz vending machine

When considering the acquisition of a Fao Schwarz vending machine, understanding its essential technical properties and trade terminology is crucial for international B2B buyers. Here’s a detailed look at these aspects, tailored specifically for buyers from regions like Africa, South America, the Middle East, and Europe.

Key Technical Properties

-

Material Grade

– Vending machines are typically constructed from materials like stainless steel or high-grade plastics. Stainless steel offers durability and resistance to corrosion, while high-grade plastics can provide a lighter, cost-effective alternative. Buyers should assess the material based on their operational environment, particularly in humid or coastal areas where corrosion may be a concern. -

Power Requirements

– Most vending machines operate on standard voltage (e.g., 110V or 220V). Understanding the power requirements is essential for compliance with local electrical standards. This knowledge helps avoid operational issues and ensures that the machine is suitable for the intended location, whether it be in urban centers or remote areas. -

Capacity and Dimensions

– The capacity of the vending machine, often measured in the number of items it can hold, is vital for determining how frequently it needs to be restocked. Dimensions will also affect where the machine can be placed. Buyers should consider their target market’s foot traffic and available space when selecting a model. -

Temperature Control

– For machines dispensing perishable goods or beverages, temperature control is essential. Look for units with adjustable temperature settings and reliable refrigeration systems to maintain product quality. This feature is particularly important in warmer climates, where maintaining freshness can directly impact sales.

- User Interface and Payment Systems

– Modern vending machines often include touch screens and multiple payment options (credit/debit cards, mobile payments). A user-friendly interface can enhance customer experience and boost sales. Buyers should evaluate the machine’s payment capabilities, especially in regions where cashless transactions are becoming more prevalent.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of vending machines, understanding OEM relationships is crucial for quality assurance and warranty considerations. -

MOQ (Minimum Order Quantity)

– MOQ represents the smallest number of units a supplier is willing to sell. This is an important consideration for buyers, particularly small businesses or startups, as it can impact initial investment and inventory management. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers asking for a price quote on specific products. For B2B buyers, submitting an RFQ can help compare prices and terms across different vendors, ensuring they get the best deal. -

Incoterms (International Commercial Terms)

– These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) related to international commercial law. Understanding Incoterms is essential for buyers to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. -

Lead Time

– Lead time refers to the amount of time it takes from placing an order to receiving the product. This is particularly critical for businesses that require timely deliveries to meet customer demands. Buyers should inquire about lead times to ensure they can stock machines when needed. -

Warranty and Service Agreements

– These terms outline the coverage for repairs and maintenance of the vending machine. Understanding warranty details is vital for managing long-term operational costs and ensuring product reliability.

Illustrative Image (Source: Google Search)

In summary, international B2B buyers must familiarize themselves with the technical specifications and trade terminology associated with Fao Schwarz vending machines. This knowledge not only aids in making informed purchasing decisions but also enhances operational efficiency and customer satisfaction in diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the fao schwarz vending machine Sector

Market Overview & Key Trends

The global vending machine sector, particularly in the context of Fao Schwarz vending machines, is experiencing dynamic shifts driven by several factors. Consumer preferences are evolving, with a marked increase in demand for interactive and engaging experiences. This trend is particularly pronounced in regions like Europe and North America, where buyers are seeking machines that offer more than just traditional snack and beverage options. In contrast, markets in Africa and South America are witnessing a surge in demand for affordable and efficient vending solutions that cater to local tastes and preferences.

Another significant driver is the integration of smart technology into vending machines. Features such as cashless payment options, inventory management systems, and remote monitoring are becoming standard. These advancements not only enhance operational efficiency but also improve the customer experience. For international B2B buyers, particularly those from Africa and South America, investing in technology-driven vending solutions can provide a competitive edge.

Furthermore, the impact of the COVID-19 pandemic has accelerated the shift towards contactless interactions and healthier product offerings, influencing sourcing decisions. Buyers should focus on sourcing machines that comply with health and safety standards while also appealing to health-conscious consumers. As the market evolves, aligning with these emerging trends will be crucial for B2B buyers looking to capture market share.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical consideration for businesses globally, influencing purchasing decisions in the vending machine sector. The environmental impact of vending machines, from energy consumption to waste generation, necessitates a shift towards sustainable practices. For B2B buyers, this means sourcing machines that utilize energy-efficient technologies, such as LED lighting and energy-saving modes, which not only reduce carbon footprints but also lower operational costs.

In addition to energy efficiency, ethical sourcing of materials is increasingly important. Buyers should prioritize vendors who provide transparency in their supply chains, ensuring that components are sourced responsibly. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) for packaging materials can serve as indicators of a supplier’s commitment to sustainability.

Moreover, the demand for recyclable and biodegradable materials is growing among consumers, particularly in Europe. Implementing a strategy that focuses on sustainable materials can enhance brand reputation and align with consumer expectations. For buyers in regions like the Middle East and Africa, where sustainability initiatives are gaining traction, investing in eco-friendly vending solutions can differentiate their offerings and appeal to a growing base of environmentally conscious consumers.

Brief Evolution/History

The Fao Schwarz brand, renowned for its innovative toys and engaging retail experiences, has extended its legacy into the vending machine sector. Originally established in 1862, Fao Schwarz has continuously evolved to meet changing consumer demands, embracing technology and creativity. The introduction of vending machines reflects a strategic move to reach consumers in various settings, including airports, malls, and schools, thus expanding their market presence.

Historically, vending machines were primarily focused on convenience. However, Fao Schwarz’s approach combines entertainment and interactivity, appealing to a broader audience, especially children and families. This evolution not only enhances customer engagement but also aligns with modern shopping behaviors, where consumers seek unique experiences even in automated retail environments. For B2B buyers, understanding this evolution can inform sourcing strategies that align with current market trends and consumer expectations.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of fao schwarz vending machine

-

What should I consider when vetting suppliers for FAO Schwarz vending machines?

When vetting suppliers, prioritize their experience in the industry, customer reviews, and the certifications they hold (e.g., ISO, CE). Evaluate their production capabilities, quality control processes, and whether they can provide references from previous clients. It is also important to verify their financial stability to ensure they can fulfill large orders over time. Engaging in preliminary discussions about their after-sales support and warranty policies can further help assess their reliability. -

Can I customize the FAO Schwarz vending machine to fit my brand?

Yes, many suppliers offer customization options for FAO Schwarz vending machines. You can discuss branding elements such as color schemes, logos, and specific product offerings to align with your market needs. Ensure to confirm the extent of customization available and any associated costs. Request samples or mock-ups to visualize the final product before committing to a bulk order. -

What are the minimum order quantities (MOQs) and lead times for FAO Schwarz vending machines?

MOQs can vary significantly by supplier, typically ranging from 10 to 100 units. Lead times may also differ based on customization requirements and supplier location, generally spanning 4 to 12 weeks. When negotiating, clarify these aspects upfront to align your purchasing strategy with your business needs and inventory management. -

What payment terms are typically expected when ordering vending machines internationally?

Payment terms often include a deposit upon order confirmation (usually 30-50%) and the balance before shipment. Some suppliers may offer trade financing options or letters of credit, especially for larger orders. Always clarify payment methods accepted (e.g., bank transfers, PayPal) and consider negotiating terms that protect your interests, such as escrow services, to mitigate risks. -

What quality assurance measures should I expect from suppliers?

Suppliers should adhere to strict quality assurance protocols, including product testing and compliance with international safety standards. Request documentation of their QA processes, including any certifications they possess (e.g., ISO 9001). It’s also advisable to inquire about the inspection process before shipment, ensuring that products meet your specifications and quality expectations. -

How can I handle logistics and shipping for my order?

Discuss logistics options with your supplier to understand their shipping capabilities and preferred carriers. Determine if they can handle customs clearance and delivery to your location. It’s important to factor in shipping costs and timelines into your overall budget. Using freight forwarders experienced in international shipments can help streamline the process and mitigate potential delays. -

What steps should I take if there is a dispute with the supplier?

In the event of a dispute, start by documenting all communications and agreements. Attempt to resolve the issue amicably through direct negotiation with the supplier. If unresolved, refer to the terms outlined in your purchase agreement, which should specify dispute resolution mechanisms, such as mediation or arbitration. Engaging legal counsel with expertise in international trade can also provide guidance on the best course of action. -

What certifications should I look for in FAO Schwarz vending machines?

When sourcing vending machines, look for essential certifications that ensure safety and compliance, such as CE (Conformité Européenne) for European markets, UL (Underwriters Laboratories) for North America, and ISO certifications for manufacturing quality. These certifications not only enhance product credibility but also facilitate smoother importation and compliance with local regulations in your target markets. Always request copies of these certifications for verification.

Strategic Sourcing Conclusion and Outlook for fao schwarz vending machine

In conclusion, strategic sourcing for the FAO Schwarz vending machine presents a unique opportunity for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe. By understanding the market dynamics and leveraging supplier relationships, businesses can enhance their product offerings while optimizing costs. Key takeaways include the importance of evaluating supplier capabilities, understanding regional market preferences, and ensuring compliance with local regulations.

Investing in high-quality vending machines not only increases customer satisfaction but also builds brand loyalty. As the demand for innovative retail solutions grows, the FAO Schwarz vending machine stands out as a vibrant and engaging option that can attract diverse customer demographics.

Looking ahead, B2B buyers are encouraged to adopt a proactive approach to sourcing. Engage with suppliers early, explore customization options, and consider the long-term benefits of strategic partnerships. By doing so, businesses can position themselves advantageously in a competitive landscape, ensuring they meet the evolving needs of their customers while driving sustainable growth.