Master the Market: Sourcing Fruitopia Vending Machine 90s

Guide to Fruitopia Vending Machine 90S

- Introduction: Navigating the Global Market for fruitopia vending machine 90s

- Understanding fruitopia vending machine 90s Types and Variations

- Key Industrial Applications of fruitopia vending machine 90s

- Strategic Material Selection Guide for fruitopia vending machine 90s

- In-depth Look: Manufacturing Processes and Quality Assurance for fruitopia vending machine 90s

- Comprehensive Cost and Pricing Analysis for fruitopia vending machine 90s Sourcing

- Spotlight on Potential fruitopia vending machine 90s Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for fruitopia vending machine 90s

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the fruitopia vending machine 90s Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fruitopia vending machine 90s

- Strategic Sourcing Conclusion and Outlook for fruitopia vending machine 90s

Introduction: Navigating the Global Market for fruitopia vending machine 90s

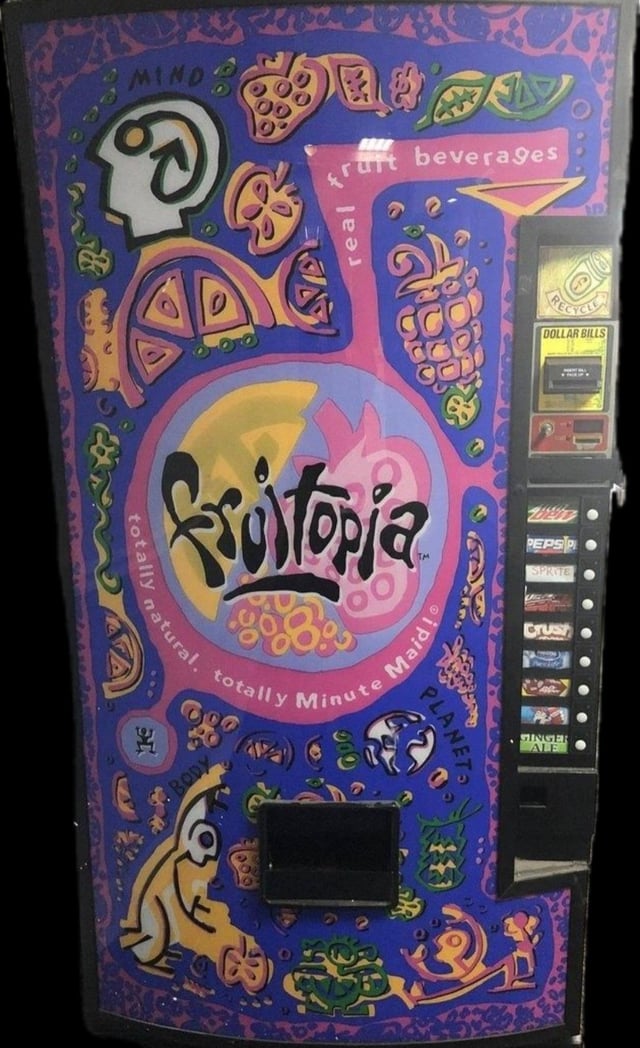

In an increasingly interconnected world, the demand for innovative vending solutions is surging, and the Fruitopia vending machine from the 90s stands out as a nostalgic yet lucrative opportunity for B2B buyers. This unique vending solution not only offers a diverse array of fruity beverages but also embodies a retro charm that appeals to various markets, especially in regions like Africa, South America, the Middle East, and Europe. As businesses strive to meet evolving consumer preferences, understanding the nuances of the Fruitopia vending machine becomes critical.

This guide provides a comprehensive overview tailored specifically for international B2B buyers. It delves into various types of Fruitopia vending machines, the materials used in their construction, and the manufacturing and quality control processes that ensure reliability. Additionally, we will explore reputable suppliers, pricing structures, and market trends to empower informed sourcing decisions.

With actionable insights and practical tips, this guide equips buyers from Kenya to Saudi Arabia with the necessary knowledge to navigate the global market effectively. By understanding the intricacies of this vending solution, businesses can not only enhance their product offerings but also capitalize on a unique niche that resonates with consumers. Prepare to unlock the full potential of the Fruitopia vending machine as we guide you through every essential aspect of this vibrant market.

Understanding fruitopia vending machine 90s Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Fruitopia Machine | Large capacity, colorful branding, diverse flavors | Schools, offices, entertainment venues | Pros: High visibility, popular flavors. Cons: Requires regular maintenance and refilling. |

| Compact Fruitopia Dispenser | Space-efficient design, limited flavor selection | Small businesses, cafes, kiosks | Pros: Ideal for tight spaces, lower upfront cost. Cons: Limited offerings may not attract all customers. |

| Multi-Flavor Vending System | Multiple flavor options in one machine | Shopping malls, airports | Pros: Variety appeals to diverse customer bases. Cons: Higher initial investment and maintenance complexity. |

| Refrigerated Fruitopia Unit | Temperature-controlled for freshness | Gyms, health clubs, supermarkets | Pros: Keeps beverages cool, enhances flavor appeal. Cons: Increased energy costs and potential for mechanical issues. |

| Customizable Flavor Machine | User-selectable flavors, interactive interface | Events, festivals, pop-up shops | Pros: Engages customers, offers personalized experience. Cons: More expensive and requires technical support. |

Classic Fruitopia Machine

The Classic Fruitopia Machine is characterized by its large capacity and vibrant branding that attracts consumers. It typically offers a wide range of fruity flavors, making it a staple in high-traffic areas such as schools, offices, and entertainment venues. For B2B buyers, the machine’s high visibility can drive significant sales, but it does require regular maintenance and refilling to ensure optimal performance.

Compact Fruitopia Dispenser

Ideal for smaller spaces, the Compact Fruitopia Dispenser offers a limited selection of flavors while maintaining a space-efficient design. This type is particularly suited for small businesses, cafes, and kiosks where floor space is at a premium. B2B buyers should consider the lower upfront cost, but they must also weigh the potential downside of limited offerings that may not attract a broad customer base.

Multi-Flavor Vending System

This system stands out by providing multiple flavors in one machine, catering to diverse consumer preferences. It is especially useful in shopping malls and airports, where foot traffic is high. The variety can significantly enhance customer satisfaction and sales, though B2B buyers should be prepared for a higher initial investment and more complex maintenance requirements.

Refrigerated Fruitopia Unit

Refrigerated units are designed to keep beverages cool, which is essential for maintaining freshness and flavor appeal. These machines are commonly found in gyms, health clubs, and supermarkets where consumers seek refreshing options. While they can enhance customer experience, buyers must consider the increased energy costs and the potential for mechanical issues that come with temperature control.

Customizable Flavor Machine

Offering an interactive experience, the Customizable Flavor Machine allows users to select their preferred flavors. This engaging feature is perfect for events, festivals, and pop-up shops, where creating a memorable customer experience is key. While it can command a premium price and requires ongoing technical support, the potential for increased customer engagement can justify the investment for B2B buyers looking to stand out in competitive markets.

Key Industrial Applications of fruitopia vending machine 90s

| Industry/Sector | Specific Application of fruitopia vending machine 90s | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality & Leisure | Hotel lobbies and recreational areas | Enhances guest experience, boosts ancillary revenue | Compact design, reliable power supply, maintenance support |

| Education | College campuses and student unions | Provides healthy beverage options, promotes wellness | High capacity for foot traffic, customization options |

| Corporate Offices | Break rooms and employee lounges | Improves employee satisfaction, encourages healthy choices | Energy efficiency, ease of restocking, payment options |

| Retail | Shopping malls and supermarkets | Attracts customers, increases impulse purchases | Product variety, location analytics, branding opportunities |

| Events & Festivals | Outdoor events and conventions | Convenient access to refreshments, enhances visitor experience | Portability, weather resistance, payment flexibility |

Hospitality & Leisure

In the hospitality sector, the Fruitopia vending machine is ideal for placement in hotel lobbies and recreational areas. It caters to guests seeking quick, healthy beverage options, enhancing their overall experience. For international buyers, especially in regions like Africa and the Middle East, it’s crucial to consider local preferences for flavors and nutritional content. Additionally, the machine’s compact design allows for easy integration into existing spaces without requiring significant renovations.

Education

Within educational institutions, particularly on college campuses, the Fruitopia vending machine serves as an accessible source of nutritious beverages for students. This application not only promotes wellness among the student body but also aligns with growing health trends. Buyers from South America and Europe should ensure the machine can handle high traffic, with the capacity for frequent restocking to meet demand during peak hours, such as between classes.

Corporate Offices

In corporate environments, the Fruitopia vending machine can be strategically placed in break rooms and employee lounges. This application enhances employee satisfaction by providing healthy drink options that contribute to a positive workplace culture. For buyers from regions like Europe, focusing on energy efficiency and low-maintenance requirements will be essential to ensure cost-effectiveness over time. Additionally, offering multiple payment options can cater to diverse employee preferences.

Retail

The retail sector benefits from the Fruitopia vending machine in locations such as shopping malls and supermarkets. By providing consumers with convenient access to beverages, the machine can drive impulse purchases and increase foot traffic. For international buyers, particularly in Africa and South America, understanding local consumer behavior and preferences is vital. Sourcing machines that offer a variety of products and can analyze customer interactions will enhance their marketability.

Events & Festivals

At outdoor events and festivals, the Fruitopia vending machine offers a portable solution for delivering refreshing beverages to attendees. This application is particularly valuable for enhancing visitor experiences and ensuring convenience. Buyers from the Middle East should consider weather-resistant models that can withstand outdoor conditions, as well as machines that accommodate various payment methods to cater to a diverse audience.

Related Video: What is Industrial Automation?

Strategic Material Selection Guide for fruitopia vending machine 90s

When selecting materials for the Fruitopia vending machine from the 90s, international B2B buyers must consider various factors that affect performance, durability, and compliance. This analysis focuses on four common materials: stainless steel, plastic (polycarbonate), glass, and aluminum. Each material presents unique properties and implications for application, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. It is particularly suitable for environments where hygiene and durability are paramount.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to corrosion, making it ideal for vending machines that dispense beverages. However, it can be more expensive than other materials and may require more complex manufacturing processes. Additionally, while it is suitable for high-temperature applications, it can be heavy, which may affect installation.

Impact on Application: Stainless steel is compatible with various media, including acidic and sugary drinks, which is essential for a vending machine that dispenses fruit-flavored beverages. Its hygienic properties ensure that the machine meets health standards.

Considerations for International Buyers: Buyers from regions like Kenya and Saudi Arabia should ensure compliance with local health and safety regulations. Additionally, they should be aware of standards such as ASTM and DIN, which govern the use of stainless steel in food and beverage applications.

Plastic (Polycarbonate)

Key Properties: Polycarbonate is a lightweight, impact-resistant plastic with good thermal stability and transparency. It can withstand a range of temperatures, making it suitable for various climates.

Pros & Cons: The main advantage of polycarbonate is its lightweight nature, which simplifies installation and reduces shipping costs. However, it may not be as durable as metals and can be susceptible to scratching and UV degradation over time.

Impact on Application: Polycarbonate is often used for the vending machine’s panels and components that require visibility, as it allows consumers to see the products inside. Its compatibility with fruit juices and drinks makes it a suitable choice.

Considerations for International Buyers: Buyers in South America and Europe should consider UV resistance and compliance with food safety standards. They should also evaluate the material’s performance in high-temperature environments typical of tropical climates.

Glass

Key Properties: Glass is a non-porous material that offers excellent clarity and aesthetic appeal. It is resistant to chemical reactions, making it suitable for various beverages.

Pros & Cons: The primary advantage of glass is its ability to maintain product integrity and flavor without leaching chemicals. However, it is heavier and more fragile than other materials, which can complicate shipping and installation. Additionally, glass can pose safety risks if broken.

Impact on Application: Glass is ideal for the display of beverages, enhancing the visual appeal of the vending machine. It is compatible with a wide range of liquids, including acidic juices.

Considerations for International Buyers: Buyers should be mindful of local regulations regarding glass usage in public spaces, especially in regions like the Middle East, where safety standards may be stringent. Compliance with standards like JIS is also crucial.

Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and possesses good thermal conductivity. It is easy to fabricate and can be anodized for enhanced durability.

Pros & Cons: The key advantage of aluminum is its lightweight nature, which facilitates easier handling and installation. However, it may not be as strong as stainless steel and can be prone to denting.

Impact on Application: Aluminum is often used for structural components of the vending machine, providing a balance between weight and strength. It is compatible with most beverages, although care should be taken with highly acidic products.

Considerations for International Buyers: Buyers in Europe should ensure that aluminum components meet local environmental regulations regarding recyclability and sustainability. Compliance with ASTM standards is also important for ensuring product safety.

Summary Table

| Material | Typical Use Case for fruitopia vending machine 90s | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, beverage dispensing areas | Excellent durability and corrosion resistance | Higher cost, heavier weight | High |

| Plastic (Polycarbonate) | Panels and visibility components | Lightweight, impact-resistant | Susceptible to scratching, UV degradation | Medium |

| Glass | Beverage display areas | Maintains product integrity, aesthetic appeal | Heavy, fragile, safety risks | Medium |

| Aluminum | Structural components | Lightweight, easy to fabricate | Less strong than stainless steel, prone to denting | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for fruitopia vending machine 90s

Manufacturing Processes for Fruitopia Vending Machines

The manufacturing of Fruitopia vending machines involves several critical stages that ensure the final product meets the quality and functionality expected by international B2B buyers. Understanding these processes not only helps in assessing the product’s reliability but also aids in making informed sourcing decisions.

Illustrative Image (Source: Google Search)

Main Stages of Manufacturing

-

Material Preparation

– Selection of Materials: The initial step involves choosing high-quality materials such as stainless steel, aluminum, and food-grade plastics. These materials are essential for durability and compliance with health standards.

– Pre-processing: Materials may undergo treatments such as cutting, shaping, and surface finishing to prepare them for the next manufacturing stages. -

Forming

– Metal Forming Techniques: Common techniques include stamping, bending, and extrusion. These methods shape the metal components of the vending machine, ensuring they fit together precisely.

– Plastic Molding: Injection molding is often used for plastic parts, allowing for complex shapes that are lightweight yet sturdy. -

Assembly

– Component Assembly: After forming, components are assembled using automated machinery or manual labor, depending on the complexity of the design. This stage usually involves integrating mechanical parts, electronic systems, and refrigeration units.

– Integration of Technology: Advanced vending machines incorporate smart technology, including touch screens and payment systems, which require precise assembly and integration. -

Finishing

– Surface Treatment: The final stage includes painting, coating, or polishing to enhance aesthetics and protect against corrosion. This step is critical for vending machines exposed to various environments.

– Final Inspection: Before shipping, machines undergo a comprehensive quality check to ensure they meet design specifications and operational standards.

Quality Assurance Protocols

Quality assurance is vital in maintaining product integrity and customer satisfaction. For Fruitopia vending machines, adherence to international quality standards is essential, especially for B2B buyers from diverse regions.

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems (QMS) and is crucial for manufacturers to demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: Particularly important in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: While primarily related to the petroleum and natural gas industry, API standards can apply to vending machines that also dispense beverages, ensuring safe operation and maintenance.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– This initial checkpoint involves inspecting raw materials and components upon arrival. It ensures that only materials meeting specified standards enter the production process. -

In-Process Quality Control (IPQC)

– Throughout the manufacturing stages, continuous monitoring is conducted. This includes checking machine calibrations, assembly accuracy, and electronic functionalities. -

Final Quality Control (FQC)

– A comprehensive evaluation of the finished product occurs before packaging. This includes functional tests, aesthetic inspections, and compliance checks with relevant standards.

Common Testing Methods

- Functional Testing: Ensures that all features of the vending machine operate as intended, including dispensing mechanisms and payment systems.

- Durability Testing: Simulates long-term usage to identify potential points of failure.

- Safety Testing: Checks for electrical safety, ensuring compliance with standards like IEC 60335 for household and similar appliances.

Verifying Supplier Quality Control

For B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality is crucial to mitigate risks associated with sourcing. Here are effective strategies:

- Supplier Audits: Conducting regular audits helps assess whether suppliers adhere to quality standards and processes. Audits can be performed by the buyer or a third-party entity.

- Requesting Quality Reports: Suppliers should provide detailed reports on their quality control processes, including results from IQC, IPQC, and FQC.

- Third-Party Inspections: Engaging independent inspection services ensures an unbiased evaluation of the product before shipment. This is particularly important for buyers unfamiliar with the supplier’s reputation.

Quality Control Nuances for International Buyers

International buyers must navigate various quality control nuances that may vary by region:

- Cultural Considerations: Different regions may have varying interpretations of quality standards. For instance, while European buyers may prioritize compliance with CE marking, African and South American buyers might focus more on durability and functionality in local conditions.

- Logistical Challenges: Buyers in remote areas may face challenges in receiving after-sales support and warranty services. Therefore, ensuring that the supplier has a robust support system in place is essential.

- Local Regulations: Understanding local regulations regarding vending machines can affect the purchasing decision. It’s advisable to work with suppliers familiar with the legal requirements of the buyer’s country.

By being well-informed about the manufacturing processes and quality assurance practices of Fruitopia vending machines, B2B buyers can make better sourcing decisions that align with their operational needs and market expectations. This knowledge not only enhances procurement strategies but also ensures a smooth integration of vending machines into their business models.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for fruitopia vending machine 90s Sourcing

When sourcing the Fruitopia vending machine from the 90s, a thorough understanding of the cost structure and pricing dynamics is essential for international B2B buyers. This analysis will delve into the various components of cost, the factors influencing pricing, and provide actionable tips for effective negotiation and procurement.

Cost Components

-

Materials: The primary materials used in the production of vending machines include steel, plastic, and electronic components. Sourcing high-quality materials is crucial, as it directly impacts the durability and functionality of the machines. Buyers should consider suppliers that offer certifications for material quality, as this can mitigate risks associated with substandard products.

-

Labor: Labor costs vary significantly across regions. For instance, manufacturing in countries with lower labor costs may reduce overall expenses. However, it is important to ensure that labor practices comply with international standards to avoid reputational risks.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and administrative expenses. Buyers should inquire about the factory’s operational efficiencies, as a well-managed facility can often pass on savings to clients.

-

Tooling: The initial investment in tooling can be significant, especially for customized designs. If standard models are acceptable, buyers can reduce tooling costs. However, if unique specifications are required, factor in these costs when negotiating.

-

Quality Control (QC): Implementing robust QC processes ensures that the machines meet the necessary standards. While this may increase upfront costs, it is essential to prevent long-term expenses associated with defective machines.

-

Logistics: Shipping costs can vary based on the origin and destination of the machines. Understanding Incoterms is critical in determining which party is responsible for shipping costs, insurance, and tariffs. This can significantly influence the Total Cost of Ownership (TCO).

-

Margin: Suppliers will typically include a profit margin in their pricing. This margin can vary widely based on the supplier’s market position and competitive strategy. It is beneficial to compare multiple suppliers to understand the average margin in the market.

Price Influencers

-

Volume/MOQ: Ordering in bulk can lead to reduced per-unit costs. Establishing a Minimum Order Quantity (MOQ) can also influence pricing, so buyers should clarify these terms during negotiations.

-

Specifications/Customization: Custom features may necessitate higher costs due to additional tooling and labor. Buyers should weigh the benefits of customization against the potential price increase.

-

Materials: The choice of materials will affect pricing significantly. High-end materials can enhance durability but may raise costs. Buyers should balance quality and expenditure based on their target market.

-

Quality/Certifications: Machines with recognized certifications (e.g., ISO) may command higher prices but can offer reassurance regarding reliability and safety.

-

Supplier Factors: The reputation and track record of the supplier can influence both cost and reliability. Established suppliers may charge more but offer better service and quality assurance.

-

Incoterms: Understanding shipping terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential. These terms dictate cost responsibilities and can affect the final price.

Buyer Tips

-

Negotiation: Always approach negotiations with a clear understanding of your requirements and budget. Leverage competition among suppliers to achieve better pricing and terms.

-

Cost-Efficiency: Consider the TCO rather than just the upfront price. This includes maintenance, operational costs, and potential resale value.

-

Pricing Nuances for International Buyers: Be mindful of currency fluctuations and how they may affect costs. Additionally, tariffs and import duties should be factored into the final pricing.

-

Local Partnerships: Establishing relationships with local partners can facilitate smoother transactions, reduce logistical challenges, and provide insights into regional market dynamics.

In conclusion, a meticulous approach to analyzing costs and pricing dynamics will empower international B2B buyers to make informed decisions when sourcing Fruitopia vending machines from the 90s. Always remember that indicative prices can fluctuate based on market conditions, so continual assessment and strategic planning are essential.

Spotlight on Potential fruitopia vending machine 90s Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for fruitopia vending machine 90s.)*

Essential Technical Properties and Trade Terminology for fruitopia vending machine 90s

Essential Technical Properties

When considering the acquisition of a Fruitopia vending machine from the 90s, it’s crucial to understand several key technical properties that impact both functionality and durability. Here are some critical specifications to assess:

-

Material Grade

The material grade of the vending machine primarily refers to the quality of metals and plastics used in its construction. High-grade stainless steel is common for the exterior, providing resistance to rust and corrosion, which is vital for machines placed in humid or outdoor environments. This ensures longevity and reduces maintenance costs, making it a smart investment for international buyers. -

Power Consumption

Understanding the power consumption rating (measured in watts) is essential for operational cost management. A vending machine with a lower power consumption rating will incur lower electricity bills, which is particularly important in regions where energy costs are high. Buyers should analyze the power requirements to ensure compatibility with local electrical standards and infrastructure. -

Capacity

The capacity of a vending machine, often measured in the number of products it can hold, directly affects sales volume and inventory management. For B2B buyers, selecting a machine with appropriate capacity based on foot traffic and expected sales can maximize return on investment. This consideration is crucial in various markets, from bustling urban centers in Europe to remote areas in Africa. -

Temperature Control Range

The temperature control range indicates the machine’s ability to maintain optimal conditions for perishable items. A well-functioning refrigeration system is vital for preserving product quality and ensuring customer satisfaction. Buyers should look for machines that can maintain a consistent temperature, especially in regions with extreme weather conditions. -

User Interface

The user interface, including the display and payment systems, affects customer interaction. A modern interface with touch capabilities and multiple payment options (including mobile payments) can enhance user experience and drive sales. Buyers should evaluate the interface’s usability to ensure it meets the expectations of their target market.

Industry Trade Terminology

Familiarity with specific trade terms can facilitate smoother transactions and negotiations. Here are several common jargon terms relevant to the vending machine industry:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can help in sourcing high-quality replacement parts and ensuring compatibility with existing machines. -

MOQ (Minimum Order Quantity)

MOQ is the lowest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for buyers to avoid excess inventory and manage cash flow effectively. This is especially important for smaller businesses or those entering new markets. -

RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers. B2B buyers should utilize RFQs to gather competitive pricing and terms from multiple vendors, enabling informed decision-making. It helps in establishing clear expectations regarding costs and delivery timelines. -

Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of sellers and buyers in global trade. Understanding these terms, such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight), is crucial for buyers to comprehend shipping costs and liability, ensuring they are protected during transit. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. For B2B buyers, understanding lead times is essential for inventory planning and ensuring that machines are available when needed, especially in peak seasons. -

Warranty

A warranty is a guarantee from the manufacturer regarding the condition of the machine and the terms of repair or replacement. Buyers should always inquire about warranty conditions to safeguard their investment and ensure they have support in case of defects or malfunctions.

By grasping these technical properties and industry terms, international B2B buyers can make informed decisions that align with their operational needs and market conditions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the fruitopia vending machine 90s Sector

Market Overview & Key Trends

The fruitopia vending machine sector, particularly those inspired by the vibrant 90s, is experiencing a resurgence driven by the global shift towards healthier snack options and convenience. In regions such as Africa, South America, the Middle East, and Europe, this trend is enhanced by increasing urbanization and busy lifestyles, leading consumers to seek quick, nutritious alternatives. International B2B buyers should note that innovative technology is reshaping this market. Smart vending machines equipped with cashless payment systems, touchless interfaces, and IoT capabilities are becoming standard, enhancing user experience and operational efficiency.

Emerging sourcing trends are also noteworthy. Buyers are increasingly prioritizing local suppliers to minimize transportation costs and support regional economies. In Africa and South America, partnerships with local producers can foster community goodwill and ensure fresher product offerings. Additionally, there’s a growing emphasis on diversification of product lines. Vending operators are not just offering traditional fruit juices but also innovative blends, organic options, and functional beverages that cater to health-conscious consumers.

Market dynamics are influenced by changing regulatory frameworks, especially concerning health standards and food safety. International buyers must stay informed about local regulations in their target markets to ensure compliance and avoid penalties. Moreover, the demand for transparency in the supply chain is rising, making it imperative for B2B buyers to establish solid relationships with suppliers who can provide traceability and quality assurance.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a core consideration in the fruitopia vending machine sector. The environmental impact of sourcing practices is under scrutiny, with consumers increasingly favoring brands that demonstrate a commitment to eco-friendly operations. For international B2B buyers, this translates into the necessity of adopting ethical sourcing practices. Engaging with suppliers who use sustainable farming methods and avoid harmful pesticides not only supports environmental health but also enhances brand reputation.

Implementing green certifications can further bolster a company’s market position. Certifications such as Fair Trade, Rainforest Alliance, and Organic can reassure consumers and partners that the products meet rigorous environmental and social standards. Moreover, sourcing materials for vending machines, such as biodegradable packaging or energy-efficient components, can significantly reduce the carbon footprint.

Investing in sustainable practices is not just ethically responsible; it can also lead to cost savings in the long run. For example, energy-efficient machines can lower operational costs, while sustainable sourcing can mitigate risks associated with supply chain disruptions. As such, buyers should actively seek out suppliers who prioritize sustainability, as this alignment can enhance resilience and long-term viability in an increasingly eco-conscious market.

Brief Evolution/History

The fruitopia vending machine concept gained traction in the 1990s as consumers sought healthier snack alternatives amidst a growing awareness of nutrition. These machines offered a diverse range of fruit-based beverages, appealing to a demographic that valued convenience without compromising on health. Over the years, technological advancements have transformed these machines from simple dispensers into sophisticated, interactive units equipped with smart technology.

Today, the evolution continues, with an emphasis on sustainability and ethical sourcing shaping the future of the sector. As international B2B buyers navigate this landscape, understanding the historical context can provide valuable insights into consumer preferences and market expectations, guiding strategic sourcing decisions and product offerings.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of fruitopia vending machine 90s

-

What should I consider when vetting suppliers for Fruitopia vending machines?

When vetting suppliers, prioritize their experience and reputation in the vending machine industry. Look for manufacturers with a proven track record of producing durable and reliable machines. Request references from previous clients, especially those in your region, and evaluate their customer service responsiveness. Additionally, check for any relevant certifications, such as ISO standards, which indicate adherence to quality management systems. Conducting a site visit or virtual tour can also provide valuable insights into the supplier’s operations. -

Can I customize the Fruitopia vending machine to suit my market?

Yes, many suppliers offer customization options for Fruitopia vending machines to cater to local preferences and branding requirements. Discuss your specific needs, such as machine size, color, and product selection, with the supplier. It is advisable to request a prototype or digital renderings of the customized machine before finalizing the order. Be mindful of any additional costs and lead times associated with customization, as these factors can affect your overall budget and timeline. -

What are the minimum order quantities (MOQs) and typical lead times for ordering?

Minimum order quantities can vary significantly by supplier and may depend on the type of vending machine and customization options. Generally, MOQs for Fruitopia vending machines range from 10 to 50 units. Lead times can also vary, typically spanning from 6 to 12 weeks, depending on production schedules and customization complexity. It’s crucial to discuss your timeline with suppliers upfront to ensure that they can meet your delivery expectations. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can differ widely based on the supplier’s policies and your negotiation. Common practices include a deposit (typically 30%-50%) upfront, with the balance due before shipment. Some suppliers may offer letter of credit arrangements, which can provide additional security for both parties. Always clarify payment methods accepted, such as bank transfers, credit cards, or escrow services, and ensure that you understand any currency conversion fees that may apply.

Illustrative Image (Source: Google Search)

-

How can I ensure quality assurance and certifications for the machines?

Request documentation that outlines the quality assurance processes used by the manufacturer. Look for certifications that indicate compliance with international standards, such as CE marking in Europe or other relevant regional certifications. Conducting quality inspections during production can also safeguard against defects. Partnering with third-party quality assurance organizations may be beneficial, especially if you are unfamiliar with the local manufacturing practices. -

What logistics considerations should I keep in mind when importing vending machines?

When importing Fruitopia vending machines, consider logistics factors such as shipping methods, customs duties, and potential tariffs. Use freight forwarders who specialize in machinery imports to navigate complex logistics. Ensure that all shipping documentation is accurate to avoid delays. Additionally, factor in the costs of insurance for the machines during transit and be prepared for potential delays due to customs clearance processes in your country. -

How should I handle disputes with suppliers?

To minimize disputes, establish clear contractual terms that outline responsibilities, delivery timelines, and quality standards before placing orders. In the event of a dispute, maintain open communication with the supplier to resolve issues amicably. If necessary, refer to the terms of the contract regarding dispute resolution, such as mediation or arbitration. Having a well-documented history of communications and agreements will also strengthen your position if legal action becomes necessary. -

What support can I expect from suppliers post-purchase?

After your purchase, suppliers typically provide various levels of support, including installation assistance, user manuals, and maintenance guidelines. Clarify the warranty terms and the duration of support services at the time of purchase. Some suppliers may offer training for your staff on machine operation and troubleshooting. Establishing a solid post-purchase relationship can also be advantageous for future orders or additional support as your business scales.

Strategic Sourcing Conclusion and Outlook for fruitopia vending machine 90s

In conclusion, the strategic sourcing of the Fruitopia vending machine from the 90s presents a unique opportunity for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Key takeaways emphasize the importance of understanding local market preferences, regulatory environments, and logistical considerations when sourcing these nostalgic vending machines. By leveraging regional trends and consumer behavior insights, businesses can effectively position themselves to meet the growing demand for innovative beverage solutions.

Value of Strategic Sourcing:

– Cost Efficiency: Streamlined procurement processes can lead to significant savings.

– Quality Assurance: Partnering with reliable suppliers ensures product quality and consistency.

– Market Responsiveness: A well-executed sourcing strategy allows for quicker adaptation to market changes.

As the demand for unique and engaging vending solutions rises, it is imperative for buyers to remain proactive in their sourcing strategies. By embracing the rich cultural contexts and preferences of their target markets, businesses can create tailored offerings that resonate with consumers.

Call to Action: Engage with local suppliers and distributors to explore how the Fruitopia vending machine can enhance your product portfolio. Start building strong partnerships today for a successful tomorrow in the vending industry.