Master the Market with Essential Pics of Vending Machines

Guide to Pics Of Vending Machines

- Introduction: Navigating the Global Market for pics of vending machines

- Understanding pics of vending machines Types and Variations

- Key Industrial Applications of pics of vending machines

- Strategic Material Selection Guide for pics of vending machines

- In-depth Look: Manufacturing Processes and Quality Assurance for pics of vending machines

- Comprehensive Cost and Pricing Analysis for pics of vending machines Sourcing

- Spotlight on Potential pics of vending machines Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for pics of vending machines

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the pics of vending machines Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pics of vending machines

- Strategic Sourcing Conclusion and Outlook for pics of vending machines

Introduction: Navigating the Global Market for pics of vending machines

In today’s fast-paced global economy, the vending machine industry is evolving rapidly, presenting lucrative opportunities for international B2B buyers. Pictures of vending machines serve as essential marketing tools that showcase the versatility and innovative designs of these machines, which can cater to a wide range of consumer needs—from snacks and beverages to personal protective equipment and tech accessories. For businesses in Africa, South America, the Middle East, and Europe, understanding the nuances of vending machine options is critical for making informed purchasing decisions.

This comprehensive guide delves into the various aspects of vending machines, including types and materials, manufacturing and quality control standards, key suppliers, and cost considerations. It will also explore market trends and provide answers to frequently asked questions, ensuring that buyers are well-equipped to navigate the complexities of sourcing vending machines.

By leveraging this guide, B2B buyers can enhance their understanding of the market landscape, identify reliable suppliers, and optimize their procurement strategies. Whether you are looking to expand your current offerings or enter the vending machine market for the first time, the insights provided here will empower you to make strategic decisions that align with your business goals. Embrace the potential of vending machines and transform your operational efficiency today.

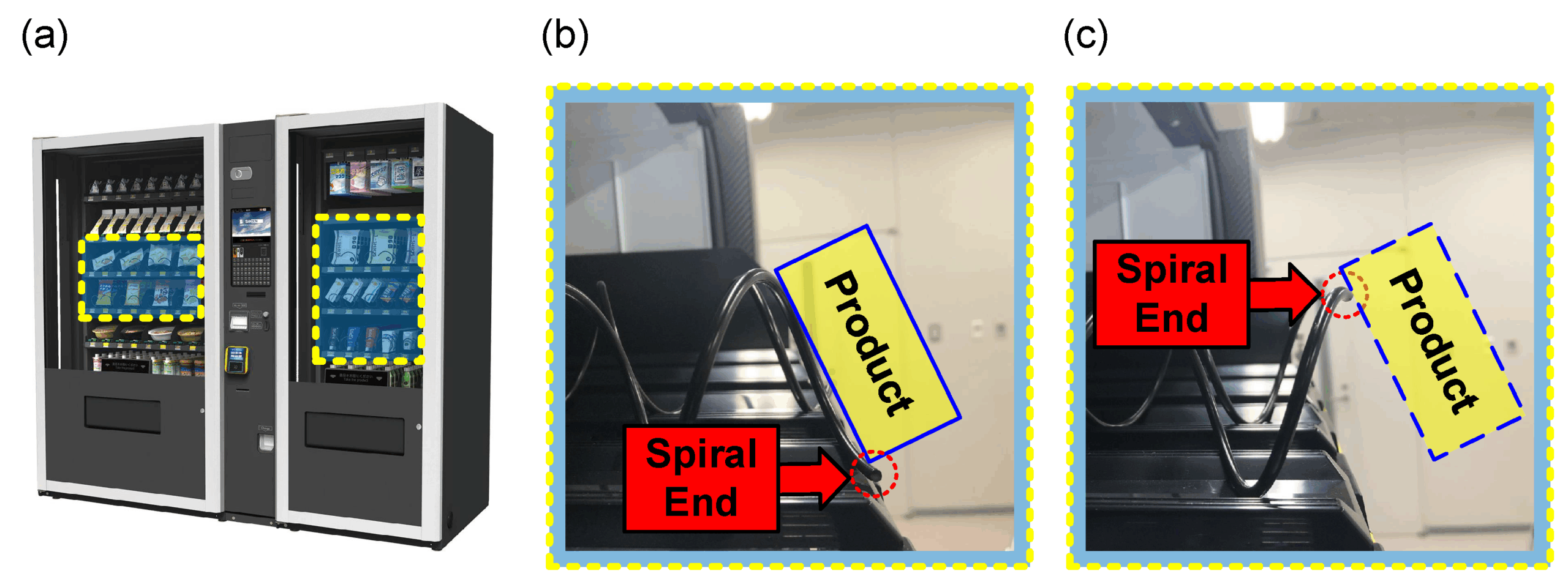

Illustrative Image (Source: Google Search)

Understanding pics of vending machines Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Snack Vending Machines | Dispense snacks and beverages; cash and card payment options | Office break rooms, schools, gyms | Pros: Low initial cost, easy to maintain. Cons: Limited product variety, lower engagement. |

| Healthy Food Vending Machines | Focus on nutritious options; often refrigerated | Corporate wellness programs, health clubs | Pros: Appeals to health-conscious consumers. Cons: Higher upfront costs, may require specialized suppliers. |

| Smart Vending Machines | Internet connectivity, cashless payments, inventory tracking | Airports, retail stores, hospitals | Pros: Enhanced customer experience, real-time inventory management. Cons: Higher maintenance costs, tech reliance. |

| Specialty Product Vending Machines | Tailored for specific items (e.g., electronics, PPE) | Construction sites, tech retail | Pros: Meets niche market needs, can drive higher sales. Cons: Limited customer base, requires careful location selection. |

| Beverage Vending Machines | Focused solely on drinks; often refrigerated | Restaurants, cafes, schools | Pros: High turnover rate, low spoilage. Cons: Seasonal demand fluctuations, competition with local shops. |

Traditional Snack Vending Machines

Traditional snack vending machines are ubiquitous in various environments, including offices, schools, and gyms. They typically offer a range of snacks and beverages, accepting both cash and card payments. For B2B buyers, these machines present a low-cost entry point into the vending business, with straightforward maintenance and operation. However, their limited product variety may not engage all customer segments, potentially leading to lower sales in diverse environments.

Healthy Food Vending Machines

These machines cater to the growing demand for nutritious options, offering items such as salads, protein bars, and fresh juices. Commonly found in corporate wellness programs and health clubs, they align with the increasing focus on health and wellness. B2B buyers should consider the initial investment and the need for specialized suppliers to maintain product quality. While appealing to health-conscious consumers, these machines may face challenges in terms of higher upfront costs and the necessity for consistent product availability.

Smart Vending Machines

Smart vending machines integrate technology to enhance user experience and operational efficiency. With features like cashless payments, inventory tracking, and data analytics, they are well-suited for high-traffic locations such as airports and retail stores. For B2B buyers, the benefits include improved customer engagement and real-time inventory management, which can significantly reduce stockouts. However, these machines often come with higher maintenance costs and depend on reliable internet connectivity, which may pose challenges in certain regions.

Specialty Product Vending Machines

Designed for specific items such as personal protective equipment (PPE) or electronics, specialty vending machines serve niche markets. These machines are particularly effective in environments like construction sites or tech retail settings, where they can meet unique demands. B2B buyers should weigh the potential for higher sales against the limited customer base and the necessity for careful location selection. While they can drive substantial revenue, the success of these machines hinges on understanding the specific needs of the target audience.

Beverage Vending Machines

Focusing exclusively on drinks, beverage vending machines are popular in restaurants, cafes, and schools. They typically offer a variety of beverages, including soft drinks, bottled water, and energy drinks, often in refrigerated units. For B2B buyers, these machines boast a high turnover rate and lower spoilage risk, making them a viable option for generating consistent revenue. However, buyers should be aware of seasonal demand fluctuations and competition from local shops, which can impact sales performance.

Related Video: FINTECH BUSINESS MODELS EXPLAINED

Key Industrial Applications of pics of vending machines

| Industry/Sector | Specific Application of pics of vending machines | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Corporate Offices | Snack and beverage vending for employee break rooms | Increases employee satisfaction and productivity | Machine size, product variety, payment options |

| Educational Institutions | Vending machines for stationery and tech supplies in libraries | Supports learning continuity and convenience for students | Customization options, cashless payment systems |

| Healthcare Facilities | Dispensing personal protective equipment (PPE) and hygiene products | Enhances safety compliance and accessibility for staff and patients | Temperature control features, remote monitoring capabilities |

| Transportation Hubs | Vending machines for travel essentials at airports and train stations | Provides convenience for travelers and boosts revenue | Multi-language interfaces, robust inventory management |

| Manufacturing Facilities | On-site distribution of tools and parts | Reduces downtime and improves inventory management | Role-based access controls, durable machine design |

Corporate Offices

In corporate environments, vending machines serve as a convenient solution for providing snacks and beverages in break rooms. These machines cater to employee preferences, offering a variety of healthy options alongside traditional snacks. By enhancing employee satisfaction and productivity through easy access to refreshments, businesses can foster a more engaged workforce. For international buyers, it’s crucial to consider machine size and product variety to meet local tastes, along with flexible payment options, including cashless transactions.

Educational Institutions

Vending machines in educational settings, particularly in libraries, offer essential items such as stationery, USB drives, and tech accessories. This application supports students’ immediate needs, ensuring that they have access to necessary supplies without leaving the campus. For international buyers, customization options are vital to reflect the institution’s branding, and implementing cashless payment systems can streamline transactions, catering to the tech-savvy student demographic.

Healthcare Facilities

In healthcare environments, vending machines can be utilized to dispense personal protective equipment (PPE) and hygiene products, such as masks and hand sanitizers. This application enhances safety compliance by ensuring that staff and patients have immediate access to essential items. For international buyers, sourcing machines with temperature control features is critical for preserving sensitive products, and remote monitoring capabilities can help maintain inventory levels efficiently.

Transportation Hubs

Vending machines placed in airports and train stations provide travelers with easy access to essential items, including snacks, bottled water, and charging devices. This application not only enhances the travel experience but also generates significant revenue for operators. International buyers should prioritize machines that feature multi-language interfaces to cater to diverse clientele, alongside robust inventory management systems to ensure consistent service availability.

Manufacturing Facilities

In manufacturing settings, vending machines can automate the distribution of tools and parts directly at the assembly line. This application minimizes downtime by ensuring that workers have immediate access to necessary items, while also enhancing inventory management through role-based access controls. For B2B buyers, durability and reliability of the vending machine design are essential, as well as features that support accountability and reduce manual inventory audits.

Related Video: Kooler Ice Vending Machines – IM600XL vs. IM1000

Strategic Material Selection Guide for pics of vending machines

When selecting materials for vending machines, B2B buyers must consider various factors that influence performance, durability, and cost-effectiveness. Below are analyses of four common materials used in the construction of vending machines, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high tensile strength, and ability to withstand a wide range of temperatures. It typically has a temperature rating of up to 800°F (427°C) and is resistant to rust and staining.

Pros & Cons: The primary advantages of stainless steel include its durability and aesthetic appeal, making it suitable for high-traffic environments. However, it is more expensive than other materials, and its manufacturing can be complex due to the need for specialized equipment.

Impact on Application: Stainless steel is ideal for vending machines that dispense food and beverages, as it is easy to clean and resistant to bacterial growth. It is also compatible with various media, including liquids and gases.

Considerations for International Buyers: Compliance with food safety standards (like FDA in the U.S. or EU regulations in Europe) is crucial. Buyers should also be aware of local corrosion rates, which can vary significantly by region, especially in humid or coastal areas.

Aluminum

Key Properties: Aluminum is lightweight, has good corrosion resistance, and can be easily extruded or molded into various shapes. It typically has a temperature rating of around 600°F (316°C).

Pros & Cons: The lightweight nature of aluminum makes it easier to transport and install. It is generally less expensive than stainless steel but may not be as durable in high-impact situations. Additionally, aluminum can be prone to denting and scratching.

Impact on Application: Aluminum is suitable for vending machines that require mobility or frequent relocation, such as those used in temporary events or outdoor settings. Its corrosion resistance makes it a good choice for environments with high moisture.

Considerations for International Buyers: Buyers should consider the local availability of aluminum and any applicable standards (like ASTM or JIS) for quality assurance. In regions with high humidity, additional treatments may be required to enhance corrosion resistance.

Polycarbonate

Key Properties: Polycarbonate is a thermoplastic known for its high impact resistance and transparency. It can withstand temperatures up to 270°F (132°C) and is often used for protective covers and windows.

Pros & Cons: The primary advantage of polycarbonate is its lightweight and shatter-resistant properties, making it ideal for safety applications. However, it may not be suitable for high-temperature applications and can become discolored over time when exposed to UV light.

Impact on Application: Polycarbonate is often used for the front panels of vending machines, allowing visibility of products while providing protection. It is compatible with a range of internal components and is often used in environments where safety is a concern.

Considerations for International Buyers: It is essential to ensure compliance with local safety standards and regulations regarding plastics. Buyers should also consider the potential for UV degradation in sunny regions.

Mild Steel

Key Properties: Mild steel is a low-carbon steel known for its good machinability and weldability. It has a temperature rating of around 400°F (204°C) and is often used in structural applications.

Pros & Cons: Mild steel is cost-effective and offers good strength, making it suitable for structural components of vending machines. However, it is susceptible to corrosion and requires protective coatings to enhance durability.

Impact on Application: Mild steel is often used in the frame and structural components of vending machines. It is best suited for indoor applications where exposure to moisture is limited.

Considerations for International Buyers: Buyers should be aware of the need for protective coatings to prevent corrosion, especially in humid climates. Compliance with local standards for steel quality (like DIN or ASTM) is also important.

Summary Table

| Material | Typical Use Case for pics of vending machines | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and beverage dispensing | Excellent durability and corrosion resistance | Higher cost, complex manufacturing | High |

| Aluminum | Mobile or outdoor vending machines | Lightweight and cost-effective | Prone to denting and scratching | Medium |

| Polycarbonate | Front panels and protective covers | Shatter-resistant and lightweight | UV degradation over time | Medium |

| Mild Steel | Structural components | Cost-effective and strong | Susceptible to corrosion | Low |

This guide provides a comprehensive overview of material selection for vending machines, enabling international B2B buyers to make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for pics of vending machines

Manufacturing Processes for Vending Machines

Manufacturing vending machines involves several critical stages, each designed to ensure the final product meets the demands of diverse markets. The primary stages of manufacturing include material preparation, forming, assembly, and finishing. Each stage employs specific techniques to ensure durability, functionality, and aesthetic appeal.

Material Preparation

The first step in the manufacturing process is material preparation. Vending machines are typically constructed from metals like steel or aluminum due to their strength and corrosion resistance. The selection of materials is crucial, as it affects the machine’s longevity and operational efficiency.

-

Material Sourcing: Suppliers should provide certifications for the materials used, ensuring they meet industry standards. B2B buyers should verify that raw materials are sourced from reputable suppliers, particularly those that comply with international standards like ISO 9001.

-

Quality Checks: Before moving to the next stage, incoming materials undergo Incoming Quality Control (IQC). This includes visual inspections and tests for material integrity to prevent defects in the final product.

Forming

The forming stage involves shaping the prepared materials into the components of the vending machine. This can include stamping, bending, and welding processes.

- Key Techniques:

- Laser Cutting: Ensures precision in component shapes and sizes, which is essential for fitting parts together seamlessly.

- CNC Machining: Provides high accuracy in creating complex parts that are critical for electronic components and vending mechanisms.

B2B buyers should inquire about the technology used in forming processes, as advanced techniques can significantly enhance the quality and precision of the finished product.

Assembly

Assembly is where the various components come together to form the complete vending machine. This stage typically involves both manual and automated processes.

-

Assembly Line Techniques: Utilizing an assembly line allows for efficient production while maintaining quality control at each step. Workers are trained to adhere to strict assembly protocols, ensuring consistency across units.

-

Inter-Process Quality Control (IPQC): During assembly, various checkpoints are established where components are tested to ensure they meet operational specifications. This might include electrical testing for the machine’s circuitry and mechanical testing for moving parts.

B2B buyers should ensure that suppliers have well-defined assembly procedures and that they conduct regular training for assembly staff to maintain high standards.

Finishing

The finishing stage is crucial for the aesthetics and durability of the vending machines. This includes painting, coating, and installing electronics.

-

Coating and Painting: Machines are often coated with powder or painted to enhance their resistance to wear and corrosion. The choice of finish can also affect the machine’s marketability.

-

Final Quality Control (FQC): Before shipping, each machine undergoes a final inspection to check for defects and to ensure all components function correctly. This is vital for preventing issues once the machines are deployed in the field.

Quality Assurance Standards

For B2B buyers, understanding the quality assurance processes in place is essential. Various international standards govern the manufacturing and quality assurance of vending machines.

-

ISO 9001: This standard outlines the requirements for a quality management system and is critical for ensuring consistent quality in manufacturing processes.

-

CE Marking: For machines sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards. Buyers should verify that machines have this certification to avoid regulatory issues.

-

API Standards: If vending machines are used in specialized environments (e.g., hospitals or laboratories), adherence to American Petroleum Institute (API) standards may also be relevant.

Quality Control Checkpoints

Effective quality control involves multiple checkpoints throughout the manufacturing process. These checkpoints help identify defects early, reducing waste and ensuring product reliability.

- Incoming Quality Control (IQC): Verification of materials upon arrival.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process.

- Final Quality Control (FQC): Comprehensive testing before shipment.

Common Testing Methods

To ensure quality, manufacturers employ a variety of testing methods, including:

- Functional Testing: Verifying that the vending machine operates correctly, including product dispensing and payment processing.

- Durability Testing: Assessing the machine’s ability to withstand environmental factors and regular use.

- Electrical Safety Testing: Ensuring compliance with safety standards to prevent electrical hazards.

Verifying Supplier Quality Control

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial. Here are some actionable steps:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should look for certifications and compliance with relevant standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the QC processes in place and any issues that may have arisen during production.

-

Third-Party Inspections: Engaging third-party inspectors to evaluate manufacturing facilities can offer an unbiased view of compliance with quality standards.

Conclusion

Understanding the manufacturing processes and quality assurance measures in place for vending machines is vital for B2B buyers. By focusing on material quality, manufacturing techniques, and adherence to international standards, buyers can make informed decisions that lead to successful partnerships and high-quality products. Ensuring robust quality control mechanisms are in place will ultimately safeguard investments and enhance customer satisfaction in diverse markets.

Related Video: Most Satisfying Factory Production Processes And Heavy-Duty Factory Machines!

Comprehensive Cost and Pricing Analysis for pics of vending machines Sourcing

When sourcing images of vending machines, understanding the comprehensive cost structure and pricing analysis is crucial for international B2B buyers. The costs associated with acquiring high-quality images can vary significantly based on several factors, including materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins.

Cost Components

-

Materials: The primary cost for sourcing images lies in the quality of the digital assets. High-resolution images, often shot with professional equipment, can increase the overall cost. Additionally, licensing fees for using specific images can be a significant factor.

-

Labor: The cost of hiring professional photographers or graphic designers should not be overlooked. Depending on their expertise and the complexity of the shoot, labor costs can vary widely. For instance, hiring a local photographer in Europe may differ significantly from sourcing in Africa or South America.

-

Manufacturing Overhead: This includes costs related to the operational aspects of image production, such as studio space, equipment depreciation, and maintenance.

-

Tooling: While less relevant for digital images than for physical products, this can include software tools used for editing and enhancing images, which can be a recurring cost.

-

Quality Control (QC): Ensuring that the images meet specific quality standards may involve additional costs. This could include multiple rounds of edits or re-shoots if the initial images do not meet client specifications.

-

Logistics: For international buyers, logistics can involve the transfer of digital assets across borders, which may require robust data management systems and cloud storage solutions.

-

Margin: Suppliers typically include a profit margin in their pricing, which can range from 15% to 40%, depending on the market and competition.

Price Influencers

-

Volume/MOQ: The cost per image may decrease significantly with higher order quantities. Suppliers often have minimum order quantities (MOQs) that can affect pricing.

-

Specifications/Customization: Custom shoots tailored to specific branding requirements can increase costs. This includes the need for unique settings, props, or models.

-

Materials: The type of images required (e.g., stock vs. custom photography) will influence the final price. Stock images are generally more affordable than custom shots.

-

Quality/Certifications: Higher quality images that meet certain industry standards (like resolution or licensing for commercial use) will typically come at a premium.

-

Supplier Factors: The reputation and experience of the supplier can greatly affect pricing. Established suppliers may charge more based on their proven track record.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) that apply to your purchase can help in calculating the total landed cost, including any shipping and handling fees.

Buyer Tips

-

Negotiation: Don’t hesitate to negotiate prices, especially if you are ordering in bulk. Suppliers may be willing to offer discounts for large orders or repeat business.

-

Cost-Efficiency: Consider the total cost of ownership (TCO) rather than just the upfront price. For example, investing in higher-quality images may yield better marketing results and higher conversion rates.

-

Pricing Nuances: Be aware of the different pricing strategies across regions. For instance, prices may be lower in South America compared to Europe due to varying labor costs and market dynamics.

-

Research and Comparison: Use multiple suppliers to compare costs and quality. This can provide leverage in negotiations and ensure you are getting the best deal for your needs.

Disclaimer

Prices for images of vending machines can vary widely based on the aforementioned factors, and the figures provided here are indicative. It is essential to obtain quotes from multiple suppliers to understand the market rates and make informed purchasing decisions.

Spotlight on Potential pics of vending machines Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘pics of vending machines’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for pics of vending machines

Understanding the technical properties and trade terminology related to vending machines is essential for international B2B buyers looking to invest in this industry. Below are key specifications and terms that can guide decision-making and enhance operational efficiency.

Critical Technical Properties

-

Material Grade

– Definition: This refers to the type of materials used in the construction of vending machines, such as stainless steel, plastic, or aluminum.

– Importance: High-grade materials ensure durability and resistance to rust and wear, which is crucial for machines placed in high-traffic locations. For buyers, selecting machines made from quality materials can reduce long-term maintenance costs. -

Capacity

– Definition: Capacity indicates the number of items a vending machine can hold, often measured in terms of product slots or total volume.

– Importance: Understanding capacity helps buyers choose machines that fit their target market’s demand. A larger capacity may be beneficial in busy locations, while smaller machines can be effective in niche markets.

Illustrative Image (Source: Google Search)

-

Power Consumption

– Definition: This specification outlines the amount of electrical power a vending machine requires to operate efficiently.

– Importance: Energy-efficient machines can significantly lower operating costs, especially in regions with high electricity prices. For B2B buyers, selecting energy-efficient models aligns with sustainability goals and reduces overhead. -

Payment Options

– Definition: Payment options include the types of transactions the machine can accept, such as cash, credit cards, mobile payments, or digital wallets.

– Importance: Offering diverse payment methods can enhance customer experience and increase sales. B2B buyers should consider machines that cater to local payment preferences, especially in emerging markets. -

Dimensions

– Definition: This refers to the physical size of the vending machine, including height, width, and depth.

– Importance: Knowing the dimensions is crucial for ensuring the machine fits in the designated location. Buyers should consider space constraints and accessibility when selecting a model.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: Refers to a company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships is vital for B2B buyers as it affects pricing, quality assurance, and availability of replacement parts. -

MOQ (Minimum Order Quantity)

– Definition: This is the smallest amount of product a supplier is willing to sell.

– Importance: Knowing the MOQ can help buyers negotiate better deals and manage inventory levels effectively. It’s particularly relevant for bulk purchases or when entering new markets. -

RFQ (Request for Quotation)

– Definition: A formal document requesting suppliers to provide pricing and terms for specific products or services.

– Importance: An RFQ is essential for ensuring competitive pricing and can facilitate better supplier relationships. It helps buyers get a comprehensive view of market rates and options. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international rules published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms is crucial for B2B buyers engaged in cross-border trade, as they define liability, risk, and shipping responsibilities, thereby minimizing misunderstandings. -

Lead Time

– Definition: The amount of time it takes from placing an order to receiving the goods.

– Importance: Understanding lead time is essential for inventory management and planning, particularly in regions with longer shipping durations. Buyers should consider lead times when forecasting demand and ensuring product availability. -

Warranty Period

– Definition: The time frame during which a manufacturer guarantees that the product will perform as expected, often including repairs or replacements.

– Importance: A comprehensive warranty can indicate the manufacturer’s confidence in their product quality. Buyers should prioritize vendors that offer favorable warranty terms to safeguard their investment.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when purchasing vending machines, ensuring they select the right products that meet their business needs and market demands.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the pics of vending machines Sector

In recent years, the vending machine sector has experienced a significant transformation driven by technological advancements and changing consumer preferences. The global market for vending machines is projected to grow steadily, fueled by increasing demand for convenience and innovative solutions in retail. International B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe, should be aware of several key trends shaping the industry.

Market Overview & Key Trends

-

Technological Integration: The rise of smart vending machines equipped with IoT technology is a defining trend. These machines offer cashless payment options, real-time inventory tracking, and personalized product recommendations based on customer data. B2B buyers can leverage these features to enhance user experience and streamline operations.

-

Health and Wellness: There is a growing demand for healthier snack options in vending machines. As consumers become more health-conscious, machines that offer nutritious products like organic snacks, fresh fruits, and beverages are gaining popularity. This trend presents a lucrative opportunity for B2B buyers looking to source machines that cater to health-oriented consumers.

-

Sustainability: The focus on eco-friendly practices is reshaping the vending machine landscape. Buyers are increasingly seeking machines made from sustainable materials and those that minimize energy consumption. Sustainability initiatives not only appeal to environmentally conscious consumers but also improve brand image.

-

Customization and Localization: Successful vending operations often involve tailoring offerings to local tastes and preferences. B2B buyers should consider sourcing machines that allow for easy customization of product assortments to meet the specific demands of different markets.

-

Emerging Markets: Countries in Africa and South America are witnessing an uptick in vending machine adoption due to urbanization and changing lifestyles. These markets present unique opportunities for international buyers to establish operations and tap into new revenue streams.

Sustainability & Ethical Sourcing in B2B

The environmental impact of vending machines is becoming a critical consideration for B2B buyers. As the industry evolves, the importance of ethical sourcing and sustainable practices is paramount.

-

Environmental Impact: Vending machines contribute to waste through packaging and energy consumption. Buyers should look for machines that utilize energy-efficient technologies and reduce plastic waste by offering refillable or recyclable packaging options.

-

Ethical Supply Chains: Establishing ethical supply chains is essential for maintaining a positive brand reputation. Buyers should prioritize suppliers who adhere to fair labor practices and environmental standards, ensuring that products sourced for vending machines are produced responsibly.

-

Green Certifications and Materials: Look for machines that are certified by recognized environmental standards, such as Energy Star or ISO 14001. Using materials that are recyclable or made from sustainable sources can significantly enhance the sustainability profile of vending operations.

-

Consumer Demand for Transparency: Today’s consumers are increasingly interested in the sustainability practices of the brands they support. Providing clear information about the sourcing and environmental impact of products in vending machines can foster trust and loyalty among customers.

Brief Evolution/History

Vending machines have evolved significantly since their inception in the late 19th century. Initially designed to dispense simple items like postcards and chewing gum, they have transformed into sophisticated, high-tech retail solutions. The introduction of electronic payment systems in the 1980s marked a turning point, allowing for increased transaction security and convenience. Over the past two decades, advancements in technology and a shift toward consumer-centric offerings have led to the rise of smart vending machines, capable of catering to diverse needs and preferences across various sectors. This evolution not only reflects changes in consumer behavior but also highlights the importance of adaptability in the vending machine industry for B2B buyers looking to thrive in a competitive market.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of pics of vending machines

-

What criteria should I use to vet suppliers of vending machine pictures?

When vetting suppliers, consider their experience and reputation in the industry. Look for suppliers who provide references or case studies that demonstrate their expertise in vending machine photography. Assess the quality of their previous work by reviewing their portfolio. Additionally, ensure they have the capability to meet your specific requirements, such as image resolution and customization needs. Establish clear communication lines to discuss your expectations and confirm their understanding of your project scope. -

Can I customize the vending machine pictures I purchase?

Yes, many suppliers offer customization options for vending machine images. This can include specific angles, backgrounds, or even product placements tailored to your branding. When discussing customization, provide clear guidelines and examples of what you envision. Be sure to clarify any additional costs associated with custom work and confirm the supplier’s ability to meet your deadlines for delivery. -

What are the typical minimum order quantities (MOQ) and lead times for vending machine pictures?

MOQs for vending machine images can vary significantly based on the supplier and the complexity of your request. Some suppliers may offer single images, while others might require larger orders. Lead times also depend on the supplier’s workload and your customization requests; generally, expect a timeframe of 1-4 weeks. Always discuss these details upfront to align your expectations and ensure timely delivery for your marketing or operational needs. -

What payment methods are generally accepted for purchasing vending machine images?

Most suppliers accept various payment methods, including credit cards, bank transfers, and digital payment platforms like PayPal. Ensure that the payment method you choose is secure and offers buyer protection. Discuss payment terms upfront, including any deposits required for custom work. Additionally, inquire about currency exchange rates if dealing with international suppliers, as this may affect your total cost. -

What quality assurance measures should I expect from suppliers?

Reliable suppliers should have quality assurance (QA) processes in place to ensure the images meet your specifications. This includes reviewing images for clarity, composition, and adherence to your guidelines. Ask about their QA procedures and whether they offer revisions if the images do not meet your expectations. It’s also beneficial to request samples before finalizing your order to assess the quality firsthand. -

Are there any certifications or standards I should check for?

While there may not be specific certifications for vending machine photography, it’s essential to check if the supplier adheres to industry standards for image quality and copyright regulations. Ensure that they provide proper licensing agreements that allow you to use the images commercially. Suppliers with a history of compliance with international trade regulations can also be more trustworthy, especially in cross-border transactions.

-

What logistics should I consider when sourcing images from international suppliers?

When sourcing images from international suppliers, consider potential shipping costs and import taxes if physical media is involved. However, if you are purchasing digital images, ensure that the file transfer method is secure and reliable. Discuss the format in which the images will be delivered, ensuring compatibility with your systems. Additionally, clarify the terms of service regarding the usage of the images to avoid any future disputes. -

How can I resolve disputes with suppliers over vending machine images?

To resolve disputes effectively, maintain clear and open communication with the supplier. Document all agreements and correspondence related to your order, including specifications and payment terms. If an issue arises, attempt to address it directly with the supplier first. If necessary, escalate the matter through formal dispute resolution channels, such as mediation or arbitration, especially if you have a written contract that outlines these processes.

Strategic Sourcing Conclusion and Outlook for pics of vending machines

In conclusion, strategic sourcing for vending machines is vital for international B2B buyers looking to capitalize on a growing market. Understanding customer demographics and preferences allows businesses to select the right machines and products, maximizing profitability. Moreover, leveraging technology, such as smart vending solutions, can enhance operational efficiency and customer satisfaction by providing innovative services, cashless transactions, and data-driven inventory management.

For businesses in Africa, South America, the Middle East, and Europe, the potential for growth in the vending machine sector is significant. By identifying high-traffic locations, tailoring product offerings to local tastes, and implementing effective marketing strategies, companies can establish a competitive edge.

As the global market continues to evolve, now is the opportune moment for B2B buyers to invest in vending machine solutions. Embrace the future of vending by exploring partnerships with reliable suppliers, utilizing smart technology, and focusing on sustainable practices. This proactive approach not only positions your business for immediate success but also ensures long-term viability in an increasingly dynamic landscape.